Professional Documents

Culture Documents

Sdarticle 7

Sdarticle 7

Uploaded by

kmprabhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sdarticle 7

Sdarticle 7

Uploaded by

kmprabhaCopyright:

Available Formats

Nuclear Engineering and Design 236 (2006) 758769

Critical Facility for lattice physics experiments for the Advanced Heavy Water Reactor and the 500 MWe pressurized heavy water reactors

V.K. Raina a, , R. Srivenkatesan b , D.C. Khatri a , D.K. Lahiri a

a

Research Reactor Design & Projects Division, Bhabha Atomic Research Centre, Mumbai 400085, India b Reactor Physics Design Division, Bhabha Atomic Research Centre, Mumbai 400085, India Received 11 March 2004; received in revised form 26 September 2005; accepted 28 September 2005

Abstract Bhabha Atomic Research Centre (BARC), Mumbai, is embarking on a broad based program for thorium utilization in power production to achieve all-round capability in the entire thorium cycle. As a step in this direction, a low power Critical Facility is under construction at BARC. The facility will greatly contribute to the understanding and validation of the calculational models and nuclear data used in the design of thorium based Advanced Heavy Water Reactor. The facility is also designed to cater to the experimental requirements of future lattice studies related to 500 MWe pressurized heavy water reactors. This paper covers the basic design features, safety aspects and the planned experimental program of the new facility. 2006 Elsevier B.V. All rights reserved.

1. Introduction A low power Critical Facility is under construction as a part of the overall technology development program to support the design effort essential for evolution of improved nuclear reactor systems utilizing new design concepts and abundant reserves of thorium which have remained mostly untapped till now due to enormous challenges involved in their practical utilization for power generation. As a step in this direction, conceptual design and technical feasibility of the thorium fuel cycle based Advanced Heavy Water Reactor (AHWR) has been established and its detailed design is in an advanced stage of completion (Srivenkatesan et al., 2000a,b; Sinha et al., 2000). The AHWR is being designed for maximum power generation from thorium. The reactor has many inherent safety concepts. The design envisages using 54 pin MOX clusters with different enrichment of 233 U and Pu in Thoria fuel pins and a dysprosium displacer rod at the centre. The simulation of this 54 pin cluster with all its heterogeneity is very involved, wherein a circular cluster with a displacer rod is placed inside a circular pressure tube, which is located inside a calandria tube. Theoretical models developed to simulate the physical processes and

the geometrical details of the reactor including all the reactivity devices involve approximations in modeling, resulting in uncertainties. Similarly power peaking and void reactivity show signicant sensitivity to modeling. With a view to minimize these uncertainties, the need for a low power Critical Facility (CF) in which cold clean fuel can be arranged in a desired and precise geometry was felt essential. Such a facility will greatly contribute to understanding and validation of the physics design parameters and calculational models of AHWR which will include the basic multi-group cross-section libraries, lattice variables like K , Keff , pin power distributions, simulation of reactivity devices, core ux/power distribution, etc. Since fuel design is becoming increasingly more complex, the Critical Facility can cater to the experimental requirements of future lattice/core studies including pressurized heavy water reactors (PHWRs). 2. General design features The Critical Facility has been designed to facilitate study of different core lattices based on various fuel types, moderator materials and reactivity control devices. The reactor is designed for a nominal ssion power of 100 W with an average ux of 108 n/cm2 /s. The reactor can be operated at higher power levels of up to 400 W to obtain a neutron ux of 109 n/cm2 /s for short durations to facilitate special experimental campaigns. The

Corresponding author. Tel.: +91 22 25594608; fax: +91 22 25505311. E-mail address: vkrain@magnum.barc.ernet.in (V.K. Raina).

0029-5493/$ see front matter 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.nucengdes.2005.09.021

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

759

Fig. 1. Overall plan of reactor complex.

design provides enough exibility to arrange the fuel inside the core in a precise geometry at the desired pitch. Reactor criticality is achieved by the manual control of moderator level in the core. Initially, three types of cores using heavy water as moderator and reector will be studied. The three cores are based on different fuel types, i.e., (i) 19 pin natural uranium metal fuel clusters to constitute the reference core; (ii) 54 pin (ThPu) MOX/(Th233 U) MOX clusters to constitute the representative AHWR core; (iii) 37 pin natural uranium oxide fuel clusters to constitute the 500 MWe PHWR core. Salient design features of the facility are presented here. 2.1. Building layout The reactor is housed in a concrete reactor block of overall size 11.5 m 10.75 m 8.7 m. The concrete wall of the reactor

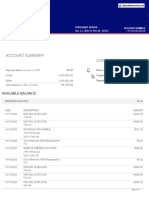

block provides shielding in the radial direction. Shielding in the axial direction is provided by two motor operated movable shield trolleys provided at the top. The reactor block is located inside a reactor building of overall size 35 m 18 m 21 m. The reactor hall is serviced by a 15/1 tonne electrical overhead traveling crane and is provided with personnel and vehicle entrances. An 18 m 15 m basement is provided on one side of the reactor block to house process equipment related to moderator and cover gas system. A 33 m 8 m 12 m high annex building is provided for housing control room, health physics unit, change room, laboratories and ofces. A 33 m 6 m 5 m high extension building adjacent to the reactor building houses the air compressor, ventilation system equipment and research laboratory. Fig. 1 gives the overall plan of the reactor complex and Fig. 2 gives the sectional view of the reactor building. 2.2. Reactor block The reactor tank, square box and the lattice girders which support the fuel and control assemblies are housed inside a cavity

760

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

Fig. 2. Sectional view of reactor building.

