Professional Documents

Culture Documents

HD ss3 One Page

HD ss3 One Page

Uploaded by

Jose Daniel Rodriguez RivasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HD ss3 One Page

HD ss3 One Page

Uploaded by

Jose Daniel Rodriguez RivasCopyright:

Available Formats

HD Super Slider 3 (SS3)

Non-Rotating Protectors (NRP)™

Reduce torque and drag • Protect against casing, riser, and drill pipe wear

Reduce buckling, heat checking, vibration and stick-slip · Open-hole capabilities

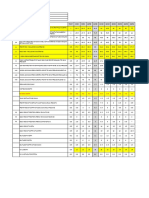

HD- HD- HD-

SS3- HD- SS3- HD- HD- HD- HD- SS3- HD-

400- SS3- 450- SS3- SS3- SS3- SS3- 658- SS3-

WWT NRP Model SLIM 400 SLIM 450 500 550 578 SLIM 658

Drill Pipe Size 4.00” 4.00” 4.50” 4.50” 5.00” 5.50” 5.88” 6.63” 6.63”

Sleeve Max OD 5.50” 5.75” 6.25” 6.75” 7.30” 7.75” 8.00” 8.75” 9.13”

Sleeve Effective OD 5.30” 5.47” 6.00” 6.25” 6.79” 7.26” 7.52” 8.31” 8.52”

Collar OD 5.07” 5.38” 5.88” 6.00” 6.50” 7.00” 7.38” 8.13” 8.13”

Sleeve Length 12” 12” 12” 12” 12” 12” 12” 12” 12”

Sleeve Volume 111 in 3

120 in 3

153 in 3

168 in 3

177 in 3

203 in 3

206 in 3

233 in 3

252 in3

Sleeve Weight 6.7 lbs 9 lbs 9.5 lbs 10 lbs 11 lbs 13 lbs 13.3 lbs 15.8 lbs 16 lbs

Assembly Weight 19 lbs 22 lbs 24 lbs 25 lbs 27 lbs 30 lbs 31 lbs 39 lbs 40 lbs

Continuous Side-Load Rating 2,200 lbs 2,200 lbs 3,000 lbs 3,000 lbs 3,000 lbs 3,000 lbs 4,000 lbs 5,000 lbs 5,000 lbs

Intermittent Side-Load Rating 6,600 lbs 6,600 lbs 9,000 lbs 9,000 lbs 9,000 lbs 9,000 lbs 12,000 lbs 15,000 lbs 15,000 lbs

Cross-Sectional Area 9.5 in2 10.9 in2 12.4 in2 14.8 in2 16.6 in2 17.6 in2 17.3 in2 19.8 in2 22.6 in2

Total Flow Area

7” x 32 ppf Csg. 7.1 in2 5.7 in2

7” x 29 ppf Csg. 8.0 in 2

6.6 in2

7” x 26 ppf Csg. 8.9 in2 7.5 in2

7-5/8” x 39 ppf Csg. 12.4 in 2

11.0 in2 6.2 in2

9-5/8” x 53.5 ppf Csg. 35.1 in2 33.7 in2 28.9 in2 26.5 in2 21.0 in2 15.8 in2 12.8 in2

10-3/4” x 55.5 ppf Csg. 52.7 in 2

51.3 in 2

46.5 in 2

44.1 in 2

38.6 in 2

33.5 in 2

30.4 in2 20.5 in2

13-3/8” x 72 ppf Csg. 97.7 in2 96.3 in2 91.4 in2 89.0 in2 83.5 in2 78.4 in2 75.3 in2 65.5 in2 62.7 in2

Collar Material 6061-T651 Extruded Aluminum Alloy With Features for Wear Resistance

Sleeve Material Advanced Low-Friction Polymer With Proprietary Wear Additives, Nitrile Rubber and Alloy Steel Sheet

Max. Temperature 220° F (105° C)

Refer to document TSI017 for additional information regarding side force capabilities

Features and Benefits SS3 Protector design allows for open-hole applications.

New sleeve design enhances side force capabilities. Optimum operating performance range of 20 – 250 RPM.

Positive protection against casing and riser wear during drilling Each assembly accepts up to 80,000 lbs. of axial force before slippage.

and completion operations. Installation time per assembly: less than 1 minute.

Significant torque reduction created by WWT’s patented fluid Free, no-obligation, confidential torque, drag and wear analysis.

bearing design allows for improved ROP, RPM, and hole cleaning. Global leadership in some of the world’s most challenging drilling

Compatible with almost all drilling and completion fluids. environments since 1989.

On/off-site technical support 24/7.

