Professional Documents

Culture Documents

Ic Filling Systems 2pp A4 Microblock 662 Semi Automatic 2022 Web

Ic Filling Systems 2pp A4 Microblock 662 Semi Automatic 2022 Web

Uploaded by

Ivan KatančićOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ic Filling Systems 2pp A4 Microblock 662 Semi Automatic 2022 Web

Ic Filling Systems 2pp A4 Microblock 662 Semi Automatic 2022 Web

Uploaded by

Ivan KatančićCopyright:

Available Formats

NEW 662 COMPACTBLOCK

NEW COMPACTBLOCK

SEMI-AUTOMATIC

SEMI - AUTOMATIC COUNTER-PRESSURE

COUNTER - PRESSURE RINSER-FILLER-CAPPER

RINSER - FILLER - CAPPER- -SEAMER

SEAMER

FlexibleRinser

Flexible Rinser--Filler

Filler--Capper

Capper--Seamer Forglass

Seamer for glassbottle

bottle&&aluminium

aluminium can

can filling

filling

Improved

Improved2019 design

design withwith

newnewand and enhanced

enhanced features

features

MICROBLOCK 661 EPV

Rinser - Filler - Seamer - Capper

Counter- pressure Triblock – “COMPACTBLOCK”

Rinser

Flexible - Filler

Rinser – Capper-

- Filler Seamer

– Capper- Seamer

General view of bottling Detail of rinser General view of canning

Product description Products: Carbonated

Carbonated beer,

beer,cider,

cider,water,

drinks, kombucha sparkling wine

water,carbonated

carbonatedsoft

soft

TheCOMPACTBLOCK

The COMPACTBLOCK isis also

also available

available in

in 441,

441, 442,

442, 661 &

662

661configurations. We can Also

& 662 configurations. also able

supply

to the unitthe

supply in 4counter-

&6 ••Bottle

Bottle type:

type: Glass

Glass , PET

, PET bottles

bottles & Aluminium

& Aluminium cans

cans

valve configurations

pressure filler in 4 & without rinser or capper.

6 valve configurations without rinser or ••Cap

Captype:

type:Crown

Crown caps,

caps ROPP,

(otherplastic screw cap,

cap types cork oron

available

capper. can seamer request) can seamer

••Output:

Output:UpUptoto 500bottles

500 bottlesper

perhour

hour(depending

(dependingononbottle

bottle formatformat

& fill temperature)

& fill temperature)

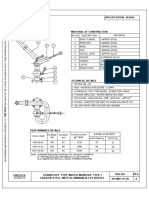

Specifications •Bottle dimensions: 370mm high max – 150mmdiamer max

This COMPACTBLOCK

COMPACTBLOCKhas been

has designed

been to package

designed to package

carbonated products

productssuch

suchas carbonated

as carbonated beer,beer,

cider, cider,

wine,

NEW!

kombucha, water water &and

carbonated

soft drinkssoftinto

drinks intobottles

glass glass and

close them

bottles with crown

and close It is also

caps.crown

them with caps.possible

It is alsotopossible

fill PET Aluminium can filling

bottles

to with

fill PET this machine

bottles and it cans

or aluminium can be fitted

with thiswith different

machine and and seaming kit

types

it can be of fitted

capping

withmachines on request

different types of cappingandmachines

now also on now available as an option

aluminium

request andcans.

now also aluminium cans.

Machineframe

ͳ- Machine frameininstainless

stainlesssteel,

steel,on

onself-locking

self-lockingwheels

wheels

for easy mobility.

for easy mobility.

Nobottle

ͳ- No bottle– –nonorinse

rinsedevice

devicetotoavoid

avoid sprays.

sprays

ͳ- Fully automaticfillfillcycle

Fullyautomatic cycleoperation througha aPLC

operationthrough PLC(which

(which

is fully adjustable by the client) for pre-evacuation ofofair.

is fully adjustable by the client) for pre-evacuation

CO²air.injection,

CO² injection,

filling filling & degassing

and degassing which

which is is required

required for

products sensitive to oxygen such as beer ororcider

for products sensitive to oxygen such as beer cidertoto

reduce as much as possible the dissolved

reduce as much as possible the dissolved oxygen levels in oxygen levels

theinbottles

the bottles

after after theysealed.

they are are sealed. 5“ colour

5 “ colour HMI HMI

screenscreen

as

as option.

option.

