Professional Documents

Culture Documents

Ointment MFG System

Ointment MFG System

Uploaded by

Vaidyanathan KesavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ointment MFG System

Ointment MFG System

Uploaded by

Vaidyanathan KesavanCopyright:

Available Formats

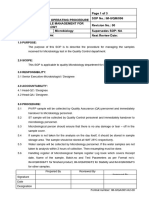

Ointment manufacturing vessel and its components:

Scope:

Ointment manufacturing vessel is used for manufacturing of Semi solid products.

The Semi solid manufacturing system consists of 3 components namely

1. Water phase vessel

2. Wax phase vessel

3. Mixing vessel

All vessel are jacketed with input for steam or cold water for heating or cooling respectively.

The water phase vessel has propeller type stirrer for mixing aqueous solution with

temperature controlled system to maintain constant temperature.

The wax phase vessel has cawl cutter type stirrer for mixing high viscous oil materials.

The mixing vessel has anchor type stirrer with homogeniser for mixing of aqueous and wax

phase materials.Homogeniser is installed at the bottom of the vessel for intense and

homogeneous mixing.

To avoid entrapment vacuum is available for mixing vessel to remove any air .

All are topospherical shaped vessel for uniform mixing.

The water based transfer pump used for transferring of phases for one vessel to another

vessel.

Provision is available for re circulation of materials in mixing vessel.

Clean in place skit is used for easy and proper cleaning of all vessels

All the functions are controlled through HMI panel where heating/cooling is performed by

using thermostat set at required temperature,

The complete system shall be designed as per current relevant standards,agreed technical

specification and User requirement specifications to comply with the clients requirement.

Technical specifications of all the equipment, instruments, valves etc. are as per the offer, the

Purchase Order, and the client’s Requirements.

Training on the system to be provided to operation staffs those are involved in Blister

packing system

Operation and Maintenance:

1. The vessel system and its components are maintained in clean room area

2. The inflated Silicone seals are checked for its wear and tear on daily basis.

3. The upward and downward movement of the lid of mixing vessel is due to hydraulic

cylinder action where oil level is checked weekly.

4. Monthly,half yearly and yearly preventive programmed to be done to keep machine in

proper working condition

You might also like

- GETrans - GEVO Tier 4 Locomotive Support SystemsDocument142 pagesGETrans - GEVO Tier 4 Locomotive Support SystemsTim MarvinNo ratings yet

- Ship Air Conditioning SystemDocument9 pagesShip Air Conditioning SystemMEET PATEL100% (2)

- Ointment MFG System - UpdatedDocument2 pagesOintment MFG System - UpdatedVaidyanathan KesavanNo ratings yet

- Unit 3Document92 pagesUnit 3Kishore KumarNo ratings yet

- Milk Factory Visit ReportDocument10 pagesMilk Factory Visit ReportshubhamrasalNo ratings yet

- 01 IntroductionDocument6 pages01 IntroductionHamilton MupoperiNo ratings yet

- Long-Life MilkDocument34 pagesLong-Life MilkM Umer SaeedNo ratings yet

- Fermentor Design and BioreactorDocument40 pagesFermentor Design and BioreactorVivek Dhiman0% (1)

- Cleaning and Sanitizing of Milk Processing EquipmentDocument11 pagesCleaning and Sanitizing of Milk Processing EquipmentRajat SinghNo ratings yet

- Canning Industry InstrumentationDocument11 pagesCanning Industry InstrumentationS DispiserNo ratings yet

- Project ReportDocument85 pagesProject ReportArunodayaprojectsNo ratings yet

- WC Centrifugal Chiller 400V-SSDocument8 pagesWC Centrifugal Chiller 400V-SSAhmadNo ratings yet

- WCFX-E Guide SpecificationDocument3 pagesWCFX-E Guide SpecificationaftabNo ratings yet

- Engine Simulator Room FamiliarizationDocument93 pagesEngine Simulator Room FamiliarizationJohnarey Galve PantuaNo ratings yet

- Module 4: Valves, Pumps, Ballast and CoolersDocument22 pagesModule 4: Valves, Pumps, Ballast and CoolersEmerson LinconNo ratings yet

- 14Document26 pages14Nguyên NguyễnNo ratings yet

- Bitumen Emulsion Production Plant: Capacity: 10 M /HDocument10 pagesBitumen Emulsion Production Plant: Capacity: 10 M /HAPE MKTNo ratings yet

- Verka Milk PlantDocument23 pagesVerka Milk PlantSahdibAli0% (1)

- Protocol For Perfomance Qualification of Water For Injection Generation, Storage and Distribution System - Pharmaceutical GuidanceDocument7 pagesProtocol For Perfomance Qualification of Water For Injection Generation, Storage and Distribution System - Pharmaceutical Guidancedecio ventura rodrigues miraNo ratings yet

- Preparations, Operation and Safety Measures For Main EngineDocument35 pagesPreparations, Operation and Safety Measures For Main Engineart estacioNo ratings yet

- Cooling SystemDocument4 pagesCooling Systemshyam jushiNo ratings yet

- WCB FreezerDocument50 pagesWCB FreezerDay StefanAticNo ratings yet

- Krones: Varioflash and VarioaseptDocument13 pagesKrones: Varioflash and VarioaseptHoa XaNo ratings yet

- Production DepartmentDocument54 pagesProduction DepartmentAshik SureshNo ratings yet

- Vaccum Dehydrator 1Document7 pagesVaccum Dehydrator 1Simbu ArasanNo ratings yet

- 6.water Treatment and Make-Up Water SystemDocument18 pages6.water Treatment and Make-Up Water Systempepenapao1217100% (1)

