Professional Documents

Culture Documents

Detailed Strain Field Analyses of Fatigue Cracks in Friction Stir Welded Joints

Detailed Strain Field Analyses of Fatigue Cracks in Friction Stir Welded Joints

Uploaded by

yijunjieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detailed Strain Field Analyses of Fatigue Cracks in Friction Stir Welded Joints

Detailed Strain Field Analyses of Fatigue Cracks in Friction Stir Welded Joints

Uploaded by

yijunjieCopyright:

Available Formats

Detailed strain field analyses of fatigue

cracks in friction stir welded joints

ICAF 2009, Rotterdam

H.J.K. Lemmen,

R.C. Alderliesten,

R. Benedictus

Aerospace Structures and Materials, Faculty of Aerospace Engineering

6-7-2009

Delft

University of

Technology

Challenge the future

Introduction

ICAF 2007: Fatigue crack initiation behaviour of friction stir

welded joints in aluminium alloy

σ∞ Direction of crack growth Hole

Width of

nugget

Fracture

σ∞

Different material flows

Width = 50mm

How affects an FS weld the fatigue crack growth behaviour?

Detailed strain field analyses of fatigue cracks in FS welded joints 2

Contents

• Introduction

• Friction Stir (FS) welding

• Residual stress profiles

• Yield strength profiles

• Fatigue Crack Growth (FCG) test

• Loads & specimen configuration

• Digital Image Correlation (DIC)

• FCG test results

• FCG curves

• Results from DIC

• Conclusions

• Questions

Detailed strain field analyses of fatigue cracks in FS welded joints 3

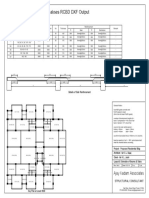

Friction Stir Welding

FS welding performed by EADS in Munich

Downward

Welding crown

welding force

Shoulder direction AS RS

Pin Tool rotation HAZ HAZ

TMAZ

L Nugget

LT

root

weld

Advancing Retreating Process parameters: Alloys:

Side (AS) Side (RS) AA2024-T3 AA7075-T6 AA6013-T4

Thickness: 2.5 mm 2.0 mm 1.8 mm

Welding speed: 350 mm/min 300 mm/min 1000 mm/min

Rotational speed: 550 rpm 280 rpm 1500 rpm

Downward force: 19 kN 18 kN 14 kN

Detailed strain field analyses of fatigue cracks in FS welded joints 4

Residual stress profiles in FS welds

Tool shoulder

500

RS Tool Pin AS

400

300 AA7075-T6

stress [MPa]

200

100

AA2024-T3 AA6013-T4

-100

-20 -15 -10 -5 0 5 10 15 20

distance from weld centre [mm]

Residual stresses measured by X-ray diffraction

Detailed strain field analyses of fatigue cracks in FS welded joints 5

Yield strength profiles of FS welds

Tool shoulder

500

RS Tool Pin AS

AA7075-T6

400

300

AA2024-T3

stress [MPa]

200

AA6013-T4

100

-100

-20 -15 -10 -5 0 5 10 15 20

distance from weld centre [mm]

results presented at AIAA/SDM conference 2008

Detailed strain field analyses of fatigue cracks in FS welded joints 6

FS weld properties & FCG behaviour

yield strength: residual stress: Residual stress

σcrack tip = Kt * σ∞ Profile:

Yield strength profile:

Fatigue σyield, 0.2

crack Undisturbed

plastic zone

Direction of

FS weld

crack growth

σcrack tip

centre

Kt * σ∞

ld

we

σresidual

FS

FCG retardation? ?? FCG Direction in FS weld

Detailed strain field analyses of fatigue cracks in FS welded joints 7

Fatigue crack growth test

Goal: to repeat and measure the behaviour observed in the FI specimen

Constant amplitude loading; R = 0.1; σa = 60MPa

Three configurations of centre crack FCG test specimen:

