Professional Documents

Culture Documents

Fluid Lab Report by Umair

Fluid Lab Report by Umair

Uploaded by

Umair KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluid Lab Report by Umair

Fluid Lab Report by Umair

Uploaded by

Umair KhanCopyright:

Available Formats

LAB REPORT

University of Engineering and

Technology Peshawar

FLUID MECHANICS – II (LAB)

CE-330L

By

Engr. TABINDA MASUD

5rd Semester FALL 2022

LAB REPORT

Prepared by

MUHAMMAD UMAIR UMAR.

Reg. # 20pwciv5529

Roll # 168

MUHAMMAD UMAIR UMAR 1

LAB REPORT

CONTENT

S.NO EXPERIMENT NAME PAGE NO.

1 Demonstration of various parts of hydraulic bench 3

2 To determine the discharge and coefficient of Discharge 6

over rectangular Notch

3 To determine the discharge and coefficient of Discharge 8

over triangular Notch

To determine the discharge and coefficient of Discharge

over rectangular and triangular Notch

4 Investigation of different types of flows using Osborne 10

Reynolds’s apparatus (by visual observation)

5 Investigation of different types of flows using Osborne 12

Reynolds’s apparatus (by Reynolds’s number formula)

6 To determine the theoretical and actual center of pressure on 13

partially submerged body.

7 To determine hydraulic co-efficient and to study jet 16

profile of a small circular orifice provided at side of

tank

8 To determine the hydraulic coefficients for a circular orifice 21

at the bottom of tank

9 To investigate the velocity of Bernoulli’s theorem as applied 23

to the flow of water by Bernoulli’s theorem demonstration

10 To determine the relationship between head loss due to 25

friction and velocity for flow of water through smooth bore

pipe

MUHAMMAD UMAIR UMAR 2

LAB REPORT

Experiment # 1

DEMONSTRATION OF VARIOUS PARTS OF HYDRAULIC BENCH

Objectives of the Experiment:

To obtain knowledge about various parts of a Hydraulic Bench.

Introduction:

Hydraulic bench is a volumetric flow measurement apparatus that consists

of a water receptacle present at the bottom, through which water is pumped up to

an open channel through a control valve by a centrifugal pump. This water is finally

discharged into the volumetric tank and the change in level of water in the

volumetric tank, as given by the calibrated scale, gives the flow rate.

VARIOUS PARTS OF HYDRAULICS BENCH

Sight tube and Scale:

A sight tube and scale is connected to tapping in the base of the volumetric tank and give an

instantaneous indication of water flow.

Flow Control Valve:

It is used to regulate the flow in the pipe i.e. to increase or decrease the inflow of water in

hydraulic bench. When it is rotated clockwise it reduces the water flow and when it is moved

counterclockwise it increase the water flow.

Motor On\Off Button:

This button is used to start or close the motor.

Centrifugal Pump:

It draws water from sump tank and supplies it for performing experiment.

Dump Valve and dump Valve Handle:

Dump valve is in the base of the volumetric tank opening the dump valve with dump valve handle

allows the entrained water to return to the sump tank to recycling and closing the dump valve

gathers the water in the volumetric tank.

Drain Valve:

Drain valve is used for discharging of water form sump tank.

MUHAMMAD UMAIR UMAR 3

LAB REPORT

Sump Tank:

The fluid used in hydraulic bench is stored in sump tank located at the bottom of hydraulic bench.

The water from the sump tank is supplied through pump. Sump tank has the capacity of 160

liters.

Quick Release Connector:

The connector allows flow for rapid substitution of accessories. Special purpose terminations

may be connected to the pump supply by screwing connector. No hand tools are required for

doing so.

Side Wall Slots\Channel:

Side channels are provided to support the accessory on test.

Inlet Stilling Baffle Valve:

Inlet stilling baffle valve is used to supply water in the open channel.

Open Channel:

It is used in number of experiments. It provides passage for water for different

experiments.

Weir Carrier:

Two types of weirs are used frequently

• Rectangular weir

• Triangular weir

Tank Stilling Baffle:

Volumetric measuring tank incorporates a stilling baffle inclined to reduce turbulence.

Volumetric Tank:

Water discharging form the accessory (channels) on test is collected in a volumetric measuring

tank. This tank is stepped to accommodate low or high flow rates.

Overflow:

An over flow adjacent to the sump returns the water to the sump tank in the event of incorrect

use of water.

MUHAMMAD UMAIR UMAR 4

LAB REPORT

Hydraulic bench

MUHAMMAD UMAIR UMAR 5

LAB REPORT

Experiment No. 02

To Determine the Discharge and Coefficient of Discharge over Rectangular Notch

Apparatus:

• Hydraulic Bench

• Hook and Point Gauge

• Stop Watch

• Rectangular notch plate

Notch:

An opening in a tank/vessel in which the top edge of opening lies above the water surface. It is

used to find discharge in open channel.

