Professional Documents

Culture Documents

Section 28 Irrigation System

Section 28 Irrigation System

Uploaded by

Nisamudeen H KklOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 28 Irrigation System

Section 28 Irrigation System

Uploaded by

Nisamudeen H KklCopyright:

Available Formats

QCS 2010 Section 28 Part 2 Irrigation System Page 13

(f) The supplier should submit a guarantee of 2 days maximum repair time for the pump

including availability of spare parts.

(g) The pump warranty should cover all parts of the pumping system including the control

board piping and check valve to a minimum of five years against manufacturer

defects.

20. Flow Sensor

(a) The flow meter shall be of an Electromagnetic insertion type, operated with 24 V direct

current.

(b) It shall be compatible with the irrigation control system. And Capable of reading flow

from 0 to 25% higher than the maximum flow in the largest mainline pipe.

(c) Frequency of sampling and reading flow shall be selectable from 10 times per second

to one time in 10 minutes or (As per manufacture requirements).

(d) The wire of flow sensor should be minimum 20 AWG.

(e) The warranty shall include the flow meter and the signal converter and should be for 5

years suppliers’ warranty.

21. Master Control Valve

(a) The master control valve should be cast iron compatible with the existing controller

and operated with 24 V direct Electrical current.

(b) The warranty should be for 3 years suppliers warranty and 1 years minimum

manufacturer warranty.

(c) The local supplier should be an existing Qatari firm with minimum 5 years of

operational history.

22. Miscellaneous

(a) Irrigation Drip Line Stakes: Stakes for securing flexible pipes shall be heat resistant

plastic.

(b) Keys: the Contractor shall provide Keys for all valves, controller cabinets, boxes, quick

couplers, etc. The number of keys to be provided to the Engineer for each type of

fitting shall be six (6).

(c) Hoses: Hoses, quick couplers and appropriate connectors shall be provided by the

Contractor for quick coupling valves, drain down points, etc. The number of

hoses/connectors shall be: 1 (one as sample) the hose should be fifty (50) meters of

industrial weight double nylon cord reinforcement or double tire cord reinforced of an

untangling and high pressure type.

(d) Quick couplers Swivel end unit: One (1) quick coupler with swivel end unit shall be

provided for each installed eight (8) quick coupling valves.

(e) Distribution chamber: Should be made of reinforced concrete as specified and

approved by the drainage department, it should allow for easy installation and removal

of component inside and should be water proofed with waterproofing paints and

membrane. The membrane should be protected with a protection board.

(f) Chamber Aluminum cover: The aluminum cover should be made to fit the new

chambers shown on the project details drawing and it should have the following:

(i) Hinged aluminum access cover shall be obtained from an approved

experienced manufacturer and shall be fabricated from checker-plate. The

QCS 2010

You might also like

- 4f27e 2006 Workshop ManualDocument23 pages4f27e 2006 Workshop ManualTransmisiones Automáticas Chepe100% (7)

- V 300Document64 pagesV 300Serrefriair Garcia Refri50% (2)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Wet ScrubberDocument5 pagesWet ScrubberBia AkramNo ratings yet

- TS - 25 KV Current TransformerDocument9 pagesTS - 25 KV Current TransformerbinodeNo ratings yet

- API 570 Mock Exam Closed BookDocument17 pagesAPI 570 Mock Exam Closed Bookaasatti100% (1)

- 385C Excavator Hydraulic System: Eda1-Up Kgb1-Up Kbc1-Up Sbe1-Up T2E1-UP Kkk1-Up Jcm1-Up Mnz1-UpDocument2 pages385C Excavator Hydraulic System: Eda1-Up Kgb1-Up Kbc1-Up Sbe1-Up T2E1-UP Kkk1-Up Jcm1-Up Mnz1-UpMilorad Zelenovic100% (1)

- Pei Rp1000 Final TocDocument4 pagesPei Rp1000 Final Tocmedrascom0% (1)

- Pump DatasheetDocument4 pagesPump Datasheetbmanojkumar16No ratings yet

- Vendor ListDocument48 pagesVendor ListSunil KoricherlaNo ratings yet

- Chapter 8 - Swing System: Service ManualDocument26 pagesChapter 8 - Swing System: Service ManualHamid Essarbouti100% (1)

- Lecture1 IntroDocument28 pagesLecture1 IntroSergio Fernández BlancoNo ratings yet

- Thornycroft Marine Engine PDFDocument42 pagesThornycroft Marine Engine PDFAnonymous 3xJyAmc100% (1)

