Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

0 viewsAmmonia 6000 Brochure

Ammonia 6000 Brochure

Uploaded by

Vaibhav Mishra 83Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- KBR - Ammonia Specific ExamplesDocument16 pagesKBR - Ammonia Specific Examplesqwerty9123467% (6)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Single PhaseDocument15 pagesSingle PhaseDhafin RizqiNo ratings yet

- J1237 Asian Paints HAZOP WSDocument98 pagesJ1237 Asian Paints HAZOP WSrohitkushNo ratings yet

- Bernoulli EquationDocument4 pagesBernoulli EquationShida Shidot100% (1)

- Consultation and Questionnaire 2021 Peric ElectrolyzersDocument2 pagesConsultation and Questionnaire 2021 Peric ElectrolyzersCristian BarrazaNo ratings yet

- Ammonia TechnologyDocument13 pagesAmmonia TechnologyMihaela Popescu-NeagoeNo ratings yet

- Blue Ammonia BrochureDocument8 pagesBlue Ammonia BrochureelenaNo ratings yet

- KBR Blue Ammonia BrochureDocument8 pagesKBR Blue Ammonia BrochureSuryo BrahmantioNo ratings yet

- Ammonia TechnologyDocument7 pagesAmmonia TechnologyAbhiyan Anala ArvindNo ratings yet

- Quantima BrochureDocument12 pagesQuantima BrochurePauline LunaNo ratings yet

- Chris DiFrancesco CORMETECHDocument22 pagesChris DiFrancesco CORMETECHDesign TeamNo ratings yet

- KRSD CompressorDocument7 pagesKRSD CompressorMohit PanchalNo ratings yet

- New SynCOR Ammonia™ ProcessDocument12 pagesNew SynCOR Ammonia™ Processrukam18No ratings yet

- Case Study Holcim Cement PlantDocument2 pagesCase Study Holcim Cement PlantAiman DadoushNo ratings yet

- Robust and Powerful: Oil-Free Piston CompressorsDocument8 pagesRobust and Powerful: Oil-Free Piston CompressorsMAZENNo ratings yet

- Driving Centrifugal Compressor TechnologyDocument52 pagesDriving Centrifugal Compressor TechnologySHRIKANT GADENo ratings yet

- Ammonia Process For FutureDocument5 pagesAmmonia Process For FutureSARFRAZ ALINo ratings yet

- CABP Feb 10 LR 0Document52 pagesCABP Feb 10 LR 0karun agrawalNo ratings yet

- 06 - KBR Ammonia Revamp Technology PDFDocument30 pages06 - KBR Ammonia Revamp Technology PDFMufadhzil M100% (1)

- Brochure Kboost V1 1sep2022Document5 pagesBrochure Kboost V1 1sep2022parsiti unnes100% (1)

- Lean Burn Product BrochureDocument8 pagesLean Burn Product BrochurepradeeepgargNo ratings yet

- 4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev ClaesDocument8 pages4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev Claesvaratharajan g rNo ratings yet

- Adi Anmbr BrochureDocument2 pagesAdi Anmbr BrochureprannoyNo ratings yet

- 05-NEWJCM Brochure 2016Document8 pages05-NEWJCM Brochure 2016RAVI SHANKARNo ratings yet

- K-Max: Industrial RangeDocument16 pagesK-Max: Industrial RangeAMIR100% (1)

- Nitrogen Generator Atlas CopcoDocument4 pagesNitrogen Generator Atlas CopcoVladimirNo ratings yet

- ScanTech Offshore Brochure 2020 OptimisedDocument28 pagesScanTech Offshore Brochure 2020 OptimisedMariana HusainNo ratings yet

- Johnson Matthey Ammonia Brochure PDFDocument24 pagesJohnson Matthey Ammonia Brochure PDFscribd405100% (1)

- Industrial: ApplicationsDocument18 pagesIndustrial: ApplicationsZakariya AbdiNo ratings yet

- KBR Advanced Ammonia Process PlusDocument1 pageKBR Advanced Ammonia Process PlusGajanan PadamwarNo ratings yet

- Ammonia TechnologyDocument13 pagesAmmonia TechnologyBai Singh100% (4)

