Professional Documents

Culture Documents

Feasibility Study of A Heavy-Duty Tractor - Motorized Semi-Trailer Hybrid Electric Combination

Feasibility Study of A Heavy-Duty Tractor - Motorized Semi-Trailer Hybrid Electric Combination

Uploaded by

Not NowCopyright:

Available Formats

You might also like

- Price List Parts MITSUBISHI FUSO SEPTEMBER 2018Document660 pagesPrice List Parts MITSUBISHI FUSO SEPTEMBER 2018Andreas Hendramartani100% (10)

- Innovation Landscape brief: Electric-vehicle smart chargingFrom EverandInnovation Landscape brief: Electric-vehicle smart chargingNo ratings yet

- A320 LimitationsDocument1 pageA320 Limitationssimcity3000No ratings yet

- Spoke Wheel Building & TruingDocument5 pagesSpoke Wheel Building & TruingmrmrvaNo ratings yet

- Alert Indicators: Operation and Maintenance ManualDocument6 pagesAlert Indicators: Operation and Maintenance ManualSanath Jayanetti100% (5)

- Joint Routing of Conventional and Range-Extended Electric Vehicles in A Large Metropolitan NetworkDocument28 pagesJoint Routing of Conventional and Range-Extended Electric Vehicles in A Large Metropolitan NetworkArtem Sergeevich AkopyanNo ratings yet

- Assessment of Battery-Hybrid Diesel-Electric Locomotive Fuel SavingsDocument18 pagesAssessment of Battery-Hybrid Diesel-Electric Locomotive Fuel SavingsZahra AfrazNo ratings yet

- Loader Power-Split Transmission System Based On A Planetary Gear SetDocument8 pagesLoader Power-Split Transmission System Based On A Planetary Gear SetsughieantoNo ratings yet

- Agriculture 12 00436 v2Document22 pagesAgriculture 12 00436 v2Adrian MarinNo ratings yet

- s12302-020-00307-8Document17 pagess12302-020-00307-8Chiara GastaldiNo ratings yet

- Modelling and Analysis of Plug-In Series-Parallel Hybrid Medium-Duty VehiclesDocument10 pagesModelling and Analysis of Plug-In Series-Parallel Hybrid Medium-Duty VehiclesEduardo Garcia VázquezNo ratings yet

- Banerjee 2018Document14 pagesBanerjee 2018Prasad JoshiNo ratings yet

- Energy: Yanbiao Feng, Zuomin DongDocument14 pagesEnergy: Yanbiao Feng, Zuomin DongdinkuinkuNo ratings yet

- A Study of Energy Requirements For Electric and HyDocument9 pagesA Study of Energy Requirements For Electric and HyAntoine LemaireNo ratings yet

- Machines: Optimized Energy Management Control of A Hybrid Electric LocomotiveDocument16 pagesMachines: Optimized Energy Management Control of A Hybrid Electric LocomotivebartolomeuzNo ratings yet

- Neural Network Surrogate Models For Aerodynamic Analysis in Truck Platoons Implications On Autonomous Freight DeliveryDocument10 pagesNeural Network Surrogate Models For Aerodynamic Analysis in Truck Platoons Implications On Autonomous Freight DeliveryrublasterNo ratings yet

- A Recent Review of Hybrid Automotive Systems in Gulf Corporation Council RegionDocument65 pagesA Recent Review of Hybrid Automotive Systems in Gulf Corporation Council RegionSanjay SanjayNo ratings yet

- Eevc 2014Document12 pagesEevc 2014ThejaswiniNo ratings yet

- Journal of Power Sources: Emiliano Pipitone, Gianpaolo VitaleDocument10 pagesJournal of Power Sources: Emiliano Pipitone, Gianpaolo VitaleBT20MEC120 Jyoti ThakurNo ratings yet

- Multi-Speed Gearboxes For Battery Electric Vehicles Current Status and Future TrendsDocument17 pagesMulti-Speed Gearboxes For Battery Electric Vehicles Current Status and Future TrendsSamial HasnatNo ratings yet

- AusRAILPLUS 2019 - Spiryagin - WuDocument12 pagesAusRAILPLUS 2019 - Spiryagin - Wumuj_aliNo ratings yet

- Applied Energy: Chiara Fiori, Kyoungho Ahn, Hesham A. RakhaDocument12 pagesApplied Energy: Chiara Fiori, Kyoungho Ahn, Hesham A. RakhaJosé GonzálezNo ratings yet

- Control Strategy of A Fuel-Cell Power Module For Electric ForkliftDocument11 pagesControl Strategy of A Fuel-Cell Power Module For Electric Forkliftcan kaplanNo ratings yet

- Design of B-S SystemDocument6 pagesDesign of B-S SystemRadoy CristyNo ratings yet

- Retpr 2015 2 (2) 29 36Document8 pagesRetpr 2015 2 (2) 29 36zeyad alsaroriNo ratings yet

- Combined Optimisation of Design and Power Management of The Hydraulic Hybrid Propulsion System For The 6Document31 pagesCombined Optimisation of Design and Power Management of The Hydraulic Hybrid Propulsion System For The 6AlfinThariqNo ratings yet

- Energies 15 07243 v3Document26 pagesEnergies 15 07243 v3Tran DanteNo ratings yet

- Efficiency Enhancement of A New Two-Motor Hybrid SystemDocument11 pagesEfficiency Enhancement of A New Two-Motor Hybrid SystemAnchal SaxenaNo ratings yet

- Energy Management Strategy For Plug-In H PDFDocument9 pagesEnergy Management Strategy For Plug-In H PDFruxandaNo ratings yet

- 4 A Comparison of Vehicle Simulation Software and Dynamometer Results For Battery Electric VehiclesDocument6 pages4 A Comparison of Vehicle Simulation Software and Dynamometer Results For Battery Electric Vehiclesbirdview champlainNo ratings yet

- Design Modeling and Hardware Implementation of Regenerative Braking For Electric Two-Wheelers For Hilly RoadsDocument17 pagesDesign Modeling and Hardware Implementation of Regenerative Braking For Electric Two-Wheelers For Hilly RoadsH.BheemeshwaraNo ratings yet

- Dual-Function Wheel Drives Using Rotary-Linear Actuators in Electric and Hybrid VehiclesDocument6 pagesDual-Function Wheel Drives Using Rotary-Linear Actuators in Electric and Hybrid VehiclesAndres MoranNo ratings yet

- Hitachi ReviewDocument5 pagesHitachi Reviewbobcat3304No ratings yet

- 2020 Ditrolio ''A Hybrid Power-Unit Based On A Passive Fuel Cellbattery System For Light Weight Vehicles''Document11 pages2020 Ditrolio ''A Hybrid Power-Unit Based On A Passive Fuel Cellbattery System For Light Weight Vehicles''Abdul RehmanNo ratings yet

- 1 s2.0 S221313881930548X MainDocument7 pages1 s2.0 S221313881930548X MainNurrahma Salsabila HadimaNo ratings yet

- Electric Vehicles: - The Challenges Facing The Widespread Adoption of Electric CarsDocument3 pagesElectric Vehicles: - The Challenges Facing The Widespread Adoption of Electric CarsDenny YenNo ratings yet

- Ijsrp p9415Document6 pagesIjsrp p9415adharshaj2255No ratings yet

- Design and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanDocument8 pagesDesign and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanPrafulla DandgeNo ratings yet

- Potential of Hybrid Powertrains in A Variable Compression Ratio Downsized Turbocharged VVA Spark Ignition EngineDocument19 pagesPotential of Hybrid Powertrains in A Variable Compression Ratio Downsized Turbocharged VVA Spark Ignition EngineCostin DanielNo ratings yet

- Brazilian Hybrid Electric-Hydrogen Fuel Cell Bus: Improved On-Board Energy Management SystemDocument11 pagesBrazilian Hybrid Electric-Hydrogen Fuel Cell Bus: Improved On-Board Energy Management SystemMiguelGuavitaRojasNo ratings yet

- Nonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesDocument6 pagesNonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesasadjadiNo ratings yet

- Paper 3Document23 pagesPaper 3Swati NikamNo ratings yet

- Traction Electrification of Heavy Off-Road Vehicle: Case Study of Backhoe Loader Operating in BackfillDocument8 pagesTraction Electrification of Heavy Off-Road Vehicle: Case Study of Backhoe Loader Operating in BackfillPedro Andrade de OliveiraNo ratings yet

- Energies 15 03348 v2Document19 pagesEnergies 15 03348 v2Rkd PadsNo ratings yet

- Bartlomiejczyk 2019 Driving Performance Indicators of eDocument10 pagesBartlomiejczyk 2019 Driving Performance Indicators of eLiangbin cuiNo ratings yet

- Bartolo ZZ I 2013Document9 pagesBartolo ZZ I 2013Fernanda MoreiraNo ratings yet

