Professional Documents

Culture Documents

Reinforced Masonry

Reinforced Masonry

Uploaded by

addrien daniel0 ratings0% found this document useful (0 votes)

1 views1 pageOriginal Title

Reinforced masonry

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageReinforced Masonry

Reinforced Masonry

Uploaded by

addrien danielCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

1.

5 REINFORCED AND PRESTRESSED MASONRY

The preceding paragraphs in this chapter have been concerned with the

use of unreinforced masonry. As masonry has relatively low strength in

tension, this imposes certain restrictions on its field of application.

Concrete is, of course, also a bri le material but this limitation is

overcome by the introduction of reinforcing steel or by prestressing. The

corresponding use of these techniques in masonry construction is not

new but, until recently, has not been widely adopted. This was partly due

to the absence of a satisfactory code of practice, but such codes are now

available so that more extensive use of reinforced and prestressed

masonry may be expected in future.

By the adoption of reinforced or prestressed construction the scope of

masonry can be considerably extended. An example is the use of

prestressed masonry walls of cellular or fin construction for sports halls

and similar buildings where the requirement is for walls some 10 m in

height supporting a long span roof. Other examples include the use of

easily constructed, reinforced masonry retaining walls and the

reinforcement of laterally loaded walls to resist wind or seismic forces.

In appropriate cases, reinforced masonry will have the advantage over

concrete construction of eliminating expensive shu ering and of

producing exposed walls of a ractive appearance without additional

expense.

Reinforcement can be introduced in masonry elements in several

ways. The most obvious is by placing bars in the bed joints or collar

joints, but the diameter of bars which can be used in this way is limited.

A second possibility is to form pockets in the masonry by suitable

bonding pa erns or by using specially shaped units. The steel is

embedded in these pockets either in mortar or in small aggregate

concrete (referred to in the USA as ‘grout’). The third method, suitable for

walls or beams, is to place the steel in the cavity formed by two leaves (or

wythes) of brickwork which is subsequently filled with small aggregate

concrete. This is known as grouted cavity construction. Elements built in

this way can be used either to resist in-plane loading, as beams or shear

walls, or as walls under lateral loading. In seismic situations it is possible

to bond grouted cavity walls to floor slabs to give continuity to the

structure. Finally, reinforcement can be accommodated in hollow block

©2004 Taylor & Francis

walls or piers, provided that the design of the blocks permits the

formation of continuous ducts for the reinforcing bars.

Prestressed masonry elements are usually post-tensioned, the steel, in

strand or bar form, being accommodated in ducts formed in the

masonry. In some examples of cellular or diaphragm wall construction

the prestressing steel has been placed in the cavity between the two

masonry skins, suitably protected against corrosion. It is also possible to

prestress circular tanks with circumferential wires protected by an outer

skin of brickwork built after prestressing has been carried out.

You might also like

- Palm Kernel Expeller - MSDSDocument6 pagesPalm Kernel Expeller - MSDSZubaidi Othman67% (3)

- 1409 Thiruvasagam Lyrics Tamil ThiruvasagamDocument133 pages1409 Thiruvasagam Lyrics Tamil ThiruvasagamSivasangar Seenivasagam67% (3)

- Sample Assignment of Prestressed Concrete DesignDocument21 pagesSample Assignment of Prestressed Concrete DesignjrmmansayonNo ratings yet

- Retaining Wall PDFDocument18 pagesRetaining Wall PDFG. M. BayazidNo ratings yet

- Embedded Walls Finished)Document17 pagesEmbedded Walls Finished)Tun Sheikh HambaleeNo ratings yet

- BIA - Steel Lintel DesignDocument7 pagesBIA - Steel Lintel Designgpax42No ratings yet

- Retaining Walls - Caltrans - Section5Document106 pagesRetaining Walls - Caltrans - Section5ekaamf100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Brodkorb Trucktrolley Luleaminingday HandoutDocument45 pagesBrodkorb Trucktrolley Luleaminingday HandoutArtur KanashNo ratings yet