Orifice:

An opening in a tank/vessel in which the top edge of the opening lies below the water surface.

It is used to find discharge in open channel

Rectangular Notch:

A rectangular weir is used to meter flow in an open channel. The head over the

rectangular weir is measured and correlated with the water flow rate through the

open channel (and over the weir). A rectangular weir equation gives water flow

rate as a function of head over the rectangular weir. The discharge can be

calculated with following formula.

MUHAMMAD UMAIR UMAR 6

LAB REPORT

Rectangular Notch

Observation and Calculation

S.No Volume Time Q H2 H1 H=H2-H1 Log(Q) Log(H)

1 20 17.29 1.156738 152 84 0.68 0.063235 -0.16749

2 15 13.29 1.128668 150 84 0.66

3 15 15.4 0.974026 145 84 0.61 -0.01143 -0.21467

𝐶𝑑=0.76

0.8

0.6

y = 1.515x + 0.3141

0.4

0.2

0

-0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8

-0.2

-0.4

-0.6

-0.8

MUHAMMAD UMAIR UMAR 7

LAB REPORT

Rectangular Notch

Experiment No. 03

“Determine the Discharge and Coefficient of Discharge over Triangular Notch”

Triangular Notch

A triangular notch is also called a V-notch. Consider a triangular notch, in one side

of the tank, over which water is flowing as shown in figure. Let, H = Height of the

liquid above the apex of the notch. θ = Angle of the notch.

Triangular Notch

To calculate discharge through triangular notch following formula is use.

Observations and Calculations

S/N0 Vol(L) Time(sec) 𝑄𝑎𝑐𝑡(L/s) 𝐻1 𝐻2 𝐻 LogQ LogH

1 30 50.54 0.593589 127 161 34 -0.2265 1.5315

2 20 58 0.344828 127 161 34 -0.4624 1.5315

3 10 129.8 0.077042 127 146 19 -1.1135 1.2788

MUHAMMAD UMAIR UMAR 8

LAB REPORT

0.5

0.3

0.1

-0.8 -0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1 -0.1 0 0.1

-0.3

-0.5

y = 2.5764x + 0.7447

-0.7

-0.9

-1.1

-1.3

GRAPH OF FLOW OF THROUGH TRIANGULAR NOTCH

𝐶𝑑 = 0.75

MUHAMMAD UMAIR UMAR 9

LAB REPORT

Experiment No. 04

“Investigation of different types of flows using Osborne Reynold’s apparatus by

visual observation”

Objective:

In this experiment we investigated the type of flow, using the Osborne Reynolds apparatus.

Apparatus

Osborne Reynold’s apparatus

Hydraulic bench

Glass marbles.

OSBORNE REYNOLDS APPARATUS

MUHAMMAD UMAIR UMAR 10

LAB REPORT

Types of Flow

Laminar Flow

The flow in which fluid moves in liquid particles moves in form of thin sheets in which the particles

are not intersecting the path lines of each other such type of flow is known as laminar flow. In

this flow streamlines follow parallel path. The dye remains easily identifiable as solid core, denote

steady condition.

R≤2000

Turbulent Flow

The flow in which liquid particles move in zig zag path and intersecting the path lines of each

other is called as turbulent flow. In this flow streamlines interacts and completely disperses in

flow of water, denotes highly unsteady condition.

R>4000

Transition Flow

The flow that takes place during the inter-conversion of laminar and turbulent flow is called

transition flow or transition zone between laminar flow and turbulent flow is called transition

flow. In this flow the streamlines interact and partial mixing of flow occurs. Dye form eddies while

flowing through water, denotes unsteady condition.

4000≥R>2000

4.5. Observations and Calculations:

TABLE NO. 04:

Serial No. Observation Type of flow

1 Solid line of dye laminar

2 Discontinuity, partial mixing transition

3 Dye disappears, complete mixing turbulent

MUHAMMAD UMAIR UMAR 11

LAB REPORT

Experiment No. 05

“Investigation of different types of flow by using Osborne Reynold’s Apparatus by

(Reynolds number formula)”

Apparatus:

• Hydraulic Bench

• Osborne Reynolds Apparatus

• Dye Reservoir

• Thermometer

Procedure:

Fill the dye reservoir with dye.

Then lowered the dye injector until it just above the bell mouth.

Turn on the pump to supply water to the head tank.

Slowly fill head tank to the overflow level.

Closed the inlet valve.

Open the control value so that the dye mixes with the water.

Open and close the velocity control valve to admit the water to the flow visualization pipe.

Open the inlet valve slightly until water travelled from outlet pipe.