- Jjmie: A Study of Fuel Cell Hybrid Auto Rickshaws Using Realistic Urban Drive CyclesDocument6 pagesJjmie: A Study of Fuel Cell Hybrid Auto Rickshaws Using Realistic Urban Drive CyclesJosé GonzálezNo ratings yet

- Fuel Cell Electric Vehicle Characterisation Under Laboratory and in Use OperationDocument13 pagesFuel Cell Electric Vehicle Characterisation Under Laboratory and in Use OperationalexandmagaraNo ratings yet

- Energies: Electrification of A Heavy-Duty CI Truck-Comparison of Electric Turbocharger and Crank Shaft MotorDocument21 pagesEnergies: Electrification of A Heavy-Duty CI Truck-Comparison of Electric Turbocharger and Crank Shaft Motorhektor AtkinsonNo ratings yet

- Modeling and Simulation of Plug-In Hybrid Electric Powertrain System For Different Vehicular ApplicationDocument7 pagesModeling and Simulation of Plug-In Hybrid Electric Powertrain System For Different Vehicular ApplicationYoussef OubelaidNo ratings yet

- Comparison of Power Consumption Efficiency of CVT and Multi-Speed Transmissions For Electric VehicleDocument8 pagesComparison of Power Consumption Efficiency of CVT and Multi-Speed Transmissions For Electric VehicleNguyen Ke DucNo ratings yet

- Converging Technologies For Electric Hybrid Vehicles and More Electric Aircraft SystemsDocument12 pagesConverging Technologies For Electric Hybrid Vehicles and More Electric Aircraft SystemsO GoogleNo ratings yet

- Energy Policy: Sarah G. Nurre, Russell Bent, Feng Pan, Thomas C. SharkeyDocument14 pagesEnergy Policy: Sarah G. Nurre, Russell Bent, Feng Pan, Thomas C. SharkeySumit RathorNo ratings yet

- Multi Speed Transmission For ElectDocument4 pagesMulti Speed Transmission For ElectHamza TAKTINo ratings yet

- BeltconveyorwileyDocument12 pagesBeltconveyorwileySimone MastrogiacomoNo ratings yet

- Static and DynamicDocument8 pagesStatic and Dynamicchenxi.cugNo ratings yet

- Coches de CarrerasDocument8 pagesCoches de CarrerasJesús GarcíaNo ratings yet

- Evaluation of Electric Vehicle Component Performance Over Eco-Driving CyclesDocument17 pagesEvaluation of Electric Vehicle Component Performance Over Eco-Driving CyclesPawan DhakalNo ratings yet

- Hybrid Electric Vehicles and Regenerative BrakingDocument7 pagesHybrid Electric Vehicles and Regenerative BrakinggadrumNo ratings yet

- Energies 17 01484Document22 pagesEnergies 17 01484Maher AzzouzNo ratings yet

- Design of A Hybrid Electric Motorcycle For OptimumDocument9 pagesDesign of A Hybrid Electric Motorcycle For OptimumAryan AmeenNo ratings yet

- EV Walker ComparationDocument8 pagesEV Walker Comparationmihai_1957No ratings yet

- Autonomous Hybrid Tractor Unit With A Predictive Control SystemDocument8 pagesAutonomous Hybrid Tractor Unit With A Predictive Control SystemTJPRC PublicationsNo ratings yet

- Trancossi2016 Article WhatPriceOfSpeedACriticalRevisDocument24 pagesTrancossi2016 Article WhatPriceOfSpeedACriticalRevisTrancossi MicheleNo ratings yet

- Police Log September 18, 2016Document11 pagesPolice Log September 18, 2016MansfieldMAPoliceNo ratings yet

- Repair Manual: MZ Riders ClubDocument105 pagesRepair Manual: MZ Riders ClubDaniel PopescuNo ratings yet

- With New Hi-Line Versions: Traditionally InnovativeDocument16 pagesWith New Hi-Line Versions: Traditionally InnovativemiminiweweNo ratings yet

- Ae MCQDocument12 pagesAe MCQYuvraaj Singh100% (3)

- 58X Crank Shaft: Vehicle Connector, Key 8Document1 page58X Crank Shaft: Vehicle Connector, Key 8Andrei BaluseNo ratings yet

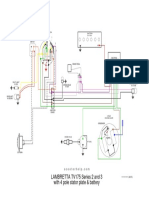

- Diagrama Electrico Lambretta 175 Serie 2 BDocument1 pageDiagrama Electrico Lambretta 175 Serie 2 BCamiloNo ratings yet

- A Holistic Approach To The Tank DevelopmentDocument11 pagesA Holistic Approach To The Tank Developmentcjnjr1No ratings yet

- PC210-8M0 Tunnel SpascdsdscecDocument2 pagesPC210-8M0 Tunnel Spascdsdscecgaurav champawatNo ratings yet

- Mitsubishi Parts V4a51 Manual de UsuarioDocument6 pagesMitsubishi Parts V4a51 Manual de Usuariocarlos andres velez calleNo ratings yet

- 807 Timetable WebDocument11 pages807 Timetable WebHoang NguyenNo ratings yet

- Truck Driver Resume Sample MSWord DownloadDocument2 pagesTruck Driver Resume Sample MSWord DownloadnadiaNo ratings yet

- Engineering Inspiration - Brake System Design CalculationsDocument17 pagesEngineering Inspiration - Brake System Design CalculationsManjeet SinghNo ratings yet

- Owner S Manual: Hybrid BicycleDocument141 pagesOwner S Manual: Hybrid BicycleKaiser ShaikhNo ratings yet

- Zovik Spare Price ListDocument92 pagesZovik Spare Price ListBhagwan ShresthaNo ratings yet

- Er650 Fefw Lams Parts List PDFDocument105 pagesEr650 Fefw Lams Parts List PDFOliverNo ratings yet

- Manual de Taller Volkswagen Bora 2007 PDFDocument3 pagesManual de Taller Volkswagen Bora 2007 PDFPanXo Gutierrez Chavez0% (2)

- Fuller Heavy Duty Transmissions TRDR0500: Driver InstructionsDocument20 pagesFuller Heavy Duty Transmissions TRDR0500: Driver InstructionsBart JohnNo ratings yet

- Demag DF 115p Wheel PaverDocument174 pagesDemag DF 115p Wheel PaverHữu Dũng Nguyễn86% (7)

- Toyota Business StrategyDocument10 pagesToyota Business StrategyzurriyashaNo ratings yet

- February 2017Document16 pagesFebruary 2017Pumper TraderNo ratings yet

- JCB 205 NXT Export Brochure en-GB LRDocument20 pagesJCB 205 NXT Export Brochure en-GB LRm. rahmat hidayatNo ratings yet

- About TellusDocument54 pagesAbout Tellusabeldiaz7No ratings yet

- Generators Portable Supersilent DCA40SSI Rev 0 Final ManualDocument140 pagesGenerators Portable Supersilent DCA40SSI Rev 0 Final ManualЕвгений Иванов100% (1)

- Decoder New 2013Document13 pagesDecoder New 2013viraj patelNo ratings yet

- MAN TGX TgaDocument9 pagesMAN TGX TgaKosoe ShweNo ratings yet

- 1.0 INTRODUCTIONS Electronic Fuel Injection (EFI)Document28 pages1.0 INTRODUCTIONS Electronic Fuel Injection (EFI)Sravan GundamNo ratings yet

Feasibility Study of A Heavy-Duty Tractor - Motorized Semi-Trailer Hybrid Electric Combination

Feasibility Study of A Heavy-Duty Tractor - Motorized Semi-Trailer Hybrid Electric Combination

Uploaded by

Not NowOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Feasibility Study of A Heavy-Duty Tractor - Motorized Semi-Trailer Hybrid Electric Combination

Feasibility Study of A Heavy-Duty Tractor - Motorized Semi-Trailer Hybrid Electric Combination

Uploaded by

Not NowCopyright:

Available Formats

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Feasibility Study of a Heavy-duty Tractor - 2010-01-1932

Motorized Semi-trailer Hybrid Electric Published

10/05/2010

Combination

Marius-Dorin Surcel and Jan Michaelsen

FPInnovations

Copyright © 2010 SAE International

ABSTRACT The analysis of traction performances showed evident gains

both in tractive force and gradeability for the motorized semi-

The objective of this study was to evaluate the concept of a

trailer. Moreover, the use of motorized axles on the semi-trailer

heavy-duty tractor - motorized semi-trailer hybrid electric

would improve the longitudinal stability of the vehicle

combination, which would have electric drive axles on the

combination by decreasing the potential for sliding, especially

semi-trailer.

in off-highway conditions.

