Professional Documents

Culture Documents

Project Execution Plan

Project Execution Plan

Uploaded by

Chiamaka ObadiegwuCopyright:

Available Formats

You might also like

- Full Corporate Offer FcoDocument3 pagesFull Corporate Offer FcoFantania Berry100% (1)

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- HDD Procedure - HDD PengaponDocument46 pagesHDD Procedure - HDD PengaponBubu Keke Caca100% (3)

- Trade Assurance Purchase ContractDocument2 pagesTrade Assurance Purchase ContractmanueldjmNo ratings yet

- How The West Grew RichDocument15 pagesHow The West Grew Richstef_al68No ratings yet

- 12 MEPL P 1019 0 (Pipeline Calculation Book)Document40 pages12 MEPL P 1019 0 (Pipeline Calculation Book)Ibad Alam100% (4)

- Technical Specifications of Tubewell WorksDocument13 pagesTechnical Specifications of Tubewell WorksLeng Chai100% (1)

- Ground Improvement Procedure Rev.0Document14 pagesGround Improvement Procedure Rev.0Muhammad AfrasiyabNo ratings yet

- Introduction To Piping Material ActivitiesDocument23 pagesIntroduction To Piping Material ActivitiesAnh Vân TrầnNo ratings yet

- Specification For Construction, Testing & Commissioning of Ductile Iron Pipe SystemDocument46 pagesSpecification For Construction, Testing & Commissioning of Ductile Iron Pipe SystemAmro HarasisNo ratings yet

- TS For Pipe-Duct DismantlingDocument10 pagesTS For Pipe-Duct DismantlingAmitava SilNo ratings yet

- Pipelines Repair and Maintenance PDFDocument36 pagesPipelines Repair and Maintenance PDFMohd Idris MohiuddinNo ratings yet

- MST Installation of UPVC PIPESDocument10 pagesMST Installation of UPVC PIPESShahzaib ShahidNo ratings yet

- NM2-SCI-HT-0-EXC-MS-0007-B-PRL - CMS For Inlet and Headrace Tunnel Excavation, Temparory ProtectionDocument35 pagesNM2-SCI-HT-0-EXC-MS-0007-B-PRL - CMS For Inlet and Headrace Tunnel Excavation, Temparory ProtectionJoseph NguyenNo ratings yet

- Method Statement For RebarDocument8 pagesMethod Statement For RebarEng hassan hussien100% (1)

- Sow E&c Pipeline Gsd-GospaDocument33 pagesSow E&c Pipeline Gsd-GospasoufienNo ratings yet

- NACE TR21473-2024 In-Situ Coating of Steel Pipelines Via PiggingDocument16 pagesNACE TR21473-2024 In-Situ Coating of Steel Pipelines Via Piggingahugandkiss77071No ratings yet

- Technical SpecificationsDocument135 pagesTechnical SpecificationsSrinivasan RajenderanNo ratings yet

- MS For Diaphragm Wall Repair Works PDFDocument17 pagesMS For Diaphragm Wall Repair Works PDFHema100% (1)

- MNTQ-CW03-AMCT-MEC-MST-000002 Rev03Document21 pagesMNTQ-CW03-AMCT-MEC-MST-000002 Rev03ZuberYousufNo ratings yet

- Method Statement For CPVC & UPVC PIPINGDocument14 pagesMethod Statement For CPVC & UPVC PIPINGVikramNo ratings yet

- D1 DRAFTDocument24 pagesD1 DRAFTSumantra ChattopadhyayNo ratings yet

- JMS For Drainage & Sewage WorksDocument16 pagesJMS For Drainage & Sewage WorksazrulNo ratings yet

- Specification For Construction, Testing & Commissioning of High Density Polyethylene (Hdpe) Pipe SystemDocument35 pagesSpecification For Construction, Testing & Commissioning of High Density Polyethylene (Hdpe) Pipe SystemCristel Diane Dela CruzNo ratings yet

- DNV RP F102 (Pipe Line Coating) (2003)Document38 pagesDNV RP F102 (Pipe Line Coating) (2003)Rana krupalNo ratings yet

- Design Guidelines Wastewater Networks - Gravity Foul Sewers SystemsDocument13 pagesDesign Guidelines Wastewater Networks - Gravity Foul Sewers Systemshajer100% (1)

- Section 8: Water Supply NetworkDocument34 pagesSection 8: Water Supply Networkayaz hasanNo ratings yet

- Field CoatingDocument26 pagesField Coatingsohn2342100% (1)

- PIP CVS02830 Chain Link Fence and GatesDocument11 pagesPIP CVS02830 Chain Link Fence and Gatesnoto.sugiartoNo ratings yet

- CMIT-796-PIP-15.69-00-0008 - 0 3D Model Review ProcedureDocument10 pagesCMIT-796-PIP-15.69-00-0008 - 0 3D Model Review ProcedurenadaNo ratings yet

- Guidelines For Horizontal Directional Drilling Pipe Bursting Microtunnelling and PJDocument60 pagesGuidelines For Horizontal Directional Drilling Pipe Bursting Microtunnelling and PJBayu Setiawan100% (1)

- T Proc Notices Notices 040 K Notice Doc 35270 446041633Document12 pagesT Proc Notices Notices 040 K Notice Doc 35270 446041633Amjad aliNo ratings yet

- Ballast TK HempelsDocument15 pagesBallast TK HempelsGeorgios PapakostasNo ratings yet

- Method Pumps) (K)Document7 pagesMethod Pumps) (K)Tagel MarkosNo ratings yet

- 002 Tipp-sct-Ahc-ms-002 Method Statment For GRP Pipe InstallationDocument30 pages002 Tipp-sct-Ahc-ms-002 Method Statment For GRP Pipe InstallationZishan AliNo ratings yet