- Survey Check ListDocument11 pagesSurvey Check Listjothi subraNo ratings yet

- Operators ManualDocument134 pagesOperators ManualMark Bennett67% (3)

- DM Structural MeasuresDocument8 pagesDM Structural Measuressurya kumarNo ratings yet

- Hybrid Masonry Design 2.13.01 - 12.29.09Document6 pagesHybrid Masonry Design 2.13.01 - 12.29.09Sovich82No ratings yet

- Hybrid Concrete Masonry Design: TEK 14-9ADocument8 pagesHybrid Concrete Masonry Design: TEK 14-9AMega EstructurasNo ratings yet

- Concrete Slab RepairDocument6 pagesConcrete Slab Repairsrk2002No ratings yet

- Design of Brick Diaphragm WallsDocument43 pagesDesign of Brick Diaphragm WallsdavidongpongNo ratings yet

- Retaining WallDocument20 pagesRetaining WallCharlesNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentRemya R. KumarNo ratings yet

- Learning Outcome 4 Retaining WallsDocument9 pagesLearning Outcome 4 Retaining WallsChris FindlayNo ratings yet

- Thesis Draft Christian M. TadeoDocument1 pageThesis Draft Christian M. TadeoChristian TadeoNo ratings yet

- Pre Stressed ConcreteDocument5 pagesPre Stressed Concreteridzwan8789No ratings yet

- Concrete Construction Article PDF - Detailing Brick SpandrelsDocument3 pagesConcrete Construction Article PDF - Detailing Brick SpandrelskebebewNo ratings yet

- Seismic RetrofittingDocument22 pagesSeismic RetrofittingJeevan ReddyNo ratings yet

- Columns and PilastersDocument2 pagesColumns and PilastersKevin Alexander González ReyezNo ratings yet

- Research Architectural: Tech VDocument6 pagesResearch Architectural: Tech VMark DanielNo ratings yet

- Ekistics YJPDocument19 pagesEkistics YJPYogesh J. ParekhNo ratings yet

- Pre-Tensioning and Post-Tensioning in Prestressed Concrete DesignDocument17 pagesPre-Tensioning and Post-Tensioning in Prestressed Concrete DesignEarl UbiñaNo ratings yet

- Retaining WallsDocument12 pagesRetaining WallsSIZA THE POETNo ratings yet

- Types of Retaining WallsDocument8 pagesTypes of Retaining WallscedaserdnaNo ratings yet

- Hybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDocument6 pagesHybrid-Masonry-Design-2 13 01 - 12 29 09 PDFDennier CHÁVEZ GARRONo ratings yet

- Seminar On Steel Plate Shear WallDocument24 pagesSeminar On Steel Plate Shear WallNilesh Saksena0% (2)

- Structural DesignDocument71 pagesStructural DesignJam CamuNo ratings yet

- Types of Masonry WallsDocument30 pagesTypes of Masonry Wallsbereket100% (1)

- Geotechnical Consultants For DA Approvals - Geotechnical Site Investigation, Geotechnical Design and Footing Inspections!Document1 pageGeotechnical Consultants For DA Approvals - Geotechnical Site Investigation, Geotechnical Design and Footing Inspections!kaung sanNo ratings yet

- Te HWDocument2 pagesTe HWAngel RondillaNo ratings yet

- Research I Reinforcement Concrete II Prestressed Reinforced ConcreteDocument6 pagesResearch I Reinforcement Concrete II Prestressed Reinforced ConcreteHamez HabibiNo ratings yet

- Module 3Document36 pagesModule 3Lionel LapuzNo ratings yet

- 3-Type of Retaining WallsDocument3 pages3-Type of Retaining Wallsone engNo ratings yet

- Design of Lintel BeamDocument10 pagesDesign of Lintel BeamAnonymous LiddTaTaZTNo ratings yet

- Earth-Retaining StructuresDocument4 pagesEarth-Retaining StructuresJulie BajadoNo ratings yet

- Building Technology 5: (Assignment No. 5)Document4 pagesBuilding Technology 5: (Assignment No. 5)Daryl AguilarNo ratings yet