The scope of the project included an analysis of the general

The evaluation of the impact on greenhouse gas emissions

concept of a power-driven semi-trailer, the positioning of the

shows that the electric motorized semi-trailer concept would

concept of the heavy-duty tractor - motorized semi-trailer

offer important annual reductions for all the analyzed transport

hybrid electric combination in the general context of the

activities, with generally attractive payback periods.

technology, and the evaluation of the applicability of the

Exemplifying for the off-highway hauling of raw materials

concept for different duty cycles.

using off-highway vehicles, GHG emissions reduction would

be up to 108 tons/year per vehicle combination, with a payback

Several transport activities were analyzed to determine specific

period as low as 18 months, which is explained by very

duty cycles for heavy-duty vehicles: highway line haul and

important quantitative fuel savings coupled with a relatively

regional haul, construction haul, and off-highway hauling of

moderate increase in vehicle purchase costs. However, for

raw materials, such as forestry transport with Class 8 and

highway and regional haul, the relative increase of the semi-

off-highway tractor-trailer combinations.

trailer cost by a factor of three would make the concept

unattractive.

The concept of a heavy-duty tractor - motorized semi-trailer

hybrid electric combination was compared with a corresponding

The concept of a heavy-duty tractor - motorized semi-trailer

conventional combination (conventional tractor and semi-trailer),

hybrid electric combination would offer the best dynamic,

and with a combination of a parallel hybrid electric tractor with a

environmental, and economical advantages when implemented

conventional semi-trailer. PSAT simulations were conducted to

for off-highway transport of raw materials, such as forestry or

evaluate the fuel efficiency and the influence on traction and

mining transport, for which the relative cost increases are

stability was evaluated for each representative duty-cycle.

acceptable and payback periods are relatively short.

The simulation results generally predict comparable fuel

efficiencies for the heavy-duty tractor - motorized semi-trailer INTRODUCTION

hybrid electric combination, and the correspondent parallel Hybrid vehicle technology is already a reality for urban

hybrid electric tractor with conventional semi-trailer applications where stop-and-go driving cycles offer many

combination. Depending on the duty-cycle, both hybrid versions opportunities to recover and recycle braking energy, such as

would offer substantial fuel savings when compared to the delivery, waste management and public transportation, for

conventional tractor-semi-trailer combination, such as up to which minimum fuel savings of 15% have been proven. Hybrid

30% for off-highway hauling of raw materials. vehicle technology is gradually finding specific applications in

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 69

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

the heavy-duty vehicle market, with several manufacturer The project included the following stages: determining specific

already offering Class 8 hybrid vehicles. duty cycles for different types of heavy-duty hauling,

evaluation of dynamic demands for each cycle, analyzing the

Regenerative braking and hybrid technology could be concept of a heavy-duty tractor - motorized semi-trailer hybrid

interesting for forestry and mining applications, which are electric combination, assessing the fuel efficiency and dynamic

characterized by difficult terrain and climatic conditions. performances of the concept, and evaluating the commercial

Operating a hybrid forestry truck would make it possible potential of the concept.

to recover braking energy when the vehicle travels on forest

roads. The vehicle would use this energy during non-working

time (for powering the loader, when waiting, for other

SPECIFIC DUTY CYCLES FOR

idling, or for powering other auxiliary systems and devices), HEAVY-DUTY VEHICLES

and during times when power needs are higher, by assisting Several transport activities were analyzed to determine specific

the engine. The forestry truck can be equipped with a duty cycles for heavy-duty vehicles: highway line haul and

smaller, more economical engine and will use significantly regional haul, construction haul, and off-highway hauling

less fuel. of raw materials, such as forestry transport with Class 8 and

off-highway tractor-trailer combinations.

Power-driven trailers have been tested and used in the last one

hundred years for surmounting traction issues in low adherence

conditions, such as those encountered in mining, forestry,

ON-HIGHWAY HAULING

agriculture or military applications. These power-driven Two types of operations were considered: highway line haul

trailers used or are using mechanical, hydraulic or electrical and regional haul.

traction systems.

Highway line haul operations are characterized by high

The concept of a heavy-duty tractor - motorized semi-trailer average speeds, long trips, more constant engine operation,

hybrid electric combination would have electric drive axles and overnight rest stops, which sometimes involve long idling.

on the semi-trailer [1]. The scope of this project was to analyze The typical combination is a Class 8 three-axle tractor with a

the concept of a power-driven semitrailer and to evaluate the two-axle semi-trailer, with a tare weight of 15,000 kg or more.

applicability of the concept for different transport sectors. The semi-trailer could be a dry van-box, a reefer-van, a tanker,

a flat bed, a curtain trailer, a trans-container, or other [2].

A literature research was conducted to analyse the history of Several vehicles have been monitored and a representative trip

the technology, the technical solutions and present applications, was chosen. The corresponding duty cycle was determined by

the advantages and disadvantages of the system, as well as the simulation, using Otto 2000 software, which simulates the

foreseen evolution. Despite the extensive research, not many performance of haul vehicles and estimates fuel consumption,

actual application of the power-driven trailer concept were average travel speeds and trip times. Performance modeling

found. The mechanical traction systems, consisting of a for haul operations is based on mathematical models and the

combustion engine and a transmission installed on the trailer or development of equations for the three factors that control

on the dolly, are the most common, this technology being well performance: the vehicle, the driving technique and the road

developed and known within the mining industry, particularly [3]. The duty cycle is shown in Figure 1. The vehicles models

in Australia. The hydrostatic systems are mainly used for correspond to the tractor and two-axle or four-axle semi-

military and forestry applications, designed for difficult terrain trailers presented in Table 1.

conditions but with limited loading capacity. Their main

disadvantage is the low travel speed range, limiting their

usefulness to applications that do not required high velocity,

such as off-road forestry or agricultural machineries. The

hydrostatic-mechanical systems, which use a combustion

engine and a hydraulic motor, suffer from energy losses in both

hydraulic and mechanical systems. The electric traction systems

presents infinitely variable transmissions, high reliability and

very effective braking capabilities. The disadvantages are

related to the larger space and tare weight requirements, and to

the accessibility to the electric energy (such as the limited

autonomy of battery systems). There are several examples of

electric traction systems for trailers and semi-trailers but, as far

as we know, they have not gotten past the patent or prototype

phases.

Figure 1. Duty cycle for highway line haul.

70 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

The regional haul is similar to highway line haul, but the trip

lengths are shorter, the haul includes some suburban-type

operation, and has none, or fewer, overnight stays. The average

speeds are lower, and they are relatively more frequent traffic

congestion situations. Two representative vehicles were

followed in operation for three months. The vehicles were

equipped with onboard computers and GPS systems. Based on

the analysis of these trips, a representative route was built

using the GPS profiles. The corresponding duty cycle was

determined by simulation, using the Otto 2000 software

(Figure 2), and the vehicles models also correspond to the

tractor and two-axle or four-axle semi-trailers presented in

Table 1.

Figure 2. Duty cycle for regional haul.

Table 1. Vehicles type specifications for highway line haul and regional haul

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 71

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

CONSTRUCTION HAULING OFF-HIGHWAY HAULING OF RAW

A study conducted with four categories of dump trucks is MATERIALS

presented in [4]. Twelve different vehicles had been The off-highway hauling of raw materials, such as forestry

instrumented and monitored during work shifts composed by 4 transport, includes transport with Class 8 tractor -trailers as

to 5 duty cycles each. A representative duty cycle, with duration well as with off-highway tractor-trailer combinations. A large

of 1.2 hours, is composed of loading at the charging point, amount of operational data for logging transport was analyzed

delivering the load to destination, dumping, and returning to to determine representative trips and routes.

the charging point. The duty cycle is a combination of nine

operation modes defined by a function dependent on travel An example of a representative logging operation with Class

speed (V, km/h), acceleration (a, m/s2) and engine power 8 vehicles is a trip with a length of 158 km, from which 115 km

demand (Dp, kW/kg). Engine power demand is given by the is on gravel forestry roads, and a total duration of 2 h 25 min.

equation: The corresponding duty cycles is presented in Figure 5,

obtained through simulation using a vehicle model as detailed

in Table 4.

(1)

An example of a representative logging operation with off-

Figure 3 shows the structure of a representative cycle and highway tractor-trailer combinations is a trip with length of

Table 2 presents the definitions of operation modes. It can be 110 km on gravel forestry roads, and a total duration of 2 h 18

observed that idling is a significant part of the cycle, more than min. The corresponding duty cycle is presented in Figure 6,

half of the distance was covered in cruise mode, and obtained through simulation using the vehicle model detailed

deceleration mode represents almost 15% of the total distance. in Table 4.

The duration of the round trip cycle is approximately 28 min.

Vehicle specification is presented in Table 3.

