Professional Documents

Culture Documents

Managed Pressure Drilling-3

Managed Pressure Drilling-3

Uploaded by

x4zzyjgdwwCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Managed Pressure Drilling-3

Managed Pressure Drilling-3

Uploaded by

x4zzyjgdwwCopyright:

Available Formats

Oil and Gas Wells - Recent Advances in Drilling and Completion Technologies

Furthermore, we venture into the digital frontier where automation and high-

speed data transmission converge to revolutionize drilling. Wired drill pipes, acting as

the neural pathways of this digitalization, enable seamless communication between

downhole and surface, ushering in an era of real-time monitoring and decision-

making. The marriage of digitalization and automation with MPD and CML systems

forms the nucleus of our discussion, as we explore how these technologies can be

harnessed synergistically to create semi or fully automated systems that optimize

drilling processes, enhance accuracy, and ultimately reduce NPT. Join us on this

journey through the cutting-edge realms of drilling technology, where innovation

knows no bounds, and the future of energy exploration and production is being

reshaped before our very eyes.

2. Managed pressure drilling

Managed Pressure Drilling (MPD) is a drilling approach born out of the need to

combat the high costs associated with NPT caused by the precarious balance between

pore pressure and fracture pressure during drilling operations both onshore and

offshore drilling rigs.

MPD stands as an adaptable drilling technique deployed to regulate the annular

pressure configuration within the wellbore. Its primary aims encompass defining the

constraints of downhole pressure conditions and effectively orchestrating the

hydraulic pressure profile surrounding the annulus. Implicit in this definition is the

use of a single-phase drilling fluid treated to minimize flow friction losses.

Broadly speaking, Managed Pressure Drilling presents itself as a drilling approach

that empowers precise oversight of wellbore pressure dynamics.

MPD is a broad concept encompassing various strategies and equipment designed

to effectively control wellbore pressure. Its primary objectives are to prevent kicks,

lost circulation, and differential pressure sticking, all with the aim of reducing the

need for additional casing strings to reach the desired total depth.

This field of wellbore pressure management finds wide-ranging applications

within the drilling industry, offering solutions to issues like:

1. Reducing lost circulation occurrences.

2. Preventing the sequence of lost circulation followed by a kick.

3. Minimizing NPT associated with pipe differentially stuck.

4. Enabling drilling operations with total lost returns.

5. Enhancing drilling speed.

The primary objective of MPD is to prevent the continuous inflow of formation

fluids into the well [1]. Any unintended influx during operations is safely managed

through suitable processes. Additionally, MPD employs a range of tools and tech-

niques aimed at mitigating the risks and expenses linked to drilling wells with tight

mud window. This is achieved through proactive management of the annular

hydraulic pressure profile. MPD may encompass the control of various factors such as

back pressure, fluid density, fluid rheology, annular fluid level, circulating friction,

2

You might also like

- Society of Petroleum Engineers Nigeria Annual International Conference and Exhibition 2011Document12 pagesSociety of Petroleum Engineers Nigeria Annual International Conference and Exhibition 2011Eyituoyo OgbemiNo ratings yet

- API 618 Compressors1 PDFDocument0 pagesAPI 618 Compressors1 PDFAnonymous ffje1rpaNo ratings yet

- OTC-29054-MS Qualification of New Technologies in Subsea Processing 2018Document12 pagesOTC-29054-MS Qualification of New Technologies in Subsea Processing 2018HunterNo ratings yet

- Development of Technological Applications of Managed Pressure DrillingDocument9 pagesDevelopment of Technological Applications of Managed Pressure DrillingMehrnoosh ArefNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument30 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistshachitrung1603No ratings yet

- Managed Pressure Drilling-2Document1 pageManaged Pressure Drilling-2x4zzyjgdwwNo ratings yet

- A Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisDocument13 pagesA Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisMaulana Alan MuhammadNo ratings yet

- As The Search For Hydrocarbon Offshore Runs Deeper and Farther FromDocument11 pagesAs The Search For Hydrocarbon Offshore Runs Deeper and Farther Frommustafasavci900No ratings yet

- Drilling Optimization TechnologiesDocument9 pagesDrilling Optimization TechnologiesSergio RamirezNo ratings yet