- Design and Construction of Brick Fin WallsDocument5 pagesDesign and Construction of Brick Fin Wallschoriya007No ratings yet

- Internship ReportDocument17 pagesInternship ReportEBIN JACOB ANISH CE A 16-20No ratings yet

- Retrofit Group StudyDocument30 pagesRetrofit Group StudyDivith B SannakkiNo ratings yet

- Precast Concrete WallsDocument3 pagesPrecast Concrete WallsInzaghi BirdNo ratings yet

- Difference Between PrestressedDocument6 pagesDifference Between Prestressedaceboy_17100% (2)

- Repair and Retrofit of Non-Ductile Reinforced Concrete FramesDocument10 pagesRepair and Retrofit of Non-Ductile Reinforced Concrete FramesmanalNo ratings yet

- Cyclic Behavior of Traditional and Innovative Composite Shear WallsDocument15 pagesCyclic Behavior of Traditional and Innovative Composite Shear WallsSocio JiwapatriaNo ratings yet

- Masonry: A Mason Laying Mortar On Top of A Finished Course of Blocks, Prior To Placing The Next CourseDocument6 pagesMasonry: A Mason Laying Mortar On Top of A Finished Course of Blocks, Prior To Placing The Next CourseFelixNo ratings yet

- Retaining Wall: For Most Readers To Understand. Please HelpDocument7 pagesRetaining Wall: For Most Readers To Understand. Please HelpbaktinusantaraNo ratings yet

- 5 Rammed EarthDocument138 pages5 Rammed EarthSilviu PaduraruNo ratings yet

- Masonry Box Behavior (Marques, R. 2015)Document181 pagesMasonry Box Behavior (Marques, R. 2015)Jose ManuelNo ratings yet

- Strata Control in Underground Tunnels Perspectives For DevelopmentDocument16 pagesStrata Control in Underground Tunnels Perspectives For DevelopmentEko RandiNo ratings yet

- On Pre Stressed ConcreteDocument6 pagesOn Pre Stressed ConcreteArjun Kisan Shende50% (2)

- Elvis and OnitshaDocument21 pagesElvis and OnitshaWilfred NnadiNo ratings yet

- Tech pj1Document26 pagesTech pj1api-266772895No ratings yet

- Introduction To Masonry StructuresDocument33 pagesIntroduction To Masonry StructuresNiraj JhaNo ratings yet

- Earth Retaining Structures-1 PDFDocument27 pagesEarth Retaining Structures-1 PDFSury100% (1)

- Design of Tall Buildings - Prelim. Design & Optim PDFDocument22 pagesDesign of Tall Buildings - Prelim. Design & Optim PDFsekharbrsNo ratings yet

- Seismic Strengthening and Repair of RC Shear Walls PDFDocument8 pagesSeismic Strengthening and Repair of RC Shear Walls PDFSri LathaNo ratings yet

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteMariz Ellaine BaltazarNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Structural ShapesDocument1 pageStructural Shapesaddrien danielNo ratings yet

- A Pell Out The ProvisionsDocument1 pageA Pell Out The Provisionsaddrien danielNo ratings yet

- Struction Documents Must Clearly Spell Out The ProvisionsDocument1 pageStruction Documents Must Clearly Spell Out The Provisionsaddrien danielNo ratings yet

- SegmentingDocument2 pagesSegmentingaddrien danielNo ratings yet

- Heat CurvingDocument2 pagesHeat Curvingaddrien danielNo ratings yet

- CurvedDocument1 pageCurvedaddrien danielNo ratings yet

- Structural Design Guidelines For Aluminum Framed SkylightsDocument1 pageStructural Design Guidelines For Aluminum Framed Skylightsaddrien danielNo ratings yet

- Serviceability Considerations: "X" Indicates Location ofDocument2 pagesServiceability Considerations: "X" Indicates Location ofaddrien danielNo ratings yet

- Diaphragm Design Manual (Steel Deck Institute, 1987) : 4.2 Metal RoofsDocument1 pageDiaphragm Design Manual (Steel Deck Institute, 1987) : 4.2 Metal Roofsaddrien danielNo ratings yet