- Driving Expander TechnologyDocument24 pagesDriving Expander TechnologysajadranjbaranNo ratings yet

- Champion Scroll Brochure GB WorkDocument8 pagesChampion Scroll Brochure GB WorkAndy KershawNo ratings yet

- D Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Document16 pagesD Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Luran JuNo ratings yet

- Link No 71 Customer Magazine 86450 Original English 86450Document32 pagesLink No 71 Customer Magazine 86450 Original English 86450Muhammad Farooq KokabNo ratings yet

- Marine Compressed Air SystemsDocument13 pagesMarine Compressed Air SystemsCompresores y Aplicaciones CyANo ratings yet

- Spesifikasi HCR 910 DSDocument7 pagesSpesifikasi HCR 910 DSYudi YusufNo ratings yet

- Cpa - CPB New Cataloge 11082016Document14 pagesCpa - CPB New Cataloge 11082016YugmeshNo ratings yet

- Asphalt Drum MixersDocument22 pagesAsphalt Drum MixersautocadNo ratings yet

- HYUNDAI Mitsubishi Gas Compressor Joint VentureDocument16 pagesHYUNDAI Mitsubishi Gas Compressor Joint Venturechimmy chinNo ratings yet

- Ready For More.: Cummins Tier 4 Final High-Horsepower Engines For The Mining IndustryDocument8 pagesReady For More.: Cummins Tier 4 Final High-Horsepower Engines For The Mining IndustryzugupubexeNo ratings yet

- KTR Kat99pp01 Coupling GuardDocument20 pagesKTR Kat99pp01 Coupling Guardmoorthymech1979100% (1)

- Working in A Fertilizer ComplexDocument49 pagesWorking in A Fertilizer ComplexSurendarNo ratings yet

- Biomod: Packaged Moving Bed Biofilm ReactorDocument4 pagesBiomod: Packaged Moving Bed Biofilm ReactorAlvaro Huete100% (1)

- Miller Welding Generator-Big Blue 500x Eco ProDocument8 pagesMiller Welding Generator-Big Blue 500x Eco Progroshan20No ratings yet

- A Guide To Cannabis Extraction Equipment and Machines - Articles - Analytical CannabisDocument25 pagesA Guide To Cannabis Extraction Equipment and Machines - Articles - Analytical CannabisCamilo Serna Restrepo100% (1)

- Oxymat N&O Onsite Solution, New - CompressedDocument4 pagesOxymat N&O Onsite Solution, New - CompressedHaad AhmedNo ratings yet

- Burton Corblin BrochureCompressorsBCDocument16 pagesBurton Corblin BrochureCompressorsBCmatteo2009No ratings yet

- Xas 47 Spec1 PDFDocument4 pagesXas 47 Spec1 PDFacarisimovicNo ratings yet

- Revamping Concepts For Urea Plants by Hans Van Den TillaartDocument31 pagesRevamping Concepts For Urea Plants by Hans Van Den TillaartMarc NijsseNo ratings yet

- Oil Free All MachineDocument20 pagesOil Free All Machinejennlin.changNo ratings yet

- WrightBus BrochureDocument11 pagesWrightBus BrochureB7 StudiosNo ratings yet

- ATB - GROUP BROCHURE RENEWABLES Small - WindDocument8 pagesATB - GROUP BROCHURE RENEWABLES Small - WindT Tryhard FnNo ratings yet

- CB-8494 C-B NATCOM Brochure - 2020-WEBDocument16 pagesCB-8494 C-B NATCOM Brochure - 2020-WEBChris Ian RaulNo ratings yet

- Andritz Air Pollution Control A4 201907 Screen DataDocument36 pagesAndritz Air Pollution Control A4 201907 Screen DataVinas KusdinarNo ratings yet

- KUKA KR QUANTEC Foundry ENDocument2 pagesKUKA KR QUANTEC Foundry ENjulián Andrés ToroNo ratings yet

- CMPL Corporate PresentationDocument27 pagesCMPL Corporate PresentationWatchara Thepjan100% (1)

