Professional Documents

Culture Documents

Specification

Specification

Uploaded by

Alif FirdausCopyright:

Available Formats

You might also like

- DCS SpecificationDocument75 pagesDCS Specificationchida moha67% (3)

- Air Cooled COndenser PDFDocument7 pagesAir Cooled COndenser PDFRajAnandNo ratings yet

- Ahu SpecificationDocument8 pagesAhu SpecificationUzair QuraishiNo ratings yet

- SECTION 23 65 00 Cooling TowersDocument28 pagesSECTION 23 65 00 Cooling TowersDivyansh Singh ChauhanNo ratings yet

- Technical Specification ColtcsDocument60 pagesTechnical Specification Coltcsproloy12No ratings yet

- Hvac Tech, Doc For Tender - II 02 03Document108 pagesHvac Tech, Doc For Tender - II 02 03kishore vpNo ratings yet

- Bdo Ortigas Gf&2fDocument182 pagesBdo Ortigas Gf&2fArvin BuhiaNo ratings yet

- TECH SPEC QAP DATASHEET Buyer88.iocl - DigboiDocument24 pagesTECH SPEC QAP DATASHEET Buyer88.iocl - DigboiChunnesh meshramNo ratings yet

- A-ACMV SpecDocument50 pagesA-ACMV Specchong khengNo ratings yet

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- Technical Specification - ACMV 221222Document82 pagesTechnical Specification - ACMV 221222yuzzaen.execproNo ratings yet

- SECTION 23 34 00 Hvac FansDocument10 pagesSECTION 23 34 00 Hvac FanshtanhNo ratings yet

- BC01C1-Soot Blower Spec - R0Document6 pagesBC01C1-Soot Blower Spec - R0JKKNo ratings yet

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- F-2015030 - Manual de Instalacion de Co2Document16 pagesF-2015030 - Manual de Instalacion de Co2COLCAFÉ SERIINCONo ratings yet

- Barmer To Salaya Pipeline Project: Material RequisitionDocument12 pagesBarmer To Salaya Pipeline Project: Material Requisitionsajeesh5113699No ratings yet

- Va 23 34 00Document10 pagesVa 23 34 00hardik033No ratings yet

- Model 4WI 100 - 800 HP Boilers: 1.4 SubmittalsDocument4 pagesModel 4WI 100 - 800 HP Boilers: 1.4 SubmittalssebaversaNo ratings yet

- DHRM Office Tech Spec VacDocument19 pagesDHRM Office Tech Spec VacAngga WijayaNo ratings yet

- Aux Prds Techincal SpecificationDocument30 pagesAux Prds Techincal SpecificationSwaraj BiswasNo ratings yet

- Series e 80 SpecificationsDocument7 pagesSeries e 80 SpecificationsJavier CastilloNo ratings yet

- Technical Specifications of Precision AiDocument30 pagesTechnical Specifications of Precision AiKumar GauravNo ratings yet

- Specification - Carbon Dioxide Fire Suppression System With Cheetah Xi Control Panel Section 1 - General Conditions I. ScopeDocument11 pagesSpecification - Carbon Dioxide Fire Suppression System With Cheetah Xi Control Panel Section 1 - General Conditions I. ScopeGustavo Márquez TorresNo ratings yet

- Building Automation General RequirementsDocument11 pagesBuilding Automation General RequirementsMohammad Hossein SajjadNo ratings yet

- 1334p Addendumno1 15460 SuDocument10 pages1334p Addendumno1 15460 Suwael72No ratings yet

- 22 21 Hvac Fan Coil Units 1Document2 pages22 21 Hvac Fan Coil Units 1Alaguraja SubramanianNo ratings yet

- AC Survey Report CO-GEN PLANT JDW Sugar Mills Unit IIDocument8 pagesAC Survey Report CO-GEN PLANT JDW Sugar Mills Unit IIAwaisNo ratings yet

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- Volume-Ia Part - I Chapter - Ii: Scope of WorksDocument4 pagesVolume-Ia Part - I Chapter - Ii: Scope of WorksMirhasan GaziNo ratings yet

- SECTION 6 SCH - of - Design - Req - ACPDocument6 pagesSECTION 6 SCH - of - Design - Req - ACPSj PaduNo ratings yet

- Tech Spec Bhel PheDocument55 pagesTech Spec Bhel PheYasmin 2021No ratings yet

- Part 1 - General: SpecificationsDocument6 pagesPart 1 - General: SpecificationsDiego Plata VasquezNo ratings yet

- SECTION 21 22 00 Clean Agent Fire Suppression SystemsDocument19 pagesSECTION 21 22 00 Clean Agent Fire Suppression SystemsWaheeb SaidNo ratings yet

- 23 08 00 Commissioning of HVACDocument10 pages23 08 00 Commissioning of HVACSoumojit SamantaNo ratings yet

- 15785-Pca Air Handling UnitsDocument10 pages15785-Pca Air Handling Unitsadel rihanaNo ratings yet

- CONTOH Technical Specification PUMPDocument43 pagesCONTOH Technical Specification PUMPSoegiantoro SoegiantoroNo ratings yet

- 12 Fire Protection SystemDocument8 pages12 Fire Protection SystemunnicyriacNo ratings yet

- 0726 Precision Air Conditioning SystemDocument10 pages0726 Precision Air Conditioning SystemKeo SokhimNo ratings yet