- Automatic Control of Managed Pressure DrillingDocument6 pagesAutomatic Control of Managed Pressure DrillingSeong Ju KangNo ratings yet

- MECATRONICADocument7 pagesMECATRONICAdaniel_paz_zNo ratings yet

- Best Real Time Model Development of An Oil Well Drilling SystemDocument6 pagesBest Real Time Model Development of An Oil Well Drilling SystemProf YoupaNo ratings yet

- Early Kick Detection and Well Control de PDFDocument13 pagesEarly Kick Detection and Well Control de PDFAhmed AdilNo ratings yet

- CTDDocument6 pagesCTDNabihah ZulhairiNo ratings yet

- Intro To Manage Pressure Drilling: RAO Mubarak AliDocument12 pagesIntro To Manage Pressure Drilling: RAO Mubarak AliSohaib Rashid100% (1)

- Chapter-22 Role of Instrumentation Engineers in Ongc PDFDocument7 pagesChapter-22 Role of Instrumentation Engineers in Ongc PDFPradeep EapenNo ratings yet

- Beltranparedes 2010Document12 pagesBeltranparedes 2010Abdillah MuharramNo ratings yet

- Hussain 2014Document13 pagesHussain 2014aidaNo ratings yet

- Improving Real-Time Drilling Optimization Applying Engineering Performance From Offset WellsDocument15 pagesImproving Real-Time Drilling Optimization Applying Engineering Performance From Offset Wellsdrilling moneytreeNo ratings yet

- Advantages of Managed Pressure Drilling and The Recent Deployment of The Technology in Vietnam PDFDocument9 pagesAdvantages of Managed Pressure Drilling and The Recent Deployment of The Technology in Vietnam PDFYudha Yusriansyah100% (1)

- 1 s2.0 S1474667016453553 MainDocument9 pages1 s2.0 S1474667016453553 MainRoberto PalmerNo ratings yet

- Managed Pressure Drilling - What's in A NameDocument3 pagesManaged Pressure Drilling - What's in A NameAnonymous H9n5g3aaCENo ratings yet

- Managed Pressure Drilling (SPE MPD Seminar Abstracts)Document6 pagesManaged Pressure Drilling (SPE MPD Seminar Abstracts)Anonymous H9n5g3aaCENo ratings yet

- Petroleum Production Optimization: TechnologyDocument18 pagesPetroleum Production Optimization: TechnologybehnamjpNo ratings yet

- AbstractDocument1 pageAbstractAjay KumawatNo ratings yet

- Hard Rock TBM Performance PredictionDocument5 pagesHard Rock TBM Performance PredictionantoniusnoroNo ratings yet

- Jan4 DirectionalDocument2 pagesJan4 DirectionalAkshay MakhareNo ratings yet

- Scope of CFD in The Process IndustryDocument10 pagesScope of CFD in The Process IndustrydkrnambiarNo ratings yet

- Leak Detection A4 2013Document17 pagesLeak Detection A4 2013Sharon LambertNo ratings yet

- Close Loop System Enak Grayson2012Document12 pagesClose Loop System Enak Grayson2012Fikri Adji WirantoNo ratings yet

- Technology For Drilling EfficiencyDocument8 pagesTechnology For Drilling Efficiencysaa6383No ratings yet

- Petsoc 2004 020 PDFDocument9 pagesPetsoc 2004 020 PDFAhmed Ali AlsubaihNo ratings yet

- Managed Pressure Drilling Modeling & Simulation (A Case Study)Document8 pagesManaged Pressure Drilling Modeling & Simulation (A Case Study)Mejbahul SarkerNo ratings yet

- HPHT Well Construction With Closed-Loop Cementing (C-LC) TechnologyDocument16 pagesHPHT Well Construction With Closed-Loop Cementing (C-LC) TechnologyRafael_F_Antunes100% (1)

- Design and Calculation of A MPD Model With ConstanDocument6 pagesDesign and Calculation of A MPD Model With ConstanMejbahul SarkerNo ratings yet

- Master of Business AdministrationDocument7 pagesMaster of Business AdministrationAnand Prasad0% (1)

- Master of Business Administration - MBA Semester 2 MB0044 - Production & Operations Management - 4 Credits (Book ID: B1133) Assignment Set-1 60 MarksDocument30 pagesMaster of Business Administration - MBA Semester 2 MB0044 - Production & Operations Management - 4 Credits (Book ID: B1133) Assignment Set-1 60 MarksMeetu MasihNo ratings yet