WWT International supports your

operations from start to finish with

full-service onsite mobilization and

support 24/7. To find out more, visit:

www.wwtco.com

Houston, Texas, USA · Midland, Texas, USA · Anaheim, California, USA · Aberdeen, Scotland

Al Khobar, KSA · Abu Dhabi, UAE · Dubai, UAE · Singapore · Quito, Ecuador

© 2021 WWT North America Holdings, Inc. All rights reserved. ® is a registered trademark of WWT North America Holdings, Inc.

™ WWT Super 4 Long (S4-L) Non-Rotating Protector is a trademark of WWT North America Holdings, Inc.

Document #: PS013A Produced in the U.S.A. 09/2021

You might also like

- Government Departments Contact Emails/Phone Numbers EtcDocument149 pagesGovernment Departments Contact Emails/Phone Numbers EtcPaul Smith0% (1)

- Universal Milling Machine Catalog PDFDocument2 pagesUniversal Milling Machine Catalog PDFDharmik SoniNo ratings yet

- Selangor Uniform Building By-Laws 2012 - Sel. P.U. 142-2012 PDFDocument53 pagesSelangor Uniform Building By-Laws 2012 - Sel. P.U. 142-2012 PDFAnwar Yacob67% (3)

- Horizontal Milling Machine Catalog PDFDocument2 pagesHorizontal Milling Machine Catalog PDFDharmik SoniNo ratings yet

- Vertical Milling Machine Catalog PDFDocument2 pagesVertical Milling Machine Catalog PDFDharmik SoniNo ratings yet

- Crown-RR5220-45 EspecificacionesDocument6 pagesCrown-RR5220-45 EspecificacionesAlmaVillanuevaNo ratings yet

- Retractil 5700sDocument4 pagesRetractil 5700sLuis MartinNo ratings yet

- Wheel LoaderDocument7 pagesWheel LoaderleoNo ratings yet

- RR 5200 Series: SpecificationsDocument6 pagesRR 5200 Series: SpecificationsEstefanny ArispeNo ratings yet

- Value Leader EF Flail SpecsDocument1 pageValue Leader EF Flail SpecsBetstProductsNo ratings yet

- Eeud - 1563-2023 Bengaline SopDocument11 pagesEeud - 1563-2023 Bengaline SopfazlulNo ratings yet

- Value Leader EFGC Flail SpecsDocument1 pageValue Leader EFGC Flail SpecsBetstProductsNo ratings yet

- Kebutuhan Pipa Chiller & HydrantDocument4 pagesKebutuhan Pipa Chiller & HydrantAngga EmartNo ratings yet

- Crown rr5000 Spec SheetDocument6 pagesCrown rr5000 Spec SheetHagan WalkerNo ratings yet

- Weld Fittings - Dimensional Specification: Matco-Norca Commercial / Industrial Sales TeamDocument2 pagesWeld Fittings - Dimensional Specification: Matco-Norca Commercial / Industrial Sales Teampanks03No ratings yet

- Wire Rope Sling, Precision Swaged Assemblies HHDocument2 pagesWire Rope Sling, Precision Swaged Assemblies HHMichNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-11. Model ICB-LE Steam Boiler Dimensions, 4-Pass and 3-PassDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-11. Model ICB-LE Steam Boiler Dimensions, 4-Pass and 3-PasssebaversaNo ratings yet

- AS Fase (1) REV #2 Acero Zapatas Z11 y Z3 Junto A GrúaDocument87 pagesAS Fase (1) REV #2 Acero Zapatas Z11 y Z3 Junto A GrúaFrancis Alberto Espinosa PerezNo ratings yet

- Teknisk-Katalog StubendsDocument1 pageTeknisk-Katalog Stubendsaceengineering08No ratings yet

- 2-Leg BridleDocument1 page2-Leg BridleAndre MenezesNo ratings yet

- Stainless Steel Cast FittingsDocument7 pagesStainless Steel Cast FittingsKoya ThangalNo ratings yet

- Galaxy Stone Measurements & Granite Work RatesDocument10 pagesGalaxy Stone Measurements & Granite Work RatesBANDARPALLY PRABHAKARNo ratings yet

- Sewing Pattern - Childrens Woven ShortsDocument25 pagesSewing Pattern - Childrens Woven Shortszoe earthbornNo ratings yet

- CHS0004 PN Bella CHS TR21Document1 pageCHS0004 PN Bella CHS TR21manuel radulescuNo ratings yet

- 16 Additional Technical Information 2007Document12 pages16 Additional Technical Information 2007Andrew LimNo ratings yet