in the reactor block. Access to the reactor cavity from the reactor hall is through a lead shielded door provided in the reactor block. 2.2.1. Reactor tank The reactor tank, which accommodates the fuel, moderator and shut-off rods, is a 10 mm thick cylindrical aluminium tank of 3300 mm inside diameter and 5000 mm height. The tank is open at the top to facilitate connection with a square box through an elastomer expansion joint. The expansion joint between the reactor tank and the square box provides exibility for any mis-

alignment and takes care of thermal expansion of the reactor tank during reactor operation. The reactor tank is supported on an aluminium grid structure formed by joining fabricated aluminium I-sections. The empty spaces of the aluminium grid structure are lled with machined graphite blocks. All neutronic detectors and the startup source (optional) are located within the graphite blocks. The supporting I-sections are bolted to a carbon steel structure, which is anchored to and grouted into the oor of the reactor block cavity. The reactor tank is clamped to the grid support structure.

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

761

2.2.2. Lattice girder assemblies Lattice girder assemblies are designed to support the test fuel assemblies and reactivity control devices and offer the exibility of conguring the desired core lattice, at the required pitch. The system comprises of nine stainless steel girder assemblies to cater to the core conguration requirements of AHWR and PHWR experiments. Each girder assembly comprises of two 20 mm thick 300 mm deep and 3720 mm long stainless steel plates connected to each other by a distance piece and a carriage assembly at either end. Stainless steel bridge plates of 196 mm 190 mm 27 mm thick are clamped to the top of girder plates at the desired pitch to support the lattice assemblies. Each carriage assembly has two stainless steel rollers, which move in accurately machined grooves provided in the top ange of the rail beams. The lattice girder assemblies can be spaced as desired with the help of centre zero scale provided along the side of stainless steel rail beams. 2.2.3. Square box The square box houses the lattice girder assemblies. It is a leak-tight enclosure made of stainless steel and has overall dimensions of 4610 mm 4610 mm 1550 mm high in fully assembled condition. The bottom plate of the square box has a 3300 mm diameter opening in the centre to provide full access to reactor tank. The top plate of square box has a 3350 mm diameter opening at the centre to allow access to the lattice girders and the reactor tank. The opening is covered by a 25 mm thick revolving plate supported on a bearing, which in turn rests on the square box top plate. Four sealed oval shaped openings are provided on the revolving plate to provide access to all lattice positions in the reactor, when desired. A circular degree scale provided on the top plate of the square box facilitates for accurate positioning of the revolving plate to access a particular lattice position through one of the four openings. Flanged openings are provided in all sidewalls of the square box to provide leak-tight access of cables and cover gas piping connections. An oil seal is provided between the xed top plate of the square box and revolving plate to conne the cover gas within the square box and to avoid ingress of atmospheric air and moisture into the heavy water contained in the reactor tank. The oil seal is so designed that the cover gas pressure inside the square box can be maintained between +15 and 6 cm water column. Two 4000 mm long rail beams are clamped to the bottom plate of the square box at a centre to centre distance of 3600 mm, for support and safe transmission of fuel suspension system load to the square box support structure. The rail beams consist of fabricated I-beams with 8 mm deep accurately milled slots provided on top anges. The slots provided on the top anges of the rail beams act as guides for roller wheels provided in the carriage assembly of the lattice girders. 2.3. Moderator and cover gas system 2.3.1. Moderator system For the initial set of experiments heavy water acts as the moderator and reector. Nitrogen gas is used as the cover gas for

the heavy water. The system is designed to supply the required inventory of heavy water in a controlled manner to the reactor tank to attain reactor criticality for various core congurations/reactor experiments as per the researchers requirements. Since the reactor is operated at a very low power level, no dedicated core cooling system has been provided. The small amount of heat generated in the core is transferred to the moderator and cover gas and gets eventually dissipated to atmosphere by natural convection. A simplied ow diagram of the moderator and cover gas system is shown in Fig. 3. Heavy water from the dump tanks is pumped to the reactor tank through a supply line, which has been designed to ll the reactor tank at two different ow rates. The initial maximum pump-up rate of 300 lpm will be maintained till the moderator level in the reactor tank reaches a preset value based on the estimated critical height for the specic experiment. At moderator levels above the preset value, addition rate is restricted to a maximum of 100 lpm into the reactor tank. This ow restriction is to maintain the reactivity addition rate well below the permissible limits keeping in view the eff of the core. The lower ow rate is achieved by diverting the supply ow through a parallel line provided with a ow restricting orice by suitable valve manipulation. Two dump connections have been provided in the reactor tank, one at the bottom of the tank (total dump line) and the other at a height of 125 cm from the bottom of the tank (partial dump line) to facilitate dumping of the moderator to the dump tanks from the reactor tank. Two fast acting dump valves with opening time of less than 1 s are provided in parallel on the partial dump line to dump heavy water from the reactor tank at an initial rate of not less than 1000 lpm, on a reactor trip. Considering that only one of the two dump valves open on a reactor trip, the dump rate calculated for various critical heights is given in Fig. 4. A batch addition and a batch removal facility are incorporated in the system to permit addition or removal of exact quantity of moderator to or from the reactor tank. For this purpose, two tanks have been provided which are adequately sized to add or remove heavy water to effect a moderator level change of 1 mm in the reactor tank. Only one batch can be added or removed at a time. The number of batches that can be added during an operation is restricted to 10, whereas no restriction is placed on the number of batches during removal operation. Since these operations of addition and removal contribute to change in reactivity of the reactor, they are carried out with the reactor in sub-critical state. In order to ensure that the increase in moderator level is not more than 1 mm, the batch addition tank is provided with an overow line. System interlocks are provided in such a manner that at a time only one operation, i.e., batch addition or batch removal, is possible. Three dump tanks each of 12.5 m3 capacity are provided to hold the entire inventory of moderator in the system. During normal operation, only two of the three dump tanks are kept in service in a manner that the specied quantity of moderator authorized for a particular core conguration will only be stored in these two tanks. The remaining quantity of moderator available in the system will be stored and locked in the third tank.