DYNAMIC DEMANDS

The analysis of the database allowed us to choose a route Kinetic energy variation (ΔEc, in kW) between two moments

on which the representative vehicle model could perform (t0 and tf) can be calculated as a function of speed (V0 and Vf)

a duty cycle with a structure similar to those presented in and of vehicle mass (Mv), with the following equation (adapted

Figure 3. The duty cycle, obtained by simulation, is shown in from [5]):

Figure 4. The cycle corresponds to a round trip (going loaded

and back empty) on an 11 km length route, with total duration

of 29 min.

(2)

Table 2. Operation modes for dump duty cycle (adapted from [4])

72 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Table 3. Vehicle type specification for construction haul

Figure 3. Construction haul duty cycle structure

Figure 4. Duty cycle for construction haul.

(adapted from [4]).

Equation (3) gives the power dissipated by this variation: The operation modes can be defined based on kinetic energy

variation and fuel consumption (Cc), as shown in Table 5.

The structure of the analyzed duty cycles is presented in

Figure 7. Kinetic energy variation and fuel consumption were

(3) calculated using dynamic simulation.

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 73

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Figure 5. Duty cycle for off-highway hauling of raw Figure 6. Duty cycle for off-highway hauling of raw

materials with a class 8 tractor-trailer. materials with off-highway tractor-trailer.

Table 4. Vehicles type specifications for off-highway hauling of raw materials

74 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Table 5. Operation modes The system would improve the braking performances of the

vehicle combination and would increase the climbing ability.

When needed, the electric powered axles of the trailer would

assist the tractor’s power train. The trailer would be equipped

with means for controlling the power, speed and acceleration

and grade sensors would be used for automatically activate the

electric driven axles, either in acceleration or in deceleration

modes. A manual control would also be provided. The batteries,

installed on the trailer or on the tractor, would be recharged by

using a regenerative braking system or other sources of energy,

such as tractor’s engine or a fuel cell.

Several configurations are possible. Figure 8 presents the

version with the electric motor installed on the semitrailer’s

axle that it drives, whose motor is controlled by an electronic

control module that communicates with the vehicle’s electronic

control module. In another variant, the electric motor is always

installed on the semitrailer, but external to the axles: the axles

are driven through a drive shaft and a differential. Another

version uses wheel electric motors.

Two main architectures are possible for the hybrid electric

systems: series and parallel. In the case of the series systems,

the primary power source, which is a combustion engine, does

not power the drive train directly; it propels the vehicle through

the secondary power source, which is the electric motor.

For the parallel hybrids, the engine or the electric motor can

propel the vehicle independently, or in combination.

The heavy-duty tractor and motorized semi-trailer hybrid electric

combination corresponds to the parallel-split architecture, in

Figure 7. Duty cycles structure for the analyzed which the engine drives one or more axles (on the tractor), while

transport activities. the electric motor drives other axles (on the semi-trailer, in the

case of this concept). Contrary to the classic parallel system, the

parallel-split version does not require any integration with

The cycles that would offer a more efficient usage of

tractor’s power train and allows the use of wheel motors. On the

regenerative braking and hybrid system would be those with

other hand, the control system would be more complicated,

lesser cruise time and more engine braking and deceleration

because it must assure the synergy between tractor’s power train

(Figure 7), as well as those showing more substantial kinetic

and semi-trailer’s power train. The parallel-split architecture

energy losses and dissipated power (Table 6). Based on these

would offer the advantage of supplementary traction, but it would

criterions, it can be preliminarily concluded that most

complicate the regenerative braking, the charging of the batteries,

appropriate cycles would be those corresponding to the

and the control of propelling and braking, because in some cases

off-highway hauling of raw materials.

the semi-trailer axles could work in regenerative braking mode,

while the tractor’s drive axles could work in propelling mode [6].

HYBRID ELECTRIC SEMI-TRAILER

CONCEPT DEGREE OF HYBRIDIZATION

The analysis of the concept considered the architecture of the Hybrid systems are also frequently classified as mild hybrids

system, the degree of hybridization, and the secondary source and full hybrids according to the degree of hybridization,

of energy. based on the ratio between the energy supplied by the primary

source (combustion engine) and the energy supplied by the

SYSTEM ARCHITECTURE secondary source (electric motor). The mild hybrids are not

intended to operate in pure electric mode: the electric motor

In the heavy-duty tractor - motorized semi-trailer hybrid

assists the engine for starting and launching the vehicle, or

electric combination concept, besides the main power coming

accelerating it, or for powering some auxiliary systems. In the

from the combustion engine, the wheels of one or more trailer

case of full hybrids, additionally to the functionalities of mild

axles are powered by electric motors [1].

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 75

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Table 6. Dynamic demands for the analyzed duty cycles

hybrids, the electric motor is capable of propelling the vehicle usually equipped with downsized engines compared to the

alone in certain conditions, such as starting and launching [7]. corresponding conventional vehicles.

In the case of the heavy-duty tractor and motorized semi-trailer

hybrid electric combination, the semi-trailer’s motorized axles

would never be capable of the propelling the combination

SECONDARY ENERGY SOURCE

by themselves, therefore this concept would be consider as a The electric energy can be stored using batteries, ultra-

mild hybrid. It should be mentioned that hybrid versions are capacitors or fuel cells. Batteries are still the most common

76 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Figure 8. Heavy-duty tractor - motorized semi-trailer hybrid electric combination with the electric motor on semi-trailer axle

electric storage system, and the majority of commercial hybrid the vehicle and its components. Besides the component

vehicles from class 4 to 8 use Nickel-Metal-Hydride (NiMH) models available in PSAT libraries, specific model files and

or Lithium-Ion (Li-Ion) batteries. NiMH batteries are used, initialization files were created for specific components, such

among others, for the Allison hybrid power trains (330 V as engines, transmissions, differentials, tires, as well as for the

Panasonic) and the Hino 714 medium-duty trucks (274 VDC complete vehicles. The model for the heavy-duty tractor and

- 6.5Ah Panasonic). Presently, Li-Ion batteries are the most motorized semi-trailer hybrid electric combination were

used batteries for hybrid electric vehicles. The class 8 Mercedes compared with the models of the corresponding conventional

Benz Axor uses an 8 kWh water-cooled block of Li-Ion combination (conventional tractor and semi-trailer), and with

batteries, and Eaton’s hybrid electric systems, which equip the model of the most common combination of a parallel

Peterbilt and Kenworth vehicles, also use Li-Ion batteries, hybrid electric tractor with a conventional semi-trailer, which

such as the 340 VDC 7.2 Ah Shin-Kobe. The batteries has the electric motor integrated in the tractor’s power train.

envisaged for the heavy-duty tractor and motorized semi-

trailer hybrid electric combination would be Li-Ion batteries We saw that the heavy-duty tractor and motorized semi-trailer

with 340 to 360 VDC voltage rating and approximately 14Ah hybrid electric concept corresponds to the parallel-split

capacity. architecture. The PSAT vehicle model that would represent

this configuration would be for a parallel hybrid vehicle with

Electric motors supply their maximum torque at low speeds, four drive axles, where the tractor’s power train propels two of

and therefore they offer very good traction performances. The the axles and the other axles are powered by electric motor(s).

peak efficiency of electric motors is 93 - 95 % for permanent The generic model is shown in Figure 9.

magnet motors and 92 - 93 % for induction motors, but it

decreases to 80 - 85 % at low speeds and loads. Besides their The duty cycles presented in figures 1, 2, 4, 5 and 6

higher efficiency, the permanent magnet motors are more were imported into the PSAT software. For calibration and

compact, whilst they are more expensive than the induction evaluation purposes, the results of PSAT simulations conducted

motors [8]. for each duty cycle with conventional vehicles models

were compared with the results of the corresponding Otto

simulations, because Otto software had been previously

FUEL EFFICIENCY EVALUATION validated for conventional vehicles through a multitude of test,

The scope of the simulation is to verify if the chosen and therefore its results are proven to be very reliable. The

components are functioning correctly within the vehicle comparisons between Otto and PSAT simulation for each duty

model, and if the hybrid version fulfills the objectives of the cycle showed a very good similarity of the results, with an

project, such as offering a better fuel efficiency without average accuracy of 0.5 % and average precision of 3%.

sacrificing other performances.

Figure 10 illustrates the comparison between the speed graph

PSAT (« Powertrain Systems Analysis Toolkit ») is a simulation given by the duty cycle (input) and the speed graph obtained

software developed by Argonne National Laboratory, which through PSAT simulation (output), for the construction haul

allows conducting dynamic analysis of vehicle performance duty cycle. It can be observed that the PSAT model for

and energy efficiency, to assist in developing and validating conventional vehicle followed the duty cycle very well, which

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 77

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Figure 9. PSAT model of the heavy-duty tractor - motorized semi-trailer hybrid electric combination.

demonstrates the very good compatibility of the model with duty cycles and to obtain significant fuel savings, and the best

the specification. results found are presented below. However, considering that

the purpose of this study was to assess the feasibility of the

concept, and not to develop a vehicle, to simplify the analysis

one electric motor of 62 kW and 14 Ah Li-Ion batteries were

used for all these models.