- 1.00.00 GENERAL Information: (For Vendor Registration Purpose)Document7 pages1.00.00 GENERAL Information: (For Vendor Registration Purpose)Rajendran SrnNo ratings yet

- SECTION 23 09 11 Instrumentation and Control For Boiler PlantDocument79 pagesSECTION 23 09 11 Instrumentation and Control For Boiler PlantJaime Enrique Salazar JaimesNo ratings yet

- Condensor DetailsDocument241 pagesCondensor Detailsramnadh803181No ratings yet

- ACCEPT CRITERIA_AC SPLIT DUCTED_INSTALLATION_060509Document7 pagesACCEPT CRITERIA_AC SPLIT DUCTED_INSTALLATION_060509asyrafNo ratings yet

- i-BX-N-Y 004 - 035: 4,20-35,1 KW Reversible Heat Pump, Air Source For Outdoor InstallationDocument52 pagesi-BX-N-Y 004 - 035: 4,20-35,1 KW Reversible Heat Pump, Air Source For Outdoor InstallationPedroNo ratings yet

- Draft Specification No - RDSOPESPECAC0200 - 2020 (Rev - 1)Document63 pagesDraft Specification No - RDSOPESPECAC0200 - 2020 (Rev - 1)Anil VermaNo ratings yet

- Heat Exchangers SpecsDocument4 pagesHeat Exchangers SpecsElias RizkNo ratings yet

- If TCCDocument38 pagesIf TCCKasturi MJNo ratings yet

- H-ST-2001 Rev.4Document23 pagesH-ST-2001 Rev.4Erol DAĞNo ratings yet

- DQ__LegacyDocument17 pagesDQ__Legacyworkupdate.visontekengineersNo ratings yet

- Technical Specification For Level Control ValvesDocument13 pagesTechnical Specification For Level Control ValvesAylaNo ratings yet

- Screenshot 2023-11-17 at 10.28.54 PMDocument40 pagesScreenshot 2023-11-17 at 10.28.54 PMmye ryeNo ratings yet

- SECTION 23 52 39 Fire Tube BoilersDocument38 pagesSECTION 23 52 39 Fire Tube BoilersresalNo ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- Preq - Al Jaber Engineering - Wiltz - TemboDocument292 pagesPreq - Al Jaber Engineering - Wiltz - Tembo721917114 47No ratings yet

- Computer-Room Air ConditionersDocument19 pagesComputer-Room Air ConditionersAbdullah.N FAAliNo ratings yet

- 23 81 26Document8 pages23 81 26KHMHNNo ratings yet

- WeatehrDocument1 pageWeatehrriyasudheenmhNo ratings yet

- Project Standard Specification: Condensers) (Integral Air-Cooled Condensers)Document6 pagesProject Standard Specification: Condensers) (Integral Air-Cooled Condensers)adel rihanaNo ratings yet

- Ventilation FansDocument39 pagesVentilation FanskalaiNo ratings yet

- Es 0 07 0028-Rev-DDocument24 pagesEs 0 07 0028-Rev-DMuhammed AslamNo ratings yet

- Hva ErpDocument143 pagesHva ErpAlif FirdausNo ratings yet

- Duct HeaterDocument1 pageDuct HeaterAlif FirdausNo ratings yet

- Pe - Hvac Mto - 0Document10 pagesPe - Hvac Mto - 0Alif FirdausNo ratings yet

- 3.4 SJ1085-RHD-ZZ-XX-SP-Z-0015-P01.01 - C04 Preliminaries RequirementsDocument26 pages3.4 SJ1085-RHD-ZZ-XX-SP-Z-0015-P01.01 - C04 Preliminaries RequirementsAlif FirdausNo ratings yet

- 3.2 SJ1085-RHD-ZZ-XX-SP-Z-0014 - C04 General SpecificationDocument180 pages3.2 SJ1085-RHD-ZZ-XX-SP-Z-0014 - C04 General SpecificationAlif FirdausNo ratings yet

- Control Panel HVAC BMDocument4 pagesControl Panel HVAC BMAlif FirdausNo ratings yet

- Scope of Work Gas Turbine MaintenanceDocument37 pagesScope of Work Gas Turbine MaintenanceAlif FirdausNo ratings yet

- Zone 1 VRF Outdoor Unit Cariflex HVAC BMDocument1 pageZone 1 VRF Outdoor Unit Cariflex HVAC BMAlif FirdausNo ratings yet

- Sound Attenuator HVAC BMDocument1 pageSound Attenuator HVAC BMAlif FirdausNo ratings yet

- SOW TF0P003B TotalOverhaulAndInpection Rev1Document6 pagesSOW TF0P003B TotalOverhaulAndInpection Rev1Alif FirdausNo ratings yet

- IPMPS (HQ) 21004 - SPCI OSC (Schedule of Approved Material List)Document8 pagesIPMPS (HQ) 21004 - SPCI OSC (Schedule of Approved Material List)Alif FirdausNo ratings yet

- Tenancy Agreement: TA - Ws-Cshh-DuragateDocument12 pagesTenancy Agreement: TA - Ws-Cshh-DuragateAlif FirdausNo ratings yet

- William Gann Method PDFDocument1 pageWilliam Gann Method PDFchandra widjajaNo ratings yet

