Professional Documents

Culture Documents

RZK NSS AVN IRF QAC 90101 00 E - EN - Signed

RZK NSS AVN IRF QAC 90101 00 E - EN - Signed

Uploaded by

Nitin JadhavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RZK NSS AVN IRF QAC 90101 00 E - EN - Signed

RZK NSS AVN IRF QAC 90101 00 E - EN - Signed

Uploaded by

Nitin JadhavCopyright:

Available Formats

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

ROZHKOVSKOYE FIELD DEVELOPMENT PROJECT

INSPECTION AND FAT REPORT / IRF

WELLHEAD CONTROL PANEL

Tag No: WHCP-U10

Tag No: WHCP-U12

Tag No: WHCP-U21

Tag No: WHCP-U23

Tag No: WHCP-U26

Tag No: 1 WHCP (U-XX-SPARE).

CLIENT DOC: NO:

RZK-NSS-AVN-IRF-QAC-90101-00-E

NSS-RZK-PO-0009

AVANCEON: DOC: NO: AVN-2022-IRF-001

27-SEP-2023

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 1 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

REVISION:

Balaji Suresh

E 27-SEP-2023 Issued for review Mangeram Tyagi

Radhakrishnan Balakrishna

Balaji Suresh

D 20-JULY-2023 Issued for review Mangeram Tyagi

Radhakrishnan Balakrishna

Balaji Suresh

C 28-MAR-2023 Issued for review Mangeram Tyagi

Radhakrishnan Balakrishna

Issued for Inter Discipline Balaji

B 16-MAR-2023 Mangeram Tyagi Sadha Baskaran

Review Radhakrishnan

Issued for Discipline Balaji

A 13-FEB-2023 Mangeram Tyagi Sadha Baskaran

Internal Review Radhakrishnan

Rev. Date Issue, Modification Prepared Checked Approved

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 2 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

Approvals:

Prepared by Name: BALAJI RADHAKRISHNAN

Job Title: Project Engineer

Signed:

Date: 27-SEP-2023

Checked by Name: Mangeram Tyagi

Job Title: QA AC Manager

Signed:

Date: 27-SEP-2023

Approved by Name: Suresh Balakrishna

Job Title: QA/QC Manager.

Sures

Digitally signed by Suresh

Signed: DN: cn=Suresh,

o=Neftestroiservice Ltd,

Date: ou=QA/QC Department,

h

email=rzk-

mgrqaqc@nss.kz, c=US

Date: 2023.09.30 15:50:01

+05'30'

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 3 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

HOLD RECORD:

Where a <HOLD> status has been included within the body of the document please indicate its location by

detailing the relevant page number.

Hold Nr. Section Description of Hold

REVISION HISTORY:

Specify significant changes from previous revisions of the document:

Rev. Date Description of Revision

A 13-FEB-2023 Issued for Discipline Internal Review

B 16-MAR-2023 Issued for Inter Discipline Review

C 28-MAR-2023 Issued for review

D 19-JULY-2023 Issued for review

E 27-SEP-2023 Issued for review

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 4 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

TABLE OF CONTENT

1. PURPOSE

2. SCOPE

3. APPLICABLE PANEL TAGS NO

4. ABBREVIATIONS.

5. REFERENCE DOCUMENT LIST

6. CERTIFICATE / TEST REPORT VERIFICATION

7. REQUIRED EQUIPMENT & UTILITIES.

8. PRE- REQUISITES GENERAL.

9. VISUAL INSPECTION.

10. PRE-TEST VISUAL EXAMINATION.

11. PUMP FUNCTIONALITY TEST.

12. FUNCTIONAL TEST FOR VALVE - MANUAL OPENING / CLOSING OF THE SSSV, MV &

WV VALVES.

13. WHCP WELL ESD CLOSING BY FUSIBLE LOOP LOGIC: (FIRE

ACTIVATION) SEQUENECE OF SSV ----- SSSV VALVES CLOSES BY FUSIBLE LOOP

LOGIC

14. PUMP PRESSURIZATION TIME TEST.

15. PRESSURE TEST PROCEDURE.

16. FLUSHING PROCEDURE.

17. SIGNOFF

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 5 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

1. PURPOSE:

The document outlines the procedure for factory acceptance testing (FAT) of wellhead control

panels which serves for SSSV valves, MV valves, WV Valves & fusible plugs (Based on client

specification RZK-NSS-000-SDR-INS-00001-00-C.

Manufactured for the project – “ROZHKOVSKOYE FIELD DEVELOPMENT PROJECT”.

FAT shall be held at AVANCEON facility FZE, DUBAI- UAE.

