Professional Documents

Culture Documents

Southwire OHL Data

Southwire OHL Data

Uploaded by

poci11Copyright:

Available Formats

You might also like

- Hands On Electronics A Practical Introduction To Analog and Digital Circuits by Daniel M Kaplan and Christopher G WhiteDocument228 pagesHands On Electronics A Practical Introduction To Analog and Digital Circuits by Daniel M Kaplan and Christopher G WhiteInstalatiiGenerale100% (3)

- Mechanics of Drillstrings and Marine Risers PDFDocument401 pagesMechanics of Drillstrings and Marine Risers PDFlfsijNo ratings yet

- (C. Christopoulos, A. Wright (Auth.) ) Electrical PDFDocument619 pages(C. Christopoulos, A. Wright (Auth.) ) Electrical PDFNicolás Cáceres García100% (2)

- TL BookDocument16 pagesTL Booktchhrao83% (6)

- Mechanics of Drilling PDFDocument200 pagesMechanics of Drilling PDFJosué Emmanuel Blásquez Contreras50% (2)

- Concrete Blocks NotesDocument16 pagesConcrete Blocks NotesDharshan KNo ratings yet

- High Voltage EngineeringDocument157 pagesHigh Voltage EngineeringDima Drobiazko100% (2)

- Modern Methods of ConstructionDocument13 pagesModern Methods of ConstructionRigina Jeanne Celestino Young100% (1)

- 6 Table of ContentsDocument4 pages6 Table of ContentsCho Lin MaungNo ratings yet

- Table of ContentsDocument5 pagesTable of ContentsSatheesh Kumar NatarajanNo ratings yet

- Electric Power Transmission System Engineering Analysis and DesignDocument10 pagesElectric Power Transmission System Engineering Analysis and DesignMonzter CarlNo ratings yet

- Electrical Power System Protection PDFDocument18 pagesElectrical Power System Protection PDFAlberto José Bermúdez AriasNo ratings yet

- FlursDocument12 pagesFlurssimonNo ratings yet

- Concepts Engineering: ApplicationsDocument11 pagesConcepts Engineering: ApplicationsGS AryaNo ratings yet

- MicrowaveDocument464 pagesMicrowavenouriNo ratings yet

- Electronic Devices and Analog ElectronicsDocument524 pagesElectronic Devices and Analog ElectronicsAnonymous S6UCpG1ZuP100% (2)

- Hands On ElectronicsDocument228 pagesHands On Electronicsapi-17233982100% (12)

- CMOS Digital Integrated CircuitsDocument405 pagesCMOS Digital Integrated CircuitsAmr Yassin100% (1)

- Coll. - Antennas Fundamentals, Design, Measurement, 3rd Edn (Standard) PDFDocument527 pagesColl. - Antennas Fundamentals, Design, Measurement, 3rd Edn (Standard) PDFAbdalrazaq Ajaj100% (1)

- Preface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDocument6 pagesPreface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDara HengNo ratings yet

- SuperconductingDocument165 pagesSuperconductinghemanth727No ratings yet

- 1HSE 9543 40-00en IT Application Guide Ed2.0Document124 pages1HSE 9543 40-00en IT Application Guide Ed2.0karim_ouakliNo ratings yet

- Electronics 11 PDFDocument342 pagesElectronics 11 PDFKawsar Mobin100% (1)

- Fundamental of Turbomachiner PDFDocument13 pagesFundamental of Turbomachiner PDFM Hilman GumelarNo ratings yet

- A Low Voltage Rail-To-Rail Operational Amplifier With Constant OpDocument104 pagesA Low Voltage Rail-To-Rail Operational Amplifier With Constant OpLaurMateiNo ratings yet

- 1HC0075573 AC EN UeberspannungsBahnanlagenDocument40 pages1HC0075573 AC EN UeberspannungsBahnanlagenErick Santiago CardosoNo ratings yet

- Basic ElectronicsDocument398 pagesBasic Electronicsgugusli2005No ratings yet

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- WCDMA: Requirements and Practical DesignFrom EverandWCDMA: Requirements and Practical DesignRudolf TannerNo ratings yet

- System Integration: From Transistor Design to Large Scale Integrated CircuitsFrom EverandSystem Integration: From Transistor Design to Large Scale Integrated CircuitsNo ratings yet

- Charge-Based MOS Transistor Modeling: The EKV Model for Low-Power and RF IC DesignFrom EverandCharge-Based MOS Transistor Modeling: The EKV Model for Low-Power and RF IC DesignNo ratings yet

- Signal Integrity and Radiated Emission of High-Speed Digital SystemsFrom EverandSignal Integrity and Radiated Emission of High-Speed Digital SystemsNo ratings yet