Twin

Twin head

head capping

cappingturret

turretwith

withautomatic

automatic capcap

sorter to to

sorter

close

close two bottles simultaneously

two bottles simultaneously (for

(for crown

crown caps only). CO²

capsonly).

injection device

CO² injection into the

device intoneck

the of theof

neck bottle

the prior

bottletoprior

closing,

to

to remove

closing, residualresidual

to remove oxygen in the neck-space.

oxygen in the neck-space.

CIP - high pressure

Spray-balls inside cleaning

header of theand

tank internal

CIP parts of the unit

in continuous

which

motionareforinhigh

contact with the

pressure product.

cleaning of the internal parts of

the unit which are in contact with the product.

IC Filling Systems Srl. IC Filling Systems Ltd. IC Filling Systems Inc.

Regione

Via Roma Prata,

16/i,25/D, 14045

Telgate (BG), 264 Banbury Road 3558 Round Barn Blvd. Suite #200

Incisa Scapaccino (AT), Italy

24060, Italy Oxford OX2 7DY UK Santa Rosa, CA 95403 USA

Email: sales@icfsgroup.com Email: sales@icfsgroup.com Email: sales@icfsgroup.com

Website: www.icfillingsystems.com Website: www.icfillingsystems.com Website: www.icfillingsystems.com

Tel: +39 035 046 0297 Tel: +44 1865 520083 Tel: +1 707 236 6353

You might also like

- (AC-S09) Week 9 - Task: Assignment - Tourist Places in My TownDocument3 pages(AC-S09) Week 9 - Task: Assignment - Tourist Places in My TownLuis LC75% (4)

- Level A01 - City of GoldDocument10 pagesLevel A01 - City of GoldHà PhươngNo ratings yet

- Tricocat PDFDocument44 pagesTricocat PDFJuan PabloNo ratings yet

- The Odyssey Group Catalog 2020Document41 pagesThe Odyssey Group Catalog 2020Tsunami Vapor and GlassNo ratings yet

- MGT 361 - International BusinessDocument43 pagesMGT 361 - International BusinessAhmad FaezNo ratings yet

- Floating Ball Catalog - UnlockedDocument42 pagesFloating Ball Catalog - UnlockedRafael HeemsenNo ratings yet

- PTD BSSP - 2 On Jul 30, 2020Document19 pagesPTD BSSP - 2 On Jul 30, 2020setiawan.dedy123No ratings yet

- Zippo 2015 Complete Line CollectionDocument100 pagesZippo 2015 Complete Line CollectionJason HoneggerNo ratings yet

- Prestons Specials 6-20 August 2018Document1 pagePrestons Specials 6-20 August 2018Tiso Blackstar GroupNo ratings yet

- Q 13097 Ce2236 Prestons Weekly 18 22 Oct 2018 Tearsheets Eph Print ReadyDocument1 pageQ 13097 Ce2236 Prestons Weekly 18 22 Oct 2018 Tearsheets Eph Print ReadyHerald AdvertisingNo ratings yet

- Prestons Weekly Specials 23 - 27aug 2018Document1 pagePrestons Weekly Specials 23 - 27aug 2018Tiso Blackstar GroupNo ratings yet

- Document 2Document1 pageDocument 2leoNo ratings yet

- Flujos RE DELFIDocument19 pagesFlujos RE DELFIfelipetuqueres87No ratings yet

- Oil Tank Metering: GIS - Insulation Is Sf6 Gas Oil Tank Hermetically SealedDocument1 pageOil Tank Metering: GIS - Insulation Is Sf6 Gas Oil Tank Hermetically SealedMahyar MashayekhiNo ratings yet