Company: M/s Ural oil & gas.

WHCP Manufacturer: M/s Avanceon Jafza-FZE

PLC / ICSS contractor: Not in Avanceon scope.

2. SCOPE:

The scope is to carry out the FAT of the Wellhead Control Panel, broadly outlined as below:

The procedure is Typical for wellhead hydraulic panel 5+1 spares, the control and check activities

are related to the following project, Avanceon Project: Ref: F23-02-001.

Panel Dimensional check.

Functional Check.

Marking & Tagging Check.

BOM Check.

3. APPLICABLE PANEL TAGS NO:

Tag No: WHCP-U10

Tag No: WHCP-U12

Tag No: WHCP-U21

Tag No: WHCP-U23

Tag No: WHCP-U26

Tag No: 1 WHCP (U-XX-SPARE).

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 6 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

4. ABBREVIATIONS:

The following abbreviations are used throughout this procedure:

BV Ball Valve.

HP High Pressure

LP Low Pressure.

MP Medium Pressure.

PM Pump / Motor.

PG Pressure Gauge.

FA Flame Arrester

FB Filler Breather.

PSV Pressure safety valve.

NV Needle Valve.

FCV Flow Control Valve.

NSPK Nitrogen Skid Package.

PT Pressure Transmitter.

LS Level Switch.

PCV Pressure Control Valve.

HR Hydraulic Regulator.

PS Pressure Switch.

SOV Solenoid valve.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 7 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

5. REFERENCE DOCUMENT LIST:

The reference documentation is as follow:

Document Number Description

RZK-NSS-AVN-DGA-ENG-0001-01-C General Arrangement Drawing.

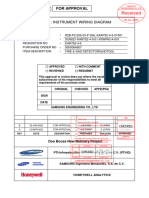

RZK-NSS-AVN-PID-ENG-0001-01-C Piping & Instrumentation Diagram.

RZK-NSS-AVN-SDR-QAC-0001-01-C SUPPLIER DOCUMENT REQUIRTMENTS (SDR)

RZK-NSS-AVN-SLD-0001-01-C ELECTRICAL / SINGLE LINE DIAGRAM / SLD

RZK-NSS-AVN-ITP-ENG-0001-01-C INSPECTION TEST PLAN / ITP

6. CERTIFICATE / TEST REPORT VERIFICATION:

CLIENT / TPI

ACCEPTED

WHCP FLUSHING REPORT

WHCP PRESSURE TEST REPORT

7. REQUIRED EQUIPMENT & UTILITIES:

Nitrogen rack filled with dry nitrogen c/w suitable hoses & regulator.

Mineral based hydraulic oil as required. (Castrol Hyspin AWH M32 is used for

testing purpose).

24V DC power supply for instruments (PT).

400V AC power supply for motor.

Handheld Hart communicator & digital multi meter.

35L bladder accumulator, 600 barg.

Hydraulic pressure regulator.

Hand tools.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 8 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

8. PRE-TEST VISUAL EXAMINATION:

Mode of Client / TPI

sl:no: Activity Accepted criteria

inspection sign off.

Check Visual and dimensions of the wellhead As per approved

☐ Visual GA drawings, RZK-

10.1 module as per the approved General Check NSS-AVN-DGA-ENG-

Arrangement Drawings. 0001-01_0

☐ Visual As per approved

Check tubing runs for neatness & fixture and

10.2 Check PID, RZK-NSS-AVN-PID-

Ensure all tube work have sufficient support. ENG-0001-00_0

Mode of Client / TPI

sl:no: Activity Accepted criteria

inspection sign off.

☐ Visual As per approved

Check labelling of components and controls

10.3 Check PID, RZK-NSS-AVN-PID-

in line with the relevant GA. ENG-0001-00_0

☐ Visual As per approved

Check relief valve set points report & tags in

10.4 Check PID, RZK-NSS-AVN-PID-

line with schematic drawing. ENG-0001-00_0

☐ Visual As per approved

Check the cabinet front fascia components

10.5 Check PID, RZK-NSS-AVN-PID-

mounting Tags. ENG-0001-00_0

☐ Visual As per approved

10.6 Check Motor supply Voltage 400V, AC 3PH. Check- PID, RZK-NSS-AVN-PID-

___________ V ENG-0001-00_0

Finally - Check all the BV, NV, HR, PT & LT ☐ Visual As per approved

10.7 Check PID, RZK-NSS-AVN-PID-

and all the components fixed in panels are as

per PID. ENG-0001-00_0

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 9 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

9. PUMP FUNCTIONALITY TEST:

Mode of Accepted Client / TPI

sl:no: Activity inspection criteria sign off.