0º 45º 90º

LT L LT

AS RS

AS L

a = 2.5mm 2a = 5mm

y

AS

RS

x

y

x

d = 3mm RS

L

y

LT

x

Effect of residual stress Combined effect & Effect of yield strength

Change of FCG direction

Detailed strain field analyses of fatigue cracks in FS welded joints 8

Digital image correlation

Strains are determined by analysing the images of a test

DIC software has been developed by the author

Images after DIC analyses,

with overlay of strain field

X-Y-Z axes CCT specimen

electronically

controlled rack

Digital

camera

Grid of images

For examples of applications for this DIC tool have a look at the poster presentations of

Mr. Wilson, Mr. Rodi, Mr. Khan, and Mr. Delgrange.

Detailed strain field analyses of fatigue cracks in FS welded joints 9

Results DIC

Details: alloy = AA2024-T3; 90º configuration; y= 6.5mm;

Centreline FS weld

Centreline FS weld

Centreline FS weld

Detailed strain field analyses of fatigue cracks in FS welded joints 10

Plastic zone behaviour

550

Y = 6.5 mm AA7075-T6

450

stress [MPa]

350 AA2024-T3

Details:

> AA2024-T3; 250

> 90º conf.; 150 Small butterfly wings AA6013-T4

> y= 6.5mm; -15 -10 -5 0 5

distance from weld centre [mm]

10 15

σ∞

a=6.5mm Weld

σ∞

Crack path centre

a=9mm

a=11mm

Large butterfly wings

Detailed strain field analyses of fatigue cracks in FS welded joints 11

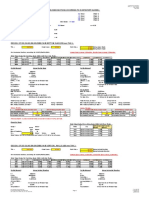

FCG behaviour 90º conf.

Details: 5.E-03

base AA2024-T3

> AA2024-T3; FS weld, 90º config, spec 1, y = 0.0mm

FS weld, 90º config, spec 2, y = 3.0mm

4.E-03

> 90º conf.; FS weld, 90º config, spec 3, y = 6.5mm

da/dN [mm/cycle]

FS weld, 90º config, spec 4, y = 6.5mm

3.E-03

σ∞

m

m

m m

5

mm 0.0

6.

2.E-03

6.5 e

bas

1.E-03

3.0mm

0.E+00

0 5 10 15 20

σ∞ a [mm]

FCG acceleration

FCG retardation

Detailed strain field analyses of fatigue cracks in FS welded joints 12

Plastic zone behaviour

Y=3.0mm

Details: Y=0.0mm

> AA2024-T3; base

> 90º conf.;

σ∞

a=5.0mm

a=8.0mm

a=10.5mm

σ∞

Detailed strain field analyses of fatigue cracks in FS welded joints 13

FCG behaviour 0º configuration

5.E-03

Details:

Tool edge

Weld centre

Weld centre

Tool edge

Tool edge

base AA7075-T6-3, 1 saw cut

> AA7075-T6;

FS welded AA7075-T6; 0º conf; spec 1

4.E-03 FS welded AA7075-T6; 0º conf; spec 2

> 0º conf.;

da/dN [mm/cycle]

σ∞

3.E-03

acceleration

2.E-03

1.E-03 Base material

0.E+00

σ∞ 0 5 10 15 20 25

a [mm] rapid acceleration

retardation

Detailed strain field analyses of fatigue cracks in FS welded joints 14

FCG behaviour 45º behaviour

Details:

> AA2024-T3;

> 45º conf.;

σ∞

σ∞

Detailed strain field analyses of fatigue cracks in FS welded joints 15

FCG behaviour 45º behaviour

n

io

ct

Details:

re

di

> AA2024-T3;

ng

di

el

> 45º conf.;

W

σ∞

a=5mm

a=7.5mm

a=20mm

Crack path

a=12mm

σ∞

Tool edge

Weld centre

Detailed strain field analyses of fatigue cracks in FS welded joints 16

FCG behaviour 45º behaviour

1 2 3 7

4 5 6 8

Details:

> AA7075-T6; Failure after

> 45º conf.; several

centimetres

σ∞

σ∞

Detailed strain field analyses of fatigue cracks in FS welded joints 17

FCG behaviour 45º behaviour

W Material flows

el

Details: di

ng

in Nugget

> AA7075-T6; di

re

> 45º conf.; W

ct

io

n

el

d

σ∞ ce

nt

re Crack path

To

ol

ed

σ∞ ge

Detailed strain field analyses of fatigue cracks in FS welded joints 18

FCG behaviour 45º behaviour

Material flows

n

io

ct

in Nugget

re

di

Details:

ng

di

> AA7075-T6;

el

W

> 45º conf.;

σ∞ nt

re

ce

ge

ed

d

el

σ∞

W

Crack path

ol

To

Detailed strain field analyses of fatigue cracks in FS welded joints 19

Introduction

ICAF 2007: Fatigue crack initiation behaviour of friction stir

welded joints in aluminium alloy

σ∞ Direction of crack growth Hole

Width of

nugget

Fracture

σ∞

Different material flows

How affects an FS weld the fatigue crack growth behaviour?

Detailed strain field analyses of fatigue cracks in FS welded joints 20

Conclusions

• The yield strength affects the FCG rate, depending on the

orientation of the FS weld.

• The residual stresses affect the FCG rate, with the largest effect

found for the 90º configuration

• The micro structure in the nugget of the FS weld provides a path

with low fatigue resistance

• Digital image correlation has a large potential in future research in

fatigue.

Detailed strain field analyses of fatigue cracks in FS welded joints 21

Questions?

Detailed strain field analyses of fatigue cracks in FS welded joints 22

FCG behaviour 0º configuration

Details: Weld centre Tool edge

> AA2024-T3; Welding

direction

> 0º conf.;

σ∞ Tool edge

a=5mm

a=7.5mm a=22mm

a=10mm a=15mm

Crack path

σ∞

Detailed strain field analyses of fatigue cracks in FS welded joints 23

You might also like

- Workbench Technology Showcase Example ProblemsDocument692 pagesWorkbench Technology Showcase Example Problemsrama BaruvaNo ratings yet

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- MS-264 Change Y Jul 06Document17 pagesMS-264 Change Y Jul 06Mike FiorenNo ratings yet

- Bolted Connections 1Document45 pagesBolted Connections 1Nicole ReyesNo ratings yet

- API Valve Trim ChartDocument2 pagesAPI Valve Trim ChartkhaireddinNo ratings yet

- Space Welding TermpaperDocument11 pagesSpace Welding Termpapersai vamsiNo ratings yet

- Optimized Light Tactical VehicleDocument8 pagesOptimized Light Tactical VehicleRajeev Ranjan100% (2)

- BHMH - Al Alloy - 2014 T6 Iss - 01Document4 pagesBHMH - Al Alloy - 2014 T6 Iss - 01Beni hidayatullahNo ratings yet

- 0218 Ja enDocument1 page0218 Ja enHoque AnamulNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNo ratings yet

- Datasheet Sandvik 2212htDocument2 pagesDatasheet Sandvik 2212htDarryl007No ratings yet

- 12F0011X0 Stainless Steel Fastener Mechanical PropertiesDocument2 pages12F0011X0 Stainless Steel Fastener Mechanical PropertiespkdscdubaiNo ratings yet

- Metric DIN 6885 SpecDocument4 pagesMetric DIN 6885 SpecDobrica PetrovicNo ratings yet

- 03112015000000B - Boehler FOX SUM - CeDocument1 page03112015000000B - Boehler FOX SUM - Cekapster KannourNo ratings yet

- Catalogue GUNUNG GARUDADocument40 pagesCatalogue GUNUNG GARUDAhendrobama50% (2)

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- Esab 36H: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab 36H: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesAkash SainNo ratings yet

- Work Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyDocument2 pagesWork Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyLetacio OliveiraNo ratings yet