- 9th Biology NotesDocument12 pages9th Biology Notesramaiz darNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Error Message Reference: Oracle® Hyperion Tax GovernanceDocument6 pagesError Message Reference: Oracle® Hyperion Tax GovernanceAbayneh AssefaNo ratings yet

- Thrift Banks ActDocument25 pagesThrift Banks ActMadelle Pineda100% (1)

- Iklan Transtv - Ani, Adel, Vinda - Kelas ADocument9 pagesIklan Transtv - Ani, Adel, Vinda - Kelas ANur JamilaNo ratings yet

- PTS MATH GRADE 3 ICP (2022-2023) - Abidah FixDocument4 pagesPTS MATH GRADE 3 ICP (2022-2023) - Abidah FixAnita Noor Maidah S.Pd.i. SD Lab UMNo ratings yet

- Parasnis - 1951 - Study Rock MidlandsDocument20 pagesParasnis - 1951 - Study Rock MidlandsIsaac KandaNo ratings yet

- Indian Standard: Methods of Test For Stabilized SoilsDocument10 pagesIndian Standard: Methods of Test For Stabilized Soilsphanendra kumarNo ratings yet

- The Strategy of Successful Total ProductDocument10 pagesThe Strategy of Successful Total ProductPham GHNo ratings yet

- Shapes of NailsDocument14 pagesShapes of NailsIyannNo ratings yet

- Whittaker Dynamics 17Document442 pagesWhittaker Dynamics 17Mahmoud Ahmed 202201238No ratings yet

- About BITS CmdletsDocument3 pagesAbout BITS CmdletsvashsauNo ratings yet

- WRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkDocument2 pagesWRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkFatmah El WardagyNo ratings yet

- Cost FM Sample PaperDocument6 pagesCost FM Sample PapercacmacsNo ratings yet

- Lesson Plan Sience - Body PartsDocument4 pagesLesson Plan Sience - Body Partsapi-307376252No ratings yet

- Quick Reference Guide: 65 Degree 1800 MHZ Dual Polarized 90 Degree 1800 MHZ Dual PolarizedDocument20 pagesQuick Reference Guide: 65 Degree 1800 MHZ Dual Polarized 90 Degree 1800 MHZ Dual PolarizedРоманКочневNo ratings yet

- Housekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesDocument8 pagesHousekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesMehwish FatimaNo ratings yet

- ScheduleDocument2 pagesScheduleJen NevalgaNo ratings yet

- Alcantara - Module 10 - 2ged SS-03Document2 pagesAlcantara - Module 10 - 2ged SS-03Janine AlcantaraNo ratings yet

- Ai PresentationDocument13 pagesAi Presentationapi-534191655No ratings yet

- EDU CAT EN DF1 FI V5R19 Toprint PDFDocument14 pagesEDU CAT EN DF1 FI V5R19 Toprint PDF3pherNo ratings yet

- Channel DecisionsDocument30 pagesChannel Decisionsuzmatabassum1996No ratings yet

- Free CV Template 31Document1 pageFree CV Template 31Aaron WilsonNo ratings yet

- SPB ClientDocument4 pagesSPB ClientRKNo ratings yet

- The Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full ChapterDocument67 pagesThe Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full Chaptersharon.tuttle380100% (6)

- WhatsApp v. Union of India Filing VersionDocument224 pagesWhatsApp v. Union of India Filing VersionVinayNo ratings yet

- Tranzen1A Income TaxDocument46 pagesTranzen1A Income TaxMonica SorianoNo ratings yet

- g8 With Answer SheetDocument4 pagesg8 With Answer SheetMICHAEL REYESNo ratings yet

- Gen Studs and Engg AptiDocument1 pageGen Studs and Engg AptiasishNo ratings yet

Specification

Specification

Uploaded by

Alif FirdausCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification

Specification

Uploaded by

Alif FirdausCopyright:

Available Formats

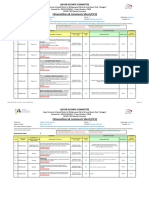

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 2 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

1.0 SCOPE OF SUPPLY

1.1 The VENDOR shall be responsible for the engineering design,

supplies of new, unused materials, manufacture, assembly,

inspection, testing, certification, painting packing,

preservation, preparation for shipment, documentation,

delivery support services for installation, pre-commissioning,

commissioning and start-up of HVAC system listed in

accordance with this specification, datasheets attachments,

sketches, drawings and applicable Codes, Standards and PTS

Specifications.

1.2 The VENDOR shall be responsible for following HVAC Split Unit

and HVAC Package System:

a) Bekok-A (Instrument & Control Room / Battery

Room)

• Split Unit

• Fan Coil Unit

• Exhaust Fans for Battery Room

b) Bekok-B (Instrument Panel Room)

• Split Unit

• Fan Coil Unit

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 3 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

c) Bekok-C (UPS Room / Battery Room)

• Split Unit

• Fan Coil Unit

• Exhaust Fans for Battery Room

d) Tiong A (Compressor Control Room – Module 9)

• Air Cooled Condensing Units (Duty & Standby)

• Air Handling Units (Duty & Standby)

• Electric Duct Heater

• Filter Coalescer

• Gas Tight dampers

• Non return dampers

• Volume Control Dampers

• Pressure Relief Dampers

• Fire Dampers

• Modulating Dampers

• Duct Silencers

VENDOR scope of supply for each HVAC Split Unit / HVAC

Package System above shall include but not limited to the

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 4 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

following:

a) Direct Expansion Split Unit Air Conditioning system will

be adopted for Instrument & Control Room at Bekok A

and Instrument Panel Room at Bekok B. CFC-free

environment friendly refrigerant i.e. R134a, R-407C or

approved equivalent shall be used.

b) Dehumidification of fresh and recycled air is carried out

by the cooling coil in the HFU, where excess moisture is

condensed and removed.