Confirm 400VAC power is available at the

11.1 ☐ …………V 400V AC

Motor Control Panel.

11.2 Pump-A Duty mode ☐ Visual Check Pump-A Duty

11.3 Pump-A manual/Auto Mode ☐ Visual Check Manual Mode

Mode of Accepted Client / TPI

sl:no: Activity

inspection criteria sign off.

11.5 Pump A start Pressure ☐ ………. BARG 0 Bar

11.6 Current Reading Pump A at 0 Bar ☐ ………. A 2.5 to 3 Amps

11.7 Current Reading Pump A at 450 Bar ☐ ………. A <=40 Amps

PUMP HEADER START UP:

Start the pump by pressing the start As per

push button and observe the approved PID,

11.8 ☐ Visual Check

RZK-NSS-AVN-PID-

corresponding indication “PUMP-A ENG-0001-00_0

Running” on LCP.

Now Start the Pump-A and start closing

the recirculation valve NV-03) and allow

to pressurize. Monitor the gauge

As per

PUMP HEADER discharge pressure approved PID,

11.13 ☐ Visual Check

PG-01 on the front side of the panel. RZK-NSS-AVN-PID-

when the pump discharge pressure ENG-0001-00_0

reaches 450 Barg, stop the pump and

allow to settle for some time.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 10 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

Mode of Accepted Client / TPI

sl:no: Activity

inspection criteria sign off.

VALVE HEADER LINE STARTUP:

SSSV: Now Regulate the HP SSSV header

11.14 regulator (HR-01) to reach 600 Barg; ☐ ………. BARG

monitor in (PG-04) in the front face panel, 600 BARG

Line-up the HP header pressure to the

respective SUPPLY LINE.

WV & MV: Now Regulate the MP header

regulator (HR-02) gradually to reach 340

Barg; monitor the header pressure (PG-

03) in the front face panel. 340 BARG

11.15

Ensure MP header pressure gauge ☐ ………. BARG

MV&WV (PG-03) is reading 340 barg.

Line-up the MP header pressure to the

respective SUPPLY LINE.

FUSIBLE LOOP:

Now open the ball valve (BV-07) in

Control / Fusible Header line.

11.16 ☐ ………. BARG

Now open the regulator (HR-03) on the

LP header of control/fusible line and set 7 – 8.5 BARG

the pressure to 7 barg by observing the

LP header pressure gauge (PG-08).

NOTE 1:

CLOSING TIME DELAYS PROVIDED THROUGH THE FLOW CONTROL VALVE (F-FCV-01) IS

FOR LOGIC VERIFICATION PURPOSE ONLY, ACTUAL TIME DELAYS WILL BE SET DURING

THE COMMISSIONING STAGE OF THE RESPECTIVE WELL.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 11 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

10. FUNCTIONAL TEST:

12.1 FUNCTIONAL TEST FOR VALVE - MANUAL OPENING / CLOSING OF THE SSSV, MV & WV VALVES

Accepted Client / TPI

sl:no: Activity

criteria sign off.

NO CRITERIA

SSSV MANUAL 10.1.1. Make sure the all the bulk heads are FOR THIS.

OPENING & properly connected with temporary

CLOSING THIS IS

pressure gauges to monitor the INTERNAL TEST

pressure at the outlet side. ACTIVITY.

10.1.2. Check the connections for (SSSV-SOV-1)

well solenoid valves from the 24VDC

OBSERVE SSSV

SSSV MANUAL stimulator shall be energized. SUPPLY LINE

OPENING &

PRESSURE

CLOSING

10.1.3. Pull the Handle Valve (SSSV-PB-01) to GAUGE PG-05

open the SSSV, observe the pressure READS 600 BARG

gauge (PG-05) and shall read 580 barg

in supply line.

10.1.4. Push the Handle Valve (SSSV-PB-01) to OBSERVE SSSV

SSSV MANUAL SUPPLY LINE

OPENING &

close the SSSV, observe pressure gauge

PG-05 and shall reads 0 Barg after 60 PRESSURE

CLOSING

GAUGE PG-05

seconds Delay (Adjustable in HP-FCV- READS 0 BARG.

01).

Accepted Client / TPI

sl:no: Activity criteria sign off.

OBSERVE MV

SUPPLY LINE

MV MANUAL 10.1.5. Pull the Handle Valve (MV-PB-02) to open PRESSURE

OPENING & the MV, observe the pressure gauge (PG- GAUGE PG-06

CLOSING

06) and shall read 340 barg in supply line. READS 340

BARG.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 12 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

OBSERVE MV

10.1.6. Push the Handle Valve (MV-PB-02) to close SUPPLY LINE

the MV, observe pressure gauge (PG-06) PRESSURE

GAUGE PG-06

and shall reads 0 Barg.).