- V04 Neu090608 PDFDocument15 pagesV04 Neu090608 PDFarmin heidariNo ratings yet

- New Prime 140Document16 pagesNew Prime 140Eduardo BallesterNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- Modeling, Analysis and Optimization of Process and Energy SystemsFrom EverandModeling, Analysis and Optimization of Process and Energy SystemsNo ratings yet

- Solution Chemistry OPTandonDocument24 pagesSolution Chemistry OPTandonCaleb AsharleyNo ratings yet

- 20 PSV 202 Pws SizingDocument6 pages20 PSV 202 Pws SizingsegunNo ratings yet

- PR-1047 Well Integrity MaintenanceDocument159 pagesPR-1047 Well Integrity Maintenancearslanadeel100% (2)

- Bete Fog Whitepaper PDFDocument9 pagesBete Fog Whitepaper PDFmalikaNo ratings yet

- KTA - TB-PAC03-M07-008.Rev0 - PRODUCED WATER PUMPS PIDDocument2 pagesKTA - TB-PAC03-M07-008.Rev0 - PRODUCED WATER PUMPS PIDlamNo ratings yet

- Flowfit CYA251: Technical InformationDocument12 pagesFlowfit CYA251: Technical InformationAngelica BarbaraNo ratings yet

- Chapter 3.3 - Conservation Laws (Conservation of Momentum)Document13 pagesChapter 3.3 - Conservation Laws (Conservation of Momentum)Nhlanhla PowerNo ratings yet

- Indian Standard-Industrial Process Control Valves PDFDocument48 pagesIndian Standard-Industrial Process Control Valves PDFMedaculoNo ratings yet

- ESA - GAS-1228 Adaptors Product Data Page EmailDocument2 pagesESA - GAS-1228 Adaptors Product Data Page EmailCharlie BrownNo ratings yet

- Module No 3: Boil Off Gas ManagementDocument30 pagesModule No 3: Boil Off Gas ManagementkhenzyNo ratings yet

- A700 EnglishDocument16 pagesA700 EnglishPablo MNo ratings yet

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 pagesBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoNo ratings yet

- 1 The Particles in Liquids and Gases Show Random MotionDocument2 pages1 The Particles in Liquids and Gases Show Random MotionDeshpande Shashibhushan AshokNo ratings yet

- ME-601 (TEGdDocument17 pagesME-601 (TEGdrohit choudharyNo ratings yet

- Development of Standards For Hydrogen SafetyDocument4 pagesDevelopment of Standards For Hydrogen SafetyJesusNo ratings yet

- Ficha VenturiDocument2 pagesFicha VenturiMaruRoja100% (1)

- Chloromethan PDFDocument6 pagesChloromethan PDFMatilda Gerbi ZazoNo ratings yet

- KVT Series - 31 - 11 - 2021Document2 pagesKVT Series - 31 - 11 - 2021csrc.1990scribdNo ratings yet

- Texas Air MoversDocument9 pagesTexas Air MoversAmran NazrinNo ratings yet

- BHBDocument6 pagesBHBHîsökå WMNo ratings yet

- Thermoflow OutputDocument40 pagesThermoflow Outputtiarrubuh100% (1)

- SMPV Draft Notification 2015 EnglishDocument66 pagesSMPV Draft Notification 2015 Englishsathish_iyengarNo ratings yet

- SeparatorsDocument18 pagesSeparatorsmohdusama100% (1)

- PED Guidelines EN v1.6 PDFDocument263 pagesPED Guidelines EN v1.6 PDFAdrian CeplinschiNo ratings yet

- MC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1Document8 pagesMC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- Esp Calculation StudioDocument7 pagesEsp Calculation StudioMohsin ShaikhNo ratings yet

Ammonia 6000 Brochure

Ammonia 6000 Brochure

Uploaded by

Vaibhav Mishra 830 ratings0% found this document useful (0 votes)

0 views4 pagesOriginal Title

Ammonia-6000-Brochure

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views4 pagesAmmonia 6000 Brochure

Ammonia 6000 Brochure

Uploaded by

Vaibhav Mishra 83Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

AMMONIA 6000®

Single Stream 6,000 MTPD Ammonia Plant

Single Stream 6,000 MTPD Ammonia Plant Using KBR’s

PurifierTM based technology

KBR offers its commercially well-proven and reliable uses an optimized equipment/piping count and sizes,

