Professional Documents

Culture Documents

HCPRROI007E

HCPRROI007E

Uploaded by

hufuents0 ratings0% found this document useful (0 votes)

1 views2 pagesa

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenta

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views2 pagesHCPRROI007E

HCPRROI007E

Uploaded by

hufuentsa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

HCPRROI007E.

COST ANALYSIS REPORT

INDUSTRY: WOOD PLANT

EQUIPMENT: SIEMPELKAMP 4300t, 2 cylinder press for decorative

plastic laminating of chipboards

FLUID: Water emulsion (5,5% oil)

SYSTEM PRESSURE: 200 bar

TEMPERATURE: 40°C max

SEAL: CHESTERTON 10K, 95A/75D; 1050×1100×35, #65951

SERVICE LIFE: 1600 cycles or ONE YEAR and it is still in service

PREVIOUS SEAL: Leather-rubber kind of seal

PREVIOUS LIFE: 400 cycles or 3 months average

PROBLEM: Extrusion, poor memory

HCPRROI007E.PDF

PREVIOUS METHOD OF SEALING

SEAL COST: $350×2seals×4changes………………………………………………$2,800

OIL LOSS: 200l/change; 500$/drum

$500×4changes…………………………………………………………………$2,000

ENERGY LOSS: 12t of steam or 500kg havey oil, 0,17$/kg

$0,17×500$×4changes………………………………………………………$340

LABOR: 2 men, 6 hours

2×6h×15$/h×4 changes……………………………………………………$720

$5,860

NEW METHOD OF SEALING

SEAL COST: $1339×2 seals…………………………………………………………………$2,676

OIL LOSS: $500………………………………………………………………………………………………$500

ENERGY LOSS: 12t of steam or 500kg havey oil, 0,17$/kg

$0,17×500$…………………………………………………………………………………$85

LABOR: 2×6h×15$/h………………………………………………………………………………$180

$3,441

SAVINGS U$ 12.095,00

NOTE: Lost of production, downtime and pollution costs were not included

into the report.

You might also like

- Manual de Servicio 821CDocument716 pagesManual de Servicio 821CAlma Rosa Montejo100% (19)

- Manual Partes PIV351Document1,058 pagesManual Partes PIV351Diego Rodriguez100% (1)

- Atlas Copco Drilling Solutions: Part List Model: Dm45/Hp S/N: US009639Document678 pagesAtlas Copco Drilling Solutions: Part List Model: Dm45/Hp S/N: US009639Manuel Maya100% (1)

- Simjet Miniature Turbojet Engine: Owner'S ManualDocument20 pagesSimjet Miniature Turbojet Engine: Owner'S Manualamir hosseinNo ratings yet

- T-88 Structural Aircraft Adhesive: Technical Data SheetDocument2 pagesT-88 Structural Aircraft Adhesive: Technical Data Sheetanon_271015207No ratings yet

- Us080101 114Document1,088 pagesUs080101 114MAURICIO CASTRONo ratings yet

- Cabo NA2XS (F) 2YDocument2 pagesCabo NA2XS (F) 2YEgizian MartinsNo ratings yet

- CL-PG 11-Jun08Document1 pageCL-PG 11-Jun08Gary GodffreyNo ratings yet

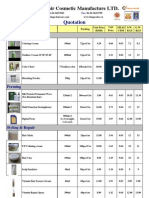

- Bingo Hair Cosmetic Manufacture LTD.: QuotationDocument2 pagesBingo Hair Cosmetic Manufacture LTD.: QuotationJoveth YanesNo ratings yet

- Report - 3833735810557724151 PUMA 185Document3 pagesReport - 3833735810557724151 PUMA 185Ozenildo FerrNo ratings yet

- B41821 Single-Ended CapacitorsDocument19 pagesB41821 Single-Ended Capacitorsprpabst8514No ratings yet

- Krauss-Maffai 3200T ROIDocument3 pagesKrauss-Maffai 3200T ROIhufuentsNo ratings yet

- Filtro DELTA70109gbDocument3 pagesFiltro DELTA70109gbClaudio TurlherNo ratings yet

- Techsheet AuDocument2 pagesTechsheet AuidrisssoftNo ratings yet

- Atlas Copco Drilling Solutions: Part List Model: DML/HP S/N: US009411Document300 pagesAtlas Copco Drilling Solutions: Part List Model: DML/HP S/N: US009411klaus100% (2)