READS 0 BARG.

10.1.7. Make sure the all the bulk heads are

properly connected with temporary

pressure gauges to monitor the

pressure at the outlet side. OBSERVE WV

SUPPLY LINE

10.1.8. Check the connections for (WV-SOV-3) PRESSURE

well solenoid valves from the 24VDC GAUGE PG-07

stimulator shall be energized. READS 340

10.1.9. Pull the Handle Valve (WV-PB-03) to BARG.

WV MANUAL

OPENING & open the WV, observe the pressure

CLOSING

gauge PG-07 and shall read 340 barg in

supply line.

OBSERVE WV

10.1.10. Push the Handle Valve (WV-PB-03) SUPPLY LINE

to close the WV, observe pressure PRESSURE

GAUGE PG-07

gauge PG-07 and shall reads 0 Barg. READS 0 BARG.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 13 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

11. PRESSURE TEST PROCEDURE:

Client /

sl:no: Mode of Accepted criteria

Activity

inspection TPI sign

off.

After the completion of all tubing

assembly activities if no further activities

are required the equipment will be

cleared for the pressure testing.

Pressure gauges & chart recorders using

for the test should have a valid calibration

certificate as per specification or relevant

National / International Standards.

A minimum of two pressure gauges is

required for the test system. One pressure LP Header (Logic

Pressure) - 7 barg

gauge shall be on the test pump and the

MP Header

other(s) on the test system. Their accuracy (Medium Pressure)

shall be within 1 % of one another. - 340 barg

The test fluid shall be filled at the lowest HP Header (High

Pressure) - 2 barg

01 point in the system to minimize entrapped Visual

air. All vents shall be open during filling. 15 minutes –

After test pressure is reached and before above pressure x

1.1 times, all

the commencement of inspection of the tubing should

system, the isolation valve between the hold pressure

without any

test manifold and the system under leakage.

pressure test shall be closed and the test

pump disconnected.

During pressure test minimum 2 pressure

hold steps should be maintained to

stabilize the volume of test.

During depressurizing test line drop down

pressure shall be minimum 2 steps.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 14 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

Pressure test pressure shall be as below:

Pressure Test:

Start external pressure Test pump and

bring pressure to the first hold point which

shall be around 1.1 TIMES of the test

pressure.

Check leak if any.

If leaks are present, drop the pressure to

atmospheric pressure and arrest the leak

by necessary tightening of the connectors

/ repair of the defective parts and then From the above

design pressure x

again start pressurizing. 1.1 times

Hold pressure for Minimum 15 minutes. Pressure holding

time 15 minutes

Observe and record pressure from the

pressure gauges.

Get clearance of the QC personnel/Client

representative Inspector for de

pressurizing.

Release of pressure and draining shall be

done on the downstream side. All vents

shall be opened before draining to

facilitate drainage and to prevent

formation of a vacuum.

All temporary installed for testing

purposes (External Devices, valves, etc.)

shall be removed.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 15 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 16 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

12. FLUSHING PROCEDURE:

1. Test Equipment:

AVANCEON will provide the following services and equipment to perform the flushing process.

Testing Engineer and Technicians

Hydraulic fluid / Shop air supply

Plugs and caps as required.

Flushing rig (AVANCEON).

Flushing fluid (Mineral based Hydraulic oil as required, CASTROL HYSPIN AWH M32 is used for

Flushing of the panels)

Particles Laser counter machine (PLCM)

Laser Particle Analyzer.

2. Requirements:

Prior to flushing:

Remove all relief valves and cap tubing

Cap all output bulkheads

Check calibration certificates of all equipment used.

3. Flushing the Rig:

Fit a filter element to the filter in the flushing rig

Re-circulate the fluid for a minimum of 20 minutes in initial stage; take a sample every 15 minutes

using the Particles Laser counter machine (PLCM)/Laser Particle counter (LPA).

Check that the fluid being flushed is reading Nas Class 6.

Repeat paragraphs 5. If the cleanliness of the fluid is not to the required standard.

4. Flushing the HPU System:

Flush the system for a minimum of 30 minutes

Flushing times will vary’s according to tube diameter, length and contamination levels present.

Change filters elements as indicated by the filter indicator or slide results

Turbulent flow shall be maintained at all times where possible

Approximately after a further 15 minutes, take a sample. Award the sample a unique number

Particles Laser Counter machine PLCM/Laser particle counter (LPA) will give sample result NAS

Class 6.