Observations and Calculations:

Diameter of pipe = 1 cm = 0.01 m

Area of pipe = 0.0000785 𝑚²

Temperature of water = 25 ̊C

Kinematic viscosity of water =1.003x10−6m²/sec

S.NO Volume Time Temperature Discharge Reynolds Remarks

(m3) (Sec) ( ̊C ) (m3/sec) number

01 0.0002 87.05 20 0.029 289 Laminar

02 0.0008 40.00 20 0.25 2492 Transition

03 0.003 51.78 20 0.73 7278 Turbulent

MUHAMMAD UMAIR UMAR 12

LAB REPORT

Experiment No. 06

“To Determine Theoretical and Actual Center of Pressure on Partially Submerged

Body”

Objective

To determine the theoretical and actual center of pressure

Apparatus

• Different Weights

• Hydrostatic pressure apparatus

• Graduated cylinders

Hydrostatic Force Theory

Fluid force is constant at any particular depth but varies vertically. This force is calculated as

liquid weight per unit volume times the depth. The total force exerted by the liquid on the ring

section is non-uniformly applied vertically. When the quadrant is immersed in water it is possible

to analyze the forces acting on the surfaces of the quadrant as follows: Hydrostatic forces on the

upper and lower curved surfaces therefore have no net effect – no torque to affect the

equilibrium of the assembly because all of these forces pass through the pivot. The forces on the

sides of the quadrant are horizontal and cancel out The hydrostatic force on the vertical

submerged face is counteracted by the balanced weight W. The resultant hydrostatic force on

the face can therefore be calculated from the value of the balance weight and the depth of the

water.

Centre of Pressure

All submerged surfaces experience a hydrostatic force. The point through which this force acts is

called the center of pressure. The total force vector acting at the center of pressure is the value

of the integrated

vectoral pressure field.

The resultant force and

center of pressure

location produce

equivalent force and

moment on the body as

the original pressure field.

MUHAMMAD UMAIR UMAR 13

LAB REPORT

WEIGHT AND HYDROSTATIC PRESSURE APPARATUS

HYDROSTATIC CENTRE OF PRESSURE

The theoretical center of pressure can be calculated as

𝟐

𝐇𝐩 = 𝐲 + 𝐚

𝟑

Where

y = Depth of water

a = Distance of water level from pivot

Actual Centre of Pressure

𝑭𝒓 = 𝑷 ∗ 𝑨

𝒉𝒃

= 𝒓 ∗ 𝟐

𝟏

= ∗ 𝒉𝟐 ∗ 𝒃

𝟐𝒓

According to condition of equilibrium we know that

WEIGHT AND HYDROSTATIC PRESSURE APPARATUS

𝐖 ∗ 𝐋 = 𝐅𝐫 ∗ 𝐇𝐩

𝐋

𝐇𝒑 = 𝐖 ∗

𝐅𝐫

Where

W= weight

Fr= Resultant force

L = Moment arm =27.5cm

a= distance of water level from pivot=20-y

y= depth of water

MUHAMMAD UMAIR UMAR 14

LAB REPORT

r=9.81KN/m^3

Procedure:

Check the bench is leveled properly with the use of spirit level.

• Add a small mass (50g) to the weight hanger.

• Get tap water using steel vessel and fill up the flotation tank.

• Fill the floatation tank with water initially until the balance arm rises.

• Continue to add water until the balance arm is horizontal, checking this by aligning the flat of

the balance arm with the central mark on the level indicator.

• When the arm is horizontal read the depth of immersion from the scale on the face of the

quadrant.

• Repeat the above procedure for different load increments by adding further weights to the

weight hanger

• Repeat the procedure in order to get accurate result.

Precautions

• First of all, clean the apparatus.

• Level the apparatus with the help of screws.

• Balance the apparatus.

Conclusion

By the above experiment we are able to determine the theoretical as well as actual center of

pressure on partially submerged body.

Observations and Calculations:

S.No Weight Depth of water Distance of water Resultant Hp (actual) Hp

(kg) (mm) level from pivot (q) force (mm) (theoretical)

(mm) (N) (mm)

1 0.05 45 155 0.74 181 185

2 0.10 66 134 1.60 172 178

3 0.15 83 117 2.53 163 172

MUHAMMAD UMAIR UMAR 15

LAB REPORT

Experiment No. 07

“To determine the hydraulic coefficients (Cv, Cc and Cd) for small circular orifice provided

at the side of the tank”

Theoretical background

Orifice:

An opening in the vessel through which water flows is known as orifice. Orifice may small and

large depending upon the diameter of the orifice and the diameter of the vessel or tank.

Orifice is used to determine the discharge through it. Discharge through the orifice

depends upon the head of the water above the center of the orifice which is denoted by

“ho”.

An orifice is called as small orifice when the diameter of the tank is larger than five times

the diameter of the orifice.

Vena contracta:

It is the portion of the jet with least diameter.

Hydraulic coefficients:

Hydraulic coefficients are three in number, denoted as Cc, Cd and Cv.

The ratio of the area of the jet at vena contracta to the area of the orifice is known as

coefficient of contraction i.e. Cc.