- Design and Characterization of Integrated Varactors for RF ApplicationsFrom EverandDesign and Characterization of Integrated Varactors for RF ApplicationsNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Microwave Electronics: Measurement and Materials CharacterizationFrom EverandMicrowave Electronics: Measurement and Materials CharacterizationNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- IEEE 802 Wireless Systems: Protocols, Multi-Hop Mesh / Relaying, Performance and Spectrum CoexistenceFrom EverandIEEE 802 Wireless Systems: Protocols, Multi-Hop Mesh / Relaying, Performance and Spectrum CoexistenceNo ratings yet

- ACSR AlCladWire Data - ProcablesDocument6 pagesACSR AlCladWire Data - Procablespoci11No ratings yet

- ACSR SD Data - Alan CableDocument4 pagesACSR SD Data - Alan Cablepoci11No ratings yet

- Copper-Bonded Vs Galvanized Ground RodsDocument10 pagesCopper-Bonded Vs Galvanized Ground Rodspoci11No ratings yet

- Copper Clad Steel Rod BrochureDocument8 pagesCopper Clad Steel Rod Brochurepoci11No ratings yet

- 3 Avialite Product Brochure - MS-20KP+CAAM+SirimDocument4 pages3 Avialite Product Brochure - MS-20KP+CAAM+Sirimpoci11No ratings yet

- Silcosil-Silicone-Insulators-AI-EN - 01 Technical Article Composite InsulatorDocument20 pagesSilcosil-Silicone-Insulators-AI-EN - 01 Technical Article Composite Insulatorpoci11No ratings yet

- 2 Avialite Product Brochure - MS-20-2KP+CAAM+SirimDocument5 pages2 Avialite Product Brochure - MS-20-2KP+CAAM+Sirimpoci11No ratings yet

- Acsr/Gz - Aluminium Conductors, Galvanised Steel Reinforced: Physical CharacteristicsDocument1 pageAcsr/Gz - Aluminium Conductors, Galvanised Steel Reinforced: Physical Characteristicspoci11No ratings yet

- 1 Avialite Product Brochure - MS-2KP - Series V2.89aDocument4 pages1 Avialite Product Brochure - MS-2KP - Series V2.89apoci11No ratings yet

- TE Creepage Extender ENG - DS - EPP-3180 - 1911 TE Bird GuanoDocument2 pagesTE Creepage Extender ENG - DS - EPP-3180 - 1911 TE Bird Guanopoci11No ratings yet

- TE HVCE Product Datasheet BirdDocument2 pagesTE HVCE Product Datasheet Birdpoci11No ratings yet

- Phase Arrangement OHLDocument5 pagesPhase Arrangement OHLpoci11No ratings yet

- AFL - Quick - Compress Repair Sleeve Installation Instructions For ACSRConductorsDocument1 pageAFL - Quick - Compress Repair Sleeve Installation Instructions For ACSRConductorspoci11No ratings yet

- Erico-Eritech-Lightning-Protection - IEC62305-Earthing-Design-Guide IEC StddsDocument92 pagesErico-Eritech-Lightning-Protection - IEC62305-Earthing-Design-Guide IEC Stddspoci11No ratings yet

- 4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance TestDocument24 pages4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance Testpoci11No ratings yet

- Test-Meter Co UkDocument5 pagesTest-Meter Co Ukpoci11No ratings yet

- Metrel MI3210 TeraOhmXA 10kV Insulation Tester - Test-Meter - Co.ukDocument2 pagesMetrel MI3210 TeraOhmXA 10kV Insulation Tester - Test-Meter - Co.ukpoci11No ratings yet

- Pre Qualification Test of 500kV XLPE Cable in ChinaDocument1 pagePre Qualification Test of 500kV XLPE Cable in Chinapoci11No ratings yet

- TEC-033000.1-MET-DoR-001 (Method Statement For Foundation Preparations Up To Blinding)Document10 pagesTEC-033000.1-MET-DoR-001 (Method Statement For Foundation Preparations Up To Blinding)Tomi Wiryandi SaputraNo ratings yet

- Thin Wall BeamsDocument32 pagesThin Wall BeamsAllan Marbaniang100% (1)

- 05 Design ExamplesDocument3 pages05 Design ExamplesDiana MorosanuNo ratings yet

- Vision Built Steel Frame Building System: Systèmes Pour Constructions BausystemDocument36 pagesVision Built Steel Frame Building System: Systèmes Pour Constructions BausystemKyaw Zin HeinNo ratings yet

- Ampro: Availability AMPRO™ Multi-Purpose System Order CodesDocument2 pagesAmpro: Availability AMPRO™ Multi-Purpose System Order CodesBlair ForemanNo ratings yet

- Masterroc Hca 20: Liquid Hydration Inhibitor For ConcreteDocument3 pagesMasterroc Hca 20: Liquid Hydration Inhibitor For Concretez_sheriNo ratings yet

- SprinklersDocument16 pagesSprinklersAdel Suker100% (1)

- Flexural Behavior of Engineered Cementitious Composite (ECC) Slabs With Polyvinyl Alcohol BersDocument13 pagesFlexural Behavior of Engineered Cementitious Composite (ECC) Slabs With Polyvinyl Alcohol BerssandroNo ratings yet