762

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

Fig. 3. Simplied ow diagram of moderator and cover gas systems.

The heavy water system chemistry is maintained by recirculating the heavy water through a deuterized ion-exchanger bed and a lter. For carrying out experiments at elevated moderator temperatures up to 60 C, an electrical heater has been provided at the

pump discharge. Initially, the heavy water in the dump tanks is recirculated using the heavy water pump. The heater in the circuit is switched on and the recirculation is continued until the temperature of the heavy water at the heater inlet reaches the specied value and then the heavy water from the dump tanks is transferred to the reactor tank as per normal procedure till the critical height is achieved. The moderator temperature is maintained at a steady value by continuous addition of heavy water into the reactor tank at a reduced rate with the heater on line and removing the heavy water at the same rate from the reactor tank by adjusting the control valve in the partial dump line so that the level in the reactor tank is maintained constant. The heater power will be controlled in such way that the heavy water temperature in the reactor tank in maintained constant. 2.3.2. Cover gas system The nitrogen cover gas system is designed to maintain a dry gas blanket at a pressure of 58 cm water column (gauge) in all the tanks containing heavy water to prevent degradation due to ingress of atmospheric moisture. A nitrogen gas tank is provided to supply nitrogen gas to the cover gas system through a set of pressure reducing valves to compensate for any gas leakage from the system. Two banks of nitrogen cylinders are connected to the gas tank for make up through a molecular sieve dehumidier to reduce the moisture content in the nitrogen gas to a dew point of about 30 C. A 100 NB line connects the reactor tank to the dump tanks to ensure proper gas balance during lling, dumping or draining of the reactor tank. An oil relief pot is provided to relieve the pressure in case system pressure exceeds 12 cm water column (gauge) and also to break the vacuum in case system pressure drops below 5 cm water column (vacuum).

Fig. 4. Variation in dump rate from critical height to dump level for different cores.

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

763

Fig. 5. Operational ranges and overlaps of nuclear channels.

A nitrogen drying circuit has been provided to facilitate drying of the reactor tank, square box and connected piping. The same circuit is used for drying and recovery of heavy water from equipment/components like ion-exchanger, lter cartridge, etc., as and when required. 2.4. Control and instrumentation system 2.4.1. Neutronic power measurement For reliable neutronic power measurement and protection from source range to power range, neutron detectors and associated electronics, working on diverse principles and having sufcient redundancy, have been used. These detectors are located in the graphite llers below the reactor tank. Since there is substantial difference in expected critical heights of AHWR and PHWR core congurations, the neutron detectors have been located below the core, to minimize the effects of variation of critical height on the incident neutron ux seen by the detectors. For reactor start-up, two pulse channels are provided with boron-lined proportional counters. Each of these two pulse channels provides independent trip on high log counts through the reactor protection system. For power measurements and protection in intermediate range and power range, six dc channels are provided, based on boron coated uncompensated ion chambers. One of the detectors is connected to a multi-range dc (MRDC) channel, two are connected to log/linear safety channels and the remaining three are connected to log-linear channels for reactor regulation. The MRDC channel has seven ranges, having full-scale values of 0.5 mW to 500 W. Each log-linear channel used for safety or regulation function provides reactor power information on six

decade logarithmic scale covering a range of 0.5 mW to 500 W. Two log-linear safety channels are exclusively used for reactor protection, whereas the other three log-linear channels are used to provide log-rate and linear power signals for manual regulation of the reactor power. Range overlap diagram of the neutronic instrumentation in various power ranges is given in Fig. 5. 2.4.2. Reactor regulation system Reactor start-up and approach to criticality are achieved by providing an inow of moderator into the reactor tank using the moderator pumps at two discrete ow rates. A fast ll rate of 300 lpm is used till the moderator level reaches a preset value beyond which the inow is restricted to a maximum of 100 lpm through suitable interlocks to restrict reactivity addition rate to well below the acceptable limit depending upon the eff of the core. The moderator addition/removal is continued in steps till the reactor becomes critical and the desired power level is reached. The moderator inventory is then locked in the reactor tank to ensure stable power. Power regulation can also be achieved under dynamic conditions by providing constant inow together with variable outow through manually regulated control valve. 2.4.3. Comparator and error channel The three log-linear power signals are compared with each other in the comparator channel. There are three comparators for comparing each channel with the other two and a fourth module for averaging the healthy power signals. If the signal differs beyond a preset value with the signals of the other two channels, then comparator rejects the power signal and the average output of the other two healthy channels is generated.