Ac

Cc =

Ao

The ratio of the actual discharge to the theoretical discharge is known as coefficient of

discharge i.e. Cd.

Qact. Vol./time

Cd = =

Qth. Ao√2𝑔𝐻𝑜

The ratio of the actual velocity to the theoretical velocity is called as coefficient of velocity

i.e. Cv.

√2𝑔𝐻𝑐. Hc

Cd = =

√2𝑔𝐻𝑜. Ho

Do = Diameter of the orifice = 6mm

Objective:

To determine the hydraulic coefficients and to study the jet profile.

Apparatus and parts of the apparatus:

i. Constant head inlet tank

ii. Circular orifice

iii. Hydraulic bench

MUHAMMAD UMAIR UMAR 16

LAB REPORT

iv. Needle apparatus

v. Clip board

vi. A3 size white paper sheet

vii. Stop watch

Different parts of the apparatus are:

i. Turbulancy diminisher

ii. Orifice

iii. Supply

iv. Pipe for static head measurement

v. Micrometer and pitot tube

vi. Scales overflow

Procedure:

Adjust the appartus which is going to be used in this very experiment.

Open the inlet valve and adjust the inflow to make the head of the water above the orifice

be constant.

Water will come from the orifice and the discharge i.e. actual discharge can be found by

using hydraulic bench volumetric tank and stopwatch to measure the volume and time

and the discharge will be found as:

𝑉𝑜𝑙.

𝑄𝑎𝑐𝑡 =

𝑡𝑖𝑚𝑒

The water coming out of the orifice follow certain trajactory. This trajactory is traced by

using needles.

The path is traced on an A3 size paper sheet.

The coordinates of these points which are eight in number are then found in terms of x

and y coordinates.

Needles are 5cm apart, so x distances will differ by 5 starting from zero.

Then Cv is found by using the formula:

𝑋2

𝐶𝑣 = √

4𝑌𝐻𝑜

Cd is found by dividing the actual discharge by the theoretical discharge.

And at the last Cc is found from Cd and Cv already computed.

Here we cannot use the direct formulas for the computations of C v and Cc due to the

limitations of the current experiment.

Repeat the same procedure for three times.

Conclusion:

With the help of this experiment we found the hydraulic coefficients by using the formulas and

also studied the jet profile by using the needles arrangement.

MUHAMMAD UMAIR UMAR 17

LAB REPORT

NEEDLE APPARATUS AND CONSTANT HEAD INLET TANK

NEEDLE APPARATUS

MUHAMMAD UMAIR UMAR 18

LAB REPORT

Observations and Calculations:

Reading No. 01:

Do = 6 mm

ho = 300 mm X Y X2

Vol. = 3 lit. 0 0 0

Time = 76.22 s

Qact. = 0.0394 lit./s 5 0.75 25

Qth. = 0.0686 lit./s

10 1.75 100

Cv = 0.869 15 3.2 225

20 5 400

Cd = 0.574

25 7.45 625

Cc = 0.66 30 10.35 900

35 13.3 1225

Slope = 93.077

1400

1200 y = 93.077x - 48.828

1000

800

X2

600

400

200

0

0 2 4 6 8 10 12 14

-200

Y

RELATIONSHIP BETWEEN X2 AND Y

MUHAMMAD UMAIR UMAR 19

LAB REPORT

Reading No. 02:

X Y X2

Do = 6 mm

ho = 283 mm 0 0 0

Vol. = 2 lit.

5 0.7 25

Time = 56.87 s

Qact. = 0.03517 lit./s 10 1.85 100

Qth. = 0.06662 lit./s

15 3.4 225

Cv = 0.883 20 5.6 400

25 7.95 625

Cd = 0.528

30 10.8 900

Cc = 0.598 35 14 1225

Slope = 88.321

1400

1200 y = 88.321x - 51.579

1000

800

X2

600

400

200

0

0 2 4 6 8 10 12 14 16

-200

Y

FIGURE 15: RELATIONSHIP BETWEEN X2 AND Y

MUHAMMAD UMAIR UMAR 20

LAB REPORT

Experiment No. 8

“To determine the hydraulic coefficients (Cv , Cc and Cd) for a small circular orifice provided

at the bottem of the tank”

Theoretical background:

Orifice:

An opening in the vessel through which water flows is known as orifice. Orifice may small and

large depending upon the diameter of the orifice and the diameter of the vessel or tank.

Vena contracta:

It is the portion of the jet with least diameter.

Pitot tube:

It is a tube used to measure the static pressure head plus elevation head and also the velocity

head, kept in the direction of the upstream side.

Objective: To determine the hydraulic coefficients without studying the jet profile from the

proposed formulas. That is done by using a pitot tube.

Apparatus:

i. Hydraulic bench

ii. Constant head inlet tank

iii. Piezometer

iv. Pitot tube

v. Stop watch

Procedure:

Adjust the apparatus for the experiment.