- Construction Installation & Management PlanDocument47 pagesConstruction Installation & Management PlanSaurabh DwivediNo ratings yet

- PED PACK2 Part2A Scope RDSSDocument118 pagesPED PACK2 Part2A Scope RDSSAnil KumarNo ratings yet

- PR157117 - Section II - Scope of WorksDocument25 pagesPR157117 - Section II - Scope of Worksrad1978wanNo ratings yet

- TRHT TB PL 18 Oo 201 - 0Document21 pagesTRHT TB PL 18 Oo 201 - 0belhaskaNo ratings yet

- Cooke Ductwork ManualDocument37 pagesCooke Ductwork Manualquantum 46bNo ratings yet

- Kuwait Oil Company (Kusrncu) : Specification NumberDocument9 pagesKuwait Oil Company (Kusrncu) : Specification Numbernpwal100% (1)

- TEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Document8 pagesTEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Haymanot BaynesagnNo ratings yet

- Engineering Guide Double Contained SewersDocument12 pagesEngineering Guide Double Contained SewersAkram DriraNo ratings yet

- PART 2 - WORK REQUIREMENTS Rev 4a - May Date and Revised Schedule Dates PDFDocument20 pagesPART 2 - WORK REQUIREMENTS Rev 4a - May Date and Revised Schedule Dates PDFSureesh VRNo ratings yet

- MS - Retention Basin Leak TestingDocument4 pagesMS - Retention Basin Leak Testingmoytabura96No ratings yet

- Method Statement For Installation of MATV Distribution SystemDocument7 pagesMethod Statement For Installation of MATV Distribution SystemDong VanraNo ratings yet

- Hydrotest Pressure Procedure - 2023Document15 pagesHydrotest Pressure Procedure - 2023Amit HasanNo ratings yet

- Australasian Society For Trenchless Technologies - Guidelines For HDDDocument44 pagesAustralasian Society For Trenchless Technologies - Guidelines For HDDdiogenes_el_cinicoNo ratings yet

- HFY-GEN-CP-SPC-0001 - D Specification For Piping and Pipeline Coating Code-ADocument37 pagesHFY-GEN-CP-SPC-0001 - D Specification For Piping and Pipeline Coating Code-ATahir FadhilNo ratings yet

- Method Statement Pipe Handling and AssemblyDocument6 pagesMethod Statement Pipe Handling and AssemblyDanny NguNo ratings yet

- W C Ss 007Document25 pagesW C Ss 007Adrianto HermawanNo ratings yet

- Minor Losses in Pipe Fittings BendsDocument8 pagesMinor Losses in Pipe Fittings BendsHashim AnsariNo ratings yet

- Saes L 470Document10 pagesSaes L 470abaanNo ratings yet

- Repair Techniques For in Service and Out of Service Buried PipelinesDocument26 pagesRepair Techniques For in Service and Out of Service Buried PipelinesAnonymous wKvJXBJ2i100% (1)

- 101445-00-ER-Probe-and-Coupon-Installation-and-Commissioning-GuidelinesDocument17 pages101445-00-ER-Probe-and-Coupon-Installation-and-Commissioning-GuidelinesLuz Alexandra ManriqueNo ratings yet

- Implementation of Expansion LoopsDocument13 pagesImplementation of Expansion LoopsSSS100% (1)

- 01 Integrity Management of CRA Pipelines - 20 December 2015 PDFDocument24 pages01 Integrity Management of CRA Pipelines - 20 December 2015 PDFIndunil Prasanna Bandara WarnasooriyaNo ratings yet

- HAC-10143-MS-CIV-003-Method Statement For Concrete RepairDocument26 pagesHAC-10143-MS-CIV-003-Method Statement For Concrete RepairHema playsNo ratings yet

- Technical Specifications of Kuraz Road Final HG1Document37 pagesTechnical Specifications of Kuraz Road Final HG1ABAMELANo ratings yet

- Emergancy Response PlanDocument23 pagesEmergancy Response Plan今夕何夕No ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Methodologies for Assessing Pipe Failure Rates in Advanced Water Cooled ReactorsFrom EverandMethodologies for Assessing Pipe Failure Rates in Advanced Water Cooled ReactorsNo ratings yet

- InductiveReasoningTest7 SolutionsDocument31 pagesInductiveReasoningTest7 SolutionsChiamaka ObadiegwuNo ratings yet

- InductiveReasoningTest4 SolutionsDocument31 pagesInductiveReasoningTest4 SolutionsChiamaka ObadiegwuNo ratings yet

- InductiveReasoningTest4 QuestionsDocument16 pagesInductiveReasoningTest4 QuestionsChiamaka ObadiegwuNo ratings yet

- InductiveReasoningTest4 QuestionsDocument16 pagesInductiveReasoningTest4 QuestionsChiamaka ObadiegwuNo ratings yet

- InductiveReasoningTest2 QuestionsDocument16 pagesInductiveReasoningTest2 QuestionsChiamaka ObadiegwuNo ratings yet

- Test2 QuestionsDocument11 pagesTest2 QuestionsChiamaka ObadiegwuNo ratings yet

- Test3 QuestionsDocument10 pagesTest3 QuestionsChiamaka ObadiegwuNo ratings yet

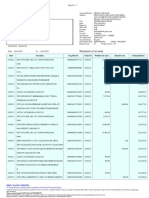

- Integrated Pipeline Repair and Maintenance Project ScheduleDocument1 pageIntegrated Pipeline Repair and Maintenance Project ScheduleChiamaka ObadiegwuNo ratings yet

- 3.6 A. Change Management PlanDocument10 pages3.6 A. Change Management PlanChiamaka ObadiegwuNo ratings yet