- Website ContentDocument6 pagesWebsite ContentLakshmi SrujanaNo ratings yet

- MET Building ChillersDocument12 pagesMET Building Chillersoth369No ratings yet

- FermentorDocument14 pagesFermentorSanthosh KaranNo ratings yet

- Model 580: Liquid Polymer Preparation ModuleDocument4 pagesModel 580: Liquid Polymer Preparation ModuleneoegoNo ratings yet

- Chapter One 1. Background of Amhara Pipe Factory 1.1 Brief History (Introduction)Document15 pagesChapter One 1. Background of Amhara Pipe Factory 1.1 Brief History (Introduction)Silesh100% (1)

- FARM - Vat PasteurizationDocument12 pagesFARM - Vat Pasteurizationford62bNo ratings yet

- Desludging of Crude Tank 111Document13 pagesDesludging of Crude Tank 111Chukwuma Emmanuel OnwufujuNo ratings yet

- Tetra Pak Linear Moulding 1500A2 80588 PD HiDocument8 pagesTetra Pak Linear Moulding 1500A2 80588 PD HiMcdonaldNo ratings yet

- Design and Operation of Conventional BioreactorDocument25 pagesDesign and Operation of Conventional BioreactorMahesh RamNo ratings yet

- Final Year Project 2 Presentation: Design Quail Egg Incubator For Experiments SystemDocument19 pagesFinal Year Project 2 Presentation: Design Quail Egg Incubator For Experiments SystemMohd Faiz Mohd ZinNo ratings yet

- Chapter 2 - Air Conditioning System - Part 2Document23 pagesChapter 2 - Air Conditioning System - Part 2khairul izzudinNo ratings yet

- 1.operation manual for 40ST Series of water-cooled stars water chillers 40ST系列螺杆式水冷机组操作手册-ENDocument47 pages1.operation manual for 40ST Series of water-cooled stars water chillers 40ST系列螺杆式水冷机组操作手册-ENNissar HussainNo ratings yet

- Bioreactor-Definition, Design, Principle, Parts, Types, Applications, LimitationsDocument14 pagesBioreactor-Definition, Design, Principle, Parts, Types, Applications, LimitationsShahriar ShamimNo ratings yet

- Hawken Engineering Building Air Conditioning SystemDocument15 pagesHawken Engineering Building Air Conditioning SystemDamien NaiduNo ratings yet

- Intercambiador de CalorDocument20 pagesIntercambiador de CalorLina Gonzalez HNo ratings yet

- Blister PackDocument1 pageBlister PackVaidyanathan KesavanNo ratings yet

- Praj Doc On 2G Ethanol PDFDocument35 pagesPraj Doc On 2G Ethanol PDFSandipan Roy100% (5)

- Reporte 2Document12 pagesReporte 2mengstuhagos1223No ratings yet

- Ice-Cream Making EquipmentDocument8 pagesIce-Cream Making EquipmentMonty KushwahaNo ratings yet

- Rundown Tank Purpose and Working - Chemical Engineering WorldDocument2 pagesRundown Tank Purpose and Working - Chemical Engineering WorldAbdul Mohid SheikhNo ratings yet

- Tetra Pak Pasteurizer BF PDDocument6 pagesTetra Pak Pasteurizer BF PDTanvir BhagatNo ratings yet

- AC-300 - Water Cooled Liquid ChillerDocument11 pagesAC-300 - Water Cooled Liquid Chillerjames_chan2178No ratings yet

- UNIT - III - Design of FermentorDocument19 pagesUNIT - III - Design of FermentorGDNo ratings yet

- Fermenter DesignDocument59 pagesFermenter DesignPratishtha RawatNo ratings yet

- Maintaining Uniform Target Temperature - Thermal Processing MagazineDocument7 pagesMaintaining Uniform Target Temperature - Thermal Processing MagazineRichardNo ratings yet

- Fuel Oil SystemDocument11 pagesFuel Oil SystemNawin Kumar100% (2)

- HaftuDocument21 pagesHaftuHaphtamu MeleseNo ratings yet

- Manufacturing ProcessDocument2 pagesManufacturing ProcessLakshmi NarasimhanNo ratings yet

- Form Fill Seal MachineDocument12 pagesForm Fill Seal Machineinfo tamil100% (1)

- Edta Cleaning PassivationDocument40 pagesEdta Cleaning Passivationsuleman247100% (1)

- Dokumen - Tips Bioflo 110 Modular Benchtop Fermentorbioreactor Fermentation Cell Culture SystemsDocument3 pagesDokumen - Tips Bioflo 110 Modular Benchtop Fermentorbioreactor Fermentation Cell Culture SystemsABMOHENo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- PW Scope and O&MDocument2 pagesPW Scope and O&MVaidyanathan KesavanNo ratings yet

- Ointment MFG System - UpdatedDocument2 pagesOintment MFG System - UpdatedVaidyanathan KesavanNo ratings yet

- Blister Pack - UpdatedDocument2 pagesBlister Pack - UpdatedVaidyanathan Kesavan100% (1)

- Air Handling Unit (AHU) System: ScopeDocument1 pageAir Handling Unit (AHU) System: ScopeVaidyanathan KesavanNo ratings yet

- Im-Ii-Qm-006-Sample Management For MicrobiologyDocument3 pagesIm-Ii-Qm-006-Sample Management For MicrobiologyVaidyanathan KesavanNo ratings yet

- IM-II-QM-001-Microbiology Department Entry & Exit FINALDocument5 pagesIM-II-QM-001-Microbiology Department Entry & Exit FINALVaidyanathan KesavanNo ratings yet