- Serviceability Design Considerations For Steel Buildings: 3.1 Slab-on-Grade DesignDocument1 pageServiceability Design Considerations For Steel Buildings: 3.1 Slab-on-Grade Designaddrien danielNo ratings yet

- 1.4 Basic Vibration Terminology: Acceleration Ratio. For The Purposes of This Design GuideDocument1 page1.4 Basic Vibration Terminology: Acceleration Ratio. For The Purposes of This Design Guideaddrien danielNo ratings yet

- W EXX EXXDocument1 pageW EXX EXXaddrien danielNo ratings yet

- CompTIA A+ Lesson 4 - Motherboard PIN Outs, Jumpers, External Ports, ConnectorsDocument9 pagesCompTIA A+ Lesson 4 - Motherboard PIN Outs, Jumpers, External Ports, ConnectorsAli Ghalehban - علی قلعه بانNo ratings yet

- Encapsulation - QuestionsDocument3 pagesEncapsulation - Questionsanand.pasunooriNo ratings yet

- Tomar TD43Document3 pagesTomar TD43Felipe HallNo ratings yet

- Data Sheet ProductDocument1 pageData Sheet ProductricardobarrocaNo ratings yet

- Flowserve ECPJ PDFDocument42 pagesFlowserve ECPJ PDFAnie Ekpenyong100% (1)

- A3 UV DTF 2H xp600 Manual BookDocument37 pagesA3 UV DTF 2H xp600 Manual BookERIC ORWANo ratings yet

- P 14Document1 pageP 14Francis V. McCannNo ratings yet

- Ethyl Alcohol, 70%, in Water: Safety Data SheetDocument6 pagesEthyl Alcohol, 70%, in Water: Safety Data SheetAmalia Desy SaputriNo ratings yet

- ST44 Metal Roof Battens Steel - Product Brochure 44Document2 pagesST44 Metal Roof Battens Steel - Product Brochure 44frogknotNo ratings yet

- QAD Procedure - Control of Inspection, Measuring & Test Equipment P2Document1 pageQAD Procedure - Control of Inspection, Measuring & Test Equipment P2sumanNo ratings yet

- LNG Plant1Document32 pagesLNG Plant1Shadi ZuraikatNo ratings yet

- Internal Reference Name CategoryDocument247 pagesInternal Reference Name CategoryM Ramiaji AnggoroNo ratings yet

- Vx86: x86 Assembler Simulated in C Powered by Automated Theorem ProvingDocument15 pagesVx86: x86 Assembler Simulated in C Powered by Automated Theorem ProvingTanzeel ShakeelNo ratings yet

- ANNEXURES Common SR Water SupplyDocument81 pagesANNEXURES Common SR Water SupplyShashikiran MavinatopuNo ratings yet

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFArdian20No ratings yet

- Magento TutorialDocument154 pagesMagento Tutorialbangke7100% (1)

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- Saet 7Document5 pagesSaet 7naefmubarakNo ratings yet

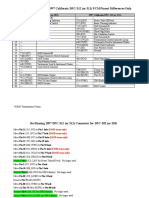

- 1996 Vs 1997 Cali PCM Pinout Differences OnlyDocument2 pages1996 Vs 1997 Cali PCM Pinout Differences OnlyWilliam PeeleNo ratings yet

- Science 6 Q1 Week8 Day 1.pptx (Repaired)Document37 pagesScience 6 Q1 Week8 Day 1.pptx (Repaired)Dianne DiazNo ratings yet

- ConsolidationDocument14 pagesConsolidationSapria AdiNo ratings yet

- PBL DocumentDocument14 pagesPBL DocumentSriniNo ratings yet

- Orphee Mythic 22-AL Hematology Analyzer - User Manual PDFDocument109 pagesOrphee Mythic 22-AL Hematology Analyzer - User Manual PDFPhan Quan100% (1)

- Solid 187Document9 pagesSolid 187niteen_mulmule485No ratings yet

- 鋼管接頭EO Fittings1Document64 pages鋼管接頭EO Fittings1a0960539335No ratings yet