Figure 11 summarizes the results obtained for the heavy-duty

tractor - motorized semi-trailer hybrid electric combinations,

and for the parallel hybrid electric tractor - conventional

semi-trailer combinations. It should be mentioned that these

models are equipped with derated (downsized) engines.

Comparisons with conventional combinations and with

parallel hybrid electric tractor - conventional semi-trailer

combinations equipped with normal engines turn out to be

interesting, and for this reason they were also presented in

Figure 10. Comparison between input cycle and simulation Figure 11.

output for the construction hauling cycle.

Figure 11 shows generally comparable results for the

heavy-duty tractor - motorized semi-trailer hybrid electric

The analysis conducted on system architecture, degree of combinations, and for the parallel hybrid electric tractor -

hybridization, and secondary energy source, allowed defining conventional semi-trailer combinations, both categories

the specifications presented in Table 7. The gross vehicle equipped with derated engines. PSAT simulations predict that

weights (GVW) were chosen based on the information these hybrid versions would obtain fuel savings from 10 - 12%

provided by the fleets which are partners of PIT (Project (for on-highway duty-cycles) to 30 % (for off-highway duty-

Innovations Transport), and on EPA recommendations [2]. cycles), compared to conventional vehicles. These results

Various combinations between diesel engines and electric should be interpreted by taking into account that any simulation

motors were tried to find solutions permitting to follow the method has limitations.

78 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Table 7. Specification of hybrid vehicles

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 79

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Figure 11. Summary of fuel consumption results.

DYNAMIC PERFORMANCES the length of cables. For example, the mass added by the

hybrid system is 264 kg for the class 8 Peterbilt hybrid vehicle,

EVALUATION and 181 kg for the class 6 and 7 Peterbilt hybrid vehicles [10].

The mass increase for the hybrid electric combination with

IMPACT ON VEHICLE WEIGHT motorized semi-trailer would be more important, because of

The distribution of the weight between drive axles and driven superior size of certain components.

axles determines the available traction and the auxiliary

traction systems installed on the trailer would increase the Table 8 shows that the masses added by the hybrid system

available traction. The downturn would be the increase in would translate in variations in gross vehicle mass of less than

vehicle weight, caused by the additional mass of the hybrid 1%. The impact on payload would not be an issue for highway,

system: if this augmentation is substantial, it will eventually regional and construction hauling, for which gross vehicle

cancel the effect of having additional drive traction available weights are usually under the legal limits. However, it should

[9]. The impact of the changes in vehicle weight on fuel be mentioned that for off-highway hauling of forestry products,

efficiency was therefore evaluated. the empiric rule is that every kilogram lost in payload would

cause 7 $ annual revenue loss, which for the 415 kg mass

Table 8 presents the weights added by the hybrid systems for added by the hybrid system would represent 2905 $ annual

the vehicles corresponding to the analyzed transport activities, revenue loss.

based on components’ masses from the PSAT library. They are

some differences between the masses of the same components Regarding the influence on axle weight distribution, the

in different vehicles, which are explained by constructive modifications would be insubstantial: for example, for the

particularities, such as the electric motors cooling needs, and highway and regional hauling 4 kg for tractor front axle,

80 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

156 kg for tractor tandem drive axles, and 139 kg for semi- Table 8. Influence of masses added by the hybrid system on

trailer tandem axles. fuel consumption

The effect of change in mass on fuel consumption (ΔCc) can

be estimated with the following equation, adapted from

[5, 11, 12]:

(4)

The results are presented in Table 8 and they show that the

impact of additional masses on fuel consumption would be

less than 1%, which is negligible compared to the fuel savings

envisaged by the implementation of the hybrid systems,

estimated through simulations to be at least 11%.

IMPACT ON TRACTION

The tractive force of a vehicle can be calculated either from

engine and transmission characteristics or from the traction

forces at vehicle wheels. The tractive force of a vehicle

equipped with a primary power train and a secondary

independent traction system can be estimated with the

following equation, adapted from [12, 13]:

(5)

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 81

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Gradeability is defined by the equation [13]: Transversal, or lateral, stability refers to a vehicle’s ability to

oppose transversal sliding and rollover relative to the line

defined by the centers of the contact areas of tires situated on

the same side of the vehicle. Lateral stability losses are caused

by road transversal gradients, vehicle speeding on curves, or

(6)

cross winds. Vehicle speed and road gradient at which rollover

occurs depend on vehicle dimensional characteristics (such as

Table 9 presents the comparison between traction performances

wheel base, wheel track, and height of the center of gravity)

of conventional vehicles and corresponding hybrid combinations

and road design (curve radius and friction coefficient) [12].

with motorized semi-trailers. Transmissions ratios corresponding

Therefore, it is obvious that a supplementary motorized axle

to the average duty-cycle speed were considered for calculation

mounted low on the semi-trailer would not have a significant

purposes. The results show that they are considerable gains in

influence on lateral stability.

tractive force, from 5 to 16%, and gradeability, from 4 to 15%,

depending on application, when the two power trains, primary

Longitudinal stability represents a vehicle’s ability to resist

and secondary, are simultaneously used.

longitudinal sliding and rollover relative to a transversal axle.

The grade at which the longitudinal rollover happens is also

IMPACT ON STABILITY function of vehicle characteristics, such as the longitudinal

Vehicle stability represents the vehicle’s capacity to resist distance between the center of gravity and the rearmost axle,

sliding, skidding and rollover, and considering that the and the height of the center of gravity. Consequently, a

movements are relative to the vehicle’s main axis, it can be supplementary motorized axle on the semi-trailer would not

defined as longitudinal and transversal stability. have a significant influence on longitudinal rollover stability.

Table 9. Impact on tractive force and gradeability

82 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

The longitudinal stability at sliding is expressed by the

maximum slope that the vehicle can climb without sliding

(PLS). For a vehicle combination consisting of a three-axle

tractor with two drive axles and a loaded two-axle semi-trailer, (8)

this slope is given by equation (7), which was derived by

considering equilibrium of normal and parallel forces to road In the normal conditions for on-highway transport, such as

surface, equilibrium of moments, and considering that the highway haul and regional haul, the longitudinal stability at

maximum usable thrust is the normal force at the drive axles sliding is not an issue. Therefore, we limited the analysis to

multiplied by the traction coefficient [14]. the off-highway hauling of raw material. The following

calculations illustrate the situation for a Class 8 vehicle

combination effectuating off-highway hauling of raw material

in difficult road conditions (gravel roads, with fR = 0.018

et µ = 0.3). Equations (7) and (8) were consequently applied.

The comparative results are presented in Table 10, and they

show that a motorized semi-trailer would allow improving the

longitudinal stability as it relates to sliding: the maximum

grade that vehicle could climb without sliding would increase

from 10 to 14%.

(7)

ANALYSIS OF THE IMPACT ON

GHG EMISSIONS

The most important greenhouse gases emitted by the burning of

diesel fuel are carbon dioxide (CO2), methane (CH4) and nitrous

oxide (N2O). Emission factors have been developed based on

standard fuel properties and an assumed fuel combustion

efficiency of 98.5% [16]. These data show that the production of

the other two GHGs are extremely low compared with CO2, so

The dimensional parameters are defined in Figure 12. these values are usually not considered for estimation purposes.

Therefore, for evaluating the potential to reduce emissions of

For the combination consisting of a three-axle tractor with two GHGs, we have assumed that combustion of diesel fuel produces

drive axles and a loaded two-axle semi-trailer with motorized 2.73 kg CO2 equivalent per litter of fuel [17].

axles, the simplified methodology proposed by [15] was used,

which gives the following equation : For highway and regional hauling the average annual mileage

from the Canadian Vehicle Survey was considered [18]. From

Figure 12. Dimensional parameters for the calculation of the maximum slope (adapted from [14]).

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 83

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Table 10. The impact on the maximum grade that the vehicle can climb without sliding

Table 11. The impact of hybrid combination conventional tractor - motorized semi-trailer on GHG emissions (annual data)

this data, the average annual mileage in the Province of Quebec these estimations, which show that the implementation of the

is of 120,983 km. For off-highway and construction hauling, heavy-duty tractor - motorized semi-trailer hybrid electric

the in-house data collected for logging transport and road combination concept could decrease the GHG emissions from

construction related transport were used. Table 11 presents 19 to 108 tonnes, depending on the type of transport operation.