- Unconfined Compression Test: Experiment No. 7Document8 pagesUnconfined Compression Test: Experiment No. 7Carmela Ayessa PiguerraNo ratings yet

- Switchgear Standard Operating ProceduresDocument22 pagesSwitchgear Standard Operating ProceduresM DuraiNo ratings yet

- RETAINING WALL-ModelDocument1 pageRETAINING WALL-ModelArchana PansareNo ratings yet

- Effect of Studs On The Heat Loss and Insulation Value of A WallDocument4 pagesEffect of Studs On The Heat Loss and Insulation Value of A WallGreen Action Sustainable Technology GroupNo ratings yet

- Seismic Performance of Steel-Reinforced Concrete Composite Columns in Existing and Modern ConstructionDocument19 pagesSeismic Performance of Steel-Reinforced Concrete Composite Columns in Existing and Modern ConstructionNarsingha KharosekarNo ratings yet

- Piping Codes & Standards - Piping GuideDocument8 pagesPiping Codes & Standards - Piping Guideabhilibra14No ratings yet

- Engineering Metallurgy MM207 IIT Bombay Kashyap Sir Dislocation Grains Grain Boundary SlidesDocument97 pagesEngineering Metallurgy MM207 IIT Bombay Kashyap Sir Dislocation Grains Grain Boundary SlidesPratik BabhulkarNo ratings yet

- ASTM A283 A283M 18 - PreDocument2 pagesASTM A283 A283M 18 - Prebruno.abuafNo ratings yet

- Carel Controler PDFDocument80 pagesCarel Controler PDFGinguba100% (1)

- Radiographic Examination Report: Page 1 of 2 Report No: VNIS/SMA/00057 Customer: L&T Valves LimitedDocument2 pagesRadiographic Examination Report: Page 1 of 2 Report No: VNIS/SMA/00057 Customer: L&T Valves LimitedSathish JayaprakashNo ratings yet

- Slab Thickness Sunken Depth: LoadingDocument10 pagesSlab Thickness Sunken Depth: LoadingSuson DhitalNo ratings yet

- 2021 11 Facade Principles - CompressedDocument43 pages2021 11 Facade Principles - CompressedKayzha Shafira Ramadhani460 105No ratings yet

- MIL-DTL-24441D, TYPE IV: Protective & Marine CoatingsDocument4 pagesMIL-DTL-24441D, TYPE IV: Protective & Marine CoatingsEduardo Antonio Burgos RuidíasNo ratings yet

- Mahiyangana D.S.qur ModelDocument1 pageMahiyangana D.S.qur ModelMuhammadWazimAkramNo ratings yet

- Determination of True Stress Strain CharacteristicDocument9 pagesDetermination of True Stress Strain CharacteristicEng Hinji RudgeNo ratings yet

- 2005 Load CalculatorDocument4 pages2005 Load CalculatorShang Divina EbradaNo ratings yet

- Smart Freeze Drying: Basic Principles, Optimum Procedures and ApplicationsDocument56 pagesSmart Freeze Drying: Basic Principles, Optimum Procedures and Applicationssubarna_75No ratings yet

- Mechanical Systems Design Utilizing BIM As A Tool For Efficient ImplementationDocument47 pagesMechanical Systems Design Utilizing BIM As A Tool For Efficient ImplementationJacob Chico SueroNo ratings yet

- C-AJ-1380 2 HR Thru Wall-Flr MTL Pipe PenetrationDocument3 pagesC-AJ-1380 2 HR Thru Wall-Flr MTL Pipe PenetrationmikeNo ratings yet

- 319 Docol Product ProgramDocument2 pages319 Docol Product Programchristos032No ratings yet

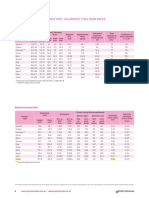

Southwire OHL Data

Southwire OHL Data

Uploaded by

poci11Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Southwire OHL Data

Southwire OHL Data

Uploaded by

poci11Copyright:

Available Formats

TABLE OF CONTENTS

1.0 INTRODUCTION TO BARE OVERHEAD CONDUCTORS 1

1 1.1 TYPES OF CONDUCTOR MATERIALS 2

1.1.1 Aluminum and Aluminum Alloy Wire 2

1.1.2 Coated Steel Core Wire 3

1.1.3 Selected Physical and Mechanical Properties 3

1.1.4 Mechanical Properties of 1350 and 6201 Aluminum Alloy Wire 4

1.1.5 Mechanical Properties of Steel Wire 5

1.2 CONCENTRIC-LAY-STRANDED CONDUCTOR CONSTRUCTION 5

1.2.1 Round-Wire Construction 6

1.2.2 Trapezoidal-Shaped Wire Construction 7

1.2.3 Stranded Conductor Size 8

1.2.4 ACSR Stranding Ratios 9

1.3 ELECTRICAL CHARACTERISTICS OF CONDUCTORS 9

1.3.1 DC Resistance 9

1.3.2 AC Resistance 11

1.3.3 Inductance and Inductive Reactance 16

1.3.4 Shunt Capacitance and Capacitive Reactance 24

1.4 MECHANICAL CHARACTERISTICS OF STRANDED CONDUCTORS 28

1.4.1 Rated Strength of Concentric-Lay-Stranded Conductors 28

1.4.2 Stress-Strain Characteristics of Stranded Conductors 31

1.5 THERMAL RATING OF BARE OVERHEAD CONDUCTORS 33

1.6 CONDUCTOR SELECTION 34

1.6.1 Conventional Round Wire Conductors 36

1.6.2 Trapezoidal-Shaped Wire Conductors 37

1.6.3 Wind-Motion Resistant Conductors 39

1.6.4 High Temperature Conductors 40

1.7 REFERENCES 43

CHAPTER 1 APPENDIX 45

Conductor Tables 47

iv Southwire Overhead Conductor Manual

2.0 SAG AND TENSION OF CONDUCTORS 1

2 2.1 THE CATENARY OF A SINGLE SPAN 2

2.1.1 Level Spans 2

2.1.2 Conductor Length 3

2.1.3 Conductor Slack 3

2.1.4 Total and Horizontal Tension 4

2.1.5 Inclined Spans 5

2.2 RULING SPAN CONCEPT 7

2.2.1 Ruling Span Calculation 8

2.2.2 Stringing Sag Tables 8

2.2.3 Tension Differences for Adjacent Dead-End Spans 10

2.2.4 Tension Equalization by Suspension Insulators 10

2.3 CONDUCTOR TENSION LIMITS AND LOADING 12

2.3.1 Ice and Wind Loading 13

2.4 SIMPLIFIED SAG-TENSION CALCULATIONS 17

2.4.1 Sag-Tension Change with Conductor Temperature 17

2.4.2 Sag-Tension Change with Ice or Wind Loading 19

2.4.3 Sag-Tension Change of a Simple Elastic Conductor 19

2.5 PLASTIC CONDUCTOR ELONGATION 20

2.5.1 Conductor Elongation Models 21

2.5.2 Experimental Plastic Elongation Model Data 23

2.5.3 Formulas for Predicting Creep Elongation 26

2.5.4 Knee-Point 28

2.5.5 Examples of Typical Stress-Strain Conductor Curves 29

2.6 SAG -TENSION CALCULATIONS WITH EXPERIMENTAL ELONGATION 32

2.7 LINE DESIGN SAG-TENSION PARAMETERS 33

2.7.1 Catenary Constants 33

2.7.2 Wind Span 33

2.7.3 Weight Spans 35

2.7.4 Uplift at Suspension Structures 35

2.7.5 Tower Spotting 35

2.8 CONDUCTOR INSTALLATION 35

2.8.1 Conductor Stringing Methods 35

2.8.2 Tension Stringing Equipment and Setup 38

2.8.3 Sagging Procedure 39

2.9 REFERENCES 43

2.10 ADDITIONAL PUBLICATIONS 44

CHAPTER 2 APPENDIX 45

Appendix 2.1 - Figures 46

Appendix 2.2 - Glossary of Equipment Terms 52

Southwire Overhead Conductor Manual v

3.0 THERMAL RATINGS OF BARE OVERHEAD CONDUCTORS 1

3 3.1 STEADY-STATE THERMAL RATINGS 2

3.1.1 Units and Symbols 2

3.1.2 Steady-State Calculation Methods 2

3.1.3 Steady-State Heat Balance 2

3.1.4 Convected Heat Loss Rate (qc) 3

3.1.5 Radiated Heat Loss Rate(qr) 5

3.1.6 Solar Heat Gain Rate(qs) 7

3.1.7 Conductor AC Resistance 8

3.1.8 Example of a Steady-State Thermal Rating Calculation 9

3.2 TRANSIENT THERMAL RATINGS 12

3.2.1 Step Increase in Load Current 12

3.2.2 Conductor Heat Capacity 13

3.2.3 Example of Transient Thermal Rating Determination 13

3.2.4 Thermal Time Constant 14

3.3 FAULT CURRENT RATINGS 15

3.4 COMPUTER PROGRAM FOR CALCULATING THERMAL RATINGS 16

3.5 SELECTION OF WEATHER CONDITIONS FOR LINE RATING CALCULATIONS 17

3.6 CONDUCTOR LOSS OF STRENGTH 17

3.6.1 Annealing of Individual Strands 17

3.6.2 Stranded Conductor Loss of Strength 18

3.6.3 Calculation of Remaining Strength 18

3.7 SAG AT HIGH TEMPERATURE 20