- Section 28 Irrigation SystemDocument1 pageSection 28 Irrigation SystemNisamudeen H KklNo ratings yet

- Section 28 Irrigation SystemDocument1 pageSection 28 Irrigation SystemNisamudeen H KklNo ratings yet

- 68m3 - 15hasDocument4 pages68m3 - 15hasCedric AlmojuelaNo ratings yet

- Sewer Pump Stations and AppurtenancesDocument9 pagesSewer Pump Stations and AppurtenancesMussa ElbarraniNo ratings yet

- P5 Draft Technical SpecificationDocument385 pagesP5 Draft Technical SpecificationScalperNo ratings yet

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 pagesCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- ATC-E Unit SpecificationsDocument3 pagesATC-E Unit SpecificationsgamunozdNo ratings yet

- Cleaning and Cement LiningDocument8 pagesCleaning and Cement LiningLudi D. LunarNo ratings yet

- SSG App C Des Con Guide - pdf4Document7 pagesSSG App C Des Con Guide - pdf4Shohidul IslamNo ratings yet

- DM Specs For Surge Vessel PDFDocument6 pagesDM Specs For Surge Vessel PDFatadanleventNo ratings yet

- Wms Acmv Duct WorksDocument8 pagesWms Acmv Duct Worksfahmi_majid_2No ratings yet

- 03 - Cooling Towers - MWS For BS - A8Document9 pages03 - Cooling Towers - MWS For BS - A8kevin.zhaoNo ratings yet

- AC-VRF Statment MethodDocument4 pagesAC-VRF Statment MethodHassan ShamsNo ratings yet

- Particular SpecificationsDocument5 pagesParticular SpecificationsMohammed HammadNo ratings yet

- Ts of 11kv Id Combined CTPTDocument7 pagesTs of 11kv Id Combined CTPTwebseries downloadNo ratings yet

- Section-220500 Common Work Results For Plumbing Rev 1Document17 pagesSection-220500 Common Work Results For Plumbing Rev 1刘盘石No ratings yet

- Design Standards For Cross Country Pipe Lines (Unloading Lines and Pre Cooling Lines)Document14 pagesDesign Standards For Cross Country Pipe Lines (Unloading Lines and Pre Cooling Lines)MugeshNo ratings yet

- Midterm Exam Engineering Utilities 2Document54 pagesMidterm Exam Engineering Utilities 2DebbieNo ratings yet

- Submersible PumpDocument15 pagesSubmersible Pumpnwright_besterNo ratings yet

- 3rd Weekly Exam-Plumbing CodeDocument13 pages3rd Weekly Exam-Plumbing Coderyancsalcedo061586No ratings yet

- LPG NG - Gas Malaysia Requirement - 19 06 2014Document3 pagesLPG NG - Gas Malaysia Requirement - 19 06 2014SashiNo ratings yet

- Va Nca 23 13 23Document6 pagesVa Nca 23 13 23Ali AlomyNo ratings yet

- 2 HS SpecsDocument4 pages2 HS SpecscarlosvargasNo ratings yet

- Technical Specification - PumpDocument7 pagesTechnical Specification - PumpBalasundaramSrinivasaRajkumarNo ratings yet

- 1st Weekly Exam-Plumbing CodeDocument14 pages1st Weekly Exam-Plumbing Coderyancsalcedo061586No ratings yet

- AES Vol 2 P15007 Split AC UnitsDocument5 pagesAES Vol 2 P15007 Split AC UnitsShreejith PanickerNo ratings yet

- Technical Specification For 11 KV Combined Current & Potential Transformer Suitable For Three Element MeterDocument8 pagesTechnical Specification For 11 KV Combined Current & Potential Transformer Suitable For Three Element MeterAnilNo ratings yet

- PVC Coated Conduit Specification Guide 26 05 33 Raceway and Boxes For Electrical Systems in Corrosive EnvironmentsDocument2 pagesPVC Coated Conduit Specification Guide 26 05 33 Raceway and Boxes For Electrical Systems in Corrosive EnvironmentsFaheem PP13No ratings yet

- 88 Series 2 Boiler: Suggested SpecificationsDocument4 pages88 Series 2 Boiler: Suggested SpecificationsAdam Bin Abu BakarNo ratings yet

- Amc Ac VCB DGDocument9 pagesAmc Ac VCB DGbalaji bNo ratings yet

- Cathodic Protection Clarifier Specification-Jun 2010Document7 pagesCathodic Protection Clarifier Specification-Jun 2010656665665No ratings yet