764

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

The error channel receives the average linear power output from the comparator channel and the demand power from the set point cursor and generates an error output. A reactor trip is provided if the error output exceeds 10%. 2.4.4. Protection system Six fast acting cadmium shut-off rods are used as primary shutdown system. The shut-off rods are normally parked outside the core region. The total worth of the shut-off rods is about 80 mk but can vary depending on the core conguration. On reactor trip, the absorber elements of the shut-off rods get detached from their drive mechanisms allowing their free fall into the core by gravity inside an empty guide tube. Shut-off rods can be withdrawn from the core, only when the trip is reset, one at a time and parked in their normal parking positions. Withdrawal time of each shut-off rod is 132 s. The drive mechanism consists of a three phase ac electrical motor, worm and worm gear drive, an electromagnetic clutch, a set of spur gears, a sheave to translate rotary into linear motion, a hydraulic dashpot, cam operated limit switches to indicate rod end limits and a precision potentiometer for rod position monitoring. The clutch is kept in energized condition and self-locking feature of the worm gear holds the rod in its parking position. In case of reactor trip or power supply failure or any other emergency condition, the clutch is de-energized making rods to fall freely into the core and bring the reactor to sub-critical condition. Towards the end of the fall, the rod is decelerated to bring it to a smooth stop by using a set of pick-up rings and a hydraulic dashpot, which gets engaged when 90% travel is completed. The mechanism also provides a mechanical stopper, in case of failure of the dashpot. Fig. 6 gives the general arrangement of the drive mechanism. The rod drop time prole is given in Fig. 7. The protection system logic makes use of various trip parameters generated from the neutronic and process instrumentation signals. The trip parameters have been segregated into two distinct groups in order to provide two diverse chains for protection action and each group is capable of independently tripping the reactor under various postulated events. The entire protection system has been designed to work on fail safe philosophy. 2.4.5. Other instrumentation systems Adequate conventional instrumentation is provided to monitor and record the process parameters such as ows, pressures, temperatures, levels, etc., and to generate trips/alarms whenever necessary. All important neutronic and process parameters are recorded and logged on a data logger. Radiation instrumentation is provided in various areas of the reactor to monitor status of gamma and neutron radiation levels for generating alarm/reactor trip whenever the level exceeds a preset value. 3. Experimental program 3.1. Reference core The reference core is constituted by 19 pin natural uranium metallic fuel clusters moderated by heavy water to establish a

Fig. 6. General assembly of shut-off rod head gear.

Fig. 7. Drop prole of shut-off rod.

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

765

reference lattice with well established physics characteristics. The reference core is laid in a 7 7 array with three added on positions on each side at a square pitch of 27 cm. The effective core radius is 119 cm with an additional radial heavy water reector thickness of 46 cm. Out of the total 61 lattice positions, 55 positions will be loaded with 19 pin metallic natural uranium fuel clusters and the remaining 6 positions will accommodate the shut-off rods. Additionally one position will be earmarked for a low worth absorber rod. The expected critical height of the reference core is 177 cm including an axial (bottom) heavy water reector thickness of 30 cm. The level coefcient of reactivity of this core is estimated to be 0.987 mk/cm at the critical height. The total worth of the shut-off rods is 74.4 mk. 3.2. Experimental studies Since the AHWR is based on thorium fuel cycle, the neutronic simulation codes and the nuclear data used for isotopes of thorium cycle need to be validated satisfactorily. Our evaluations show discrepancies in the nuclear data and the calculation methods used for thorium based system. It is well known that the nuclear data for isotopes of thorium cycle are less accurately known compared to the isotopes of UPu cycle (Srivenkatesan et al., 2000a,b; Ganesan, 2004; Shiroya et al., 1999). The sensitivity analysis performed for AHWR clusters with various multi-group libraries obtained through the WIMS Library Update Project (IAEA, 2002) shows spread of nearly 20% variation in void reactivity of the initial fuel (and increases to nearly 30% at higher burn-ups) (Kumar et al., 2002). Typical calculations performed for the Critical Facility with AHWR clusters shows that the critical height can vary by as much as 7 cm (nearly 8 mk of reactivity) between different data libraries. Shiroya et al. (1999) have made similar observations based on the analysis of the Kyoto University Critical Assembly of Japan (Shiroya et al., 1999). Thus, both integral and differential parameters show signicant sensitivity to nuclear data. Detailed reaction rate and spectrum measurements are planned in the Critical Facility for sorting out these issues. Another example is analysis of natural thoria bundles irradiated in our pressurized heavy water reactors. Natural thoria bundles are being used for achieving ux attening in the initial core of 220 MWe PHWRs, from Kakrapar Atomic Power Station, Unit-1 onwards (Balakrishnan and Kakodkar, 1994). A discharged thoria bundle from one of the PHWRs was reprocessed and analyzed for 232 U, 233 U, 234 U, etc., content (Mukherjee et al., 2003). The theoretical models, while predicting the various bred uranium isotopes within 10%, under predicted the 232 U content by nearly a factor of ve. This was found to be due to the effective one group cross-section for the (n, 2n) cross-section of thorium used in the analysis code. The accuracy of production rates of 233 U, 232 U, etc., also depends upon the simulation of ux prole around the thoria bundles. Several theoretical models have been investigated at the lattice level. Towards resolving the anomalies, experiments are planned with special instrumented 19 pin thoria clusters having same dimensions as the natural uranium reference clusters. Flux prole in and around the clus-