• Split Unit Air Conditioning System unit shall be

provided at Bekok A and Bekok B.

• Refrigerant Piping.

• Local HVAC Control Panel

• Exhaust Fan (Bekok A-Battery Room)

c) The HVAC package system shall have the appropriate

combination of the following main components:

• Air Handling Unit (AHU) complete with all

necessary controls and linked to the Air

Conditioning Control Panel.

• Air Cooled Condensing Units (ACCU) complete

with all necessary controls and linked to the HVAC

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 5 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

Control Panel.

• Ducting complete with insulation, supports,

hangers, vapour barrier, aluminium foil, pin,

adhesive and all other items necessary for the

completeness of the ductwork installation.

• Drain Piping, refrigerant piping and accessories.

Refrigerant and condensate drain piping to be

insulated, inclusive of flow labels and colour

coding for ducting and piping, tags for equipment,

valves and dampers, warning signs and HVAC

plant schematic charts.

• Supply diffusers, return and discharge air grilles

and flexible ducting.

• All fire/ gas/ motorized/ volume/ pressurized/

non-return/ dampers and accessories.

• Complete control and instrumentation (PLC based)

including solenoid valves, tubing, fittings, and

pressurisation control system.

• All instrument item like transmitter and gauge as

per D&ID must be included.

• Field controllers, regulators, sensors, transmitters,

switches, transducers, remote control etc.

• The HVAC PLC shall be fully redundant PLC eg.

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 6 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

redundancy at CPU, power supply, I/Os, internal

communication buses etc. The system selected

shall suitable for utilization within safe area

• Start-up, pre-commissioning and commissioning

spares.

• Two (2) years maintenance spares.

• Special tools for installation, operations and

maintenance purpose.

• All consumables including welding, testing and

protective devices.

• Surface preparation, painting and galvanising of

sheet metal to be used under this contract.

• The equipment/package shall be suitable for

operation in Safe Area unless otherwise

noted in equipment datasheets.

d) Supply for all cabling and wiring (power and signal

cable) inclusive of cabling from HVAC Control Panel to

respective motors and controls in the field exclusive of

signal wiring from equipment to FGS and DCS system is

not under HVAC Vendor scope of works.

e) Complete documentation submitted in accordance with

the VDRL forms in the specification.

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 7 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

2.0 DESIGN AND MANUFACTURING REQUIREMENTS

2.1 Prior to placing any purchase order, VENDOR shall obtain

approval from the CONTRACTOR’s and COMPANY’s with regard

to the selection of manufacturers of all items of equipment and

materials. This is essential to ensure that a high degree of

quality and standardization is achieved throughout the various

available facilities.

2.2 Indoor Fan Coil Unit ▪ The fan coil unit shall be complete with draw-through type

(FCU) for Split Unit fan, DX coil to assure proper air distribution over the

evaporator coil surface.

▪ The unit shall be equipped with support and isolators for

ease of installation and to prevent any vibration being

directly transmitted to the building structure.

▪ Housing frame shall be fabricated of welded structural steel

and be painted for decorative reason as well as corrosion

protection against salt-laden marine environment. The

panels shall be removable from the exterior of the unit

providing unlimited access to the interior of the cabinet.

▪ All internal surfaces of the casing enclosure including the

framework shall be thermally and acoustically insulated

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 8 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

with neoprene-coated glass fibre. The insulating/ acoustic

materials, sealing strips and adhesives shall be inert, non-

hygroscopic, vermin proof and rot proof. They shall not

support bacteriological growth and shall have a Class 1

Rating for surface spread of flame as measured to BS 476

(Part 7). These materials shall be guaranteed against

surface erosion up to air velocity of 30.48 m/ s (6000 FPM)

and have a density of 32 kg/ m3. The insulation thickness

shall be a minimum 25 mm.

▪ Primary condensate drain pan shall be of stainless steel

construction with nonferrous connections. The condensate

drain line shall be internally trapped.

2.3 Outdoor Condensing ▪ The CU shall be suitable for corrosive outdoor platform

Unit (CU) for Split Unit environment and contain all factory assembled

compressors, condenser coils, condenser fans in weather

protected stainless steel housing or painted according

approved code and standards.

▪ Controls shall be in stainless steel construction and casings

shall be of bonded stainless steel and shall include

removable access panels.

▪ Compressors shall be semi hermetic or scroll type with

external spring isolators. Cylinder un-loaders for capacity

control shall be provided and compressor motor starter

shall be direct-on-line.

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 9 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

▪ Condensers shall be of pure copper and the coils shall be

seamless copper tubes and fins. Heresite coating or

approved anti-corrosive coating to be considered on Fins to

enhance its corrosion resistance to marine environment.

▪ Condenser fans shall be direct driven anti-static propeller

fans arranged for side discharge. Fan motors shall be

permanently lubricated and resiliently mounted.