- Ward J Barrett - The Sugar Hacienda of The Marqueses Del Valle-University of Minnesota Press ( (1970) )Document160 pagesWard J Barrett - The Sugar Hacienda of The Marqueses Del Valle-University of Minnesota Press ( (1970) )JeronimoNo ratings yet

- Poultry Development and Marketing EnterpriseDocument32 pagesPoultry Development and Marketing EnterpriseKassaye KA Arage100% (1)

- Priya Sagar Jena Hod Assignment-1 222122233Document12 pagesPriya Sagar Jena Hod Assignment-1 222122233Priya Sagar JenaNo ratings yet

- The Industrial Revolution in Great BritainDocument3 pagesThe Industrial Revolution in Great BritainIulia Badea0% (1)

- All Shut Down Request For WD-04 GIS&MAX PDFDocument235 pagesAll Shut Down Request For WD-04 GIS&MAX PDFahmed kabilNo ratings yet

- Kumbakonam Market - Traders Profile: S.No Traders Name Shop Name Address Commodities Phone NoDocument19 pagesKumbakonam Market - Traders Profile: S.No Traders Name Shop Name Address Commodities Phone NoRajan BLNo ratings yet

- 03022021080314Document97 pages03022021080314Charity Bless MontemorNo ratings yet

- Flight TicketDocument3 pagesFlight TicketAkshay KanyanNo ratings yet

- ON Dry Fish Business: Submitted byDocument6 pagesON Dry Fish Business: Submitted byKartik DebnathNo ratings yet

- ADVANCED FA Chap IIIDocument7 pagesADVANCED FA Chap IIIFasiko Asmaro100% (1)

- Digital Load Cell UpgradeDocument2 pagesDigital Load Cell UpgradeEdgarNo ratings yet

- Cerculating DryerDocument11 pagesCerculating DryerBagong anyo NAMCU FIANo ratings yet

- Startup January - 2020Document780 pagesStartup January - 2020Devansh SinghNo ratings yet

- CompReg 19JUNE2023Document963 pagesCompReg 19JUNE2023Saee SuryawanshiNo ratings yet

- Module 6 - The 2 Major Types of Accounts - RevisedDocument15 pagesModule 6 - The 2 Major Types of Accounts - Revisedgerlie gabrielNo ratings yet

- Faridabad Customer ListDocument1 pageFaridabad Customer Listsaurabh2986No ratings yet

- A Study On Nestle India - 76757220Document70 pagesA Study On Nestle India - 76757220Siddharth SinghNo ratings yet

- Trailer and Tipper Body For Printed (January 2019)Document24 pagesTrailer and Tipper Body For Printed (January 2019)mokeNo ratings yet

- La Concepcion College City of San Jose Del Monte, Bulacan Engineering Division Final Examination ES19-Technopreneurship 101 2 Semester-A.Y. 2020-2021Document4 pagesLa Concepcion College City of San Jose Del Monte, Bulacan Engineering Division Final Examination ES19-Technopreneurship 101 2 Semester-A.Y. 2020-2021John Lloyd BallaNo ratings yet

- Attachment II Importers 1Document26 pagesAttachment II Importers 1sales01No ratings yet

- BPCL Ethanol Booklet 2023Document22 pagesBPCL Ethanol Booklet 2023Subhankar SubuNo ratings yet

- Mulualem AmareDocument79 pagesMulualem AmareYitbarek GebrehiwotNo ratings yet

- UAS BING Ferdy Setyaluhur 2001061057Document11 pagesUAS BING Ferdy Setyaluhur 2001061057kibooNo ratings yet

- Holistic Environment: Current Investment Areas in KedahDocument10 pagesHolistic Environment: Current Investment Areas in Kedahhannsen13No ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument12 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceChelana JainNo ratings yet

- Afreximbank Film Development Financing FacilityDocument4 pagesAfreximbank Film Development Financing FacilityafrimagejalabNo ratings yet

- Indee KenyaDocument5 pagesIndee KenyaVishal MandlikNo ratings yet

Project Execution Plan

Project Execution Plan

Uploaded by

Chiamaka ObadiegwuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Execution Plan

Project Execution Plan

Uploaded by

Chiamaka ObadiegwuCopyright:

Available Formats

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 1 of 32

TABLE OF CONTENTS

1. INTRODUCTION...............................................................................................................3

2. ABBREVIATIONS.............................................................................................................3

3. SCOPE OF WORK SUMMARY........................................................................................4

4. GENERAL REQUIREMENTS:..........................................................................................7

4.1 PROJECT MANAGEMENT:.........................................................................................7

4.2 LOGISTICS AND ACCOMMODATION:.......................................................................8

4.3 ACCESS TO COMPANY AND OTHER SUBCONTRACTORS:..................................8

4.4 PROCUREMENT AND MATERIAL MANAGEMENT:..................................................9

4.5 DISPOSAL:...................................................................................................................9

4.6 PLANNING AND SCHEDULING:.................................................................................9

3.7 QUALITY ASSURANCE AND QUALITY CONTROL:................................................10

3.8 WORK SITES AND ACCESS:....................................................................................10

3.9 COMPANY INVOLVEMENT:.......................................................................................11

4. FABRICATION ENGINEERING..............................................................................12

5. PROCUREMENT........................................................................................................13

51 CONTRACTORS RESPONSIBILITY.................................................................13

5.2 CONTRACTOR’S MATERIAL CONTROL.......................................................15

5.3 MATERIAL MANAGEMENT................................................................................16

5.4 MATERIALS AND EQUIPMENT PRESERVATION........................................16

6. FABRICATION............................................................................................................17

6.1 GENERAL................................................................................................................17

6.2 PROCEDURE..........................................................................................................17