ter, reaction rate and neutron spectrum measurements within the fuel pins will be performed for better insight. 3.3. AHWR representative core The AHWR representative core of the Critical Facility is a variant of the reference core, wherein, initially the central nine natural uranium clusters will be replaced by 54 pin (ThPu)/(Th233 U) oxide clusters to simulate the initial AHWR core. Replication of the initial/equilibrium AHWR core entirely by (PuTh)/(Th233 U) oxide fuel in the Critical Facility is not considered economical in view of the ssile material inventory requirements. However, the central cluster in the representative core is expected to have the spectrum very close to actual AHWR spectrum. In order to facilitate extensive measurements, the central cluster is designed for the removal of pins from the cluster, placement and retrieval of foil detectors from the removable pins and features to ll/drain the desired uid into/from the cluster for experiments with different coolants as required. Typical crosssection of the experimental AHWR fuel cluster to be used in the Critical Facility is given in Fig. 8. The representative AHWR core is constituted by a mix of natural uranium and (PuTh) oxide/(233 UTh) oxide fuel clusters laid in a square pitch of 27 cm. Of the total 62 lattice positions, the central 9 positions (in 3 3 array) will be loaded with composite/(PuTh) clusters or a combination of the two fuel types. However, at any given time, only nine such clusters will be loaded in the core. Of the remaining 53 positions, 46 positions will be loaded with 19 pin natural uranium clusters, 6 positions will be dedicated to shut-off rods and 1 position will be used for a low-worth absorber rod. The critical height of the core using nine composite type AHWR fuel clusters is estimated to be 153.8 cm. The level coefcient of moderator is estimated to be 1.4 mk/cm near critical height. The total worth of shut-off rods is estimated to be 68 mk. 3.3.1. Experimental studies The studies will involve the critical height measurements for various lattice pitches involving both (PuTh) oxide and composite (PuTh) and (233 UTh) oxide fuel clusters to arrive at the most optimum lattice pitch. Measurements of level coefcient of reactivity for the core will be carried out using batch addition/removal facility and the absorber rod. Measurement of reaction rates, neutron spectrum, ux disadvantage factors and epithermal ux ratios will be established through activation foils located within the AHWR test clusters. Studies will be carried out to establish the optimum dysprosium enrichment in the central displacer rods of the AHWR fuel as also reaction rate measurements to minimize the uncertainties arising out of nuclear data used for dysprosium and the approximations in the modeling. Being a boiling light water cooled heavy water moderated reactor, void reactivity is an important parameter in the AHWR. Different void fractions will be simulated in the AHWR experimental lattices to facilitate measurement of void reactivity.

766

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

3.4. PHWR core The PHWR core is constituted by 37 pin natural uranium oxide fuel clusters laid in a square pitch of 28.6 cm using heavy water as the moderator. The core will have a total of 70 lattice positions of which 63 positions will be loaded with fuel, 6 positions will be dedicated to the shut-off rods and 1 position will be for a low worth absorber rod. The core will have an effective radius of 134 cm with an additional heavy water radial reector of 31 cm. The critical height of the core is estimated to be 220 cm. Level coefcient of reactivity for this core is estimated to be 0.43 mk/cm at the critical height. The total worth of the shut-off rods is 95.6 mk. 3.4.1. Experimental studies For extending the life of our limited uranium resources, use of (Nat.U + Pu) MOX, (Dep.U + Pu) MOX, etc., is being contemplated for use in the 500 and 220 MWe Indian PHWRs. However, a major problem related to void reactivity, which is positive in PHWRs, remains an area of concern vis-` -vis assured design a margins, especially margin to prompt criticality. The Critical Facility will be extensively used to perform such measurements and validate computational models used in the PHWR safety analysis. The facility is also ideally suited to study loosely coupled cores such as the 540 MWe PHWR by simulating the decoupling (through water curtains, etc.). Dynamic experiments with such an arrangement will also be used to generate valuable data to benchmark control stability evaluations. 4. Reactor safety 4.1. Reactor shut-down devices The Critical Facility is provided with two independent shutdown systems, viz. the shut-off rods and the moderator dump. Adequacy of each system to achieve desired sub-criticality for all the three cores has been established. 4.1.1. Shut-off rods Fast shut down of the reactor on a trip signal is achieved by gravity fall of a set of six cadmium (Cd encased in Al) shutoff rods into the core. The shut-down system has been designed to reliably provide sufcient negative reactivity insertion within a specied time for fast reduction of reactor power to render the reactor adequately sub-critical on reactor trip following any anticipated operational transients and postulated accident conditions. On a reactor trip, the shut-off rods complete 90% of the total travel in less than 1.5 s. The remaining 10% drop is damped. The negative reactivity inserted as a function of time by the drop of different combination of shut-off rods in the core with AHWR fuel is plotted in Fig. 9. The result shows that even three shut-off rods, in the worst combination, provide sufcient negative reactivity and the reactor can be shut down effectively. In the safety analysis, it has been conservatively assumed that, on a reactor trip, only ve shut-off rods are available and the maximum worth rod is unavailable. It may also be noted

Fig. 8. Cross-section of an AHWR fuel cluster.