- Beer Bottles / Standard SizesDocument31 pagesBeer Bottles / Standard SizesAllan DaastrupNo ratings yet

- Alpha Laval Heat Exchangers DatasheetDocument18 pagesAlpha Laval Heat Exchangers Datasheetjosimarj272No ratings yet

- 2019 Redding Cat PDFDocument44 pages2019 Redding Cat PDFPeter DavidsonNo ratings yet

- 1 Blomax e PDFDocument15 pages1 Blomax e PDFDevan FairzNo ratings yet

- Bell & Gossett PD-Series-Iron-Body ExplosiveDocument3 pagesBell & Gossett PD-Series-Iron-Body ExplosiveJose Juan De Dios GonzalezNo ratings yet

- Drawing AccumulatorDocument1 pageDrawing AccumulatorRudi KurniawanNo ratings yet

- Craft Beer & Brewing Winter 2023Document116 pagesCraft Beer & Brewing Winter 2023antonio alberto gutierrez suarez100% (2)

- JSGW Price List 2024-25Document193 pagesJSGW Price List 2024-25Kaushik hazarikaNo ratings yet

- HL - 056.902.0 - Fantasy Pale AleDocument24 pagesHL - 056.902.0 - Fantasy Pale AleEquity NspNo ratings yet

- Norsok: Protective Earth 'Pe' Protective Earth 'Pe' SCR BK BU BK BUDocument1 pageNorsok: Protective Earth 'Pe' Protective Earth 'Pe' SCR BK BU BK BUtxagusNo ratings yet

- Fizzi: Quick Start Guide Guide de Démarrage Rapide Guia de Inicio RápidoDocument12 pagesFizzi: Quick Start Guide Guide de Démarrage Rapide Guia de Inicio RápidoDee BarthistleNo ratings yet

- Bottle Blowing & FillingDocument14 pagesBottle Blowing & Fillingmichael odiemboNo ratings yet

- Form - DLCI-QA-xxrev.00 QA Sample Collection SlipDocument2 pagesForm - DLCI-QA-xxrev.00 QA Sample Collection SliptAYTAYNo ratings yet

- Polini Assembly StepDocument2 pagesPolini Assembly StepasNo ratings yet

- Vanson Engineering. Pvt. LTD.: B/W Outlet EDocument1 pageVanson Engineering. Pvt. LTD.: B/W Outlet Ejugal ranaNo ratings yet

- Raphic & Artoonist: Graphic & CartoonistDocument8 pagesRaphic & Artoonist: Graphic & CartoonistMenaNo ratings yet

- JB Product Catalog 53Document84 pagesJB Product Catalog 53pcna2023customerNo ratings yet

- Prestons VodkaDocument1 pagePrestons VodkaTiso Blackstar GroupNo ratings yet

- Draught Beer Basics WebDocument24 pagesDraught Beer Basics WebRamakrishnan AmbiSubbiahNo ratings yet

- CBB Issue34 AugSept 2019Document100 pagesCBB Issue34 AugSept 2019Tomatito BenzNo ratings yet

- 2 AbvDocument1 page2 AbvtambunanleonardNo ratings yet

- A19043-5 UV-365 Series FlyerDocument3 pagesA19043-5 UV-365 Series FlyerPablo RestrepoNo ratings yet

- PT CouplingDocument88 pagesPT CouplingHotnCrispy CrispyNo ratings yet

- Filters Antwerp Leaflet EN 2935093244Document11 pagesFilters Antwerp Leaflet EN 2935093244tonicmiraNo ratings yet

- Plan Ground Floor Plan: LegendDocument1 pagePlan Ground Floor Plan: Legendbenj panganibanNo ratings yet

- FIRE ExtignuishersDocument24 pagesFIRE ExtignuishersMyat Kyaw HeinNo ratings yet

- Marine Product CatalogueDocument112 pagesMarine Product Cataloguetaseas aivaNo ratings yet

- Step 3 Hydrotest Diagram Stage 1Document1 pageStep 3 Hydrotest Diagram Stage 1mansih457100% (1)