Print the sample result.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 17 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

5. Completion:

Refit all components removed to enable the flushing to be carried out.

Complete the appropriate documentation i.e. Certificate of Conformity or Certificate of

Cleanliness/Flushing report.

Note: All the field tubes shall be flushed before connecting to Avanceon panel to prevent the

contamination from field lines.

Mode of Accepted Client / TPI

sl:no: Activity

inspection criteria sign off.

Flushing of all tubing’s as per above flushing

01 procedure. visual Nas Class 6.

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 18 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 19 of 20

Ural Oil and Gas LLP Rozhkovskoye Field Development

Date Issued: 27-SEP-2023

NefteStroiService Ltd. LLP

Issue Type: Issued for review

Document Number: RZK-NSS-AVN-IRF-QAC-90101-00-E

13. COMPLETION:

13.1. Isolate all the pressure connections to the panel bulkheads.

14. FACTORY ACCEPTANCE TEST CERTIFICATE

This concludes the Performance Testing procedure for the scope of this contract and certifies that

the tests detailed in this procedure were satisfactorily completed and witnessed by the

undersigned.

TAG No: ----------------------------------------------

AVANCEON Representatives:

Name Title Signature & Date

CLIENT Representatives:

Name Title Signature & Date

End of the document

INSPECTION AND FAT REPORT WHCP

RZK-NSS-AVN-IRF-QAC-90101-00-E Page 20 of 20

You might also like

- Massey Ferguson MF 1200 Tractor Service Parts Catalogue ManualDocument14 pagesMassey Ferguson MF 1200 Tractor Service Parts Catalogue Manualqlb898316No ratings yet

- Reading: Healthy Lifestyle Role For All Society'Document4 pagesReading: Healthy Lifestyle Role For All Society'Tore CusimanoNo ratings yet

- RZK NSS Atv Pro Qac 90006 00 0 - enDocument32 pagesRZK NSS Atv Pro Qac 90006 00 0 - enNitin JadhavNo ratings yet

- RZK NSS Avn Irf Qac 90001 00 D - enDocument18 pagesRZK NSS Avn Irf Qac 90001 00 D - enNitin JadhavNo ratings yet

- RZK NSS 000 Pro Qac 00009 00 D - enDocument12 pagesRZK NSS 000 Pro Qac 00009 00 D - enAssanaliNo ratings yet

- RZK NSS KMGA REP ENG 00002 00 0 - EN - SignedDocument41 pagesRZK NSS KMGA REP ENG 00002 00 0 - EN - SignedNitin JadhavNo ratings yet

- RZK NSS CMG Cec Ins 21001 00 C1 DDocument30 pagesRZK NSS CMG Cec Ins 21001 00 C1 DNitin JadhavNo ratings yet

- CRISP-SUT2-SY2-MSRA-4-015 - RC - MSRA Instruments & Cables Dismantling InstallnDocument22 pagesCRISP-SUT2-SY2-MSRA-4-015 - RC - MSRA Instruments & Cables Dismantling InstallnKamruzzaman KhokonNo ratings yet

- Eprocurement System of Coal India LimitedDocument2 pagesEprocurement System of Coal India LimitedKrish JaiswalNo ratings yet

- VINOTH - QCI Multi - BSP ApprovalDocument2 pagesVINOTH - QCI Multi - BSP ApprovalVINOTH MECHNo ratings yet

- NCR Status SGRE 31-01-2023 - HSEDocument1 pageNCR Status SGRE 31-01-2023 - HSEIndraNo ratings yet

- Interim Payment Application-3 220KV Switching Station Project KerawalapitiyaDocument1 pageInterim Payment Application-3 220KV Switching Station Project KerawalapitiyamusthaqhassanNo ratings yet

- 20PKSA001-LNT-SPV-G-DBR-0041 - R5 Design Basis Report PV Plant - ADocument53 pages20PKSA001-LNT-SPV-G-DBR-0041 - R5 Design Basis Report PV Plant - ASamkonaya BitomNo ratings yet

- MSA - Sika Monotop 412 MYDocument3 pagesMSA - Sika Monotop 412 MYNorlizawati YusofNo ratings yet

- Period Close Exceptions Report 070423Document23 pagesPeriod Close Exceptions Report 070423mshadabalamNo ratings yet

- 210505-E-DW-2603 - B1 - KEAS-Panel Wiring Diagram - KE CODE 3 REV B1Document18 pages210505-E-DW-2603 - B1 - KEAS-Panel Wiring Diagram - KE CODE 3 REV B1benn savyasachiNo ratings yet