- SECTION 22 05 19 Meters and Gages For Plumbing PipingDocument7 pagesSECTION 22 05 19 Meters and Gages For Plumbing PipingMiguel Angel Pacahuala CristobalNo ratings yet

- 22 21 Hvac Fan Coil Units 1Document2 pages22 21 Hvac Fan Coil Units 1Alaguraja SubramanianNo ratings yet

- 6th Weekly ExamSanitary, Plumbing Design and InstallationDocument13 pages6th Weekly ExamSanitary, Plumbing Design and Installationryancsalcedo061586No ratings yet

- 6th Weekly Exam - Sanitary, Plumbing Design and Installation Weekly ExamDocument14 pages6th Weekly Exam - Sanitary, Plumbing Design and Installation Weekly ExamArchie GomocagNo ratings yet

- Division 22: PlumbingDocument6 pagesDivision 22: PlumbingRaya VillafloresNo ratings yet

- Chennai Port Trust Notice Inviting Budgetary Offer MEE/V3/289/2020/Dy - CME (OH)Document16 pagesChennai Port Trust Notice Inviting Budgetary Offer MEE/V3/289/2020/Dy - CME (OH)Gurpreet KaurNo ratings yet

- Minimum Standards For Civil Engineering Services in Townships CoCT Part 4Document165 pagesMinimum Standards For Civil Engineering Services in Townships CoCT Part 4Du Toit KotzeNo ratings yet

- STP SpecsDocument9 pagesSTP SpecsNakclean Water SolutionsNo ratings yet

- Part 1: General: Engineering Specifications For CXVB Evaporative CondensersDocument5 pagesPart 1: General: Engineering Specifications For CXVB Evaporative CondensersMARIVEL BASANo ratings yet

- Section 35 - Air Conditioning and Mechanic Ventilation SystemDocument32 pagesSection 35 - Air Conditioning and Mechanic Ventilation SystemMAYMODERN SITEINFONo ratings yet

- Mesan MXR-KM (F-K) Guide Specs r2Document4 pagesMesan MXR-KM (F-K) Guide Specs r2Renu TekumudiNo ratings yet

- Sewer Lift StationDocument15 pagesSewer Lift StationFrancisco M. RamosNo ratings yet

- Fire Protection Water Mist SystemDocument18 pagesFire Protection Water Mist SystemAhmed MahmoudNo ratings yet

- (Expansion and Compression Tanks)Document3 pages(Expansion and Compression Tanks)Mostafa SalemNo ratings yet

- Close Tolerance Horizontal Directional Drilling For Gravity MainsDocument8 pagesClose Tolerance Horizontal Directional Drilling For Gravity MainsmobtelecomNo ratings yet

- 220CDocument6 pages220Cmacanipharoldf6220No ratings yet

- Current TransformerDocument16 pagesCurrent TransformerRicardo DiasNo ratings yet

- Scope of SupplyDocument23 pagesScope of SupplymoodydoodyNo ratings yet

- AmrutDocument46 pagesAmrutJitendraHatwarNo ratings yet

- 02810Document8 pages02810uddinnadeemNo ratings yet

- Technical Instruction For Water Supply SystemDocument9 pagesTechnical Instruction For Water Supply SystemToviwaNo ratings yet

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 pagesHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilNo ratings yet

- SPAN Part C - Plumbing SystemsDocument21 pagesSPAN Part C - Plumbing Systemsang.xicongNo ratings yet

- Chapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterDocument2 pagesChapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterkapsarcNo ratings yet

- 33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARDocument9 pages33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARSatyajit RaiNo ratings yet

- Pages From Calculation REV 1 (3) .. (2) 2Document1 pagePages From Calculation REV 1 (3) .. (2) 2Nisamudeen H KklNo ratings yet

- DeliveryDocument2 pagesDeliveryNisamudeen H KklNo ratings yet

- Pages From Calculation REV 1 (3) .. (2) 1Document1 pagePages From Calculation REV 1 (3) .. (2) 1Nisamudeen H KklNo ratings yet

- Proposal Options Analysis Business Case Project Plan CompletionDocument16 pagesProposal Options Analysis Business Case Project Plan CompletionNisamudeen H KklNo ratings yet

- Pages From Pages From QP Guide For Managing HSE in Contracts 2Document1 pagePages From Pages From QP Guide For Managing HSE in Contracts 2Nisamudeen H KklNo ratings yet