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

767

4.2. Safety analysis The two possible transients that can add positive reactivity are: (a) uncontrolled moderator pump-up beyond critical height and (b) unintended withdrawal of absorber rod from a critical core. Of these, the former can add positive reactivity at a faster rate (0.1 mk/s) corresponding to moderator pump-up rate of 330 lpm with both the moderator pumps in operation while the latter can add reactivity at the rate of 0.02 mk/s. Total reactivity that can be added is also higher in case of uncontrolled moderator pump-up (up to 4.2 mk) compared to absorber rod withdrawal (1.6 mk in 76 s). The transient due to uncontrolled moderator pump-up is considered to be the enveloping scenario and is discussed here. The administrative control on moderator inventory restricts the quantity of heavy water that can be pumped into the reactor tank to a quantity equivalent to 3 cm of heavy water above the estimated critical height. The reactor is provided with independent safety and regulating channels which monitor the reactor neutronic power via their respective dedicated ion chambers. There are two safety channels and each channel generates its own overpower and log rate trips. Regulating system consists of three channels and generates two out of three coincidence mean power, overpower and log rate trips. In all, seven neutronic parameters provide protection during uncontrolled moderator pump-up transient. The values for the AHWR and uranium metal fuel are estimated as 2.58 and 7.08 mk, respectively. The core average is weighted with respect to the ssion rates in the AHWR lattice and the reference lattice and the effective value is estimated as 5.96 mk. However, conservatively, the prompt neutron lifetime of the AHWR lattice, i.e., 3.65 104 s, is considered for the entire core. Similarly the fuel temperature coefcient of reactivity considered for the analysis was also for the AHWR lattice, i.e., 1 105 mk/ C. The transients are simulated with a point kinetic code assuming average fuel temperature model without any heat transfer as no dedicated cooling is provided to the fuel. All the heat produced is retained within the fuel pins only. The reactor shut down is achieved by assuming that only three shut-off rods are available for shut-down action. Considering that the transient is initiated at 1 W operation of the reactor, the reactor will trip on high log rate (6% s1 ) at 15 s from the incident. The peak power reached is 1.78 W and the total energy released during the incident is 25.3 J. The reactivity added is observed to be 1.5 mk. If the rst trip on high log rate is neglected, the second trip on high linear power (at 55 W) will be generated at 41 s. The reactivity added is 3.6 mk. The peak power reached is 65.6 W and the total energy released during the incident is 452 J. Assuming that the reactor has not tripped on the second signal also, the third trip signal initiated on high linear power (at 110 W) will trip the reactor. This trip setting will be reached at 44 s from the incident. The reactivity added is 4.19 mk. The reactor reaches a peak power of 154.4 W and the total energy release is 913 J. Assuming that the transient is initiated at 100 W operation of the reactor, it is observed that the rst trip signal is generated on high linear power (at 110 W) in 5 s. The reactor reaches a peak power of 112.7 W and about 903 J energy gets released. The reactivity added is 0.5 mk. Ignoring the rst trip, the second

Fig. 9. Shut-off rod reactivity worth vs. time.

that in the safety analysis, no credit has been taken for the negative reactivity introduced by shut-off rods beyond 90% insertion. 4.1.2. Moderator dump On a reactor trip signal, in addition to the insertion of the shut-off rods, moderator is also dumped from the reactor tank up to a level of 125 cm (dump level) by the opening of two fast acting dump valves. Even if one of the dump valves fails to open on demand, the desired initial dump rate of 1000 lpm is achieved. The dump level has been chosen to provide a shutdown margin of at least 50 mk independent of the shut-off rods in the most reactive core. Dump reactivity as a function of time from the initial critical heights for the three cores is shown in Fig. 10. In order to appreciate the effectiveness of the relatively slow acting moderator dump as a shut-down device, analysis has also been carried out with moderator dump as the only available shut-down device in the reactivity transients considered in safety analysis.

Fig. 10. Dump reactivity vs. time for the three core conguration.

768

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

In all these transients it is seen that of the six shut-off rods the least reactive bank of three shut-off rods or moderator dump is adequate to terminate the transient safely. Though the peak power and total energy release is signicant, the rise in fuel temperature is marginal due to the large fuel inventory. 5. Radiological safety Shielding provisions have been made in conformity with the requirements of the regulatory guidelines to ensure that the dose rate in normally occupied areas is less than 1 Sv/h. Entry restrictions are followed where the dose rate exceeds 1 Sv/h. Specially designed embedments and network of trenches have been provided for routing services to and from the reactor block to minimize radiation streaming during reactor operation. 5.1. Radiological hazards of 233 U fuel

Fig. 11. Uncontrolled moderator pump-up transient initiated at 1 W reactor power (reactor trip at 110 W).

trip signal is generated on high log rate (6% s1 ) at 16 s. Reactivity added to the system is 1.6 mk. The peak power reached is 187.9 W and the total energy released is 2546 J. Assuming that both the above signals failed to trip the reactor, the third signal on high linear power (at 550 W) gets generated at 29 s. The reactivity added to the system by this time is 2.8 mk. About 7565 J energy is released and the peak power seen by the reactor is 650 W. The results of this analysis are given in Figs. 11 and 12. Similar transient analysis was also carried out assuming transient termination by moderator dump at a uniform rate of 1000 lpm ignoring the shut-off rods. The results show that although the peak power is slightly higher than the corresponding value when reactor is tripped by three shut-off rods, the minimum reactor period and maximum reactivity added remain almost the same. The total energy released in this case is higher due to the slower rate of addition of negative reactivity.

is an alpha emitter (4.823 MeV) having a half life of 1.6 104 years, the specic activity being 9.5 mCi/g. In addition, 233 U contains minute quantities of 232 U formed through (n, 2n) reaction during irradiation of 232 Th. 232 U is also an alpha emitter with half life of 72 years having much higher specic activity than that of 233 U. The daughter products in the 232 U chain, i.e., 212 Bi (half life: 60.6 min), 212 Pb (half life: 10.6 h) and 208 Tl (half life: 3.1 min), are high energy gamma emitters and are of concern in handling of 233 U fuel. Calculations carried out for the estimation of radiation eld expected in unirradiated AHWR fuel assemblies indicate a radiation eld of 0.160.92 Gy/h for 500 ppm content of 232 U for an elapsed time of 90 days and 2 years, respectively, after separation. Thus, the radiation eld on the 233 U fuel depends on the 232 U content and the time elapsed after separation of uranium from thorium. A suitable combination of the above factors is worked out to evaluate the complexities in the shielding considerations and occupational dose likely to be incurred during fuel handling. The dose rate expected for a fresh fuel cluster is 3.46 mGy/h. 5.2. Exposure control Since the reactor does not have any beam holes or facility for isotope production, the source of occupational exposures will be mainly from the fuel handling and to a minor extent from the moderator system clean up facilities. The exposure (external and internal) will be controlled so that neither the total effective dose nor the total equivalent dose to relevant organs or tissue will exceed the dose limits prescribed by Bhabha Atomic Research Centre (BARC) Safety Council (BSC). Occupational dose limits as prescribed by BSC will be enforced. The external exposure of radiation workers will be measured by thermo-luminescent dosimeter and direct reading dosimeters. Internal exposures are controlled by applying the secondary dose limits as prescribed through annual limit of intake/derived air concentration. Evaluation of potential inhalation hazards will be carried out by air sampling for 239 Pu/233 U and cold nger sampling for tritium. A program for control of area/equipment contamination will be in place.