- MAM STD - B3 - 02 - 17 - 04 - Arc WeldingDocument3 pagesMAM STD - B3 - 02 - 17 - 04 - Arc WeldingMohanrajMJNo ratings yet

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- Strength Grade of Bolts and ScrewDocument2 pagesStrength Grade of Bolts and ScrewmuathNo ratings yet

- BÖHLER Ti 52 NG T-FD (Diamondspark 31 NG) : Flux Cored Wire, Seamless, Self-Shielded, UnalloyedDocument1 pageBÖHLER Ti 52 NG T-FD (Diamondspark 31 NG) : Flux Cored Wire, Seamless, Self-Shielded, UnalloyedbrayanNo ratings yet

- Stick Electrode For Mild Steel: ClassificationDocument1 pageStick Electrode For Mild Steel: Classificationmohamed AdelNo ratings yet

- Data SoldaduraDocument2 pagesData SoldaduraChiclla Quispe PercyNo ratings yet

- Verificare Legaturi12-13 12'-13'Document11 pagesVerificare Legaturi12-13 12'-13'Ovidiu MoraruNo ratings yet

- 40m - Anchorage BlockDocument29 pages40m - Anchorage BlockShijo AntonyNo ratings yet

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocument2 pagesCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_917790% (10)

- Design of Reinforced Concrete Elements: UsingDocument62 pagesDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNo ratings yet

- Spot Weld Parameters HLSDocument10 pagesSpot Weld Parameters HLSHemantNo ratings yet

- 3-Mechanics of TurningDocument23 pages3-Mechanics of TurningOKELLO JOB LAZARUSNo ratings yet

- Hicks 2000Document3 pagesHicks 2000monikeshNo ratings yet

- Specification FOR Stranded Galvanized Steel Wire For FencingDocument3 pagesSpecification FOR Stranded Galvanized Steel Wire For FencingNarasimha DvlNo ratings yet

- 4.5.material DescriptionDocument1 page4.5.material DescriptionAhmed Hamdy WorkNo ratings yet

- Schedule of Slabs at Level - 4500: Ajay Kadam AssociatesDocument1 pageSchedule of Slabs at Level - 4500: Ajay Kadam AssociatesvinujohnpanickerNo ratings yet

- Applications: TYPE: NeutralDocument1 pageApplications: TYPE: NeutralNS QCNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Aisi E50100, E52100: 154/amoyDocument6 pagesAisi E50100, E52100: 154/amoyahmad hafizNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- Trim Number Chart API Valve PDFDocument2 pagesTrim Number Chart API Valve PDFtungxuanbrNo ratings yet

- Type AAF by Lindapter 1223Document3 pagesType AAF by Lindapter 1223CarlotaGomesNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- ZW Brochure V2 PDFDocument37 pagesZW Brochure V2 PDFCarlos SimoesNo ratings yet

- Fitting Adss Span 600Document4 pagesFitting Adss Span 600Ahmad FaisalNo ratings yet

- 5 STOREY GDS SCBF Connection DesignDocument1 page5 STOREY GDS SCBF Connection DesigndantevariasNo ratings yet

- Conformances: Type: NeutralDocument2 pagesConformances: Type: NeutralsampathkumarNo ratings yet

- Heat Exchanger 521.49Document1 pageHeat Exchanger 521.49dejanpecicNo ratings yet

- Katalog BelerDocument1 pageKatalog BelerСтефан АнтонићNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- General Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)Document6 pagesGeneral Design Parameters (For Uncracked Section According To Is:3370 (Part-Ii) - 2009)sumit_7285No ratings yet

- 7075 Aluminium BarDocument1 page7075 Aluminium Barleonardo caicedo mesaNo ratings yet

- An Analysis of The Shear Transfer Actions in RC Short Span Beams Using Crack Kinematics Recorded Via DicDocument8 pagesAn Analysis of The Shear Transfer Actions in RC Short Span Beams Using Crack Kinematics Recorded Via DicmarcuspasNo ratings yet