6.2.1 WELDING NOTES..............................................................................................18

6.2.2 MATERIAL CONTROL......................................................................................18

6.2.3 MATERIAL PREPARATION.............................................................................19

6.2.4 CONTROL ASSEMBLY.....................................................................................20

6.2.5 WELDING CONTROL........................................................................................21

6.2.6 INSPECTION AND TESTING..........................................................................21

6.2.7 WELDS REPAIR.................................................................................................22

6.2.8 INSPECTION AND TEST STATUS.................................................................23

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 2 of 32

7 LOGISTICS..................................................................................................................25

8 INSTALLATION AND CONSTRUCTION..............................................................26

8.1 GENERAL................................................................................................................26

8.2 PRE-INSTALLATION ACTIVITIES.....................................................................26

8.3 HEAVY LIFTING.....................................................................................................27

8.4 HYDROTEST AND PRE-COMMISSIONING...................................................28

8.5 FIELD JOINT COATING (FJC)...........................................................................28

8.6 PAINTING.................................................................................................................28

9. COMMISSIONING, PERFORMANCE TESTING................................................29

9.1 COMMISSIONING..................................................................................................29

9.2 PERFORMANCE TESTING.................................................................................29

10. CLEANING AND RESTORATION......................................................................30

11. PLANNING REPORTING AND CONTROL.....................................................30

12. HSE MANAGEMENT.............................................................................................32

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 3 of 32

1. INTRODUCTION

This document describes the design, supply and procurement of materials and

equipment, transportation, fabrication, site preparation, installation, welding,

hydro testing, surface preparation, painting, coating, preparation of testing

forms, developing progress reports of all labor, supervision, tools, testing

equipment, all facilities furnished by Contractor for use of Contractor employees,

specifically including, but not limited to: all Contractor’s work camps,

transportation, accommodation, mobilization and demobilization for the Pipeline

Rehabilitation and Repair Project.

The WORK shall be completed in accordance with applicable codes, standards,

procedures, specifications, good engineering practices and the programme

contained in the Contract.

2. ABBREVIATIONS

CES Contract Execution Strategy

FJC Field Joint Coating

HSE Health Safety Environment

MDR Master Document Register

MEDEVAC Medical Evacuation

MTO Material Take Off

NDT Non Destructive Testing

PO Purchase Order

PPSL Petro Pride Subsea Limited

PQR Performance Qualification Record

QA/QC Quality assurance and quality control

WPQR Welder Performance Qualification Record

WPS Welding Procedure Specification

WQT Welders Qualification Test

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 4 of 32

3. SCOPE OF WORK SUMMARY

The WORK to be covered generally consists of all works incidental and

necessary to the successful completion of pipeline maintenance and repairs

works involving manifold piping works, pipeline civil structure maintenance,

valves maintenance, low/intermediate emergency pipeline repairs, manifolds

protection systems installations/repairs, composite repairs, cathodic protection

repairs/upgrades and planned pipeline upgrades/rehabilitations in THE

COMPANY’s Land, Swamp and shallow offshore Areas of Eastern and Western

Divisions.

The scope of work to be covered includes the following:

ACTIVITY SCOPE SUMMARY DIMENSION

1. Manifolds Paintings [blasting and

Up to 48’’

painting of manifolds].

diameter

2. Scraper trap repairs / upgrades.

pipelines

3. Installation of sampling points/ other

max on land

specialized points.

terrain

Manifold piping

Up to

works

48’’diameter

4. Manifolds piping supports repairs/

pipelines

replacements

max in

5. Manifold piping repairs/upgrades

Swamp

terrains

1. Upgrade/maintenance of existing access All

roads. manifold civil

2. Dredging works

works

3. Land Manifold [M/F] civil works [hard All size

standing areas, drains, saver pits, pipe cofferdams

supports]. [24 m long x

12 m wide x

Civil & Structural 4. Pipeline Repairs supports [cofferdams,

24 m deep

Works shorings, special access]

max]

5. Construction/repairs of Warning signs, valve

operating platforms

All Swamp

6. Construction/maintenance of swamp

M/F

manifold guard huts

extensions

7. ROW Hardening using Citadel and other

approved materials

1. Design, install and repair enhanced All scope

Manifolds manifold cages. [enhanced

Protection Systems

2. Design, install and maintain pipeline cages, anti-

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 5 of 32

facilities intruder detection/remote monitoring

systems

3. Design, manufacture, installation, and tamper

maintenance of valve anti-tamper systems locks etc.] for

all land

48” Diameter

max on land

and 48"

Replacement of flanged valves

Diameter

max in

Valve replacements Swamp

48" diameter

Replacement of welded valves max land

and swamp

All scope

land and

1. In-situ valve maintenance swamp [1/2"

Valve maintenance

2. Major offline valve repairs - 48" valves

ranging from

Class 150LB

Repairs by installation of bolted split sleeve Clamping

clamps. by screwed plugs. Repairs by

Repairs and

Composites. composites

Repairs by sectional replacements [using [4" - 48"]

mechanical connector’s e.g weld plus ends including

and welding]. major

Repairs by installation of welded bolted split cofferdams

Gas lines Repairs sleeve clamps. and river

Repairs by installation of welded split sleeve crossings. –

tee. wet gas lines

sectional

replacement

Repairs by installation of Split sleeve [up to 48”

diameter

max]

1. Sectional replacements using line flushing

Major sectional 2. Sectional replacements using freeze plug

Delivery

replacements of oil isolations, mechanical plugs etc

Trunk line

lines including 3. Sectional replacements using hot tap and

(48" max]

welded valves stopple isolations

4. Sectional replacement by drain and plug

Riser burials 1. Removal of existing riser system and 4” to

replacement

2. Replacement with completely

of existing buried

corroded/damaged 48” Diameter

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 6 of 32

risers

pipelines

land and

Crossings

3km wide

1. River crossing sectional replacements

River crossings max up to

2. River crossing emergency repairs

48" diameter

pipelines

1. Casing replacements/ repairs Up to 48”

Road crossings 2. Construction of new road crossings pipeline

diameter

3. Repairs to existing road crossings

max and

Clamping +

screwed

plugs on all

1. Repairs by installation of bolted split sleeve

pipeline

Emergency clamps.

sizes [4" to

Pipeline Repairs 2. Repairs by screwed plugs.