- Hilti Core CuttingDocument5 pagesHilti Core CuttingSarinNo ratings yet

- Taper Mills: Fishing Tools ProductsDocument2 pagesTaper Mills: Fishing Tools ProductsAmmar HrzNo ratings yet

- LD Selection - Max PressureDocument1 pageLD Selection - Max PressuremanishNo ratings yet

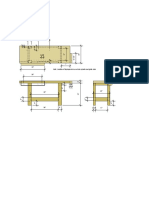

- Holtzapffel-Style Workbench Drawing by Christopher Schwarz September 2008, Knockdown VersionDocument2 pagesHoltzapffel-Style Workbench Drawing by Christopher Schwarz September 2008, Knockdown VersionRod HyattNo ratings yet

- 010 Tank Top and Shorts PatternDocument24 pages010 Tank Top and Shorts PatternKarla GMNo ratings yet

- Open Uri20201021 4 1fpv57r 1Document4 pagesOpen Uri20201021 4 1fpv57r 1lydia.s.cochraneNo ratings yet

- LoomDocument1 pageLoomvishal RokadeNo ratings yet

- 10507-Hayfield SoftTwistDK (Free)Document4 pages10507-Hayfield SoftTwistDK (Free)lia aryaniNo ratings yet

- Strength of Perforated Metal (Aluminum Sheet (Perforated) Elastic Properties)Document4 pagesStrength of Perforated Metal (Aluminum Sheet (Perforated) Elastic Properties)Wynel SadsadNo ratings yet

- Genie GS 2032, GS 2632, GS 3232 SpecificationsDocument2 pagesGenie GS 2032, GS 2632, GS 3232 SpecificationsKestutisNo ratings yet

- 10506-Hayfield SoftTwistDK (Free)Document4 pages10506-Hayfield SoftTwistDK (Free)Kyae ThawNo ratings yet

- Wire Rope CapacitiesDocument1 pageWire Rope CapacitiesJose DiazNo ratings yet

- CHS0004 PN Bella CHS TR21Document1 pageCHS0004 PN Bella CHS TR21manuel radulescuNo ratings yet

- Bomba Pz-7 Liner 6": 7 Od. Casing 9 5/8 Od. CasingDocument1 pageBomba Pz-7 Liner 6": 7 Od. Casing 9 5/8 Od. CasingBryan TaquezNo ratings yet

- Bridas Welding Neck 1500 LbsDocument1 pageBridas Welding Neck 1500 LbsAALEJO CASTRONo ratings yet

- Shoe Size Conversion Chart: (U.S. Sizes in Bold)Document1 pageShoe Size Conversion Chart: (U.S. Sizes in Bold)ThoraNo ratings yet

- Bethlehem Steel Sheet PilingDocument49 pagesBethlehem Steel Sheet Pilingakut61100% (1)

- Grade 6 Rectangular Prism Volume Surface Area ADocument2 pagesGrade 6 Rectangular Prism Volume Surface Area AFranklin N ItomayNo ratings yet

- Engineering Keys and Pins Boksburg South AfricaDocument15 pagesEngineering Keys and Pins Boksburg South AfricaCorneNo ratings yet

- EN 10255 (BS 1387) Steel TubeDocument1 pageEN 10255 (BS 1387) Steel TubeChandraAKTNo ratings yet

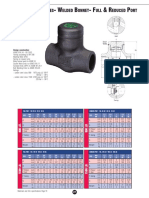

- C V - W B - F & R P: Heck Alves Elded Onnet ULL Educed ORTDocument1 pageC V - W B - F & R P: Heck Alves Elded Onnet ULL Educed ORTMostafizur RahmanNo ratings yet

- Propellor Comparison ChartDocument3 pagesPropellor Comparison ChartGuido PoppeNo ratings yet

- Flange Weight Charts Asme B16.5Document7 pagesFlange Weight Charts Asme B16.5lupiNo ratings yet

- ASME B16.5 DimensionsDocument26 pagesASME B16.5 DimensionsnirgaNo ratings yet

- Material Price List: Ppdo Description Unit PriceDocument9 pagesMaterial Price List: Ppdo Description Unit Pricekelvin karlNo ratings yet

- GL-4 GL-8 GL-10 GL-12 Spec 2015-2016Document2 pagesGL-4 GL-8 GL-10 GL-12 Spec 2015-2016GILMAR NIETONo ratings yet

- DTH1 EfqDocument7 pagesDTH1 EfqPabloRuizOlivaNo ratings yet

- Drillstar Roller ReamerDocument2 pagesDrillstar Roller ReamerLOURIDOMICHELLENo ratings yet