Open the inlet valve and maintain the head constant (at supply tank) over the orifice.

Adjust the inflow in such a way that a constant head is maintained.

Allow water to flow through the orifice and note the maximum head over the orifice that

permits the water jet to flow into the measuring tank.

Regulate the inlet valve to obtain a constant head over the orifice and note the time taken

for collecting water to a height ‘h’ in the measuring tank.

Then calculate the actual discharge by dividing the volume collected by time.

Revolve the micrometer of the pitot tube and bring the hollow needle to the center of

the jet flow so that velocity head can be calculated.

MUHAMMAD UMAIR UMAR 21

LAB REPORT

To measure the diameter at the vena contracta revolve the micrometer from one side of

the jet to the other side and note the number of revolution of the micrometer as one

revolution gives 1mm movement to the

hollow needle.

So in this way calculate the diameter

of vena contracta.

Observations and Calculations:

S.No. Do Dc ho hc Vol. Time Cv Cd Cc

(mm) (mm) (mm) (mm) (lit.) (sec.)

01 14 12 358 354 15 56.41 0.994 0.652 0.735

02 14 13 372 367 15 56.58 0.993 0.638 0.862

03 14 13 373 363 10 38.27 0.995 0.630 0.862

MUHAMMAD UMAIR UMAR 22

LAB REPORT

Experiment No. 9

“To investigate the validity of Bernoulli’s theorem as applied to the flow of water by

Bernoulli’s theorem demonstration”

Theoretical background:

Bernoulli’s Theorem:

The total head of the flowing liquid between two points remains constant provided that there is

no loss due to friction and no gain due to an application of outside work between these two

points.

Total head is given by:

𝒑 𝒗𝟐

𝑯= + +𝒛

𝜸 𝟐𝒈

Where;

p/ϒ = static pressure head

v2/2g = velocity head

z = elevation head

Flow control valve:

It is a valve used to control the amount of i.e. velocity of the fluid through a certain pipe or flow

channel.

Apparatus:

i. Bernoulli’s Apparatus

ii. Hydraulic Bench

Different parts of the Bernoulli’s apparatus:

i. Air bleed screw

ii. Monometer tubes

iii. Unions

iv. Gland nuts

v. Test section

vi. Water inlet

vii. Hypodermic probe

viii. Water outlet

ix. Flow control valve

x. Tapping Points

MUHAMMAD UMAIR UMAR 23

LAB REPORT

Procedure:

Close the inlet and outlet valves.

Open the air bled screw before starting the experiment.

Slowly open inlet valve and the water will rise in the manometer tube and will escape

through air bled screw.

Adjust the pressure in the pipes to remove the air bubbles by several trials.

Adjust the pressure heads in the tubes.

Find the actual static head with the help of the scales attached to the back of the tubes.

Find the total actual head by using gland nut at each of the tapping points.

Actual velocity head is calculated is from the above two heads.

Theoretical static head is calculated as follows:

𝒑𝟐 𝒑𝟏 𝒗𝟏 𝟐 𝒗𝟐 𝟐

= + −

𝜸 𝜸 𝟐𝒈 𝟐𝒈

The theoretical velocity head is given by:

𝒗𝟐 𝟖(𝒗𝒐𝒍. )𝟐

= 𝟐 𝟐 𝟒

𝟐𝒈 𝝅 𝒈𝒕 𝑫

Theoretical total head is equal to the sum of these two heads.

Observations and Calculations:

Tapping Actual Actual Actual Theoretical Theoretical Theoretic Head Total

position static velocit total static/pressu Velocity al total loss head

head y head head re head head head b/w loss

two up to

point point

s s

A 244 2 246 244 3.3 247.3 1.3 1.3

B 209 36 245 209 34.2 243.2 4.1 5.4

C 150 94 244 150 65.5 220.4 22.8 28.2

D 143 98 241 143 97.4 240.4 20 48.2

E 92 147 239 92 127 219 21.4 69.6

F 132 33 165 132 33 165 54 123.6

MUHAMMAD UMAIR UMAR 24

LAB REPORT

Experiment No. 10

“To determine the relationship between head loss due to friction and velocity of the flow

of water through smooth bore pipe”

Objective:

To study the laminar flow and turbulent flow. With the help of this experiment we can

determine the head loss due to friction at different velocities and eventually obtain the

relationship between these two parameters.

Theoretical background

Head:

Head is defined as the energy of the fluid per unit weight of the fluid and its unit is “meter (m)”

in S.I.

Head loss:

Head loss due to friction is the loss of the head of fluid while flowing through a pipe (i.e. smooth

pipe in present case) due to the viscous effect in the fluid. The relationship for head loss due to

friction is given by Darcy Weisbach;

𝒇𝑳𝒗𝟐

𝒉𝒇 =

𝑫𝟐𝒈

Head loss and velocity relationship:

Its relationship depends on the type of the flow i.e. whether the flow is laminar or turbulent.