PurifierTM based ammonia technology to leverage economy and the factors that make it low on capital and operating

of scale and expand single-train production capacity expenditures are:

beyond the classic threshold of just 2,700 MTPD to more

than 6,000 MTPD, using industry standard equipment sizes ■ No hazardous oxygen-fired ATR

and catalysts. ■ No expensive Air Separation Unit (ASU) or Nitrogen

Wash Unit (NWU)

PURIFIER TM

HIGHLIGHTS

■ All equipment except ammonia converter and pumps

■ Large-scale, single-train units — in single unit i.e.:

Up to 6,000 MTPD capacity

■ One Primary Reformer

■ Commercially proven technology — PurifierTM

■ One Secondary Reformer without metallic burner

■ Reduced CAPEX and OPEX - Smaller size/count

of equipment ■ One Waste Heat Boiler

■ Achieved highest energy efficiency — ■ One vessel each for HT and LT Shift

6.27 Gcal/MT (LHV basis) ■ One CO2 Absorber, HP/LP Flash Column

■ Lower environmental footprint — and Stripper

Reduced CO2 and NOX emissions ■ One Methanator

■ Proven safety and reliability record vis-à-vis ATR ■ One Purifier unit — No Purge Gas Recovery Unit

■ No oxygen-fired ATR ■ One Synthesis Loop

PROVEN DESIGN, LOW CAPEX AND OPEX ■ One each of air compressor, refrigeration

Compressor and Synthesis Compressor

KBR’s ammonia process uses its proprietary Purifier TM

based technology for expanding single-stream capacity to ■ One Unitized Chiller

6,000 MTPD, using the same proven and highly reliable ■ All exchangers in single unit

design as used in established single stream plants (PurifierTM

technology is used in 39 plants worldwide, with 33 in ■ One ammonia converter

operation). PurifierTM ammonia process uses a single top- ■ Optimized Plot size — 210 M x 120 M

fired Primary Reformer that is not limited by size, unlike

competing technologies that employ an Auto Thermal

Reformer (ATR) to overcome this limitation. The design

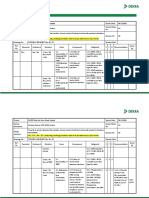

Fig : KBR PurifierTM for 6,000 MTPD Ammonia Plant

UNPARALLELED ENERGY EFFICIENCY EVOLUTION IN ECONOMY OF SCALE

The PurifierTM ammonia process exhibits a proven low As a world leader in developing design for single-stream,

energy consumption of just 6.27 Gcal/MT (LHV basis) that large-scale ammonia plants, the technology for the

can’t be matched by other technologies including Auto world’s first 600 to 2,200 MTPD single-stream plants was

Thermal Reformer (ATR) based technology. developed by KBR. Based on KBR’s PurifierTM technology,

a 2,700 MTPD capacity plant was commissioned in 2015,

SAFETY AND RELIABILITY while another plant designed for 2,700/2,890 MTPD was

commissioned in 2019. By 2017, KBR successfully completed

PurifierTM design guarantees safety as it does not use a

the design for a single-stream 4,000 MTPD ammonia plant

hazardous oxygen-fired ATR, which has been proven to

and has now completed design for a single-stream 6,000

make a plant inherently unsafe by leaving it vulnerable

MTPD ammonia plant that uses its time-tested PurifierTM

to safety incidents that occur due to explosions caused

technology.

by mishandling of oxygen or malfunction of pure oxygen

compressors and pumps. KBR PurifierTM plants have

achieved more than 1,600 consecutive on-stream days

without any shutdown!

Proven Design

No Oxygen-Fired ATR Established Commercial Base

Unmatched Energy Efficiency Smaller Plot & Carbon Footprint

Ammonia 6000®

Higher Single Stream Capacity Lowest Total Cost of Ownership

PROCESS SCHEMES

Safety & Reliability

KBR – YOUR RIGHT PARTNER

Since 1960s, KBR has licensed, engineered or constructed

more than 250 Ammonia plants worldwide and 40

of them are PurifierTM based (33 in operation), achieving

breakthrough operating performance and low energy

costs. The KBR PurifierTM Ammonia process helps

plant owners stay competitive by expanding single-

train capacity up to 6,000 MTPD to exploit economy of

scale, increase margins and reduce cost per ton of

ammonia produced.

kbr.com

Follow us on social media: Contact us for more information:

Social icon

Square

Only use blue and/or white.