84 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

PRODUCTIVITY ANALYSIS Table 12 presents the comparisons between conventional

vehicles and hybrid vehicles, for each duty-cycle. The same

For the purposes of this study, the productivity analysis used

masses were considered for both categories of vehicles because,

the energy intensity, which represents the quantity of energy

as it was showed above, the effect of additional masses of

required per unit of production. For freight transportation it is

hybrid systems on fuel consumption would be less than 1%.

usually expressed by the quantity of fuel, in liters, necessary to

transport one tonne of freight over one hundred kilometers:

The hybrid combination conventional tractor - motorized

L/t-100km. The gains in energy efficiency occur when more

semi-trailer would therefore increase the productivity from 13

weight is carried or longer distances are traveled for the same

to 28 %, compared to the correspondent conventional vehicles.

amount of consumed fuel, or when less fuel is necessary for

the same transported weight and distance. For a given trip, the

energy intensity (Ee in L/t-100km) can be calculated as a ECONOMICAL ANALYSIS

function of consumed fuel (Cf, in liters), the payload (Lu, in

tones), and the traveled distance (D, in kilometers), with the ESTIMATION OF IMPACT ON

equation:

VEHICLE COST

For evaluating the impact of hybrid technology implementation

on vehicle cost, the actual costs of class 6 to 8 hybrid vehicles

existing on the market have been considered. According to the

(9) information provided by the fleets using hybrid vehicles

Table 12. The impact of hybrid combination conventional tractor - motorized semi-trailer on productivity

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 85

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

(partners of PIT, such as Agropur and SAQ - Société des for the motorized semi-trailer combinations. The greatest

alcools du Québec), which own conventional and hybrid increase, almost three times, was calculated for highway and

Kenworth 370 vehicles, the hybrid versions were C$40,000 regional hauls. The lesser increase, roughly 22%, was evaluated

more expensive than the corresponding conventional vehicles for the off-highway hauling of raw materials. This is mainly

(C$145,000 $ compared to C$105,000). According to the because the cost of off-highway vehicles are much higher

manufacturer, the class 8 hybrid version is C$45,000 more (almost three time those of regular class 8 combinations) so that

expensive than the homologue conventional version. Taking the cost of the hybrid systems have less impact.

into account that the hybrid combination conventional tractor

- motorized semi-trailer would have some supplementary The economic impact was evaluated based on payback period

components as well, it was roughly estimated that an additional and cost of conserved energy (CCE) calculations. The payback

7% would also be added to the cost of the vehicle in addition period was calculated by dividing the total additional cost

to the cost of the hybrid system. (C$48,000 for the hybrid combination conventional tractor-

motorized semi-trailer) by the yearly net savings. CCE,

The cost increases for the assembly and for the components of expressed as the cost in dollars per liter of fuel saved, is

the hybrid tractor with conventional semi-trailer and of the independent of the price of fuel, and represents the ratio

hybrid combination conventional tractor - motorized semi- between the total additional cost and the savings. A small CCE,

trailer, compared to the conventional combinations, are generally less than 2.5, means that the price for a particular

presented in Table 13. measure to reduce fuel consumption is low, and therefore

attractive. Table 14 presents the results. The considered

Table 13 shows that the impacts on total costs of the combinations average fuel price was 0.97 C$/L for on-highway transport and

would be similar. However, the impacts on affected components, 0.80 C$/L for the off-highway transport (valid in September

which mean tractors for the hybrid tractor-conventional semi- 2009 in Province of Quebec, Canada). The excise taxes are not

trailer and respectively semi-trailers for the hybrid combination applied on fuel purchased for use in off-highway forest

conventional tractor - motorized semi-trailer, are more important operations in Quebec hence the lower cost.

Table 13. Impact on combination cost and component cost

86 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Table 14. Return on investment

The lowest payback period and CEE were calculated for the or more axles (on the tractor), while the electric motor drives

off-highway hauling of raw materials by Class 8 vehicles (two other axles (on the semi-trailer, in the case of this concept). It

years and three months and CEE of 1.8) and by off-highway should be mentioned that hybrid versions are usually equipped

combinations (a year and a half and CEE 1.2). with downsized engines compared to the corresponding

conventional vehicles. The batteries envisaged for the heavy-

These types of operations would be the most appropriate for duty tractor and motorized semi-trailer hybrid electric

the implementation of the concept of hybrid combination combination would be Li-Ion batteries with 340 to 360 VDC

conventional tractor-motorized semi-trailer. Nevertheless, it voltage and approximately 14Ah capacity.

should be mentioned that the market for this type of transport

is limited. Exemplifying for logging in Quebec, they are The evaluation of impact on fuel consumption was done by

roughly 150 off-highway vehicles and approximately 100 simulation, using the PSAT software. The objective of the

Class 8 vehicles involved in off-highway operations. simulation was to verify if the chosen components are correctly

functioning within the vehicle model, and if the hybrid version

fulfills the objectives of the projects, such as offering a better

DISCUSSION fuel efficiency without sacrificing other performances. The

Several transport activities were analyzed to determine specific results show generally comparable results for the heavy-duty

duty cycles for heavy-duty vehicles: highway line haul and tractor - motorized semi-trailer hybrid electric combinations,

regional haul, construction haul, and off-highway hauling of and for the parallel hybrid electric tractor - conventional semi-

raw materials, such as forestry transport with class 8 and trailer combinations, both categories equipped with derated

off-highway tractor-trailer combinations. engines. PSAT simulations predict that these hybrid versions

would obtain fuel savings from 10 - 12% (for on-highway

The analysis of the concept considered the architecture of the duty-cycles) to 30 % (for off-highway duty-cycles), compared

system, the degree of hybridization, and the secondary source to conventional vehicles. Therefore the most favorable

of energy. It was found that the heavy-duty tractor and applications would be for the off-highway transport of raw

motorized semi-trailer hybrid electric combination corresponds materials.

to the parallel-split architecture, in which the engine drives one

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 87

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

The impact of the hybrid system additional masses on fuel For highway and regional hauling, it should be mentioned that

consumption would be less than 1%, which is negligible there are presently in North-America 3.5 million tractors and

compared to the fuel savings envisaged by the implementation 5.3 million semi-trailers [19], and normally a tractor uses

of the hybrid systems. Concerning the traction performances, several semi-trailers for optimizing the operation. Furthermore,

the results show that there are considerable gains in tractive for the big fleets semi-trailers are work tools that must have a

force, from 5 to 16%, and gradeability, from 4 to 15%, competitive price. Consequently, a three time relative increase

depending on the application, when the two power trains, of the semi-trailer cost caused by the implementation of the

primary and secondary, are simultaneously used. A motorized concept would be prohibitive for these types of operation and

semi-trailer would allow to improve the longitudinal stability limited to the cases where a tractor uses always the same

with respect to sliding, the maximum grade that vehicle could trailer, which is very rare. An additional possibility for highway

climb without sliding increasing from 10 to 14%. and regional haul would be to use the concept for reefer-vans:

a smaller and cheaper version of the hybrid semi-trailer would

The productivity analysis showed that the hybrid combination be used exclusively for assuring the energy necessary for

conventional tractor - motorized semi-trailer would increase the refrigeration system, which would also avoid the synergy

the productivity from 13 to 28 %, compared to the correspondent issues between the motorized semi-trailer and tractor power

conventional vehicles. train.

The evaluation of the effects on GHG emissions predicts that

the implementation of the heavy-duty tractor - motorized

CONCLUSION

semi-trailer hybrid electric combination concept could Contrary to the classic hybrid electric parallel system used for

decrease the GHG emissions from 19 to 108 tones, depending Class 8 vehicles, the heavy-duty tractor and motorized semi-

on transport operation. trailer hybrid electric combination does not require integration

with tractor’s power train and offers better traction and stability

The cost analysis shows that the impacts on total costs of the performances. The constructive disadvantages refer to the

combinations would be similar for both hybrid tractor- complications brought to propelling and braking control

conventional semi-trailer and conventional tractor-motorized systems.

semi-trailer combinations. However, the impacts on affected

components, which mean tractors for the hybrid tractor- For highway and regional hauling, the concept would offer

conventional semi-trailer and respectively semitrailers for the efficiency performances similar to the classic hybrid tractor

hybrid combination conventional tractor - motorized semi- system, but the relative increase of the semi-trailer cost caused

trailer, are more important for the motorized semi-trailer by the implementation of the concept would be prohibitive for

combinations. The greatest increase, almost three times, was these types of operation.

calculated for highway and regional hauls. The lesser increase,

roughly 22%, was evaluated for the off-highway hauling of The concept of a heavy-duty tractor - motorized semi-trailer

raw materials. hybrid electric combination would offer the best dynamic,

environmental, and economical advantages when implemented

The economic impact was evaluated based on payback period for off-highway transport of raw materials, such as forestry or

and cost of conserved energy (CCE) calculations. The lowest mining transport, for which the relative cost increases are

payback period and CEE were calculated for the off-highway acceptable and the and payback periods are very short. We

hauling of raw materials by Class 8 vehicles (two years and consider that an eventual implementation should target at least

three months and respectively CEE of 1.8) and by off-highway these types of operations.

combinations (one year and a half and respectively CEE 1.2).