- MGP1-BOC1888PO001-H02-0001 - 003 - Overall - Code 1 - MK - 150823Document10 pagesMGP1-BOC1888PO001-H02-0001 - 003 - Overall - Code 1 - MK - 150823jobertNo ratings yet

- PQS FormDocument2 pagesPQS FormabbasNo ratings yet

- Rfi PlofDocument1 pageRfi PlofMuhammad Adrian AlkahfiNo ratings yet

- 077154C 27794927 0000 ZWM00 QCA B1002 001 - 6 C - UnlockedDocument6 pages077154C 27794927 0000 ZWM00 QCA B1002 001 - 6 C - UnlockedPRASHANTNo ratings yet

- P2227 Sma Est FS 00002 - AdDocument140 pagesP2227 Sma Est FS 00002 - Adxibei shanNo ratings yet

- Nfe1 Gac QM WPS 00021 - 0001 - (Gac WPS P CSLTC 0010)Document43 pagesNfe1 Gac QM WPS 00021 - 0001 - (Gac WPS P CSLTC 0010)rajan chaubeyNo ratings yet

- UntitledDocument1 pageUntitledrajesh khannaNo ratings yet

- 210505-E-DW-2603 - B2 - KEAS-Panel Wiring Diagram - KE CODE 2Document18 pages210505-E-DW-2603 - B2 - KEAS-Panel Wiring Diagram - KE CODE 2benn savyasachiNo ratings yet

- Sag 011 5267 DSN PW CD PK24.476 Ol SG2 100 06Document1 pageSag 011 5267 DSN PW CD PK24.476 Ol SG2 100 06Sanjay SwamiNo ratings yet

- Tender Summary ReportsDocument1 pageTender Summary ReportsManoj MehraNo ratings yet

- NC Vol 6 Structure GadDocument196 pagesNC Vol 6 Structure GadYogeshDuttNo ratings yet

- Ouis Erger Roup: THE, Inc., USADocument1 pageOuis Erger Roup: THE, Inc., USATitus PraveenNo ratings yet

- 92 Monthly I&M Report (October - 2022) .PDF CommentDocument2 pages92 Monthly I&M Report (October - 2022) .PDF CommentDEVENDER CHAUHANNo ratings yet

- List of Ongoing Arbitration Cases (As On 31.03.2022) : Name of Arbitrators YES NODocument2 pagesList of Ongoing Arbitration Cases (As On 31.03.2022) : Name of Arbitrators YES NOshamim ahmadNo ratings yet

- Mir 125Document1 pageMir 125MCCIN L&WNo ratings yet

- Procedure Voltage Transformer Generator Circuit Breaker ReInstallation - Rev.1 - 2023!09!08Document11 pagesProcedure Voltage Transformer Generator Circuit Breaker ReInstallation - Rev.1 - 2023!09!08azisalfaqih7No ratings yet

- Tbms - Edit ConveyanceDocument1 pageTbms - Edit Conveyancecoraldrawgraphics.inNo ratings yet

- 1 Heavy Equipment Tracking SystemDocument13 pages1 Heavy Equipment Tracking Systemqadeer55afridiNo ratings yet

- Waskita Beton Precast-15659-2023Document1 pageWaskita Beton Precast-15659-2023ArifinNo ratings yet

- RRG23D0143Document1 pageRRG23D0143Sunita SinghNo ratings yet

- P1122 Arco Gen Me Man 0023 01Document137 pagesP1122 Arco Gen Me Man 0023 01safeer SulaimanNo ratings yet

- 765662Document1 page765662Muhammad Arslan AztNo ratings yet

- Form m007b - Surveys - Secondary Certificates StatusDocument5 pagesForm m007b - Surveys - Secondary Certificates StatusMai PhamNo ratings yet

- Bill 168 - MoulyaDocument1 pageBill 168 - MoulyaRajesh RajNo ratings yet

- r2b p2 205 03 P Dal Kar752 4-5-01001 Rev.b Instrument Wiring Diagram ReviewedDocument6 pagesr2b p2 205 03 P Dal Kar752 4-5-01001 Rev.b Instrument Wiring Diagram ReviewedjonathanNo ratings yet

- 2111-122-QVC-G-001 - Civil Works FQP For DSTPS FGD Package-Proposed PDFDocument22 pages2111-122-QVC-G-001 - Civil Works FQP For DSTPS FGD Package-Proposed PDFMANNANo ratings yet

- AKKE2211-SDO-MOS-01 - Mobilization & Preliminary WorkDocument9 pagesAKKE2211-SDO-MOS-01 - Mobilization & Preliminary WorkMuhammad Hamidy KamarulZamanNo ratings yet