For laminar the relationship is given by;

𝒉𝜶𝒗

For turbulent flow the relationship is given by;

𝒉 𝜶 𝒗𝒏

Apparatus:

Fluid friction apparatus

Hydraulic bench

Stop watch

Thermometer

Parts of the fluid friction apparatus:

Smooth bore pipe

Artificially roughened pipe

Long and short radii bends

Y, elbow and T-joints

Sudden contraction

Sudden enlargement

Transparent pipe section with pitot tube

Transparent venturi meter

Transparent orifice meter

MUHAMMAD UMAIR UMAR 25

LAB REPORT

Ball valve

Isolating valve

Globe valve

Control valve

Gate valve

Water inlet and outlet

Strainer

Pressure tapping points

Tubing and connectors

Flexible tubes and monometer

FIGURE 17: FLUID FRICTION APPARATUS

MUHAMMAD UMAIR UMAR 26

LAB REPORT

Procedure:

First of all remove air from pipes i-e open all valves

Now close all valves except the pipe under observation

Close the screw above the mercury manometer such that all air is removed

Close the isolating valve

Not the head loss from the difference in mercury column of mercury manometer

Measure the discharge of water from outlet by graduated beaker and stopwatch.

Increase the velocity of flow from inlet control valve and repeat the process again

Thus we can observe that by increasing the velocity of flow of water, the head loss

increase.

Observation and Calculations:

S.no 1 2 3 1 2 3 1 2 3

Diameter(mm) 6mm 10mm 17mm

Volume(lit) 1 1 2 10 10 10 10 20 20

Time(sec) 43.7 25.9 44.02 76.17 56.65 43.09 21.72 29.68 25.36

8 9

Discharge(lit/sec .023 .038 .0454 .131 .176 .232 .46 .67 .78

) 5

Velocity(m/sec) .801 1.36 1.61 1.67 2.25 2.25 2.03 2.97 3.48

Reynolds No 5757 9729 1147 20,47 26,75 35,17 41,08 6010 7034

1 6 0 9 5 7 8

Friction factor(f) .036 .031 .029 .0256 .024 .0225 .0217 .0199 .0192

Measured head 198 490 653 365 617 1000 456 895 252

loss(mm)

Calculated head 130 241 351 142 184 295 84 348 397

loss(mm)

MUHAMMAD UMAIR UMAR 27

You might also like

- Gas Flow Calculation Aga - 3 Base On L-10 Chart: U U U C NDocument1 pageGas Flow Calculation Aga - 3 Base On L-10 Chart: U U U C NDio Masera0% (1)

- Lab Report - RotameterDocument7 pagesLab Report - RotameterYvonne Aklotsoe50% (2)

- Hele-Shaw PDFDocument5 pagesHele-Shaw PDFLakshman Dora Chandrala100% (1)

- Flow Rate ReportDocument6 pagesFlow Rate Reportضياء بن احمد الكباريNo ratings yet

- FM05 Pitot Static Tube PDFDocument2 pagesFM05 Pitot Static Tube PDFAnonymous thaRdEcpD100% (2)

- Fluid Mechanics Lab ReportDocument35 pagesFluid Mechanics Lab ReportBilal Akhundzada0% (1)

- Hydraulic Bench Experiment (Lab Experiment Number 02)Document6 pagesHydraulic Bench Experiment (Lab Experiment Number 02)Muhammad Abdullah Zafar GhauriNo ratings yet

- FLuid Lab 1Document4 pagesFLuid Lab 1bdlrhmntareenNo ratings yet

- 3029 FM LabDocument36 pages3029 FM Labmohammed sallemNo ratings yet

- Abdullah Haval ... Broad Crested Weir WeirsDocument6 pagesAbdullah Haval ... Broad Crested Weir WeirsIam A gnoomNo ratings yet

- Lab Session No.01 Objective: Apparatus: Diagram:: Hydraulic BenchDocument3 pagesLab Session No.01 Objective: Apparatus: Diagram:: Hydraulic BenchMuhammad AshfaqNo ratings yet

- FM Lab 2Document5 pagesFM Lab 2Waleed NasirNo ratings yet

- Home Experiment 4: Hp145 Compact Reciprocating Pump Test SetDocument9 pagesHome Experiment 4: Hp145 Compact Reciprocating Pump Test SetPietro Ian AbdonNo ratings yet

- Fluid Mechanics-I Lab (MEEN 2217)Document8 pagesFluid Mechanics-I Lab (MEEN 2217)waqarNo ratings yet

- Paul Gabriel Report No 4Document7 pagesPaul Gabriel Report No 4gelledNo ratings yet

- Lab Seesion No 2 FMDocument6 pagesLab Seesion No 2 FMm.sheraz malikNo ratings yet