▪ Refrigerant accessories shall include thermostatic

expansion valves, sight glasses, moisture indicators, gate

valve and filter dryers.

▪ Refrigerant shall be ozone friendly type i.e. R134a or

equivalent. All electrical components shall be housed in a

weather proof enclosure that not less than IP52 in

accordance with IEC 60529.

2.4 Air Handling Unit ▪ The unit shall be equipped with support and isolators for

ease of installation and to prevent any vibration being

directly transmitted to the deck structure and also to

ducting system.

▪ HVAC equipment shall be provided with any vibration

isolator for AHU and ACCU if required.

▪ The unit casing construction shall have double skin

construction and pre-insulated to access without

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 10 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

damaging the insulation. The casing shall have a “Penta-

Post” perimeter frame, with a wholly modular system

based on standardized panels and reinforced vertical

sections of 3mm (min.) thickness stainless steel sheet

316L. The panels shall be constructed such that they

shall comprise of two layers of 1.5mm (min) stainless

steel 316L sheet sandwiching the fire resistant “Fibretex

Rockwool” insulation in between, and the panel thickness

shall be 50mm. The fixing of each panel to the perimeter

frame shall be from inside the unit. No external panel

fixings will be acceptable except access doors. The

equipment skid shall also be under VENDOR‘s scope. The

skid shall be equipped with earthing boss and lifting

eyes. The matching AHU base frame which is welded to

the platform shall be supplied and installed by others.

All pipe-work, electrical connections, and access door

shall be sealed air and watertight to the system

maximum static pressure plus 25% against AHU static

pressure design.

▪ The unit shall be fully serviceable.

▪ Evaporator fan shall be Double-Intake-Double Width

(D.I.D.W.) forward curved centrifugal type constructed of

heavy gauge galvanized steel designed for quiet

operation. Wheels shall be statically and dynamically

balanced and arranged on a common shaft and protected

with rust inhibiting compound.

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 11 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

▪ Bearings shall be of the rugged self-aligning ball bearing

type with rubber inner liner permanently lubricated. A

large bearing load safety factor shall be used in the

selection to ensure longer life.

▪ The electrical motors shall be in accordance with PTS

13.20.01.

▪ Filters shall be the washable type. The filter media shall

have an efficiency of not less than 98% based on tests

specified in BS 2831 with test dust number 2. The air

velocity through the filter shall be such that the clean

resistance of the filter is not exceeded and that the filter

fabric is not carried over into the system. The maximum

air resistance of the filter is not to exceed 125 Pa when

dirty.

▪ A differential pressure gauge of the inclined manometer /

indication type shall be provided for the filter section

mounted onto the outside of the filter access panel.

▪ All cooling coils shall conform to ARI Standard 410 and

shall be constructed from copper tubes and copper fins

with SS316L framing. Fin spacing shall be as specified

and the face velocity shall not exceed 2.54 m/s. The coil

section face velocity exceeding 2.54m/s, drift eliminator

section fabricated in stainless steel 316L to be provided.

The coils shall have connecting headers contained within

the unit or alternatively may be external to the unit but

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 12 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

enclosed in insulated stainless steel casing with drain pan

to collect condensation. Coils shall have high capacity

drain pan and intermediate drain trough to be provided

on between cooling coil where required. The cooling coil

(tubes and fins) shall be electro-tinned or equivalent for

corrosion protection.

▪ The direct expansion evaporator coil shall be tested

according to the AHRI standard and then internally

cleaned by blowing through with dry nitrogen, the coil

shall then be positively pressurized and the refrigerant

connections sealed for shipment.

▪ Coils shall be guaranteed free of moisture carry over at

the scheduled face velocities.

▪ Primary condensate drain pan shall be of stainless steel

construction with nonferrous connections. The

condensate drain line shall be internally trapped.

Drainage from AHU shall be field routed to the nearest

drip pan or drain gutter.

2.5 Condensing Unit ▪ The compressor shall be completed with service valves,

resilient suspension system, 3 phase overload protection,

anti-slug protection, crankcase heaters and gauge ports.

▪ Refrigerant circuits shall be provided with combination

refrigerant filter-dryer, sight glass and moisture indicator

and thermal expansion valve with external equalizer.

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 13 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

High and low pressure switches to be provided with

automatic cut out in the low side and auto reset on the

high side. A solenoid valve shall be included on each

refrigerant circuit for pump down control.

▪ Suction line accumulator shall be hydrogen brazed all

steel construction and specially designed to prevent the

trapping of refrigerant oil. The suction line accumulator

shall eliminate compressor damage due to slugging of

liquid refrigerant.

▪ Head pressure controls shall be factory installed and

piped to maintain a constant head pressure under all

ambient conditions. A check valve shall be installed

between the head pressure control valve and receiver to

prevent the liquid receiver pressure from equalizing to

that of the condenser. Each receiver shall have a high

pressure relief valve, and inlet and outlet rotolock valve.

▪ The unit shall be equipped with hot gas bypass/unloader

for capacity control during partial load conditions.