- Weld Length - CheckDocument8 pagesWeld Length - CheckrishiNo ratings yet

- Combinations Update 21-06-07Document23 pagesCombinations Update 21-06-07Burcea FlorinNo ratings yet

- SloofDocument2 pagesSloofAl-Fatih Kids ChannelNo ratings yet

- Column Calculation Sheet: Title DescriptionDocument16 pagesColumn Calculation Sheet: Title DescriptionRick-baezNo ratings yet

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- Chapter 05 Bolted ConnectionsDocument9 pagesChapter 05 Bolted ConnectionsJaper WeakNo ratings yet

- ETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignMuhammad AhsunNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Test Demonstrated Damage Tolerance of F-22 Wing-Attach LugsDocument27 pagesTest Demonstrated Damage Tolerance of F-22 Wing-Attach LugsyijunjieNo ratings yet

- Finite Element Analysis On The F-35 LightningDocument28 pagesFinite Element Analysis On The F-35 LightningyijunjieNo ratings yet

- T-38 Fuselage Structural LifeDocument27 pagesT-38 Fuselage Structural LifeyijunjieNo ratings yet

- Buckling Behaviour of CFRP Sandwich StructureDocument59 pagesBuckling Behaviour of CFRP Sandwich StructureyijunjieNo ratings yet

- Fuselage Frame Stiffness RequirementDocument4 pagesFuselage Frame Stiffness RequirementyijunjieNo ratings yet

- AST Composite Wing ProgrammeDocument98 pagesAST Composite Wing Programmeismailovic2No ratings yet

- Automated Manufacture of Grid Stiffened PanelsDocument14 pagesAutomated Manufacture of Grid Stiffened PanelsyijunjieNo ratings yet

- Symbiotic Human-Robot Collaboration For Safe and DynamicDocument78 pagesSymbiotic Human-Robot Collaboration For Safe and DynamicyijunjieNo ratings yet

- Priciples For Determining Material Allowable and Design Allowable Values of Composite Aircraft StructuresDocument7 pagesPriciples For Determining Material Allowable and Design Allowable Values of Composite Aircraft StructuresyijunjieNo ratings yet

- Composite Wing Elastic Axis For Aeroelasticity Optimization DesignDocument6 pagesComposite Wing Elastic Axis For Aeroelasticity Optimization DesignyijunjieNo ratings yet

- Adhesively Bonded Joints For Fibrous CompositeDocument38 pagesAdhesively Bonded Joints For Fibrous CompositeyijunjieNo ratings yet

- Ply Drop Published VersionDocument12 pagesPly Drop Published VersionyijunjieNo ratings yet

- Mixed Mode Delamination Fracture Criteria For IM7G8552 Intermediate Modulus Carbon Epoxy Composite LaminateDocument70 pagesMixed Mode Delamination Fracture Criteria For IM7G8552 Intermediate Modulus Carbon Epoxy Composite LaminateyijunjieNo ratings yet

- Design Lugs Whitepaper - 264559110913046532Document6 pagesDesign Lugs Whitepaper - 264559110913046532yijunjieNo ratings yet

- 3D Stress Analysis of Adhesively Bonded Composite JointsDocument35 pages3D Stress Analysis of Adhesively Bonded Composite JointsyijunjieNo ratings yet

- Bsfait00 Fa Archiv-Neu Publikationsarchiv IB 2019 Massera DLR IB FA BS 2019 59 IB 2019 59 MA MasseraDocument169 pagesBsfait00 Fa Archiv-Neu Publikationsarchiv IB 2019 Massera DLR IB FA BS 2019 59 IB 2019 59 MA MasserayijunjieNo ratings yet

- An Investigation of Classical Panel Stiffener Buckling Methods FoDocument92 pagesAn Investigation of Classical Panel Stiffener Buckling Methods FoyijunjieNo ratings yet

- Heat Input & Joint Efficiency of Three Welding Processes Tig, Mig and FSW Using Aa6061Document6 pagesHeat Input & Joint Efficiency of Three Welding Processes Tig, Mig and FSW Using Aa6061V.v. TaguisNo ratings yet