233 U

Fig. 12. Uncontrolled moderator pump-up transient initiated at 100 W reactor power (reactor trip at 550 W).

V.K. Raina et al. / Nuclear Engineering and Design 236 (2006) 758769

769

5.2.1. Exposure control in fuel handling operation AHWR fuel cluster handling calls for extensive radiological measures and surveillance. To enable safe handling of the fuel pins, the pin has been designed in a manner to provide axial shielding by extending the length of the fuel pin by 1 m and lling this portion with stainless steel pellets. With the provision of this axial shielding, dose rate is expected to be reduced to manageable levels enabling the handling of the fuel pins at the top of the fuel cluster. The AHWR fuel cluster will be transported to the reactor hall in a shielded ask mounted horizontally via the vehicle entrance door. The ask is adequately designed to ensure that radiation eld on contact does not exceed 2 mGy/h. The ask will be made vertical with the help of the reactor hall crane and shifted to the assembly station using a specially fabricated gadget. After attaching the top extension assembly to the cluster, the fuel assembly can either be transferred to 1 of the 19 storage positions in the pile block or directly loaded into the reactor core. The fuel storage cavities provided in the biological shield concrete for interim storage are also provided with nominal induced air ow to ensure that there is no ingress of air from fuel storage cavities to the reactor hall environment. As and when required, these fuel clusters can be transferred with the help of a shielded ask from the storage cavities and lowered in the desired pile position with the help of the overhead crane. Since only a limited number of fuelling and defuelling operations involving AHWR fuel clusters containing 233 U are envisaged in the life time of the reactor, no mechanized fuel handling facilities are provided. The external exposure control will be based on the distance and time principles. Radiological safety adherence by use of proper personnel monitors and dose rate estimation, assessment of air concentration and enforcement of time and distance will be employed to reduce personnel exposures in fuel handling. 5.2.2. Internal exposure control The likely source of internal exposure is tritium resulting from the leaks in the moderator system. Based on an average neutron ux of 2.8 108 n/cm2 /s in heavy water moderator region of the reference core, at a power level of 100 W, the saturation tritium activity in the moderator system is estimated to be 7400 Bq/ml over the years. The tritium concentration level will be much less than the saturation value in the initial years of reactor operation. The air concentration due to minor leaks in the moderator system will not be of much signicance. However, during maintenance jobs or repair jobs of moderator system, need for proper respiratory protection may be felt. A few locations will be provided with fresh air supply lines in the basement of the reactor for using airline respirators. Spot air samples will be routinely collected using high volume air samplers in the reactor hall and other potential areas for rapid assessment of 239 Pu and 233 U. Based on the experience of air monitoring, routine assessment of activity concentration, a continuous Pu/U-in-air monitor is proposed to be installed.

5.3. Radiation monitoring instrumentation Three categories of radiation monitoring instruments have been provided. They are as follows: (i) Reactor radiation instruments. (ii) Area radiation monitors. (iii) Health physics laboratory instruments. The reactor radiation instruments are provided at various areas of the reactor to monitor the status of gamma and neutron radiation levels. In addition to providing the real time information on the radiation status in various areas, the instruments also generate necessary alarms and reactor trip in case the radiation levels exceed the prescribed limits. 6. Concluding remarks The various experimental studies planned to be carried out at the Critical Facility will provide the necessary inputs for the validation of the physics design of the Advanced Heavy Water Reactor. The facility will also be used to conduct reactor physics experiments for the 500 MWe and other future pressurized heavy water reactors. References

Balakrishnan, K., Kakodkar, A., 1994. Optimization of the initial fuel loading of the Indian PHWR with thorium bundles for achieving full power. Ann. Nucl. Energy 21, 19. Ganesan, S., 2004. New reactor concepts and new nuclear data needed to develop them. In: International Conference on Nuclear Data for Science and Technology, ND-2004, Santa Fe, USA. IAEA, 2002. WIMS Library Update Project, http://www-nds.iaea.org. Kumar, A., Kannan, U., Srivenkatesan, R., 2002. Sensitivity analysis for AHWR fuel cluster parameters using different WIMS Libraries. Ann. Nucl. Energy 29, 19671975. Mukherjee, S., et al., 2003. Theoretical and experimental analysis of irradiated thorium bundle from KAPS-2. In: 8th International Conference on CANDU Fuel, Ont., Canada. Shiroya, S., Unesaki, U., Misawa, T., 1999. Assessment of 232 Th nuclear data through critical experiments using the Kyoto University Critical Assembly (KUCA). In: Technical Committee Meeting on Thorium Fuel Utilization: Options and Trends, Tecdoc-1319, IAEA, Vienna, pp. 237248. Sinha, R.K., Kushwaha, H.S., Agarwal, R.G., Saha, D., Dhawan, M.L., Vyas, H.P., Rupani, B.B., 2000. Design and development of AHWRthe Indian thorium fuelled innovative nuclear reactor. In: Annual Conference of Indian Nuclear Society (INSAC-2000), vol. II, Mumbai, India, pp. 81106. Srivenkatesan, R., Kumar, A., Kannan, U., Raina, V.K., Arora, M.K., Ganesan, S., Degwekar, S.B., 2000a. Physics considerations for utilisation of thorium in power reactors and subcritical cores. In: Annual Conference of Indian Nuclear Society (INSAC-2000), vol. II, Mumbai, India, pp. 21 50. Srivenkatesan, R., Kannan, U., Kumar, A., Ganesan, S., Degwekar, S.B., 2000b. Indian Advanced Heavy Water Reactor for Thorium Utilisation and Nuclear Data Requirements and Status. AGM on Long Term Needs for Nuclear Data Development INDC (NDS), vol. 428. IAEA, Vienna, pp. 145161.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ClearTax Business DeckDocument11 pagesClearTax Business DeckAnonymous H8AZMsNo ratings yet