For more details check out our

Brand Guidelines.

technology@kbr.com

K18014 © 2022 Kellogg Brown & Root LLC. All Rights Reserved. 09/2022

You might also like

- KBR - Ammonia Specific ExamplesDocument16 pagesKBR - Ammonia Specific Examplesqwerty9123467% (6)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Single PhaseDocument15 pagesSingle PhaseDhafin RizqiNo ratings yet

- J1237 Asian Paints HAZOP WSDocument98 pagesJ1237 Asian Paints HAZOP WSrohitkushNo ratings yet

- Bernoulli EquationDocument4 pagesBernoulli EquationShida Shidot100% (1)

- Consultation and Questionnaire 2021 Peric ElectrolyzersDocument2 pagesConsultation and Questionnaire 2021 Peric ElectrolyzersCristian BarrazaNo ratings yet

- Ammonia TechnologyDocument13 pagesAmmonia TechnologyMihaela Popescu-NeagoeNo ratings yet

- Blue Ammonia BrochureDocument8 pagesBlue Ammonia BrochureelenaNo ratings yet

- KBR Blue Ammonia BrochureDocument8 pagesKBR Blue Ammonia BrochureSuryo BrahmantioNo ratings yet

- Ammonia TechnologyDocument7 pagesAmmonia TechnologyAbhiyan Anala ArvindNo ratings yet

- Quantima BrochureDocument12 pagesQuantima BrochurePauline LunaNo ratings yet

- Chris DiFrancesco CORMETECHDocument22 pagesChris DiFrancesco CORMETECHDesign TeamNo ratings yet

- KRSD CompressorDocument7 pagesKRSD CompressorMohit PanchalNo ratings yet

- New SynCOR Ammonia™ ProcessDocument12 pagesNew SynCOR Ammonia™ Processrukam18No ratings yet

- Case Study Holcim Cement PlantDocument2 pagesCase Study Holcim Cement PlantAiman DadoushNo ratings yet

- Robust and Powerful: Oil-Free Piston CompressorsDocument8 pagesRobust and Powerful: Oil-Free Piston CompressorsMAZENNo ratings yet

- Driving Centrifugal Compressor TechnologyDocument52 pagesDriving Centrifugal Compressor TechnologySHRIKANT GADENo ratings yet

- Ammonia Process For FutureDocument5 pagesAmmonia Process For FutureSARFRAZ ALINo ratings yet

- CABP Feb 10 LR 0Document52 pagesCABP Feb 10 LR 0karun agrawalNo ratings yet

- 06 - KBR Ammonia Revamp Technology PDFDocument30 pages06 - KBR Ammonia Revamp Technology PDFMufadhzil M100% (1)

- Brochure Kboost V1 1sep2022Document5 pagesBrochure Kboost V1 1sep2022parsiti unnes100% (1)

- Lean Burn Product BrochureDocument8 pagesLean Burn Product BrochurepradeeepgargNo ratings yet

- 4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev ClaesDocument8 pages4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev Claesvaratharajan g rNo ratings yet

- Adi Anmbr BrochureDocument2 pagesAdi Anmbr BrochureprannoyNo ratings yet

- 05-NEWJCM Brochure 2016Document8 pages05-NEWJCM Brochure 2016RAVI SHANKARNo ratings yet

- K-Max: Industrial RangeDocument16 pagesK-Max: Industrial RangeAMIR100% (1)

- Nitrogen Generator Atlas CopcoDocument4 pagesNitrogen Generator Atlas CopcoVladimirNo ratings yet

- ScanTech Offshore Brochure 2020 OptimisedDocument28 pagesScanTech Offshore Brochure 2020 OptimisedMariana HusainNo ratings yet

- Johnson Matthey Ammonia Brochure PDFDocument24 pagesJohnson Matthey Ammonia Brochure PDFscribd405100% (1)