- Intermetallic Compound Formation in FSWDocument6 pagesIntermetallic Compound Formation in FSWyogiNo ratings yet

- FSW AnalysisDocument35 pagesFSW AnalysisChinmay Dave100% (1)

- Research Paper Welding TechnologyDocument8 pagesResearch Paper Welding Technologygz8y0esp100% (1)

- Mechanical Testing and Evaluation of High-Speed and Low-Speed Friction Stir Welds. (PDFDrive)Document142 pagesMechanical Testing and Evaluation of High-Speed and Low-Speed Friction Stir Welds. (PDFDrive)taridanNo ratings yet

- Sciencedirect: Optimization of Friction Stir Welding of ThermoplasticsDocument6 pagesSciencedirect: Optimization of Friction Stir Welding of ThermoplasticsYineth PinzonNo ratings yet

- Dissimilar Friction Stir Welding of 6061 Aluminum Alloy and AZ31 Magnesium Alloy Assisted With Ultrasonic PDFDocument4 pagesDissimilar Friction Stir Welding of 6061 Aluminum Alloy and AZ31 Magnesium Alloy Assisted With Ultrasonic PDFSantiago EscobarNo ratings yet

- Pin Design 2Document18 pagesPin Design 2palash roy choudhuryNo ratings yet

- Friction Stir Welding of Steel: Mohd Zaheer Khan YusufzaiDocument11 pagesFriction Stir Welding of Steel: Mohd Zaheer Khan YusufzaiitzgayaNo ratings yet

- Dissimilar WeldingDocument42 pagesDissimilar WeldingMan MNo ratings yet

- Friction Stir WeldingDocument17 pagesFriction Stir WeldingShubham PhadtareNo ratings yet

- MP PDFDocument447 pagesMP PDFDushyanthkumar DasariNo ratings yet

- Chapter 28: Friction Stir Welding (FSW) SimulationDocument24 pagesChapter 28: Friction Stir Welding (FSW) Simulationkumar ujjwalNo ratings yet

- Eurocode Conference 2023 Mandara Eurocode 9Document25 pagesEurocode Conference 2023 Mandara Eurocode 9Rodolfo BlanchiettiNo ratings yet

- Friction Stir Welding (FSW) Seminar Report 2Document12 pagesFriction Stir Welding (FSW) Seminar Report 2RajuNo ratings yet

- Richter-Trummer2016 Article FatigueCrackGrowthBehaviourInFDocument15 pagesRichter-Trummer2016 Article FatigueCrackGrowthBehaviourInFTrimakisNo ratings yet

- Analysis of Tool Used For Friction Stir Spot Welding by Explicit Meshing SchemeDocument4 pagesAnalysis of Tool Used For Friction Stir Spot Welding by Explicit Meshing SchemeVIVA-TECH IJRINo ratings yet

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Document8 pagesAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNo ratings yet

- Latest-Emerging Manufacturing Processes PDFDocument25 pagesLatest-Emerging Manufacturing Processes PDFSaifullah AlamNo ratings yet

- Book FrictionStir WeldingDocument239 pagesBook FrictionStir WeldingKaushik SenguptaNo ratings yet

- GETO Aluminium Formwork System BrochureDocument38 pagesGETO Aluminium Formwork System BrochureGlenn RamosNo ratings yet

- Vinod ResumeDocument3 pagesVinod ResumebhvallabhaneniNo ratings yet

- Terminology in Friction Stir WeldingDocument5 pagesTerminology in Friction Stir WeldingVikram JainNo ratings yet

- Friction Stir Welding Mahesh Thesis - 10ME61R09Document52 pagesFriction Stir Welding Mahesh Thesis - 10ME61R09robertalhaNo ratings yet

- Literature Review On Metal FabricationDocument4 pagesLiterature Review On Metal Fabricationc5t0jsyn100% (1)

- 452Document365 pages452Lincoln RibeiroNo ratings yet