- Hollow Core PDFDocument19 pagesHollow Core PDFAlessandro BicegoNo ratings yet

- Socket Weld Swage NippleDocument7 pagesSocket Weld Swage NippleMdshaffiSiddu Hina2019No ratings yet

- Department of Statistics: COURSE STATS 330/762Document10 pagesDepartment of Statistics: COURSE STATS 330/762PETERNo ratings yet

- Baumfolder D5DrillDocument2 pagesBaumfolder D5DrillKBR Graphics CanadaNo ratings yet

- Estimate Tables & FormDocument21 pagesEstimate Tables & FormDvmegjefjNo ratings yet

- Catalogo Montacargas REACH RR57000Document4 pagesCatalogo Montacargas REACH RR57000fanNo ratings yet

- Nucleic Acid Metabolism Adapted From Zhihong Li Material - May 2024Document79 pagesNucleic Acid Metabolism Adapted From Zhihong Li Material - May 2024Black RavenoidNo ratings yet

- ED6008Document4 pagesED6008VolvoxdjNo ratings yet

- Davis Michael 1A Resume 1Document1 pageDavis Michael 1A Resume 1Alyssa HowellNo ratings yet

- Holiday Master 2024Document1 pageHoliday Master 2024Tanumoy SarkarNo ratings yet

- Equinix Inc. 2022 Sustainability Report HighlightsDocument25 pagesEquinix Inc. 2022 Sustainability Report HighlightsDaniel ChuaNo ratings yet

- Dance Like A ManDocument4 pagesDance Like A ManShubhadip aichNo ratings yet

- Activity 4 - TR-WPS OfficeDocument2 pagesActivity 4 - TR-WPS OfficeJed JaquecaNo ratings yet

- Motion Media and InformationDocument2 pagesMotion Media and InformationLovely PateteNo ratings yet

- Day 2UNQ3-1.docx..bakDocument13 pagesDay 2UNQ3-1.docx..bakAurellia Shafitri100% (1)

- Unit 26Document9 pagesUnit 26MuskaanNo ratings yet

- Appendix 2 Works ListDocument18 pagesAppendix 2 Works ListAnonymous 4BZUZwNo ratings yet

- 1chea Expt4 PPTDocument37 pages1chea Expt4 PPTJimin No JamsNo ratings yet

- Dinagat HVADocument55 pagesDinagat HVARolly Balagon CaballeroNo ratings yet

- Palanca vs. CADocument16 pagesPalanca vs. CASherwin Anoba CabutijaNo ratings yet

- Brigada Solicitation and InvitationDocument3 pagesBrigada Solicitation and Invitationguendolyn templadoNo ratings yet

- Systematix Sona BLW Initiates CoverageDocument32 pagesSystematix Sona BLW Initiates Coveragejitendra76No ratings yet

- Orthodontic Treatment of Mandibular Anterior Crowding: Key Words: Crowding, Malocclusion, Labial FlaringDocument4 pagesOrthodontic Treatment of Mandibular Anterior Crowding: Key Words: Crowding, Malocclusion, Labial FlaringDunia Medisku OnlineShopNo ratings yet

- Mail Delivery SubsystemDocument9 pagesMail Delivery SubsystemLu GuessaNo ratings yet

- Nkrumah NeocolonialismDocument205 pagesNkrumah Neocolonialismabdelrehman.almNo ratings yet

- Hasil To SBMPTN Gratis 7Document129 pagesHasil To SBMPTN Gratis 7MauzNo ratings yet

- Abhinavagupta (C. 950 - 1016 CEDocument8 pagesAbhinavagupta (C. 950 - 1016 CEthewitness3No ratings yet

- HW On Receivables CDocument5 pagesHW On Receivables CAmjad Rian MangondatoNo ratings yet

- Monitoring Times 1998 03Document116 pagesMonitoring Times 1998 03Benjamin DoverNo ratings yet

- Where Have All The Peasants Gone Susana NarotskyDocument21 pagesWhere Have All The Peasants Gone Susana NarotskyHoward Steven Rojas DivantoqueNo ratings yet

- Graded Lab Lab - 7 Introduction To Computing: Topics: If - Else Conditions, While LoopDocument5 pagesGraded Lab Lab - 7 Introduction To Computing: Topics: If - Else Conditions, While LoopqwertyNo ratings yet

- Workstations InventoryDocument37 pagesWorkstations InventoryPacificNo ratings yet

- PEER Report On MS ESA ProgramDocument69 pagesPEER Report On MS ESA ProgramRuss LatinoNo ratings yet

- Thesis APDocument31 pagesThesis APIvy SorianoNo ratings yet