▪ The unit shall incorporate an integral air cooled

condenser that shall be designed for year round

operation. The cooling coil (tubes and fins) shall be

electro-tinned or equivalent for corrosion protection. The

coil shall be tested at 1750 kPa (250 psig). The blower

shall be centrifugal Single- Intake-Single Width

(S.I.S.W.) forward curved type or direct drive propeller

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

PEDMS No:

IBO-PM9S-EXE-HHA-50-HVA-SPC-0001

APPENDIX A1

PROVISION OF DETAIL ENGINEERING DESIGN (DED) PM9 SIMPLIFICATION AND Page: 14 of 47

PROCUREMENT OF MATERIALS FOR BEKOK B FIRST HYDROCARBON

VENDOR’s OPTION/

ITEM DESCRIPTION COMPANY’s OPTIONS/COMMENTS *C OR X

COMMENT/EXCEPTIONS

type. The fan shall be statically and dynamically balanced

and arranged on a common shaft which shall be

protected with a rust inhibiting compound.

▪ The motor sheave shall be of the variable pitch type

allowing blower speed variation. A drain pan and drain

connection for the condenser section shall also be

included. The condenser coil fan set and casing shall be

suitable for use in an outdoor corrosive salt-laden marine

environment.

▪ HVAC equipment shall be provided with any vibration

isolator for AHU and ACCU if required.

2.6 Controls (Tiong-A) ▪ The HVAC Control Panel shall preferably be located in a

non-hazardous area connected to a lockable remote

control unit suitable for Non-hazardous duty installed on

the condensing unit. The panel shall be accessible for

inspection without interrupting incoming unit operation.

The panel shall be complete with a manual disconnecting

switch, high interrupting capacity fuse, motor starters

and control relays plus all branches circuiting to have 1

phase overload protection. The control voltage shall be

120 VAC/60Hz and shall be derived internally by HVAC

MCC. All short-circuit protective devices within the

control panel shall have a minimum interrupting capacity

of 10 kA symmetrical. The control scheme shall include

* VENDOR to state in this column: C: Full compliance; X: Exception/ Deviation

You might also like

- DCS SpecificationDocument75 pagesDCS Specificationchida moha67% (3)

- Air Cooled COndenser PDFDocument7 pagesAir Cooled COndenser PDFRajAnandNo ratings yet

- Ahu SpecificationDocument8 pagesAhu SpecificationUzair QuraishiNo ratings yet

- SECTION 23 65 00 Cooling TowersDocument28 pagesSECTION 23 65 00 Cooling TowersDivyansh Singh ChauhanNo ratings yet

- Technical Specification ColtcsDocument60 pagesTechnical Specification Coltcsproloy12No ratings yet

- Hvac Tech, Doc For Tender - II 02 03Document108 pagesHvac Tech, Doc For Tender - II 02 03kishore vpNo ratings yet

- Bdo Ortigas Gf&2fDocument182 pagesBdo Ortigas Gf&2fArvin BuhiaNo ratings yet

- TECH SPEC QAP DATASHEET Buyer88.iocl - DigboiDocument24 pagesTECH SPEC QAP DATASHEET Buyer88.iocl - DigboiChunnesh meshramNo ratings yet

- A-ACMV SpecDocument50 pagesA-ACMV Specchong khengNo ratings yet

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- Technical Specification - ACMV 221222Document82 pagesTechnical Specification - ACMV 221222yuzzaen.execproNo ratings yet

- SECTION 23 34 00 Hvac FansDocument10 pagesSECTION 23 34 00 Hvac FanshtanhNo ratings yet

- BC01C1-Soot Blower Spec - R0Document6 pagesBC01C1-Soot Blower Spec - R0JKKNo ratings yet

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- F-2015030 - Manual de Instalacion de Co2Document16 pagesF-2015030 - Manual de Instalacion de Co2COLCAFÉ SERIINCONo ratings yet

- Barmer To Salaya Pipeline Project: Material RequisitionDocument12 pagesBarmer To Salaya Pipeline Project: Material Requisitionsajeesh5113699No ratings yet

- Va 23 34 00Document10 pagesVa 23 34 00hardik033No ratings yet

- Model 4WI 100 - 800 HP Boilers: 1.4 SubmittalsDocument4 pagesModel 4WI 100 - 800 HP Boilers: 1.4 SubmittalssebaversaNo ratings yet

- DHRM Office Tech Spec VacDocument19 pagesDHRM Office Tech Spec VacAngga WijayaNo ratings yet

- Aux Prds Techincal SpecificationDocument30 pagesAux Prds Techincal SpecificationSwaraj BiswasNo ratings yet

- Series e 80 SpecificationsDocument7 pagesSeries e 80 SpecificationsJavier CastilloNo ratings yet

- Technical Specifications of Precision AiDocument30 pagesTechnical Specifications of Precision AiKumar GauravNo ratings yet

- Specification - Carbon Dioxide Fire Suppression System With Cheetah Xi Control Panel Section 1 - General Conditions I. ScopeDocument11 pagesSpecification - Carbon Dioxide Fire Suppression System With Cheetah Xi Control Panel Section 1 - General Conditions I. ScopeGustavo Márquez TorresNo ratings yet

- Building Automation General RequirementsDocument11 pagesBuilding Automation General RequirementsMohammad Hossein SajjadNo ratings yet

- 1334p Addendumno1 15460 SuDocument10 pages1334p Addendumno1 15460 Suwael72No ratings yet

- 22 21 Hvac Fan Coil Units 1Document2 pages22 21 Hvac Fan Coil Units 1Alaguraja SubramanianNo ratings yet

- AC Survey Report CO-GEN PLANT JDW Sugar Mills Unit IIDocument8 pagesAC Survey Report CO-GEN PLANT JDW Sugar Mills Unit IIAwaisNo ratings yet