- API 618 Compressors1Document2 pagesAPI 618 Compressors1Rhama WijayaNo ratings yet

- tapia2018Document10 pagestapia2018bayuNo ratings yet

- Optimization Drilling Parameters Performance During Drilling in Gas WellsDocument8 pagesOptimization Drilling Parameters Performance During Drilling in Gas WellsOmotayo Akinpelumi100% (1)

- Cathodic Protection ProjectDocument6 pagesCathodic Protection Projectjamal AlawsuNo ratings yet

- 22 - Di - 1302985 - CS - Digital ERA Saudi - WEBDocument2 pages22 - Di - 1302985 - CS - Digital ERA Saudi - WEBNew Auto TVNo ratings yet

- SPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationDocument6 pagesSPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationnabiNo ratings yet

- Australasian Society For Trenchless Technologies - Guidelines For HDDDocument44 pagesAustralasian Society For Trenchless Technologies - Guidelines For HDDdiogenes_el_cinicoNo ratings yet

- Wellplan Software: Key ValueDocument4 pagesWellplan Software: Key Valuebyed100% (1)

- Guidelines For Horizontal Directional Drilling Pipe Bursting Microtunnelling and PJDocument60 pagesGuidelines For Horizontal Directional Drilling Pipe Bursting Microtunnelling and PJBayu Setiawan100% (1)

- Production Well Testing With Non-Radiactive PDFDocument4 pagesProduction Well Testing With Non-Radiactive PDFHéctor Ramiro Pérez RodríguezNo ratings yet

- Mondali 2016Document9 pagesMondali 2016Super ExtraNo ratings yet

- Underground Piping TestingDocument2 pagesUnderground Piping TestingDouglas HillNo ratings yet

- 2021-Application of Artificial Intelligence and Machine Learning To Detect DrillingAnomalies Leading To Stuck Pipe IncidentsDocument11 pages2021-Application of Artificial Intelligence and Machine Learning To Detect DrillingAnomalies Leading To Stuck Pipe Incidentssobhan mohammadiNo ratings yet

- SPE/IADC 113682 MPD Planning: How Much Is Enough?Document8 pagesSPE/IADC 113682 MPD Planning: How Much Is Enough?Anonymous CLoxXdABNo ratings yet

- Automated Evaluation of Hole Cleaning Efficiency While Drilling Improves. Iptc-19809-MsDocument17 pagesAutomated Evaluation of Hole Cleaning Efficiency While Drilling Improves. Iptc-19809-Msمحمد مريف حسن الربعي (Mohammed M H Al Rubaii)No ratings yet

- New Choke Controller For Managed Pressure DrillingDocument8 pagesNew Choke Controller For Managed Pressure Drillingermaiez100% (1)

- Managed Pressure Drilling VietnamDocument27 pagesManaged Pressure Drilling VietnamVINCENTIUS ADVEN BRILIANNo ratings yet

- Dynamic-Topology-in-Water-Distribution-Networks_2014_Procedia-EngineeringDocument10 pagesDynamic-Topology-in-Water-Distribution-Networks_2014_Procedia-EngineeringHari YuliandraNo ratings yet

- Practical Solutions For Chalenging PipelinesDocument11 pagesPractical Solutions For Chalenging Pipelinesmajmor-1No ratings yet

- Spe-214579-Ms Rigless Solution in Replacement of Rig InterventionDocument8 pagesSpe-214579-Ms Rigless Solution in Replacement of Rig Interventionbagus918No ratings yet

- Corrosion Solutions For Gas Transmission Pipelines: Solution NoteDocument2 pagesCorrosion Solutions For Gas Transmission Pipelines: Solution NotePencari CahayaNo ratings yet

- MPD - High Performance and Reliability For MPD Control System Ensured by Extensive TestingDocument17 pagesMPD - High Performance and Reliability For MPD Control System Ensured by Extensive TestingGiang Nguyen NinhNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Project Management For Procurement Management ModuleFrom EverandProject Management For Procurement Management ModuleNo ratings yet