48"]

for Oil and 3. Repairs by Composite

Sectional

Condensate 4. Repairs by sectional replacements [using

replacement

Pipelines mechanical connectors e.g weld plus ends and

s on 4” –

welding].

48” diameter

pipelines

max

1. Repairs by installation of bolted split sleeve

clamps for defect repairs

3. Repairs by Composites.

Planned Repairs 4. Repairs by sectional replacements [using

and Upgrade for mechanical connectors e.g. weld plus ends,

Oil and replacement by welding of pipe sections, etc.].

Condensate 5. Repairs by installation of welded bolted split

Pipelines sleeve clamps.

6. Repairs by installation of welded split sleeve

tee for non -leaking illegal connections

7. Repairs by installation of Split sleeves for

defect repairs

Composites All sizes [4"

Application of composite approved by the

Repairs / to 48"

company

Upgrades diameters]

Decommissioning 1. Removal of stagnant oil including provision 4" to 48"

Abandonment of water and water supply lines diameter

disused pipelines 2. Excavation and removal of pipelines and pipelines

manifolds end facilities Land and

3. Disposal of effluents / provision of flushing Swamp

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 7 of 32

All [ground

CP Systems surveys,

Upgrade / Repairs posts,

systems,

All diameters

1. Coating surveys except where

Coating Survey

2. Repairs to damaged/deteriorated coatings major

and repairs

3. Supply of coating materials cofferdams

are required

4. GENERAL REQUIREMENTS:

CONTRACTOR shall be responsible for the execution of the WORK in

compliance with all requirements of the CONTRACT.

4.1 Project Management:

In accordance with the Project requirements, CONTRACTOR shall designate a

Project Manager with full authority to make decisions concerning the

performance and execution of the WORK. This person (or designate) shall be

available for consultation throughout the duration of the WORK.

All CONTRACTOR personnel nominated for key positions shall be approved by

COMPANY and shall meet the competency and experience levels required by

the Contract. All personnel will execute the WORK safely, consistent with quality

requirements, and in timely manner, as determined by COMPANY.

CONTRACTOR shall provide, maintain and be responsible for management and

control of all resources to deliver the WORK in accordance with the Contract

and to COMPANY satisfaction.

CONTRACTOR shall adopt and maintain a systematic approach to the WORK.

As a minimum, the activities shall include provision of the means to ensure that:

Management of and execution of the WORK are at all times conducted in

accordance with the Contract Execution Strategy(CES) (including all

procedures, programmes and plans implemented there) and all other

requirements of the Contract;

Management of all interfaces with the WORK in accordance with the

minimum requirements identified in the Contract

Management of all internal coordination between CONTRACTOR

departments involved in the execution of the WORK such that the WORK,

and the transitions and interactions between all particular phases of the

WORK, are executed in an efficient, safe and timely manner and

CONTRACTOR initiates and implements such procedures as are

appropriate to achieve the execution of the WORK in that manner;

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 8 of 32

Manage and coordinates all SUB-CONTRACTORs and Vendors involved

in execution of the WORK in accordance with the minimum requirements

identified in the Contract and initiates and implements such procedures as

are appropriate to achieve the minimum requirements so identified;

Comply with COMPANY’s requirements in the Contract;

Provide and implements an effective quality management system in

accordance with the requirements of the Contract;

Provide and implements an effective health, safety & environmental

management system in accordance with the requirements of the Contract.

4.2 Logistics and Accommodation:

CONTRACTOR shall provide transportation, accommodations, and catering

services for all its personnel at all WORK SITES inclusive of any medical

evacuations (MEDEVAC).

CONTRACTOR shall provide facilities and services at each WORK location for

the number of COMPANY and COMPANY assigned personnel specified in the

contract.

Also, CONTRACTOR shall establish office facilities at each WORKSITE

including:

CONTRACTOR’s central office(s) where overall project management and

engineering is carried out;

WORKSITE locations where the activities that cannot be carried out at

CONTRACTOR’s central offices are performed.

4.3 Access to COMPANY and Other Subcontractors:

CONTRACTOR shall allow interfacing subcontractors, unfettered access to the

parts of the WORK, and to all documentation, drawings, and data systems, that

relate to the interfaces and that can have an effect on the work of that

subcontractor. Interface requirements shall be defined in the CONTRACTOR

Interface Management Plan.

CONTRACTOR shall accept COMPANY and COMPANY-assigned personnel

into its offices to liaise closely with CONTRACTOR and improve

communications. COMPANY personnel shall be invited to participate in

CONTRACTOR-relevant Project meetings as required by the Contract.

4.4 Procurement and Material Management:

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 9 of 32

CONTRACTOR shall be responsible for the procurement of all equipment,

materials, personnel and services to perform the WORK.

CONTRACTOR shall:

Perform all procurement and subcontracting activities giving due

consideration to the quality, technical and commercial aspects of

materials and services to be procured.

Procure relevant items from the vendors on the COMPANY’s Approved

Vendors List.

Perform and control all procurement activities in accordance with the

requirements of the Contract.

Establish of a comprehensive procurement plan required to facilitate

procurement of all material, equipment or services required for the

execution of the WORK in accordance with the Contract requirements.