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDocument2 pagesObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNo ratings yet

- Volume-Ia Part - I Chapter - Ii: Scope of WorksDocument4 pagesVolume-Ia Part - I Chapter - Ii: Scope of WorksMirhasan GaziNo ratings yet

- SECTION 6 SCH - of - Design - Req - ACPDocument6 pagesSECTION 6 SCH - of - Design - Req - ACPSj PaduNo ratings yet

- Tech Spec Bhel PheDocument55 pagesTech Spec Bhel PheYasmin 2021No ratings yet

- Part 1 - General: SpecificationsDocument6 pagesPart 1 - General: SpecificationsDiego Plata VasquezNo ratings yet

- SECTION 21 22 00 Clean Agent Fire Suppression SystemsDocument19 pagesSECTION 21 22 00 Clean Agent Fire Suppression SystemsWaheeb SaidNo ratings yet

- 23 08 00 Commissioning of HVACDocument10 pages23 08 00 Commissioning of HVACSoumojit SamantaNo ratings yet

- 15785-Pca Air Handling UnitsDocument10 pages15785-Pca Air Handling Unitsadel rihanaNo ratings yet

- CONTOH Technical Specification PUMPDocument43 pagesCONTOH Technical Specification PUMPSoegiantoro SoegiantoroNo ratings yet

- 12 Fire Protection SystemDocument8 pages12 Fire Protection SystemunnicyriacNo ratings yet

- 0726 Precision Air Conditioning SystemDocument10 pages0726 Precision Air Conditioning SystemKeo SokhimNo ratings yet

- 1.00.00 GENERAL Information: (For Vendor Registration Purpose)Document7 pages1.00.00 GENERAL Information: (For Vendor Registration Purpose)Rajendran SrnNo ratings yet

- SECTION 23 09 11 Instrumentation and Control For Boiler PlantDocument79 pagesSECTION 23 09 11 Instrumentation and Control For Boiler PlantJaime Enrique Salazar JaimesNo ratings yet

- Condensor DetailsDocument241 pagesCondensor Detailsramnadh803181No ratings yet

- ACCEPT CRITERIA_AC SPLIT DUCTED_INSTALLATION_060509Document7 pagesACCEPT CRITERIA_AC SPLIT DUCTED_INSTALLATION_060509asyrafNo ratings yet

- i-BX-N-Y 004 - 035: 4,20-35,1 KW Reversible Heat Pump, Air Source For Outdoor InstallationDocument52 pagesi-BX-N-Y 004 - 035: 4,20-35,1 KW Reversible Heat Pump, Air Source For Outdoor InstallationPedroNo ratings yet

- Draft Specification No - RDSOPESPECAC0200 - 2020 (Rev - 1)Document63 pagesDraft Specification No - RDSOPESPECAC0200 - 2020 (Rev - 1)Anil VermaNo ratings yet

- Heat Exchangers SpecsDocument4 pagesHeat Exchangers SpecsElias RizkNo ratings yet

- If TCCDocument38 pagesIf TCCKasturi MJNo ratings yet

- H-ST-2001 Rev.4Document23 pagesH-ST-2001 Rev.4Erol DAĞNo ratings yet

- DQ__LegacyDocument17 pagesDQ__Legacyworkupdate.visontekengineersNo ratings yet

- Technical Specification For Level Control ValvesDocument13 pagesTechnical Specification For Level Control ValvesAylaNo ratings yet

- Screenshot 2023-11-17 at 10.28.54 PMDocument40 pagesScreenshot 2023-11-17 at 10.28.54 PMmye ryeNo ratings yet

- SECTION 23 52 39 Fire Tube BoilersDocument38 pagesSECTION 23 52 39 Fire Tube BoilersresalNo ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- Preq - Al Jaber Engineering - Wiltz - TemboDocument292 pagesPreq - Al Jaber Engineering - Wiltz - Tembo721917114 47No ratings yet

- Computer-Room Air ConditionersDocument19 pagesComputer-Room Air ConditionersAbdullah.N FAAliNo ratings yet

- 23 81 26Document8 pages23 81 26KHMHNNo ratings yet

- WeatehrDocument1 pageWeatehrriyasudheenmhNo ratings yet

- Project Standard Specification: Condensers) (Integral Air-Cooled Condensers)Document6 pagesProject Standard Specification: Condensers) (Integral Air-Cooled Condensers)adel rihanaNo ratings yet

- Ventilation FansDocument39 pagesVentilation FanskalaiNo ratings yet

- Es 0 07 0028-Rev-DDocument24 pagesEs 0 07 0028-Rev-DMuhammed AslamNo ratings yet

- Hva ErpDocument143 pagesHva ErpAlif FirdausNo ratings yet

- Duct HeaterDocument1 pageDuct HeaterAlif FirdausNo ratings yet

- Pe - Hvac Mto - 0Document10 pagesPe - Hvac Mto - 0Alif FirdausNo ratings yet

- 3.4 SJ1085-RHD-ZZ-XX-SP-Z-0015-P01.01 - C04 Preliminaries RequirementsDocument26 pages3.4 SJ1085-RHD-ZZ-XX-SP-Z-0015-P01.01 - C04 Preliminaries RequirementsAlif FirdausNo ratings yet