3.7.1 Thermal Coefficient of Expansion 20

3.7.2 Suspension Span Interaction at Elevated Temperature 22

3.7.3 Radial Temperature Difference 23

3.8 HIGH-TEMPERATURE CREEP ELONGATION 24

3.8.1 Creep of AAC, AAAC and ACAR Conductors at High Temperature 24

3.8.2 Creep of ACSR Conductors at High Temperature 25

3.8.3 Example of Creep Calculation at High Temperature 26

3.9 EFFECT OF ELEVATED TEMPERATURES ON CONNECTORS AND HARDWARE 27

3.10 REFERENCES 29

CHAPTER 3 APPENDIX 31

vi Southwire Overhead Conductor Manual

4.0 ELECTRICAL ENVIRONMENTAL EFFECTS 1

4 4.1 RADIO NOISE 2

4.1.1 Radio Noise Sources 2

4.1.2 Prediction Programs 2

4.1.3 Weather Dependence 3

4.1.4 Radio Noise Profiles 3

4.1.5 Evaluation of Radio Noise 4

4.1.6 Hardware and Insulator Radio Noise 5

4.1.7 Measurement Techniques 5

4.1.8 Noise Location Techniques 5

4.2 AUDIBLE NOISE 6

4.2.1 Audible Noise Sources 6

4.2.2 Prediction Programs 6

4.2.3 Weather Dependence 7

4.2.4 Audible Noise Profiles 7

4.2.5 Evaluation of Audible Noise 7

4.2.6 Measurement Techniques 8

4.3 ELECTRIC FIELDS 8

4.3.1 Electric Field Sources 8

4.3.2 Prediction Programs 9

4.3.3 Electric Field Profiles 9

4.3.4 Capacitive Coupling of Electric Fields 11

4.3.5 Evaluation of Electric Fields 12

4.3.6 Measurement Techniques 13

4.3.7 Grounding and Shielding 13

4.4 MAGNETIC FIELDS 13

4.4.1 Magnetic Field Characterization 13

4.4.2 Prediction Programs 14

4.4.3 Magnetic Field Profiles 14

4.4.4 Statistical Characterization of Magnetic Fields 15

4.4.5 Inductive Coupling of Magnetic Fields 16

4.4.6 Instrumentation for Magnetic Field Measurement 16

4.4.7 Measurement Procedures 17

4.4.8 Grounding and Shielding 17

4.5 REFERENCES 19

Southwire Overhead Conductor Manual vii

5.0 DESIGN OF NEW TRANSMISSION LINES 1

5 5.1 NEW TRANSMISSION LINE DESIGN CONSIDERATIONS 2

5.1.1 System Requirements 2

5.1.2 Environmental Design Constraints 2

5.1.3 Standard Line Design Considerations 3

5.2 ELECTRICAL INSULATION COORDINATION 4

5.2.1 Power Frequency Design 4

5.2.2 Switching Surge Flashover 6

5.2.3 Lightning 9

5.3 WIND-INDUCED CONDUCTOR AND INSULATOR MOTIONS 11

5.3.1 Conductor Blowout 13

5.3.2 Aeolian Vibration 14

5.3.3 Ice Galloping 20

5.3.4 Subconductor Oscillation 25

5.4 ECONOMIC DESIGN OF OVERHEAD LINES 26

5.4.1 Present Worth (PW) of Electrical Losses 28

5.4.2 Value of Increased Power Flow Capacity 29

5.4.3 Capital Construction Costs 29

5.4.4 Minimizing Total Line Cost 29

5.4.5 Supporting Structure Cost 31

5.4.6 Conductor Selection with the Typical Span Method 31

5.4.7 Economic Structure Spotting 32

5.4.8 Cost with Respect to Conductor Tension 35

5.5 VISUALLY ACCEPTABLE LINE DESIGNS 37

5.6 REFERENCES 41

viii Southwire Overhead Conductor Manual

6.0 VOLTAGE UPGRADING OF EXISTING LINES 1

6 6.1 FUNDAMENTALS OF VOLTAGE UPGRADING 2

6.2 ELEMENTS OF A VOLTAGE UPGRADING STUDY 3

6.2.1 Need for Voltage Upgrading 3

6.2.2 Analysis of the Problem 4

6.2.3 Feasibility Analysis 4

6.2.4 Detailed Studies 4

6.3 INSULATION COORDINATION 4

6.3.1 60-Hz Flashover 4

6.3.2 Insulator Contamination 5

6.3.3 Switching Surge Flashover 6

6.3.4 Lightning Performance 6

6.4 CORONA LIMITATIONS 7

6.4.1 Radio and Audible Noise 7

6.4.2 Corona Loss 8

6.5 ELECTRIC AND MAGNETIC FIELDS 8

6.6 GROUND CLEARANCE 8

6.7 RECONDUCTORING 9

6.8 SIX-PHASE CONVERSION OF EXISTING DOUBLE-CIRCUIT LINES 11

6.9 GENERAL CONCERNS 11

6.10 REFERENCES 13

Southwire Overhead Conductor Manual ix

7.0 THERMAL UPRATING OF EXISTING LINES 1

7 7.1 INTRODUCTION TO LINE UPRATING 2

7.1.1 Present Limitations 2

7.1.2 Major Economic Factors 2

7.1.3 Physical and Institutional Constraints 2

7.2 DETERMINATION OF THERMAL RATINGS FOR OVERHEAD LINES 2

7.2.1 Thermal Rating Parameters 3

7.2.2 Thermal Rating Terms and Definitions 4