- Pope Mac Series AmpilifiersDocument9 pagesPope Mac Series AmpilifiersFikri HidayatNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TFA Course For Foremen & QC TechnDocument39 pagesTFA Course For Foremen & QC TechnPrabhu RajalingamNo ratings yet

- Convergence of NM and Modified Newton Ralphon MethodDocument15 pagesConvergence of NM and Modified Newton Ralphon MethodkmprabhaNo ratings yet

- Applications of Limit Load Analyses To Assess The Structural Integrity of Pressure VesselsDocument12 pagesApplications of Limit Load Analyses To Assess The Structural Integrity of Pressure VesselskmprabhaNo ratings yet

- Kiefner & Associates, Inc. Pipe Assessment Spreadsheet DocumentationDocument8 pagesKiefner & Associates, Inc. Pipe Assessment Spreadsheet DocumentationkmprabhaNo ratings yet

- Validation of The Asme B31G and The Rstreng Methodologiies For Piipe Materiial X70 // L485 Asme B31G Calculation MethodDocument1 pageValidation of The Asme B31G and The Rstreng Methodologiies For Piipe Materiial X70 // L485 Asme B31G Calculation MethodkmprabhaNo ratings yet

- FMDS0701 PDFDocument42 pagesFMDS0701 PDFBharat VaajNo ratings yet

- MalaEmuSetup-v1 3Document46 pagesMalaEmuSetup-v1 3monkiki9024100% (1)

- LECO Evacuated Pin TubesDocument2 pagesLECO Evacuated Pin TubesBoris ChicomaNo ratings yet

- WMCC2020 Draft Program25NOVDocument2 pagesWMCC2020 Draft Program25NOVDino RatnaweeraNo ratings yet

- Remark Office OMR Demo Tutorial PDFDocument19 pagesRemark Office OMR Demo Tutorial PDFCristian NiculitaNo ratings yet

- Elastomeric Seals and Materials at Cryogenic TemeraturesDocument81 pagesElastomeric Seals and Materials at Cryogenic Temeraturesjohndoe_218446No ratings yet

- AHG PackagesDocument25 pagesAHG PackagesKasinadh SongaNo ratings yet

- BankDocument7 pagesBankSheeza NoorNo ratings yet

- Ball Valve TJ (21 Sep 16)Document24 pagesBall Valve TJ (21 Sep 16)TeukuJoharNo ratings yet

- Fluid Phase Equilibria, 87 (1993) 133-152Document20 pagesFluid Phase Equilibria, 87 (1993) 133-152Gaurav KunduNo ratings yet

- EBTANASDocument6 pagesEBTANASSri HandayaniNo ratings yet

- P AIn Analog InputDocument64 pagesP AIn Analog Inputcarbono980No ratings yet

- Case Fact LogDocument57 pagesCase Fact LogdamarlamcaNo ratings yet

- Environmental Friendly Two-Stroke Marine Diesel Engine, "MITSUBISHI UEC Eco-Engine"Document8 pagesEnvironmental Friendly Two-Stroke Marine Diesel Engine, "MITSUBISHI UEC Eco-Engine"Ahmet Serdar KarakurtNo ratings yet

- OMNIBUS SWORN CERTIFICATION NewDocument1 pageOMNIBUS SWORN CERTIFICATION NewPaul Patrick GuanzonNo ratings yet

- Rockmax DTH Hammer - Ql6Document1 pageRockmax DTH Hammer - Ql6Raul S. CotrinaNo ratings yet

- Learning From Failures: Case StudiesDocument71 pagesLearning From Failures: Case Studiesyedida v r aviswanadhNo ratings yet

- Premier Guitar 022017Document244 pagesPremier Guitar 022017franekzapa100% (3)

- MSDS - Union - I - Ni - 1 - MoCr - (EU) PDFDocument6 pagesMSDS - Union - I - Ni - 1 - MoCr - (EU) PDFEswaranNo ratings yet

- PowerwxbillsDocument2 pagesPowerwxbillsMaruli SimbolonNo ratings yet

- Playstation 4: Marketing Plan PresentationDocument18 pagesPlaystation 4: Marketing Plan PresentationJohn JacobNo ratings yet

- 2011 HSC-I Safety AnchorDocument3 pages2011 HSC-I Safety AnchorDifa LiuNo ratings yet

- TFP1320 03 2004Document14 pagesTFP1320 03 2004kaien13No ratings yet

- LG Lavadora TormDocument43 pagesLG Lavadora TormpasantitoNo ratings yet

- Chapter 2Document17 pagesChapter 2shabbirjamali0% (1)

- Dvpes2 ManualDocument10 pagesDvpes2 Manualmarie1320No ratings yet

- 1Document2 pages1Giang ĐinhNo ratings yet