These types of operations would be the most appropriate for CONTACT INFORMATION

the implementation of the concept of hybrid combination

Marius-Dorin Surcel, Eng., M.A. Sc., Researcher

conventional tractor-motorized semi-trailer. Nevertheless, it

marius.surcel@fpinnovations.ca

should be mentioned that the market for this type of transport

FPInnovations - Feric Division.

is limited. Exemplifying for logging in Quebec, they are

roughly 150 off-highway vehicles and approximately 100

Jan Michaelsen, F.E., Program Leader

Class 8 vehicles involved in off-highway operations.

jan.michaelsen@fpinnovations.ca

FPInnovations - Feric Division.

The implementation of the concept would be therefore more

efficient for off-highway hauling of raw materials, such as

forestry and mining transport, for which the concept would ACKNOWLEDGEMENTS

offer the best economic, environmental and dynamic This research program was funded by the Ministère des

advantages. Moreover, the relative cost increase would be Transports du Québec (MTQ). The authors wish to thank

acceptable and the payback period would be very short.

88 SAE Int. J. Commer. Veh. | Volume 3 | Issue 1

Downloaded from SAE International by University of British Columbia, Monday, July 30, 2018

Gaétan Leclerc, inventor, and Mario Bussières from MTQ, for 10. Kenworth Truck Company, “T270 Class 6, T370 Class 7

creating a very constructive base of discussions. Hybrid”, Kirkland, Wa, 2008.

11. Fitch, J.W., “Motor Truck Engineering Handbook, Fourth

REFERENCES Edition,” SAE International, Warrendale, PA, ISBN 978-1-

56091-378-8, 1993.

1. Leclerc, G., “Motorized Semi-trailer”, United States

Patent, Patent no. US 7,147,070 B2, 2006. 12. Untaru, M., Potincu, G., Peres, G., Tabacu, I. “Dinamica

Autovehiculelor pe roti (Dynamic of Wheeled Vehicles)”,

2. EPA, United States Environmental Protection Agency, p. 47, 153, Bucharest, Romania, 1981.

“SmartWay Fuel Efficiency Test Protocol for Medium and

Heavy Duty Vehicles”, Working Draft, EPA420-P-003, 13. MAN Nutzfahrzeuge Aktiengesellschaft, “Calculations”,

Washington, DC, 2007. p. 3-5, Munchen, Germany, 2000.

3. Michaelsen, J., “Using the OTTO Truck-Simulation 14. Sessions, J., Stewart, R., Anderson, P., Tuor, B.,

Software to Manage Haul Operations”, Proceedings of 6th “Calculating the maximum Grade a Log Truck Can Climb.

international Symposium on Heavy Vehicles Weight and Western Journal of Applied Forestry”, Volume 1, Number 2,

Dimensions, Saskatoon, Canada, 2000. 1 April 1986, pp. 43-45(3), Society of American Foresters,

1986.

4. Frey, H. C., Kangwook, K., “Comparison of Real-World

Fuel Use and Emissions for Dump Trucks Fueled with B20 15. Stryker, E., “Gradeability of Log Trucks”, M.F. Paper,

Biodiesel Versus Petroleum Diesel”, Transportation Research Oregon State University, Corvallis, Or., 1977.

Record, Journal of the Transportation Research Board, ISBN 16. Environment Canada, “National Inventory Report, 1990-

0309099978, p. 110-117, Transportation Research Board, 2005: Greenhouse Gas Sources and Sinks in Canada, Annex

Washington, D.C., 2006. 12: Emission factors”, 2005.

5. Gillespie, T.D., “Fundamentals of Vehicle Dynamics,” 17. National Resources Canada, Office of Energy Efficiency.

SAE International, Warrendale, PA, ISBN 978-1-56091- http://oee.nrcan.gc.ca/publications/transportation/fuel-

199-9, 1992. guide/2008/comparing-vehicles.cfm?attr

6. Freidman, D., “A New Road: The Technology and 18. Statistics Canada, “Canadian Vehicle Survey: Annual

Potential of Hybrid Vehicles”, UCS Publications, Cambridge, 2008”, Catalogue no. 53-223-X, ISSN 1499-318X, Ottawa,

Ma., 2003. ON, 2009.

7. Technology & Maintenance Council (TMC), “Hybrid 19. Rocky Montain Institute (RMI), “Transformational

Work Trucks, Preparing for Market Introduction”, S. 15 Trucking Initiative Report”, Rocky Mountain Institute,

Study Group, Information Report 2006-2, Alexandria, Boulder, Co., 2009.

Va., 2006.

8. Drozdz, P., “Hybrid Refuse Truck Feasibility Study, doi: 10.4271/2010-01-1932

SAE

prepared for Transportation Development Centre of Transport

Canada”, TP 14431E, Ottawa, Ontario, Canada, 2005.

9. Stjernberg, E., “Le potentiel des remorques à essieu

motorisé en exploitation forestiere”, rapport technique n°

RT-47, Forest Engineering Research Institute of Canada

(FERIC), Pointe-Claire, Qc., Canada,1981.

SAE Int. J. Commer. Veh. | Volume 3 | Issue 1 89

You might also like

- Price List Parts MITSUBISHI FUSO SEPTEMBER 2018Document660 pagesPrice List Parts MITSUBISHI FUSO SEPTEMBER 2018Andreas Hendramartani100% (10)

- Innovation Landscape brief: Electric-vehicle smart chargingFrom EverandInnovation Landscape brief: Electric-vehicle smart chargingNo ratings yet

- A320 LimitationsDocument1 pageA320 Limitationssimcity3000No ratings yet

- Spoke Wheel Building & TruingDocument5 pagesSpoke Wheel Building & TruingmrmrvaNo ratings yet

- Alert Indicators: Operation and Maintenance ManualDocument6 pagesAlert Indicators: Operation and Maintenance ManualSanath Jayanetti100% (5)

- Joint Routing of Conventional and Range-Extended Electric Vehicles in A Large Metropolitan NetworkDocument28 pagesJoint Routing of Conventional and Range-Extended Electric Vehicles in A Large Metropolitan NetworkArtem Sergeevich AkopyanNo ratings yet

- Assessment of Battery-Hybrid Diesel-Electric Locomotive Fuel SavingsDocument18 pagesAssessment of Battery-Hybrid Diesel-Electric Locomotive Fuel SavingsZahra AfrazNo ratings yet

- Loader Power-Split Transmission System Based On A Planetary Gear SetDocument8 pagesLoader Power-Split Transmission System Based On A Planetary Gear SetsughieantoNo ratings yet

- Agriculture 12 00436 v2Document22 pagesAgriculture 12 00436 v2Adrian MarinNo ratings yet

- s12302-020-00307-8Document17 pagess12302-020-00307-8Chiara GastaldiNo ratings yet

- Modelling and Analysis of Plug-In Series-Parallel Hybrid Medium-Duty VehiclesDocument10 pagesModelling and Analysis of Plug-In Series-Parallel Hybrid Medium-Duty VehiclesEduardo Garcia VázquezNo ratings yet

- Banerjee 2018Document14 pagesBanerjee 2018Prasad JoshiNo ratings yet

- Energy: Yanbiao Feng, Zuomin DongDocument14 pagesEnergy: Yanbiao Feng, Zuomin DongdinkuinkuNo ratings yet

- A Study of Energy Requirements For Electric and HyDocument9 pagesA Study of Energy Requirements For Electric and HyAntoine LemaireNo ratings yet

- Machines: Optimized Energy Management Control of A Hybrid Electric LocomotiveDocument16 pagesMachines: Optimized Energy Management Control of A Hybrid Electric LocomotivebartolomeuzNo ratings yet

- Neural Network Surrogate Models For Aerodynamic Analysis in Truck Platoons Implications On Autonomous Freight DeliveryDocument10 pagesNeural Network Surrogate Models For Aerodynamic Analysis in Truck Platoons Implications On Autonomous Freight DeliveryrublasterNo ratings yet

- A Recent Review of Hybrid Automotive Systems in Gulf Corporation Council RegionDocument65 pagesA Recent Review of Hybrid Automotive Systems in Gulf Corporation Council RegionSanjay SanjayNo ratings yet

- Eevc 2014Document12 pagesEevc 2014ThejaswiniNo ratings yet

- Journal of Power Sources: Emiliano Pipitone, Gianpaolo VitaleDocument10 pagesJournal of Power Sources: Emiliano Pipitone, Gianpaolo VitaleBT20MEC120 Jyoti ThakurNo ratings yet

- Multi-Speed Gearboxes For Battery Electric Vehicles Current Status and Future TrendsDocument17 pagesMulti-Speed Gearboxes For Battery Electric Vehicles Current Status and Future TrendsSamial HasnatNo ratings yet