7.2.3 Exact Heat Balance Equation 4

7.2.4 Approximate Thermal Rating Calculations 5

7.2.5 Influence of Primary Variables on Thermal Rating Calculations 6

7.2.6 Influence of Secondary Variables on Thermal Rating Calculations 7

7.3 UPRATING EXISTING LINES WITHOUT RECONDUCTORING 8

7.3.1 Reassessment of Weather Parameters for Static Ratings 8

7.3.2 Real-Time Thermal Rating of Overhead Lines 11

7.3.3 Increasing the Maximum Allowable Conductor Temperature 12

7.3.4 Modifications to Sag-Limited Lines 13

7.4 RECONDUCTORING EXISTING TRANSMISSION LINES 15

7.4.1 Sag Constraints for Reconductoring 16

7.4.2 Reconductoring with Conventional Conductors 16

7.4.3 Reconductoring with High Temperature Conductors 17

7.5 THERMAL UPRATING CASE STUDY 19

7.6 REFERENCES 24

x Southwire Overhead Conductor Manual

You might also like

- Hands On Electronics A Practical Introduction To Analog and Digital Circuits by Daniel M Kaplan and Christopher G WhiteDocument228 pagesHands On Electronics A Practical Introduction To Analog and Digital Circuits by Daniel M Kaplan and Christopher G WhiteInstalatiiGenerale100% (3)

- Mechanics of Drillstrings and Marine Risers PDFDocument401 pagesMechanics of Drillstrings and Marine Risers PDFlfsijNo ratings yet

- (C. Christopoulos, A. Wright (Auth.) ) Electrical PDFDocument619 pages(C. Christopoulos, A. Wright (Auth.) ) Electrical PDFNicolás Cáceres García100% (2)

- TL BookDocument16 pagesTL Booktchhrao83% (6)

- Mechanics of Drilling PDFDocument200 pagesMechanics of Drilling PDFJosué Emmanuel Blásquez Contreras50% (2)

- Concrete Blocks NotesDocument16 pagesConcrete Blocks NotesDharshan KNo ratings yet

- High Voltage EngineeringDocument157 pagesHigh Voltage EngineeringDima Drobiazko100% (2)

- Modern Methods of ConstructionDocument13 pagesModern Methods of ConstructionRigina Jeanne Celestino Young100% (1)

- 6 Table of ContentsDocument4 pages6 Table of ContentsCho Lin MaungNo ratings yet

- Table of ContentsDocument5 pagesTable of ContentsSatheesh Kumar NatarajanNo ratings yet

- Electric Power Transmission System Engineering Analysis and DesignDocument10 pagesElectric Power Transmission System Engineering Analysis and DesignMonzter CarlNo ratings yet

- Electrical Power System Protection PDFDocument18 pagesElectrical Power System Protection PDFAlberto José Bermúdez AriasNo ratings yet

- FlursDocument12 pagesFlurssimonNo ratings yet

- Concepts Engineering: ApplicationsDocument11 pagesConcepts Engineering: ApplicationsGS AryaNo ratings yet

- MicrowaveDocument464 pagesMicrowavenouriNo ratings yet

- Electronic Devices and Analog ElectronicsDocument524 pagesElectronic Devices and Analog ElectronicsAnonymous S6UCpG1ZuP100% (2)

- Hands On ElectronicsDocument228 pagesHands On Electronicsapi-17233982100% (12)

- CMOS Digital Integrated CircuitsDocument405 pagesCMOS Digital Integrated CircuitsAmr Yassin100% (1)

- Coll. - Antennas Fundamentals, Design, Measurement, 3rd Edn (Standard) PDFDocument527 pagesColl. - Antennas Fundamentals, Design, Measurement, 3rd Edn (Standard) PDFAbdalrazaq Ajaj100% (1)

- Preface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDocument6 pagesPreface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDara HengNo ratings yet

- SuperconductingDocument165 pagesSuperconductinghemanth727No ratings yet

- 1HSE 9543 40-00en IT Application Guide Ed2.0Document124 pages1HSE 9543 40-00en IT Application Guide Ed2.0karim_ouakliNo ratings yet

- Electronics 11 PDFDocument342 pagesElectronics 11 PDFKawsar Mobin100% (1)

- Fundamental of Turbomachiner PDFDocument13 pagesFundamental of Turbomachiner PDFM Hilman GumelarNo ratings yet

- A Low Voltage Rail-To-Rail Operational Amplifier With Constant OpDocument104 pagesA Low Voltage Rail-To-Rail Operational Amplifier With Constant OpLaurMateiNo ratings yet