- 3.2 SJ1085-RHD-ZZ-XX-SP-Z-0014 - C04 General SpecificationDocument180 pages3.2 SJ1085-RHD-ZZ-XX-SP-Z-0014 - C04 General SpecificationAlif FirdausNo ratings yet

- Control Panel HVAC BMDocument4 pagesControl Panel HVAC BMAlif FirdausNo ratings yet

- Scope of Work Gas Turbine MaintenanceDocument37 pagesScope of Work Gas Turbine MaintenanceAlif FirdausNo ratings yet

- Zone 1 VRF Outdoor Unit Cariflex HVAC BMDocument1 pageZone 1 VRF Outdoor Unit Cariflex HVAC BMAlif FirdausNo ratings yet

- Sound Attenuator HVAC BMDocument1 pageSound Attenuator HVAC BMAlif FirdausNo ratings yet

- SOW TF0P003B TotalOverhaulAndInpection Rev1Document6 pagesSOW TF0P003B TotalOverhaulAndInpection Rev1Alif FirdausNo ratings yet

- IPMPS (HQ) 21004 - SPCI OSC (Schedule of Approved Material List)Document8 pagesIPMPS (HQ) 21004 - SPCI OSC (Schedule of Approved Material List)Alif FirdausNo ratings yet

- Tenancy Agreement: TA - Ws-Cshh-DuragateDocument12 pagesTenancy Agreement: TA - Ws-Cshh-DuragateAlif FirdausNo ratings yet

- William Gann Method PDFDocument1 pageWilliam Gann Method PDFchandra widjajaNo ratings yet

- 9th Biology NotesDocument12 pages9th Biology Notesramaiz darNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Error Message Reference: Oracle® Hyperion Tax GovernanceDocument6 pagesError Message Reference: Oracle® Hyperion Tax GovernanceAbayneh AssefaNo ratings yet

- Thrift Banks ActDocument25 pagesThrift Banks ActMadelle Pineda100% (1)

- Iklan Transtv - Ani, Adel, Vinda - Kelas ADocument9 pagesIklan Transtv - Ani, Adel, Vinda - Kelas ANur JamilaNo ratings yet

- PTS MATH GRADE 3 ICP (2022-2023) - Abidah FixDocument4 pagesPTS MATH GRADE 3 ICP (2022-2023) - Abidah FixAnita Noor Maidah S.Pd.i. SD Lab UMNo ratings yet

- Parasnis - 1951 - Study Rock MidlandsDocument20 pagesParasnis - 1951 - Study Rock MidlandsIsaac KandaNo ratings yet

- Indian Standard: Methods of Test For Stabilized SoilsDocument10 pagesIndian Standard: Methods of Test For Stabilized Soilsphanendra kumarNo ratings yet

- The Strategy of Successful Total ProductDocument10 pagesThe Strategy of Successful Total ProductPham GHNo ratings yet

- Shapes of NailsDocument14 pagesShapes of NailsIyannNo ratings yet

- Whittaker Dynamics 17Document442 pagesWhittaker Dynamics 17Mahmoud Ahmed 202201238No ratings yet

- About BITS CmdletsDocument3 pagesAbout BITS CmdletsvashsauNo ratings yet

- WRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkDocument2 pagesWRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkFatmah El WardagyNo ratings yet

- Cost FM Sample PaperDocument6 pagesCost FM Sample PapercacmacsNo ratings yet

- Lesson Plan Sience - Body PartsDocument4 pagesLesson Plan Sience - Body Partsapi-307376252No ratings yet

- Quick Reference Guide: 65 Degree 1800 MHZ Dual Polarized 90 Degree 1800 MHZ Dual PolarizedDocument20 pagesQuick Reference Guide: 65 Degree 1800 MHZ Dual Polarized 90 Degree 1800 MHZ Dual PolarizedРоманКочневNo ratings yet

- Housekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesDocument8 pagesHousekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesMehwish FatimaNo ratings yet

- ScheduleDocument2 pagesScheduleJen NevalgaNo ratings yet

- Alcantara - Module 10 - 2ged SS-03Document2 pagesAlcantara - Module 10 - 2ged SS-03Janine AlcantaraNo ratings yet

- Ai PresentationDocument13 pagesAi Presentationapi-534191655No ratings yet

- EDU CAT EN DF1 FI V5R19 Toprint PDFDocument14 pagesEDU CAT EN DF1 FI V5R19 Toprint PDF3pherNo ratings yet

- Channel DecisionsDocument30 pagesChannel Decisionsuzmatabassum1996No ratings yet

- Free CV Template 31Document1 pageFree CV Template 31Aaron WilsonNo ratings yet

- SPB ClientDocument4 pagesSPB ClientRKNo ratings yet

- The Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full ChapterDocument67 pagesThe Body Productive Rethinking Capitalism Work and The Body Steffan Blayney Full Chaptersharon.tuttle380100% (6)

- WhatsApp v. Union of India Filing VersionDocument224 pagesWhatsApp v. Union of India Filing VersionVinayNo ratings yet

- Tranzen1A Income TaxDocument46 pagesTranzen1A Income TaxMonica SorianoNo ratings yet

- g8 With Answer SheetDocument4 pagesg8 With Answer SheetMICHAEL REYESNo ratings yet

- Gen Studs and Engg AptiDocument1 pageGen Studs and Engg AptiasishNo ratings yet