- AusRAILPLUS 2019 - Spiryagin - WuDocument12 pagesAusRAILPLUS 2019 - Spiryagin - Wumuj_aliNo ratings yet

- Applied Energy: Chiara Fiori, Kyoungho Ahn, Hesham A. RakhaDocument12 pagesApplied Energy: Chiara Fiori, Kyoungho Ahn, Hesham A. RakhaJosé GonzálezNo ratings yet

- Control Strategy of A Fuel-Cell Power Module For Electric ForkliftDocument11 pagesControl Strategy of A Fuel-Cell Power Module For Electric Forkliftcan kaplanNo ratings yet

- Design of B-S SystemDocument6 pagesDesign of B-S SystemRadoy CristyNo ratings yet

- Retpr 2015 2 (2) 29 36Document8 pagesRetpr 2015 2 (2) 29 36zeyad alsaroriNo ratings yet

- Combined Optimisation of Design and Power Management of The Hydraulic Hybrid Propulsion System For The 6Document31 pagesCombined Optimisation of Design and Power Management of The Hydraulic Hybrid Propulsion System For The 6AlfinThariqNo ratings yet

- Energies 15 07243 v3Document26 pagesEnergies 15 07243 v3Tran DanteNo ratings yet

- Efficiency Enhancement of A New Two-Motor Hybrid SystemDocument11 pagesEfficiency Enhancement of A New Two-Motor Hybrid SystemAnchal SaxenaNo ratings yet

- Energy Management Strategy For Plug-In H PDFDocument9 pagesEnergy Management Strategy For Plug-In H PDFruxandaNo ratings yet

- 4 A Comparison of Vehicle Simulation Software and Dynamometer Results For Battery Electric VehiclesDocument6 pages4 A Comparison of Vehicle Simulation Software and Dynamometer Results For Battery Electric Vehiclesbirdview champlainNo ratings yet

- Design Modeling and Hardware Implementation of Regenerative Braking For Electric Two-Wheelers For Hilly RoadsDocument17 pagesDesign Modeling and Hardware Implementation of Regenerative Braking For Electric Two-Wheelers For Hilly RoadsH.BheemeshwaraNo ratings yet

- Dual-Function Wheel Drives Using Rotary-Linear Actuators in Electric and Hybrid VehiclesDocument6 pagesDual-Function Wheel Drives Using Rotary-Linear Actuators in Electric and Hybrid VehiclesAndres MoranNo ratings yet

- Hitachi ReviewDocument5 pagesHitachi Reviewbobcat3304No ratings yet

- 2020 Ditrolio ''A Hybrid Power-Unit Based On A Passive Fuel Cellbattery System For Light Weight Vehicles''Document11 pages2020 Ditrolio ''A Hybrid Power-Unit Based On A Passive Fuel Cellbattery System For Light Weight Vehicles''Abdul RehmanNo ratings yet

- 1 s2.0 S221313881930548X MainDocument7 pages1 s2.0 S221313881930548X MainNurrahma Salsabila HadimaNo ratings yet

- Electric Vehicles: - The Challenges Facing The Widespread Adoption of Electric CarsDocument3 pagesElectric Vehicles: - The Challenges Facing The Widespread Adoption of Electric CarsDenny YenNo ratings yet

- Ijsrp p9415Document6 pagesIjsrp p9415adharshaj2255No ratings yet

- Design and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanDocument8 pagesDesign and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanPrafulla DandgeNo ratings yet

- Potential of Hybrid Powertrains in A Variable Compression Ratio Downsized Turbocharged VVA Spark Ignition EngineDocument19 pagesPotential of Hybrid Powertrains in A Variable Compression Ratio Downsized Turbocharged VVA Spark Ignition EngineCostin DanielNo ratings yet

- Brazilian Hybrid Electric-Hydrogen Fuel Cell Bus: Improved On-Board Energy Management SystemDocument11 pagesBrazilian Hybrid Electric-Hydrogen Fuel Cell Bus: Improved On-Board Energy Management SystemMiguelGuavitaRojasNo ratings yet

- Nonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesDocument6 pagesNonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesasadjadiNo ratings yet

- Paper 3Document23 pagesPaper 3Swati NikamNo ratings yet

- Traction Electrification of Heavy Off-Road Vehicle: Case Study of Backhoe Loader Operating in BackfillDocument8 pagesTraction Electrification of Heavy Off-Road Vehicle: Case Study of Backhoe Loader Operating in BackfillPedro Andrade de OliveiraNo ratings yet

- Energies 15 03348 v2Document19 pagesEnergies 15 03348 v2Rkd PadsNo ratings yet

- Bartlomiejczyk 2019 Driving Performance Indicators of eDocument10 pagesBartlomiejczyk 2019 Driving Performance Indicators of eLiangbin cuiNo ratings yet

- Bartolo ZZ I 2013Document9 pagesBartolo ZZ I 2013Fernanda MoreiraNo ratings yet

- Jjmie: A Study of Fuel Cell Hybrid Auto Rickshaws Using Realistic Urban Drive CyclesDocument6 pagesJjmie: A Study of Fuel Cell Hybrid Auto Rickshaws Using Realistic Urban Drive CyclesJosé GonzálezNo ratings yet

- Fuel Cell Electric Vehicle Characterisation Under Laboratory and in Use OperationDocument13 pagesFuel Cell Electric Vehicle Characterisation Under Laboratory and in Use OperationalexandmagaraNo ratings yet

- Energies: Electrification of A Heavy-Duty CI Truck-Comparison of Electric Turbocharger and Crank Shaft MotorDocument21 pagesEnergies: Electrification of A Heavy-Duty CI Truck-Comparison of Electric Turbocharger and Crank Shaft Motorhektor AtkinsonNo ratings yet

- Modeling and Simulation of Plug-In Hybrid Electric Powertrain System For Different Vehicular ApplicationDocument7 pagesModeling and Simulation of Plug-In Hybrid Electric Powertrain System For Different Vehicular ApplicationYoussef OubelaidNo ratings yet

- Comparison of Power Consumption Efficiency of CVT and Multi-Speed Transmissions For Electric VehicleDocument8 pagesComparison of Power Consumption Efficiency of CVT and Multi-Speed Transmissions For Electric VehicleNguyen Ke DucNo ratings yet

- Converging Technologies For Electric Hybrid Vehicles and More Electric Aircraft SystemsDocument12 pagesConverging Technologies For Electric Hybrid Vehicles and More Electric Aircraft SystemsO GoogleNo ratings yet

- Energy Policy: Sarah G. Nurre, Russell Bent, Feng Pan, Thomas C. SharkeyDocument14 pagesEnergy Policy: Sarah G. Nurre, Russell Bent, Feng Pan, Thomas C. SharkeySumit RathorNo ratings yet

- Multi Speed Transmission For ElectDocument4 pagesMulti Speed Transmission For ElectHamza TAKTINo ratings yet

- BeltconveyorwileyDocument12 pagesBeltconveyorwileySimone MastrogiacomoNo ratings yet

- Static and DynamicDocument8 pagesStatic and Dynamicchenxi.cugNo ratings yet

- Coches de CarrerasDocument8 pagesCoches de CarrerasJesús GarcíaNo ratings yet

- Evaluation of Electric Vehicle Component Performance Over Eco-Driving CyclesDocument17 pagesEvaluation of Electric Vehicle Component Performance Over Eco-Driving CyclesPawan DhakalNo ratings yet

- Hybrid Electric Vehicles and Regenerative BrakingDocument7 pagesHybrid Electric Vehicles and Regenerative BrakinggadrumNo ratings yet

- Energies 17 01484Document22 pagesEnergies 17 01484Maher AzzouzNo ratings yet

- Design of A Hybrid Electric Motorcycle For OptimumDocument9 pagesDesign of A Hybrid Electric Motorcycle For OptimumAryan AmeenNo ratings yet

- EV Walker ComparationDocument8 pagesEV Walker Comparationmihai_1957No ratings yet

- Autonomous Hybrid Tractor Unit With A Predictive Control SystemDocument8 pagesAutonomous Hybrid Tractor Unit With A Predictive Control SystemTJPRC PublicationsNo ratings yet

- Trancossi2016 Article WhatPriceOfSpeedACriticalRevisDocument24 pagesTrancossi2016 Article WhatPriceOfSpeedACriticalRevisTrancossi MicheleNo ratings yet

- Police Log September 18, 2016Document11 pagesPolice Log September 18, 2016MansfieldMAPoliceNo ratings yet

- Repair Manual: MZ Riders ClubDocument105 pagesRepair Manual: MZ Riders ClubDaniel PopescuNo ratings yet

- With New Hi-Line Versions: Traditionally InnovativeDocument16 pagesWith New Hi-Line Versions: Traditionally InnovativemiminiweweNo ratings yet

- Ae MCQDocument12 pagesAe MCQYuvraaj Singh100% (3)