- Performance Test of A Hydraulic Turbine Mid Term 2Document8 pagesPerformance Test of A Hydraulic Turbine Mid Term 2jethro ganeloNo ratings yet

- Fluid Mechanics Lab ManualDocument89 pagesFluid Mechanics Lab ManualJVC MaliackalNo ratings yet

- FM & HM Lab Lab Manual PDFDocument37 pagesFM & HM Lab Lab Manual PDFSri Gaja Govind BabuNo ratings yet

- BAB 2 FDM New22Document15 pagesBAB 2 FDM New22Dika D'PhantzerNo ratings yet

- Experiment No. 4 HP145 Compact Reciprocating Pump Test SetDocument9 pagesExperiment No. 4 HP145 Compact Reciprocating Pump Test SetPietro Ian AbdonNo ratings yet

- Fluid Mechanics ManualDocument41 pagesFluid Mechanics ManualrajmaljatNo ratings yet

- User Manual Closed Circuit Venturimeter Test Rig & Orifece Meter Test RigDocument7 pagesUser Manual Closed Circuit Venturimeter Test Rig & Orifece Meter Test Rigrohit kumarNo ratings yet

- FM & HM Lab Lab ManualDocument75 pagesFM & HM Lab Lab ManualRajib DasNo ratings yet

- The University of Hong Kong: Department of Mechanical EngineeringDocument20 pagesThe University of Hong Kong: Department of Mechanical EngineeringChristal ChukNo ratings yet

- Me 142l b39 Reyes Exp 4Document8 pagesMe 142l b39 Reyes Exp 4Cyrus ReyesNo ratings yet

- Experiment No.6: Title: Discharge Over Notches AIMDocument8 pagesExperiment No.6: Title: Discharge Over Notches AIMLowEnd GamerNo ratings yet

- Manuals He Lab ManalsDocument146 pagesManuals He Lab ManalsNIKHIL DHIMANNo ratings yet

- Lab Report 1Document9 pagesLab Report 1Mustafa BarwaniwalaNo ratings yet

- Ce016-Cec32s1 Activity6 Group4Document5 pagesCe016-Cec32s1 Activity6 Group4Janine MarzanNo ratings yet

- Fluids 2 Lab Report 4 FinalDocument9 pagesFluids 2 Lab Report 4 FinalJay-ar BensOnNo ratings yet

- Masinde Muliro University of Science and TechnologyDocument51 pagesMasinde Muliro University of Science and TechnologyKelvho GitongaNo ratings yet

- Flow Meter MeasurementDocument12 pagesFlow Meter Measurementrahman75% (8)

- Fluid Mechanics LabDocument12 pagesFluid Mechanics LabRonald Muñez BadicNo ratings yet

- Fluid Mechanics LabDocument11 pagesFluid Mechanics LabMohid KhanNo ratings yet

- Rotameter For Flow Measurement in Laboratory Based Experimental SetupDocument16 pagesRotameter For Flow Measurement in Laboratory Based Experimental SetupMuhammad FahadNo ratings yet

- 10.centrifugal Pump & Pumps in Series - Set 2Document10 pages10.centrifugal Pump & Pumps in Series - Set 2ahm531No ratings yet

- Lab 7 Laminar & Turbular FlowDocument16 pagesLab 7 Laminar & Turbular FlowLandel SmithNo ratings yet

- Experiment No. 01: Demonstration of Various Parts of Hydraulic Bench Hydraulic BenchDocument30 pagesExperiment No. 01: Demonstration of Various Parts of Hydraulic Bench Hydraulic BenchZain wazirNo ratings yet

- Experiment 7 - Performance Characteristics of Centrifugal PumpDocument7 pagesExperiment 7 - Performance Characteristics of Centrifugal PumpCassandra JienahNo ratings yet

- Fluid Mechanics and Hydraulic MachineryDocument45 pagesFluid Mechanics and Hydraulic MachineryRajeevNo ratings yet

- FLUID MECHANICS Lab ManualDocument65 pagesFLUID MECHANICS Lab ManualPaulNo ratings yet

- Lab 7-8 - Ayesha Noor - Che12ADocument14 pagesLab 7-8 - Ayesha Noor - Che12Aayesha noorNo ratings yet

- Orifice Meter ReportDocument19 pagesOrifice Meter ReportDilli Babu PNo ratings yet

- Fluid Report 3 (Modified)Document36 pagesFluid Report 3 (Modified)zohaibkhanluckNo ratings yet

- Laboratory Manual: II Year B. Tech I-Semester Mechanical EngineeringDocument45 pagesLaboratory Manual: II Year B. Tech I-Semester Mechanical Engineeringmuhammad ahsanNo ratings yet

- KCE074BCE009 Centrifugal PumpDocument8 pagesKCE074BCE009 Centrifugal Pumpबम सरकार धिरेन्द्रNo ratings yet