Ensure that procurement can commence in sufficient time to meet the

requirements of the Contract

Be responsible for the supply of all relevant documentation in accordance

with the requirements of the Contract, in sufficient time for the COMPANY

to review, approve and/or provide its comments to CONTRACTOR

without imposing delay upon CONTRACTOR.

4.5 Disposal:

CONTRACTOR shall be responsible for disposal of all scrap and unused

materials upon COMPLETION of the WORK. Such materials shall be disposed

of subject to local authority requirements and COMPANY approval.

4.6 Planning and Scheduling:

CONTRACTOR shall finalize its Organization Plan for the WORK and carry out

mobilization of personnel in accordance with the Organization Plan and

Schedule Milestones detailed Schedule Basis.

CONTRACTOR shall:

Provide the organization and procedures required to manage and control

the execution of the WORK and perform its obligations under the

Contract.

Develop all job procedures and plans for its management of the WORK in

accordance with the CONTRACT.

Plan, organize, direct, and control its activities and those of its

subcontractors and suppliers at all WORK SITES at which the WORK is

performed (e.g., at CONTRACTOR home and branch offices, fabrication

yards, supplier manufacturing locations, etc.).

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 10 of 32

Report the status and progress of the WORK as required by the Contract.

Develop a Level 3 CONTRACT SCHEDULE utilizing Microsoft Project,

Primavera or other COMPANY approved scheduling software.

CONTRACTOR shall prepare the following in accordance with the Contract:

1. CONTRACTOR's Control Schedule

2. CONTRACTOR's Detailed Schedule

3. Progress Measurement

CONTRACTOR shall proactively manage schedule risks and promptly inform

COMPANY of deviations from the approved Control Schedule, and shall

efficiently mitigate such deviations to minimize any impacts on COMPANY's

overall Project objectives.

The WORK shall be completed in accordance with the key dates agreed per

Contract and prepare all documents necessary to perform the WORK and make

such documents available to COMPANY for review, approval, or comment

sufficiently in advance of the execution of the related WORK

3.7 Quality Assurance and Quality Control:

CONTRACTOR shall implement a Quality System and Project Quality

Plan which will ensure that "all activities and functions concerned with the

attainment of quality" are properly executed and function effectively.

CONTRACTOR is registered and operates a quality management system in

compliance with ISO 9001 and shall impose a level of quality commensurate

with the supplied activity to SUB-CONTRACTORS and Vendors. The system

shall ensure that quality management of the WORKs, as a whole, is applied

from inception to completion of the WORKs itself.

3.8 WORK SITES and Access:

CONTRACTOR shall provide COMPANY with access to all WORK SITES.

These WORK SITES include, but are not limited to, CONTRACTOR'S offices,

storage WORK SITES and fabrication YARDS and WORK SITES. The

requirement for similar safe and unrestricted access to CONTRACTOR's

vendors and/or lower-tier subcontractors' work sites shall be reflected in such

purchase orders and/or subcontracts issued by CONTRACTOR.

CONTRACTOR shall be responsible for ensuring that its personnel have access

to and from each WORK SITE. Such access shall be subject to CONTRACTOR

meeting all conditions and requirements of the CONTRACT.

3.9 COMPANY Involvement:

CONTRACTOR shall coordinate all WORK with COMPANY, to ensure that

safety and operational concerns are fully considered in the execution of the

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 11 of 32

WORK. COMPANY will be invited to attend meetings related to the WORK, to

be advised directly of key events that may arise during performance of the

WORK, and will witness and otherwise participate in inspection events. Further

details of COMPANY and COMPANY involvement are outlined in the Contract.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 12 of 32

4. FABRICATION ENGINEERING

CONTRACTOR shall carry out all engineering required for the fabrication of the

PERMANENT WORKS and CONTRACTOR’s temporary works including the

preparation of studies, procedures, drawings and reports.

Fabrication engineering shall include the preparation of studies, procedure,

drawings and reports and as a minimum address the following:

Fabrication WORKSITE(s) and SUB-CONTRACTOR details;

Organisational details and schedules;

Fabrication drawings;

Fabrication procedures;

Dimensional control;

Weld, welder, coating and coater qualifications;

Welding, NDT, painting and coating procedures;

Materials receipt, handling, storage and preservation;

Cleaning, gauging and testing procedures;

Painting and coating procedures;

Repair procedures;

Temporary works;

Temporary power supplies;

Installation Aids;

Attachment of temporary closures and identifications;

Preparations for load-out and installation;

Safety, quality control and quality assurance;

Certification;

Weights and CoGs;

As-builts.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 13 of 32

5. PROCUREMENT

51 CONTRACTORS Responsibility

CONTRACTOR’s procurement activities, shall include, but not be limited to, the

following:

Provision of the necessary professional overview and control to ensure

that the highest levels of professional and ethical integrity are maintained

throughout the WORK;

Identification of procurement requirements;

Prepare procurement and subcontracting plan which shall be subject to

COMPANY review;

Preparation and updating of all procurement procedures which shall be

subject to COMPANY review;

Preparation and issue of complete requisitions (including all material take-

offs and required on-site dates) for enquiries and purchases;

Full technical and commercial evaluation of tenders and specifications,

Clarification of tenders;

Submit SUB-CONTRACTOR MDRs to COMPANY for review prior to

award of Sub-Contract;

Submit COMPANY requested SUB-CONTRACTOR documents to

COMPANY for review;

Provide COMPANY with un-priced copies of Sub-Contract agreements;

Placement of purchase orders and Sub-Contracts;

Office and field progress expediting;

Liaison and arranging stage and final testing and inspections, of

CONTRACTOR purchased materials, equipment and services;

Preparation and distribution to COMPANY of all relevant status and

progress reports, of CONTRACTOR purchased equipment materials;

Preparation and negotiation of purchase order and Sub-Contract

amendments;

Review and approve all SUB-CONTRACTOR documentation, quality and

inspection plans and manufacturing procedures;

Co-ordination and monitoring of SUB-CONTRACTOR certification

activities;

CONTRACTOR shall submit for COMPANY review all necessary Procurement

procedures for use throughout the procurement phase of the WORK which shall

include, but not be limited to, the following:

Procurement Philosophy, Plan and Organisation;

Requisitioning;

Purchasing;

Sub-contracts;

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 14 of 32

Evaluation of Tenders;

Office and Field Expediting;

Inspection and Certification Co-ordination;

Marking;

Materials Management;

Transportation;

Traceability.