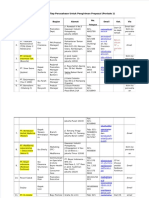

- Hasil Kontak Tiap Perusahaan Untuk Pengiriman Proposal (Periode 1)Document6 pagesHasil Kontak Tiap Perusahaan Untuk Pengiriman Proposal (Periode 1)Hartanto WirawanNo ratings yet

- Oil Sands 101 UpdateDocument36 pagesOil Sands 101 Updaterosemaryhere8649No ratings yet

- Prosper Software For Gas Lift System Design and SimulationDocument11 pagesProsper Software For Gas Lift System Design and SimulationRaunak AryanNo ratings yet

- CCUS in Indonesia IEA December 2023 1703689380Document17 pagesCCUS in Indonesia IEA December 2023 1703689380Rian AnugerahNo ratings yet

- ONGCAr 2017Document597 pagesONGCAr 2017kamaldharevaNo ratings yet

- Gas Authority of India Limited (Gail)Document15 pagesGas Authority of India Limited (Gail)19 CH 056 Vaishali VivekNo ratings yet

- Posting 100523Document8 pagesPosting 100523sameer bakshiNo ratings yet

- The Top Natural Gas Companies in The WorldDocument11 pagesThe Top Natural Gas Companies in The WorldVenkatrao VaraganiNo ratings yet

- Sui Southern Limited: GompanyDocument2 pagesSui Southern Limited: GompanyHomanam SisvyNo ratings yet

- Japon Sistema Electrico 2020Document20 pagesJapon Sistema Electrico 2020Marcelo GonzalezNo ratings yet

- Petrochemical For ExcelDocument29 pagesPetrochemical For Exceldisha sodaniNo ratings yet

- Biogas360 Event (Belgium in A Nutshell) - With LogoDocument14 pagesBiogas360 Event (Belgium in A Nutshell) - With LogolisbetNo ratings yet

- Drillships: BadrinathDocument5 pagesDrillships: BadrinathTemporiusNo ratings yet

- NGE Bio CNGDocument10 pagesNGE Bio CNGPulkit GargNo ratings yet

- Guidance On LNG - Bog MonitoringDocument6 pagesGuidance On LNG - Bog MonitoringsalemNo ratings yet

- Role of PNGRB in Oil and Gas IndustryDocument24 pagesRole of PNGRB in Oil and Gas IndustryrudrasaxenaNo ratings yet

- Natural Gas GeneratorDocument9 pagesNatural Gas GeneratorprakashNo ratings yet

- LNG-North-Dakota EN ARDocument2 pagesLNG-North-Dakota EN ARMario GutierrezNo ratings yet

- Nat LP Pipe SizeDocument1 pageNat LP Pipe SizeFranklin Daniel XalxoNo ratings yet

- Civil Designer CVDocument4 pagesCivil Designer CVPratikNo ratings yet

- List of Oil Field Acronyms (00000003)Document31 pagesList of Oil Field Acronyms (00000003)Htoo Htoo KyawNo ratings yet

- Directory: Eco Friendly GR NDocument171 pagesDirectory: Eco Friendly GR NTsunami IntelligenceNo ratings yet

- Petroleum - National Geographic SocietyDocument10 pagesPetroleum - National Geographic SocietyLiar LiarNo ratings yet

- Name of TraineeDocument6 pagesName of TraineeGab Beb HaNo ratings yet

- 189 Getting Gas Right Report PDFDocument49 pages189 Getting Gas Right Report PDFPiNo ratings yet

- FSRU Vs PipelineDocument7 pagesFSRU Vs PipelineAnkurSrivastavNo ratings yet

- Gujarat Gas, GSPC Gas AmalgamationDocument2 pagesGujarat Gas, GSPC Gas AmalgamationMedha SinghNo ratings yet

- Selecting The Right Field Development Plan For Global Deepwater Developments Richard D'Souza, Shiladitya Basu, Ray Fales Granherne A KBR CompanyDocument18 pagesSelecting The Right Field Development Plan For Global Deepwater Developments Richard D'Souza, Shiladitya Basu, Ray Fales Granherne A KBR CompanyFernando BorguettiNo ratings yet

- DNV GL Energy Transistion Outlook 2017 Oil Gas Lowres Single 3108 3Document76 pagesDNV GL Energy Transistion Outlook 2017 Oil Gas Lowres Single 3108 3tony starkNo ratings yet