- Pages From Pages From QP Guide For Managing HSE in Contracts 4Document1 pagePages From Pages From QP Guide For Managing HSE in Contracts 4Nisamudeen H KklNo ratings yet

- DPS Standard For Project Documentation - Operation and Maintenance Manuals Template and GuidelinesDocument23 pagesDPS Standard For Project Documentation - Operation and Maintenance Manuals Template and GuidelinesNisamudeen H KklNo ratings yet

- Miantnance ManualDocument30 pagesMiantnance ManualNisamudeen H KklNo ratings yet

- Jain Turbo Cascade: PC, Pcas & PCNLDocument3 pagesJain Turbo Cascade: PC, Pcas & PCNLNisamudeen H KklNo ratings yet

- Click Here To Create A Project Budget Sheet in SmartsheetDocument6 pagesClick Here To Create A Project Budget Sheet in SmartsheetNisamudeen H KklNo ratings yet

- Testing Commissioning of Water Supply Piping System NetworkDocument3 pagesTesting Commissioning of Water Supply Piping System NetworkNisamudeen H KklNo ratings yet

- Tabebuia AureaDocument3 pagesTabebuia AureaNisamudeen H KklNo ratings yet

- Company Profile-2Document2 pagesCompany Profile-2Nisamudeen H KklNo ratings yet

- VDLSE502 - VRB2-3 - Danfoss VentiliDocument8 pagesVDLSE502 - VRB2-3 - Danfoss VentilizigicsasaNo ratings yet

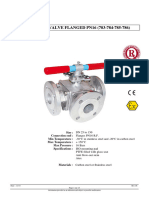

- 783 784 785 786Document8 pages783 784 785 786lesonspkNo ratings yet

- Anti Surge ControllersDocument6 pagesAnti Surge Controllersalimohebbi1361100% (1)

- Control ValvesDocument26 pagesControl ValvesTirado Melchor Angel Miguel100% (2)

- Descarga 1er Paso Mercer 91-52j11t84u1Document16 pagesDescarga 1er Paso Mercer 91-52j11t84u1Alberto Esau Reyes CruzNo ratings yet

- Smart Gas Lift ValveDocument8 pagesSmart Gas Lift ValveAhmed MamdouhNo ratings yet

- Level Gauge HydrastepDocument15 pagesLevel Gauge HydrastepashrafmuhNo ratings yet

- Kaiser AS 36.8Document73 pagesKaiser AS 36.8mailomilena75% (4)

- 01 Basic Design Structure FeaturesDocument8 pages01 Basic Design Structure FeaturesAndri AjaNo ratings yet

- Man B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesDocument347 pagesMan B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesNguyễn Công HùngNo ratings yet

- Asl - Ga11vsd Aii140337 - 30141203Document46 pagesAsl - Ga11vsd Aii140337 - 30141203manuel barberoNo ratings yet

- Peso Valvula Deluge PDFDocument8 pagesPeso Valvula Deluge PDFAndrés TobarNo ratings yet

- Power Steering System: PrecautionDocument45 pagesPower Steering System: PrecautionMusat Catalin-Marian100% (1)

- P25 Bolted Plastic Pump: Engineering Operation MaintenanceDocument24 pagesP25 Bolted Plastic Pump: Engineering Operation MaintenanceAlvaro Muñoz BNo ratings yet

- Operator'S Manual: Ept-55 Hand Pallet TruckDocument18 pagesOperator'S Manual: Ept-55 Hand Pallet TruckKenneth SaganNo ratings yet

- Price Pfister MarielleDocument1 pagePrice Pfister MarielleSaziZuniNo ratings yet

- SpecphDocument98 pagesSpecphhelloitskalaiNo ratings yet

- Hydraulic Valves - AdvanceDocument17 pagesHydraulic Valves - AdvanceSENANAYAKE S.H.RNo ratings yet

- Calibration Procedure of A Control ValveDocument12 pagesCalibration Procedure of A Control ValveAbdNo ratings yet

- Bla Power Pvt. LTD: Woodward 505 Governor Valve / Actuator Calibration &testDocument23 pagesBla Power Pvt. LTD: Woodward 505 Governor Valve / Actuator Calibration &testWilliam Will Controle WoodwardNo ratings yet

- Swagelok Gas Distribution Systems - P&ID DrawingsDocument28 pagesSwagelok Gas Distribution Systems - P&ID Drawingsken tsaiNo ratings yet