CONTRACTOR shall transport all PERMANENT WORKS equipment’

fabrications and materials from the SUB-CONTRACTORs to the WORKSITE.

All handling, storage, preservation and transportation of PERMANENT WORKS

materials and equipment, shall be in accordance with COMPANY, COMPANY’s

free-issue PERMANENT WORKS equipment SUPPLIERS and SUB-

CONTRACTOR approved procedures.

CONTRACTOR shall procure all equipment, materials, tools, and consumables

required for temporary work to support fabrication, erection, and installation.

Procurement activities for materials that shall be incorporated into the WORK

shall be conducted in accordance with COMPANY's requirements.

CONTRACTOR's procurement responsibilities include, but are not limited to,

coordination of the following:

Supplier quality assurance

In-process inspection and testing

Expediting

Packaging

Transport / freight-forwarding

Customs clearance and control of all customs-related documentation

Delivery to site

Site storage and material control

Final documentation (e.g., coatings batch compliance certificates)

CONTRACTOR shall ensure that all necessary source inspection and testing of

materials is completed and that oversight is conducted in accordance with

Contract requirements

CONTRACTOR shall safely and efficiently arrange all international and local

delivery of materials provided by CONTRACTOR to the WORK SITE.

CONTRACTOR shall ensure that all materials are supplied with current and

valid certificates including, as appropriate, original certificates or verified copies.

All certification shall, at a minimum, contain applicable verification and

compliance (e.g., with chemical composition, full mechanical properties, heat-

treated condition, or receipt and preservation requirements). COMPANY

reserves the right to reject any items to be incorporated into the WORK that do

not comply with the requirements of the Contract.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 15 of 32

As far as possible, CONTRACTOR shall utilize CONTRACTOR’s standard, in-

house, manual and/or computerized procedures by adapting them, where

necessary, to meet the specific requirements of this Contract.

5.2CONTRACTOR’s Material Control

CONTRACTOR shall ensure that items provided by CONTRACTOR are stored,

preserved, tagged or labeled, and handled in accordance with the requirements

of the Contract and Suppliers' recommendations.

The control of material includes but is not limited to the following activities:

Material control at fabrication sites

Receiving from COMPANY, unloading and examination of all materials

Compilation of certification provided by COMPANY

Marking, labeling, and color-coding

Preservation and protection activities

Storage, including temperature-control for instruments / electrical

components where required

Security

Inventory control

Issue of overage, shortage, and damage reports (OSDs)

Accounting for all unused materials to COMPANY

Segregation of material classes (e.g., low alloy, stainless, and non-ferrous

steels) including marking, labeling, stamping, etc. Positive Material

Identification (PMI) may be required for verification purpose

CONTRACTOR shall maintain an experienced Materials Control organization

supported by a COMPANY-approved Materials Management software program.

CONTRACTOR shall provide required resources (personnel and equipment,

etc.) to handle material control functions at the fabrication yards for all materials

issued by COMPANY, as well as materials purchased by CONTRACTOR, with

specific responsibility with regard to receiving, security, storage, issuing, and

preservation. CONTRACTOR shall also provide a Preservation Specialist.

CONTRACTOR shall be responsible for the traceability of materials once issued

for fabrication. This includes transferring of material identification during

fabrication and thereafter regarding correct tagging and marking and storage of

fabricated items.

CONTRACTOR shall dispose of all unused materials (whether supplied by

COMPANY or CONTRACTOR) by way of CONTRACTOR facilities upon

reconciliation on completion of the WORK. Such materials include fabrication

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 16 of 32

materials, erection and installation aids, and temporary structures, and shall be

disposed of subject to local authority requirements and COMPANY approval.

5.3Material Management

CONTRACTOR shall procure, inspect, expedite, export pack, transport, receive,

warehouse, and preserve each CONTRACTOR-procured item required for the

completed WORK.

5.4Materials and Equipment Preservation

CONTRACTOR shall establish and administer a program for preservation and

maintenance of CONTRACTOR -provided materials and equipment to protect

and prevent damage or deterioration.

CONTRACTOR shall establish a tracking system for all preservation and

maintenance activities that shall include, but not be limited to, the following:

Apply preservation and maintenance on equipment from the date of delivery of

the equipment through Turnover to COMPANY as per manufacturer's

recommendations, including routine checking of the condition of the equipment

and taking remedial action, if necessary. Date of delivery shall be defined as the

date equipment is delivered to CONTRACTOR's WORK SITE regardless of any

overages, shortages, or damages and quality and extent of documentation

provided with the equipment.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 17 of 32

6. FABRICATION

6.1General

CONTRACTOR shall fabricate, inspect and test, and perform integration testing

of all PERMANENT WORKS and temporary items required for the WORK in

accordance with the Technical Information, and CONTRACTOR’s engineering,

drawings, procedures and specifications.

CONTRACTOR shall be fully responsible for all inspection, testing and

certification required for the satisfactory execution of the WORK in accordance

with the Contract, accepted GOOD INDUSTRY PRACTICE and the

requirements and approval of the COMPANY. CONTRACTOR shall comply with

the relevant statutes and ensure that all necessary approvals are obtained from

any other relevant authorities.