- AKKE2211-SDO-MOS-02 - Hydraulic Injection PilingDocument17 pagesAKKE2211-SDO-MOS-02 - Hydraulic Injection PilingMuhammad Hamidy KamarulZamanNo ratings yet

- Cover Sheet Aux TrafoDocument1 pageCover Sheet Aux TrafoArdhendu Sekhar BhanjaNo ratings yet

- Eprocurement System For Pradhan Mantri Gram Sadak Yojana (PMGSYS)Document1 pageEprocurement System For Pradhan Mantri Gram Sadak Yojana (PMGSYS)Kumari NishaNo ratings yet

- BI-10-20676 Master Gas System Expansion Phase Iii Industrial Cluster Construction Work Package #12 Eastern and Qassim ClusterDocument9 pagesBI-10-20676 Master Gas System Expansion Phase Iii Industrial Cluster Construction Work Package #12 Eastern and Qassim Clusterpenmetsa89No ratings yet

- KP 02R HTR 25 Jan 23Document1 pageKP 02R HTR 25 Jan 23Aulia AchmadNo ratings yet

- REV-2 Master Schedule Delivery Time - LV Board Mayora TJF Pasuruan - 29102023Document3 pagesREV-2 Master Schedule Delivery Time - LV Board Mayora TJF Pasuruan - 29102023ati EngineeringNo ratings yet

- BI-10-20676 Master Gas System Expansion Phase Iii Industrial Cluster Construction Work Package #12 Eastern and Qassim ClusterDocument15 pagesBI-10-20676 Master Gas System Expansion Phase Iii Industrial Cluster Construction Work Package #12 Eastern and Qassim Clusterpenmetsa89No ratings yet

- Rfi - Request For Inspection: Epc of Lawe-Lawe Facilities RDMP Ru-V BalikpapanDocument1 pageRfi - Request For Inspection: Epc of Lawe-Lawe Facilities RDMP Ru-V BalikpapanAidil DafitraNo ratings yet

- F-Crew-01Sea Staff Application Form - Rev 2.0: 1. Personal InformationDocument4 pagesF-Crew-01Sea Staff Application Form - Rev 2.0: 1. Personal InformationСерик НузмаевNo ratings yet

- Substation Name: Installation of DRPC at Wadi Dawasir 380Kv BSPDocument52 pagesSubstation Name: Installation of DRPC at Wadi Dawasir 380Kv BSPAhmed FathyNo ratings yet

- HIJAS N CV & CertificatesDocument28 pagesHIJAS N CV & CertificatessenthilkumaraegNo ratings yet

- Organisation Chain: Tender ID:2023 - PWDRP - 935066 - 1 Tender Ref No:Northpune/2023-24 /25Document2 pagesOrganisation Chain: Tender ID:2023 - PWDRP - 935066 - 1 Tender Ref No:Northpune/2023-24 /25MirajNo ratings yet

- KVLRT3 - SIR-KVLRT3-GSTSB-GS04-EC-SIR-C& S-009272 - Launching Work of Precast Pier Cap at P8-78N PDFDocument29 pagesKVLRT3 - SIR-KVLRT3-GSTSB-GS04-EC-SIR-C& S-009272 - Launching Work of Precast Pier Cap at P8-78N PDFIzzat IzzuddinNo ratings yet

- Vn3110-Cv2-A-Pro-5086 - 00 ApprovedDocument40 pagesVn3110-Cv2-A-Pro-5086 - 00 Approvedakın bektaşNo ratings yet

- Project Transmittal NoteDocument5 pagesProject Transmittal NoteAntonius HarrisNo ratings yet

- List of Ongoing Arbitration Cases (As On 03.08.2022)Document2 pagesList of Ongoing Arbitration Cases (As On 03.08.2022)shamim ahmadNo ratings yet

- Transient Report RevA FinalDocument25 pagesTransient Report RevA Finalmzqaqila100% (1)

- RZK NSS CMG Cec Ins 21001 00 C1 DDocument30 pagesRZK NSS CMG Cec Ins 21001 00 C1 DNitin JadhavNo ratings yet

- RZK NSS CMG Pid PRS 01029 00 D2 0Document1 pageRZK NSS CMG Pid PRS 01029 00 D2 0Nitin JadhavNo ratings yet

- DS2T2 - Instrument StandDocument10 pagesDS2T2 - Instrument StandNitin JadhavNo ratings yet

- PR121124 - Instrument Bulks-FINAL - 1Document10 pagesPR121124 - Instrument Bulks-FINAL - 1Nitin JadhavNo ratings yet