- Industrial: ApplicationsDocument18 pagesIndustrial: ApplicationsZakariya AbdiNo ratings yet

- KBR Advanced Ammonia Process PlusDocument1 pageKBR Advanced Ammonia Process PlusGajanan PadamwarNo ratings yet

- Ammonia TechnologyDocument13 pagesAmmonia TechnologyBai Singh100% (4)

- Driving Expander TechnologyDocument24 pagesDriving Expander TechnologysajadranjbaranNo ratings yet

- Champion Scroll Brochure GB WorkDocument8 pagesChampion Scroll Brochure GB WorkAndy KershawNo ratings yet

- D Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Document16 pagesD Series: 75 kW-160 KW Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS)Luran JuNo ratings yet

- Link No 71 Customer Magazine 86450 Original English 86450Document32 pagesLink No 71 Customer Magazine 86450 Original English 86450Muhammad Farooq KokabNo ratings yet

- Marine Compressed Air SystemsDocument13 pagesMarine Compressed Air SystemsCompresores y Aplicaciones CyANo ratings yet

- Spesifikasi HCR 910 DSDocument7 pagesSpesifikasi HCR 910 DSYudi YusufNo ratings yet

- Cpa - CPB New Cataloge 11082016Document14 pagesCpa - CPB New Cataloge 11082016YugmeshNo ratings yet

- Asphalt Drum MixersDocument22 pagesAsphalt Drum MixersautocadNo ratings yet

- HYUNDAI Mitsubishi Gas Compressor Joint VentureDocument16 pagesHYUNDAI Mitsubishi Gas Compressor Joint Venturechimmy chinNo ratings yet

- Ready For More.: Cummins Tier 4 Final High-Horsepower Engines For The Mining IndustryDocument8 pagesReady For More.: Cummins Tier 4 Final High-Horsepower Engines For The Mining IndustryzugupubexeNo ratings yet

- KTR Kat99pp01 Coupling GuardDocument20 pagesKTR Kat99pp01 Coupling Guardmoorthymech1979100% (1)

- Working in A Fertilizer ComplexDocument49 pagesWorking in A Fertilizer ComplexSurendarNo ratings yet

- Biomod: Packaged Moving Bed Biofilm ReactorDocument4 pagesBiomod: Packaged Moving Bed Biofilm ReactorAlvaro Huete100% (1)

- Miller Welding Generator-Big Blue 500x Eco ProDocument8 pagesMiller Welding Generator-Big Blue 500x Eco Progroshan20No ratings yet

- A Guide To Cannabis Extraction Equipment and Machines - Articles - Analytical CannabisDocument25 pagesA Guide To Cannabis Extraction Equipment and Machines - Articles - Analytical CannabisCamilo Serna Restrepo100% (1)

- Oxymat N&O Onsite Solution, New - CompressedDocument4 pagesOxymat N&O Onsite Solution, New - CompressedHaad AhmedNo ratings yet

- Burton Corblin BrochureCompressorsBCDocument16 pagesBurton Corblin BrochureCompressorsBCmatteo2009No ratings yet

- Xas 47 Spec1 PDFDocument4 pagesXas 47 Spec1 PDFacarisimovicNo ratings yet

- Revamping Concepts For Urea Plants by Hans Van Den TillaartDocument31 pagesRevamping Concepts For Urea Plants by Hans Van Den TillaartMarc NijsseNo ratings yet

- Oil Free All MachineDocument20 pagesOil Free All Machinejennlin.changNo ratings yet

- WrightBus BrochureDocument11 pagesWrightBus BrochureB7 StudiosNo ratings yet

- ATB - GROUP BROCHURE RENEWABLES Small - WindDocument8 pagesATB - GROUP BROCHURE RENEWABLES Small - WindT Tryhard FnNo ratings yet

- CB-8494 C-B NATCOM Brochure - 2020-WEBDocument16 pagesCB-8494 C-B NATCOM Brochure - 2020-WEBChris Ian RaulNo ratings yet

- Andritz Air Pollution Control A4 201907 Screen DataDocument36 pagesAndritz Air Pollution Control A4 201907 Screen DataVinas KusdinarNo ratings yet