- GCP Sect5NRB NRB LineDocument24 pagesGCP Sect5NRB NRB Linelevanvui161No ratings yet

- DesignDocument9 pagesDesignissaki23No ratings yet

- Packaging Process FlowDocument1 pagePackaging Process Flowkris_naikNo ratings yet

- VAUEN Neuheiten-Fruehjahr-2016 ENDocument11 pagesVAUEN Neuheiten-Fruehjahr-2016 ENCarlos FernandesNo ratings yet

- Qaqc Organization ChartDocument1 pageQaqc Organization ChartAshishNo ratings yet

- AQVIA Balance ManualDocument204 pagesAQVIA Balance Manualtopsorprendente11No ratings yet

- Isotherm Catalog USA PDFDocument96 pagesIsotherm Catalog USA PDFPrasetyo MuhammadNo ratings yet

- Sakura Catalog v7Document76 pagesSakura Catalog v7Queremos LibrosNo ratings yet

- Aft Cart BR 0709Document36 pagesAft Cart BR 0709Robert R. TiinNo ratings yet

- PFDocument19 pagesPFAnonymous gMgeQl1SndNo ratings yet

- Krones: LightweightingDocument9 pagesKrones: LightweightingPatcharee LarpsuriyakulNo ratings yet

- APSPG Pump TubingDocument2 pagesAPSPG Pump TubingMiranti Sjahri100% (1)

- Specification:-Is:8442: Standpost Type Water Monitor - Type-I Carbon Steel With Aluminum Alloy NozzleDocument1 pageSpecification:-Is:8442: Standpost Type Water Monitor - Type-I Carbon Steel With Aluminum Alloy NozzleSwapnil MisalNo ratings yet

- 1 ClampDocument20 pages1 ClampamaldonadoNo ratings yet

- OperaDocument2 pagesOperawhaleNo ratings yet

- SodaStream Fizzi One Touch, Sparkling Water MakerDocument8 pagesSodaStream Fizzi One Touch, Sparkling Water MakerKriyashaktiNo ratings yet

- KAJIAN ANALISA KUALITAS AIR LIMBAH INFLUEN DAN EFFLUEN TERHADAP KINERJA WASTE WATER TREATMENT FACILITY DI PETROCHINA INTERNATIONAL JABUNG LTDDocument19 pagesKAJIAN ANALISA KUALITAS AIR LIMBAH INFLUEN DAN EFFLUEN TERHADAP KINERJA WASTE WATER TREATMENT FACILITY DI PETROCHINA INTERNATIONAL JABUNG LTDSuhendra, M.ScNo ratings yet

- RichmondDocument4 pagesRichmondmiha3la33No ratings yet

- Pharmaceutical Manufacturing: Filtration SolutionsDocument6 pagesPharmaceutical Manufacturing: Filtration SolutionsApril TejadaNo ratings yet

- Mobile Cylinder Div. Standard Build Series: Catalog HY18-0014/US Rev CDocument58 pagesMobile Cylinder Div. Standard Build Series: Catalog HY18-0014/US Rev CDiego PacheNo ratings yet

- Book of Abstracts 2022Document120 pagesBook of Abstracts 2022Ivan KatančićNo ratings yet

- Book of Abstracts - 2019Document108 pagesBook of Abstracts - 2019Ivan KatančićNo ratings yet

- Understanding Assessment For Learning - ReferencesDocument1 pageUnderstanding Assessment For Learning - ReferencesIvan KatančićNo ratings yet

- Cosmetics 07 00087Document19 pagesCosmetics 07 00087Ivan KatančićNo ratings yet

- AamchurDocument4 pagesAamchursadiaNo ratings yet

- The Lizards of Rhazu Adventure by Jan LoosDocument7 pagesThe Lizards of Rhazu Adventure by Jan Loosjaguarpat9402100% (2)