- JJ 308 Experiment 1Document4 pagesJJ 308 Experiment 1Edmond Emmanuel LeeNo ratings yet

- FM & HM Lab Lab ManualDocument75 pagesFM & HM Lab Lab ManualvenkiteshksNo ratings yet

- Michell Banki Turbine PDFDocument6 pagesMichell Banki Turbine PDFAnonymous Hy5Ir9QXNo ratings yet

- Rotameter Calibration SetDocument5 pagesRotameter Calibration SetnidhidarklordNo ratings yet

- Ce6461 FM Lab ManualDocument33 pagesCe6461 FM Lab Manualkannan_kcetNo ratings yet

- Lab 4 (Thermofluids Lab)Document32 pagesLab 4 (Thermofluids Lab)Adnan Nanda0% (1)

- 2.venturimeter Theory PDFDocument9 pages2.venturimeter Theory PDFSWETHANo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Groundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterFrom EverandGroundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterRating: 5 out of 5 stars5/5 (1)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Repsol Maker Hydraulico SC 46Document1 pageRepsol Maker Hydraulico SC 46ibrahim maulanaNo ratings yet

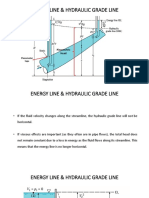

- Energy Line & Hydraulic Grade Line: Piezometric HeadDocument19 pagesEnergy Line & Hydraulic Grade Line: Piezometric HeadMaryam Arif100% (1)

- Metering FluidsDocument30 pagesMetering FluidsJournel Ann SupremoNo ratings yet

- Pages From 112006967-PRV-Sizing-for-Exchanger-Tube-Rupture-4Document1 pagePages From 112006967-PRV-Sizing-for-Exchanger-Tube-Rupture-4Ghasem BashiriNo ratings yet

- CFDDocument16 pagesCFDRangel Silva100% (1)

- Sizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JDocument1 pageSizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JekabudiartiNo ratings yet

- Flow - OrificeDocument86 pagesFlow - Orificemahadev jadhavNo ratings yet

- 37 Mohammed Falalu HamzaDocument10 pages37 Mohammed Falalu HamzatridaysNo ratings yet

- Calculation of Added Mass in The Proximity of The Seabed For An Oscillating DiscDocument64 pagesCalculation of Added Mass in The Proximity of The Seabed For An Oscillating DiscTNTNo ratings yet

- Design of Under TunnelDocument95 pagesDesign of Under TunnelNaga Moudgalya NaiduNo ratings yet

- Effect of Vortex Generators On Aerodynamics of A Car: CFD AnalysisDocument10 pagesEffect of Vortex Generators On Aerodynamics of A Car: CFD AnalysisVineet SinghNo ratings yet

- Spe 190283 MSDocument10 pagesSpe 190283 MSTASHVINDER RAONo ratings yet

- CA 2016 RheologyDocument341 pagesCA 2016 Rheologybhardwaj.mitNo ratings yet

- Quasi-3D Modelling of Two-Phase Slug Flow in PipesDocument12 pagesQuasi-3D Modelling of Two-Phase Slug Flow in PipeskumarNo ratings yet

- 250 TOP Fluid Mechanics - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsDocument22 pages250 TOP Fluid Mechanics - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsKhairy Elsayed100% (1)

- Control Valve SizingDocument4 pagesControl Valve SizingAmolNo ratings yet

- Hydraulic Engineering Lab ManualDocument34 pagesHydraulic Engineering Lab ManualK YNo ratings yet

- Ravenol Atf Dsih 6: Application NoteDocument2 pagesRavenol Atf Dsih 6: Application NoteMohammed BabatinNo ratings yet

- CFD LectureDocument51 pagesCFD LectureBilal AhmadNo ratings yet

- Foaming in Fractionation ColumnsDocument7 pagesFoaming in Fractionation ColumnsmehdiNo ratings yet

- Ogm 25Document1 pageOgm 25azimsabudinNo ratings yet

- Mann Automotive Filter Stock List19052021Document3 pagesMann Automotive Filter Stock List19052021B Sathish BabuNo ratings yet

- Select CatalogDocument68 pagesSelect CatalogDedy DayatNo ratings yet

- AD-II NEW QB FinalDocument79 pagesAD-II NEW QB Finalblack legNo ratings yet

- Esdu Aerodynamics Design CollectionDocument3 pagesEsdu Aerodynamics Design Collectionnacho1963No ratings yet

- Buoyancy Force Lab ReportDocument11 pagesBuoyancy Force Lab Reportah3422No ratings yet

- CV Calculator Explanation PDFDocument2 pagesCV Calculator Explanation PDFBill M. SpragueNo ratings yet

- NoPhalt Case StudyDocument1 pageNoPhalt Case Studymmhassan54No ratings yet

- Mee 303 Lecture 3 AdamDocument46 pagesMee 303 Lecture 3 AdamTomisin EniolaNo ratings yet