- 12.25_800 MWDDocument1 page12.25_800 MWDKautsar IsarNo ratings yet

- HCPRROI008EDocument1 pageHCPRROI008EhufuentsNo ratings yet

- Harga Retail Oki Petro Terbaru 2024Document2 pagesHarga Retail Oki Petro Terbaru 2024hotpursuit1528No ratings yet

- Filtry CaseDocument3 pagesFiltry CaseJanush BehindtorrentNo ratings yet

- XALOY F732!2!2 Extrusion Screw DesignDocument3 pagesXALOY F732!2!2 Extrusion Screw DesignVeenu ChittyNo ratings yet

- Pluto 5 & Pluto 5 Casino EPROM Configurations and Autoselect Feature ManualDocument22 pagesPluto 5 & Pluto 5 Casino EPROM Configurations and Autoselect Feature ManualMitica ScurtuNo ratings yet

- SP 8888 PDFDocument6 pagesSP 8888 PDFMohammad ShamimNo ratings yet

- Jtbaker PDFDocument57 pagesJtbaker PDFbenzen87No ratings yet

- FYH GreasingDocument2 pagesFYH Greasingbasslaboriel100% (1)

- Transocean MarianasDocument2 pagesTransocean MarianasRahardian Gusta PatriaNo ratings yet

- KarcherDocument12 pagesKarcherPrashantNo ratings yet

- Form Order Cba MDocument1 pageForm Order Cba MTIKA EMI LESTARINo ratings yet

- UID Pick List ReportDocument20 pagesUID Pick List ReportMuhammad Rafi HeryadiNo ratings yet

- Us 009532Document723 pagesUs 009532Abraham Huacasi100% (1)

- Pecifications: Ydraulic XcavatorDocument5 pagesPecifications: Ydraulic XcavatorwalisonNo ratings yet

- Canon Copier Media GuideDocument1 pageCanon Copier Media GuideJulianzah AnwarNo ratings yet

- 12-Cylinder Four-Stroke: Cycle AverageDocument6 pages12-Cylinder Four-Stroke: Cycle AverageThant Zaw AungNo ratings yet

- Us 009584Document680 pagesUs 009584Jose RivasNo ratings yet

- Discoverer Clear LeaderDocument2 pagesDiscoverer Clear LeaderTim ClarkeNo ratings yet

- Construccion IIIDocument11 pagesConstruccion IIIYor Blell GuzmánNo ratings yet

- Powertrain Combined TutorialsDocument37 pagesPowertrain Combined TutorialsrubynoblespamNo ratings yet

- 10-mL Retort Instruction ManualDocument16 pages10-mL Retort Instruction ManualGarcia ManuelNo ratings yet

- Brosur Rima Heater Simple Uk. A4 PDFDocument28 pagesBrosur Rima Heater Simple Uk. A4 PDFMichael CummingsNo ratings yet

- Pro 37 pc8000Document8 pagesPro 37 pc8000MIGUEL ARRIAGADANo ratings yet

- 23-03-2019 Kerangka Mesin Jenis PortalDocument16 pages23-03-2019 Kerangka Mesin Jenis PortalMei'o KuroNo ratings yet

- NordexpCatalogue2014v1 90Document134 pagesNordexpCatalogue2014v1 90BasNo ratings yet

- Pricelist JANUARI 2022 PPT MasterDocument7 pagesPricelist JANUARI 2022 PPT MasterriniNo ratings yet

- PP Sheet Ext GuideDocument21 pagesPP Sheet Ext GuideAliNo ratings yet

- Price Listtb2 Sept'23Document11 pagesPrice Listtb2 Sept'23NZNo ratings yet

- Disc Diffuser O & M Manual20040804Document10 pagesDisc Diffuser O & M Manual20040804Ahmed WagihNo ratings yet

- Waste Water CalculationsDocument6 pagesWaste Water Calculationsapi-296269572No ratings yet

- HCPRROI009EDocument1 pageHCPRROI009EhufuentsNo ratings yet

- Reactor & Dryer DesignDocument19 pagesReactor & Dryer DesignSepribo BraideNo ratings yet

- TD 14M Extra Crawler Dozer: Diagnostic Data & Service PartsDocument2 pagesTD 14M Extra Crawler Dozer: Diagnostic Data & Service PartsАлексейNo ratings yet

- NO Kode Nama Barang Order Harga JumlahDocument1 pageNO Kode Nama Barang Order Harga JumlahEn DhoNo ratings yet