- KUKA KR QUANTEC Foundry ENDocument2 pagesKUKA KR QUANTEC Foundry ENjulián Andrés ToroNo ratings yet

- CMPL Corporate PresentationDocument27 pagesCMPL Corporate PresentationWatchara Thepjan100% (1)

- V04 Neu090608 PDFDocument15 pagesV04 Neu090608 PDFarmin heidariNo ratings yet

- New Prime 140Document16 pagesNew Prime 140Eduardo BallesterNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Millimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyFrom EverandMillimeter-Wave Receiver Concepts for 77 GHz Automotive Radar in Silicon-Germanium TechnologyNo ratings yet

- Modeling, Analysis and Optimization of Process and Energy SystemsFrom EverandModeling, Analysis and Optimization of Process and Energy SystemsNo ratings yet

- Solution Chemistry OPTandonDocument24 pagesSolution Chemistry OPTandonCaleb AsharleyNo ratings yet

- 20 PSV 202 Pws SizingDocument6 pages20 PSV 202 Pws SizingsegunNo ratings yet

- PR-1047 Well Integrity MaintenanceDocument159 pagesPR-1047 Well Integrity Maintenancearslanadeel100% (2)

- Bete Fog Whitepaper PDFDocument9 pagesBete Fog Whitepaper PDFmalikaNo ratings yet

- KTA - TB-PAC03-M07-008.Rev0 - PRODUCED WATER PUMPS PIDDocument2 pagesKTA - TB-PAC03-M07-008.Rev0 - PRODUCED WATER PUMPS PIDlamNo ratings yet

- Flowfit CYA251: Technical InformationDocument12 pagesFlowfit CYA251: Technical InformationAngelica BarbaraNo ratings yet

- Chapter 3.3 - Conservation Laws (Conservation of Momentum)Document13 pagesChapter 3.3 - Conservation Laws (Conservation of Momentum)Nhlanhla PowerNo ratings yet

- Indian Standard-Industrial Process Control Valves PDFDocument48 pagesIndian Standard-Industrial Process Control Valves PDFMedaculoNo ratings yet

- ESA - GAS-1228 Adaptors Product Data Page EmailDocument2 pagesESA - GAS-1228 Adaptors Product Data Page EmailCharlie BrownNo ratings yet

- Module No 3: Boil Off Gas ManagementDocument30 pagesModule No 3: Boil Off Gas ManagementkhenzyNo ratings yet

- A700 EnglishDocument16 pagesA700 EnglishPablo MNo ratings yet

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 pagesBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoNo ratings yet

- 1 The Particles in Liquids and Gases Show Random MotionDocument2 pages1 The Particles in Liquids and Gases Show Random MotionDeshpande Shashibhushan AshokNo ratings yet

- ME-601 (TEGdDocument17 pagesME-601 (TEGdrohit choudharyNo ratings yet

- Development of Standards For Hydrogen SafetyDocument4 pagesDevelopment of Standards For Hydrogen SafetyJesusNo ratings yet

- Ficha VenturiDocument2 pagesFicha VenturiMaruRoja100% (1)

- Chloromethan PDFDocument6 pagesChloromethan PDFMatilda Gerbi ZazoNo ratings yet

- KVT Series - 31 - 11 - 2021Document2 pagesKVT Series - 31 - 11 - 2021csrc.1990scribdNo ratings yet

- Texas Air MoversDocument9 pagesTexas Air MoversAmran NazrinNo ratings yet

- BHBDocument6 pagesBHBHîsökå WMNo ratings yet

- Thermoflow OutputDocument40 pagesThermoflow Outputtiarrubuh100% (1)

- SMPV Draft Notification 2015 EnglishDocument66 pagesSMPV Draft Notification 2015 Englishsathish_iyengarNo ratings yet

- SeparatorsDocument18 pagesSeparatorsmohdusama100% (1)

- PED Guidelines EN v1.6 PDFDocument263 pagesPED Guidelines EN v1.6 PDFAdrian CeplinschiNo ratings yet

- MC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1Document8 pagesMC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- Esp Calculation StudioDocument7 pagesEsp Calculation StudioMohsin ShaikhNo ratings yet