- Egg StructureDocument11 pagesEgg StructureJan Carlo LorenzoNo ratings yet

- Tvl-He - Fbs-Q4-Las-2 Week 2 Melc 2 - Undertake Suggestive Selling and Upselling StrategiesDocument8 pagesTvl-He - Fbs-Q4-Las-2 Week 2 Melc 2 - Undertake Suggestive Selling and Upselling StrategiesEcho Siason EleccionNo ratings yet

- College of Marin Community Education Artisan Cheesemaking Certificate Program 2010 2011 Pilot Year SynopsisDocument12 pagesCollege of Marin Community Education Artisan Cheesemaking Certificate Program 2010 2011 Pilot Year SynopsisResourcesNo ratings yet

- jsc11 01 Que 20220520Document32 pagesjsc11 01 Que 20220520foreverblinks89No ratings yet

- Exercise 1.1 Graph The Given Inequalities. 1. y 2xDocument30 pagesExercise 1.1 Graph The Given Inequalities. 1. y 2xCRING TVNo ratings yet

- Course: ABE 144-Irrigation and Drainage EngineeringDocument10 pagesCourse: ABE 144-Irrigation and Drainage EngineeringMichael Christian TolentinoNo ratings yet

- Agile Life WorkbookDocument10 pagesAgile Life Workbookfifcos1444hNo ratings yet

- Subsistence Agriculture - WikipediaDocument23 pagesSubsistence Agriculture - WikipediaBashiir NuurNo ratings yet

- Articulo de e Coli en InglesDocument3 pagesArticulo de e Coli en Inglesjuan gonzalezNo ratings yet

- One - Million - Eggs - Program - in - Sigi - RegencyDocument4 pagesOne - Million - Eggs - Program - in - Sigi - RegencyEna EppirtaNo ratings yet

- Year 3 Fraction Problems Activity SheetDocument3 pagesYear 3 Fraction Problems Activity SheetmanojNo ratings yet

- Omafra Growing Currants and Gooseberries For Home Gardens 22 033 en 2023 03 23Document7 pagesOmafra Growing Currants and Gooseberries For Home Gardens 22 033 en 2023 03 23Fairyland Daycare WestNo ratings yet

- Fall Final Review MC 2015 - Ch. 1 - 3 - 4Document58 pagesFall Final Review MC 2015 - Ch. 1 - 3 - 4Aaron FanNo ratings yet

- Bread HandbookDocument15 pagesBread Handbookdeyu90No ratings yet

- John Karl Ferdie B. Malupeng: OBJECTIVES: To Apply Knowledge and Skill in Hospitality Industry. To Contribute MyDocument3 pagesJohn Karl Ferdie B. Malupeng: OBJECTIVES: To Apply Knowledge and Skill in Hospitality Industry. To Contribute MyEjay AbergasNo ratings yet

- FINAL Exam ASIAN CUISINEDocument3 pagesFINAL Exam ASIAN CUISINEdaycare centerNo ratings yet

- Infinitive and GerundDocument7 pagesInfinitive and GerundCNTT-1C-17 Vương Thị Diệu LinhNo ratings yet

- Answer Key Mock Test I - Class VII-2Document19 pagesAnswer Key Mock Test I - Class VII-2HACK WITH PKNo ratings yet

- Atividade Inglês Instrumental - Texto Coca ColaDocument2 pagesAtividade Inglês Instrumental - Texto Coca ColaLUCASNo ratings yet

- đầy đủ 1.Document4 pagesđầy đủ 1.Thảo Anh NguyễnNo ratings yet

- Analisis Jurnal Senyawa Beracun Dari MikroorganismeDocument13 pagesAnalisis Jurnal Senyawa Beracun Dari Mikroorganismerifa zahida listianiNo ratings yet

- Soal Ujian Semester 2022Document6 pagesSoal Ujian Semester 2022Putri AnggrainiNo ratings yet

- What You Eat Affects Your ProductivityDocument5 pagesWhat You Eat Affects Your ProductivityValeriu CosteaNo ratings yet

- ApicultureDocument4 pagesApicultureJoseph Ndungu100% (1)

- Button MuhsroomDocument5 pagesButton MuhsroomAS & AssociatesNo ratings yet