- Eco SPARDocument3 pagesEco SPARMohammad LabinNo ratings yet

- Midwater Semi-Submersible: Storage Capacities For Additional Information Please ContactDocument2 pagesMidwater Semi-Submersible: Storage Capacities For Additional Information Please ContactTim ClarkeNo ratings yet

- STATIONARYDocument3 pagesSTATIONARYvesselNo ratings yet

- Amir Enterprise: Perkara Harga Jualan Kuantiti Barang RMDocument3 pagesAmir Enterprise: Perkara Harga Jualan Kuantiti Barang RMsilent spritsNo ratings yet

- fplgtr65 PDFDocument57 pagesfplgtr65 PDFJadwani IndustriesNo ratings yet

- Manual dm9334Document844 pagesManual dm9334reumaldoNo ratings yet

- Custom Molding of Thermoset Elastomers: A Comprehensive Approach to Materials, Mold Design, and ProcessingFrom EverandCustom Molding of Thermoset Elastomers: A Comprehensive Approach to Materials, Mold Design, and ProcessingNo ratings yet

- ROI 3.1 Magna Exterior Injection MoldingDocument2 pagesROI 3.1 Magna Exterior Injection MoldinghufuentsNo ratings yet

- HCMM026EDocument1 pageHCMM026EhufuentsNo ratings yet

- Krauss-Maffai 3200T ROIDocument3 pagesKrauss-Maffai 3200T ROIhufuentsNo ratings yet

- HCAU005EDocument1 pageHCAU005EhufuentsNo ratings yet

- HCAU007EDocument1 pageHCAU007EhufuentsNo ratings yet

- HCAU006EDocument1 pageHCAU006EhufuentsNo ratings yet

- Intelliflow: Chestertont-30 Intelliflow Water SaverDocument2 pagesIntelliflow: Chestertont-30 Intelliflow Water SaverhufuentsNo ratings yet

- Application Success Story:: Food Processing Corn Mash Mechanical SealDocument1 pageApplication Success Story:: Food Processing Corn Mash Mechanical SealhufuentsNo ratings yet

- 2022 New Broaband Sensor Approach For Condition MonitoringDocument17 pages2022 New Broaband Sensor Approach For Condition MonitoringhufuentsNo ratings yet

- Application Success Story:: Excessive Flush and Leakage 1200 - 1500 GPH / High Maintenance CostsDocument1 pageApplication Success Story:: Excessive Flush and Leakage 1200 - 1500 GPH / High Maintenance CostshufuentsNo ratings yet

- Sbpln53a ENDocument2 pagesSbpln53a ENhufuentsNo ratings yet

- SpiralTrac S SuccessDocument1 pageSpiralTrac S SuccesshufuentsNo ratings yet

- ES V1 I8 Positive DisplacementDocument2 pagesES V1 I8 Positive DisplacementhufuentsNo ratings yet

- 442HP Small and Large SizeDocument2 pages442HP Small and Large SizehufuentsNo ratings yet

- Solutions Solutions Solutions Solutions: 442 Split Seals in Vacuum ApplicationsDocument1 pageSolutions Solutions Solutions Solutions: 442 Split Seals in Vacuum ApplicationshufuentsNo ratings yet

- ILK-M18-AB: Electrical Design Ac / DC Output Normally OpenDocument1 pageILK-M18-AB: Electrical Design Ac / DC Output Normally OpenhufuentsNo ratings yet

- Solutions: Sealing High ViscositiesDocument2 pagesSolutions: Sealing High ViscositieshufuentsNo ratings yet

- ILK-M18-FR: Electrical Design DC PNP/NPN Output Normally Open / Closed ProgrammableDocument1 pageILK-M18-FR: Electrical Design DC PNP/NPN Output Normally Open / Closed ProgrammablehufuentsNo ratings yet

- EN36616 - CS034 - FP - Non-Metallic Hydraulic Wear Rings Increase Lateral Load Handling of Shear CylindersDocument1 pageEN36616 - CS034 - FP - Non-Metallic Hydraulic Wear Rings Increase Lateral Load Handling of Shear CylindershufuentsNo ratings yet

- ES V1 I7 Moyno SolutionsDocument2 pagesES V1 I7 Moyno SolutionshufuentsNo ratings yet

- 370 in A Sprout Waldon Twin Flow Refiner: IndustryDocument1 page370 in A Sprout Waldon Twin Flow Refiner: IndustryhufuentsNo ratings yet

- Case History Steel Trap Live Load 2Document1 pageCase History Steel Trap Live Load 2hufuentsNo ratings yet