- DS2T2 - Cable Gland and Stopping PlugDocument1 pageDS2T2 - Cable Gland and Stopping PlugNitin JadhavNo ratings yet

- Item No. Brand Unit Price (USD) QTY Total Price (USD) System Description Overall Price ScheduleDocument1 pageItem No. Brand Unit Price (USD) QTY Total Price (USD) System Description Overall Price ScheduleNitin JadhavNo ratings yet

- PTs Transformer Package MTO-0001-C05 - MTODocument1 pagePTs Transformer Package MTO-0001-C05 - MTONitin JadhavNo ratings yet

- Toaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRDocument9 pagesToaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRNitin JadhavNo ratings yet

- DRRR2324 Q4 DRRDocument7 pagesDRRR2324 Q4 DRRh4gtg7n55gNo ratings yet

- Sore ThroatDocument10 pagesSore Throatapi-551073862No ratings yet

- 7B ReportDocument12 pages7B ReportRowena A. TomalabcadNo ratings yet

- Exercise 4:: Organic Components: CarbohydratesDocument20 pagesExercise 4:: Organic Components: CarbohydratespikachuzingungaNo ratings yet

- Chapter 7 - Morphing Skin Foams - 2018 - Morphing Wing TechnologiesDocument24 pagesChapter 7 - Morphing Skin Foams - 2018 - Morphing Wing TechnologiesRichardNo ratings yet

- Combined Cellulitis - FinalDocument78 pagesCombined Cellulitis - Finalsaru_patel0% (1)

- Mass. Proposed AddendumsDocument25 pagesMass. Proposed AddendumsKirk HartleyNo ratings yet

- Pre-Test in Science 6: M.S. Garcia Elementary SchoolDocument3 pagesPre-Test in Science 6: M.S. Garcia Elementary SchoolAnepsu HohoNo ratings yet

- Definition of Terms Mine SurveyingDocument2 pagesDefinition of Terms Mine Surveyingaquariuspj25100% (3)

- Chapter Two Micro 303-محولDocument12 pagesChapter Two Micro 303-محولshimaa dewedarNo ratings yet

- Ipsative Personality TestsDocument10 pagesIpsative Personality Testseman_tenan2220No ratings yet

- Olea Europaea A Phyto-Pharmacological ReviewDocument5 pagesOlea Europaea A Phyto-Pharmacological ReviewyigalbyNo ratings yet

- PCMP (Guzman, Renz N. Bped Ep21)Document4 pagesPCMP (Guzman, Renz N. Bped Ep21)Renz N. GuzmanNo ratings yet

- Luserne Tree InformationDocument26 pagesLuserne Tree Informationpierre van wykNo ratings yet

- Bosch ManualDocument56 pagesBosch Manualjhon manuel de jesus100% (1)

- BilcoDocument16 pagesBilcoruloNo ratings yet

- (U) Daily Activity Report: Marshall DistrictDocument5 pages(U) Daily Activity Report: Marshall DistrictFauquier NowNo ratings yet

- Final DraftDocument37 pagesFinal DraftMorareng MariettaNo ratings yet

- Beyond Mendelian GeneticsDocument73 pagesBeyond Mendelian GeneticsAldin HernandezNo ratings yet

- Manual of Temporal Bone DissectionDocument82 pagesManual of Temporal Bone DissectionBungbu Tn100% (4)

- Azeem, Et Al ('21) - Tea Leaves Biochar As A Carrier of Bacillus Cereus Improves The Soil Function And.. (ASE)Document13 pagesAzeem, Et Al ('21) - Tea Leaves Biochar As A Carrier of Bacillus Cereus Improves The Soil Function And.. (ASE)aida-69No ratings yet

- Calibration of Dosimeters Used in Radiation TherapyDocument122 pagesCalibration of Dosimeters Used in Radiation TherapySOHON SINHA MAHAPATRANo ratings yet

- Orthopaedic Study Guide 2014Document126 pagesOrthopaedic Study Guide 2014Yip Kar Jun100% (1)

- What Are The Expected Tasks You Have Successfully AccomplishedDocument1 pageWhat Are The Expected Tasks You Have Successfully AccomplishedImmortality Realm67% (18)

- RDSO Controlled Items Transferred To Other Production Units & COREDocument5 pagesRDSO Controlled Items Transferred To Other Production Units & CORERakesh RoshanNo ratings yet

- PC3SH21YFZBFDocument15 pagesPC3SH21YFZBFkrimoNo ratings yet

- Fresh and Simple PDFDocument3 pagesFresh and Simple PDFthivashnee padayacheeNo ratings yet