- 1HC0075573 AC EN UeberspannungsBahnanlagenDocument40 pages1HC0075573 AC EN UeberspannungsBahnanlagenErick Santiago CardosoNo ratings yet

- Basic ElectronicsDocument398 pagesBasic Electronicsgugusli2005No ratings yet

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- WCDMA: Requirements and Practical DesignFrom EverandWCDMA: Requirements and Practical DesignRudolf TannerNo ratings yet

- System Integration: From Transistor Design to Large Scale Integrated CircuitsFrom EverandSystem Integration: From Transistor Design to Large Scale Integrated CircuitsNo ratings yet

- Charge-Based MOS Transistor Modeling: The EKV Model for Low-Power and RF IC DesignFrom EverandCharge-Based MOS Transistor Modeling: The EKV Model for Low-Power and RF IC DesignNo ratings yet

- Signal Integrity and Radiated Emission of High-Speed Digital SystemsFrom EverandSignal Integrity and Radiated Emission of High-Speed Digital SystemsNo ratings yet

- Design and Characterization of Integrated Varactors for RF ApplicationsFrom EverandDesign and Characterization of Integrated Varactors for RF ApplicationsNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Microwave Electronics: Measurement and Materials CharacterizationFrom EverandMicrowave Electronics: Measurement and Materials CharacterizationNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- IEEE 802 Wireless Systems: Protocols, Multi-Hop Mesh / Relaying, Performance and Spectrum CoexistenceFrom EverandIEEE 802 Wireless Systems: Protocols, Multi-Hop Mesh / Relaying, Performance and Spectrum CoexistenceNo ratings yet

- ACSR AlCladWire Data - ProcablesDocument6 pagesACSR AlCladWire Data - Procablespoci11No ratings yet

- ACSR SD Data - Alan CableDocument4 pagesACSR SD Data - Alan Cablepoci11No ratings yet

- Copper-Bonded Vs Galvanized Ground RodsDocument10 pagesCopper-Bonded Vs Galvanized Ground Rodspoci11No ratings yet

- Copper Clad Steel Rod BrochureDocument8 pagesCopper Clad Steel Rod Brochurepoci11No ratings yet

- 3 Avialite Product Brochure - MS-20KP+CAAM+SirimDocument4 pages3 Avialite Product Brochure - MS-20KP+CAAM+Sirimpoci11No ratings yet

- Silcosil-Silicone-Insulators-AI-EN - 01 Technical Article Composite InsulatorDocument20 pagesSilcosil-Silicone-Insulators-AI-EN - 01 Technical Article Composite Insulatorpoci11No ratings yet

- 2 Avialite Product Brochure - MS-20-2KP+CAAM+SirimDocument5 pages2 Avialite Product Brochure - MS-20-2KP+CAAM+Sirimpoci11No ratings yet

- Acsr/Gz - Aluminium Conductors, Galvanised Steel Reinforced: Physical CharacteristicsDocument1 pageAcsr/Gz - Aluminium Conductors, Galvanised Steel Reinforced: Physical Characteristicspoci11No ratings yet

- 1 Avialite Product Brochure - MS-2KP - Series V2.89aDocument4 pages1 Avialite Product Brochure - MS-2KP - Series V2.89apoci11No ratings yet

- TE Creepage Extender ENG - DS - EPP-3180 - 1911 TE Bird GuanoDocument2 pagesTE Creepage Extender ENG - DS - EPP-3180 - 1911 TE Bird Guanopoci11No ratings yet

- TE HVCE Product Datasheet BirdDocument2 pagesTE HVCE Product Datasheet Birdpoci11No ratings yet

- Phase Arrangement OHLDocument5 pagesPhase Arrangement OHLpoci11No ratings yet

- AFL - Quick - Compress Repair Sleeve Installation Instructions For ACSRConductorsDocument1 pageAFL - Quick - Compress Repair Sleeve Installation Instructions For ACSRConductorspoci11No ratings yet

- Erico-Eritech-Lightning-Protection - IEC62305-Earthing-Design-Guide IEC StddsDocument92 pagesErico-Eritech-Lightning-Protection - IEC62305-Earthing-Design-Guide IEC Stddspoci11No ratings yet

- 4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance TestDocument24 pages4118A - IM - 92-2233A - E - L Kyoritsu Line Impedance Testpoci11No ratings yet

- Test-Meter Co UkDocument5 pagesTest-Meter Co Ukpoci11No ratings yet

- Metrel MI3210 TeraOhmXA 10kV Insulation Tester - Test-Meter - Co.ukDocument2 pagesMetrel MI3210 TeraOhmXA 10kV Insulation Tester - Test-Meter - Co.ukpoci11No ratings yet

- Pre Qualification Test of 500kV XLPE Cable in ChinaDocument1 pagePre Qualification Test of 500kV XLPE Cable in Chinapoci11No ratings yet

- TEC-033000.1-MET-DoR-001 (Method Statement For Foundation Preparations Up To Blinding)Document10 pagesTEC-033000.1-MET-DoR-001 (Method Statement For Foundation Preparations Up To Blinding)Tomi Wiryandi SaputraNo ratings yet

- Thin Wall BeamsDocument32 pagesThin Wall BeamsAllan Marbaniang100% (1)

- 05 Design ExamplesDocument3 pages05 Design ExamplesDiana MorosanuNo ratings yet

- Vision Built Steel Frame Building System: Systèmes Pour Constructions BausystemDocument36 pagesVision Built Steel Frame Building System: Systèmes Pour Constructions BausystemKyaw Zin HeinNo ratings yet

- Ampro: Availability AMPRO™ Multi-Purpose System Order CodesDocument2 pagesAmpro: Availability AMPRO™ Multi-Purpose System Order CodesBlair ForemanNo ratings yet

- Masterroc Hca 20: Liquid Hydration Inhibitor For ConcreteDocument3 pagesMasterroc Hca 20: Liquid Hydration Inhibitor For Concretez_sheriNo ratings yet

- SprinklersDocument16 pagesSprinklersAdel Suker100% (1)

- Flexural Behavior of Engineered Cementitious Composite (ECC) Slabs With Polyvinyl Alcohol BersDocument13 pagesFlexural Behavior of Engineered Cementitious Composite (ECC) Slabs With Polyvinyl Alcohol BerssandroNo ratings yet

- Unconfined Compression Test: Experiment No. 7Document8 pagesUnconfined Compression Test: Experiment No. 7Carmela Ayessa PiguerraNo ratings yet

- Switchgear Standard Operating ProceduresDocument22 pagesSwitchgear Standard Operating ProceduresM DuraiNo ratings yet

- RETAINING WALL-ModelDocument1 pageRETAINING WALL-ModelArchana PansareNo ratings yet

- Effect of Studs On The Heat Loss and Insulation Value of A WallDocument4 pagesEffect of Studs On The Heat Loss and Insulation Value of A WallGreen Action Sustainable Technology GroupNo ratings yet

- Seismic Performance of Steel-Reinforced Concrete Composite Columns in Existing and Modern ConstructionDocument19 pagesSeismic Performance of Steel-Reinforced Concrete Composite Columns in Existing and Modern ConstructionNarsingha KharosekarNo ratings yet

- Piping Codes & Standards - Piping GuideDocument8 pagesPiping Codes & Standards - Piping Guideabhilibra14No ratings yet

- Engineering Metallurgy MM207 IIT Bombay Kashyap Sir Dislocation Grains Grain Boundary SlidesDocument97 pagesEngineering Metallurgy MM207 IIT Bombay Kashyap Sir Dislocation Grains Grain Boundary SlidesPratik BabhulkarNo ratings yet

- ASTM A283 A283M 18 - PreDocument2 pagesASTM A283 A283M 18 - Prebruno.abuafNo ratings yet

- Carel Controler PDFDocument80 pagesCarel Controler PDFGinguba100% (1)

- Radiographic Examination Report: Page 1 of 2 Report No: VNIS/SMA/00057 Customer: L&T Valves LimitedDocument2 pagesRadiographic Examination Report: Page 1 of 2 Report No: VNIS/SMA/00057 Customer: L&T Valves LimitedSathish JayaprakashNo ratings yet

- Slab Thickness Sunken Depth: LoadingDocument10 pagesSlab Thickness Sunken Depth: LoadingSuson DhitalNo ratings yet

- 2021 11 Facade Principles - CompressedDocument43 pages2021 11 Facade Principles - CompressedKayzha Shafira Ramadhani460 105No ratings yet

- MIL-DTL-24441D, TYPE IV: Protective & Marine CoatingsDocument4 pagesMIL-DTL-24441D, TYPE IV: Protective & Marine CoatingsEduardo Antonio Burgos RuidíasNo ratings yet

- Mahiyangana D.S.qur ModelDocument1 pageMahiyangana D.S.qur ModelMuhammadWazimAkramNo ratings yet

- Determination of True Stress Strain CharacteristicDocument9 pagesDetermination of True Stress Strain CharacteristicEng Hinji RudgeNo ratings yet

- 2005 Load CalculatorDocument4 pages2005 Load CalculatorShang Divina EbradaNo ratings yet

- Smart Freeze Drying: Basic Principles, Optimum Procedures and ApplicationsDocument56 pagesSmart Freeze Drying: Basic Principles, Optimum Procedures and Applicationssubarna_75No ratings yet

- Mechanical Systems Design Utilizing BIM As A Tool For Efficient ImplementationDocument47 pagesMechanical Systems Design Utilizing BIM As A Tool For Efficient ImplementationJacob Chico SueroNo ratings yet

- C-AJ-1380 2 HR Thru Wall-Flr MTL Pipe PenetrationDocument3 pagesC-AJ-1380 2 HR Thru Wall-Flr MTL Pipe PenetrationmikeNo ratings yet

- 319 Docol Product ProgramDocument2 pages319 Docol Product Programchristos032No ratings yet