CONTRACTOR shall provide all necessary labor, tools, supervision (including

supervision and administration of Sub-Contracts), professional and technical

services, equipment, materials, cleaning, inspection, testing, transportation,

support services, and perform all operations required to complete the WORK.

All fabrication processes shall be fully qualified to the process, the environment

of the project and be in accordance with recognized international standards. In

the event that novel materials or processes are employed, these shall be

subjected to qualification trials and testing on non-project equipment prior to

being implemented as part of the PERMANENT WORKS. Qualification testing

shall require prior approval by COMPANY.

6.2Procedure

CONTRACTOR’s Fabrication Procedure for the execution of the WORK shall

include the control of fabrication of all structural components that are related to

the entire scope of work and also structural components to be fabricated at our

Facility.

To control and monitor the fabrication process it is necessary to implement

process control measures at each stage of fabrication as listed below. All

procedures are to be strictly followed in accordance with the industry

recommeNDTd practices and COMPANY specifications (if any) to ensure the

final completed product complies with the design function.

Documentation Requirements and Drawing Approval Controls

Material Controls

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 18 of 32

Welding Procedure and Welder Qualification Test

Fabrication and Welding Control.

Inspection and Test Controls

Blasting and Painting Controls

QA/QC Documentation and MDR

6.2.1 Welding Notes

All welders shall be qualified in accordance with the requirement of AWS D1.1 &

ASME IX. Only qualified welder who have successfully completed the WQT and

are registered in the Approved Welder list shall be allowed to weld. Welding

shall follow approved WPQR to be submitted for client approval and shall form

basis for welders’ qualification.

All welding machines and equipment shall be calibrated and certificates shall be

documented in the QA/QC Department filing system and all calibration record

maintained and made available for review for all.

Each welder shall be provided with accessories such as chipping hammer,

electrode quiver and grinder. The welder shall maintain his equipment in a good

working condition and report it to the maintenance department if any found

defective. Alternately the defective equipment shall be replaced with new one.

All welding consumables shall be handled and stored in accordance with the

manufacture recommendation. Low hydrogen electrode shall be oven baked in

accordance with the manufacture recommendation before use. Baking records

shall be maintained for recording purpose at the QA/QC department. Storage of

FCAW and TIG wire shall be segregated and stored in a cool dry place and the

practices stated in the Welding Consumables Control Procedure.

6.2.2 Material Control

Material Receiving Inspection

All received material shall undergo Receiving Material Inspection by QA/QC.

The store material controller shall inform the QA/QC department using Request

for Inspection Form for the inspection to be carried out. As a minimum, the

Request for inspection form shall include Material Request Slip, completed PO

Documentation Requirement Form, relevant mill certificates, material traceability

records and data sheets. The QA/QC department shall inspect the material and

confirm its acceptability for fabrication. Thereafter, the material shall be stored

awaiting request for fabrication use.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 19 of 32

Material Request

Material Requisition slip shall be prepared by supervisor or foremen. Any

additional Material Requisition Slip must be approved by discipline engineer or

Section Manager, before issue.

Material Identification and Verification

Material identification and traceability must be verified before any cutting and

assembly takes place on site.

Before carrying out marking and cutting, the fabrication or welding

foremen shall be responsible for performing all physical checks, i.e.;

dimensional, material type, specification, before confirming that correct

material has been delivered.

All material heat numbers, pipe numbers, traceability numbers, must be

transferred and recorded by the QA/QC Inspector onsite.

The QA/QC inspector shall perform physical material verification to

ensure that all “PIECE MARKS” and other material information is correct

and corresponding with the project specification, design drawings, MTO,

cutting plan and mill certificates.

6.2.3 Material Preparation

Joint Preparation

Joint preparation for all fabrication assembly shall be in accordance with

relevant welding and cutting plan, detail drawings or owner sketch, unless

otherwise instructed.

Joint Inspection and Repair (H)

Gas notches or imperfections on joints or adjacent surfaces

resulting from oxy-cutting are to be repaired or re-cut. Should repair

be required it must be carried out in accordance with the owners

approved welding and repair procedures.

NDT examination, if required, shall be performed after cutting, after

surface repair and before fit-up. Assemblies that required NDT

examination are to be indicated on weld & NDT map.

Assembly and Dimension Verification

Fabrication or welding foremen in conjunction with QA/QC shall be

responsible for verifying all the followings items before releasing for final

assembly.

Dimensional control

Joint preparation in accordance with approved WPS

Weld details and profile in accordance with the approved WPS

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 20 of 32

6.2.4 Control Assembly

Fit- up Control

Fit-up dimension and location references shall be referenced to:

Tubular or Structural: Design and shop, owner’s drawings.

Other steel structures: Shop Drawing

Joint tolerances shall be within the specified allowances given in

the applicable specification or WPS as appropriate to the work.

Production supervisor and foremen shall be responsible for

monitoring the fit-up and workmanship to closely verify all of the

overall dimensional accuracy.

When any discrepancy or reference marking on assembly is found

the error shall be rectified. The fabrication or welding foreman shall

consult the engineer, superintendent or owners representative

before continuing.

Any rectification that will introduce welding or heat application on

the material shall be notified to the QA/QC inspectors. The QA/QC

inspector will coordinate with discipline engineer who shall provide

advice for any correction.

Fit- up Inspection

The QA/QC inspector will coordinate with fabrication or welding

foremen on all fit-up completion status and perform inspection,

traceability and dimensional verification.

In addition to inspection on the fit-up joints, the QA/QC inspector

shall verify dimension for overall assembly before welding

commence. Any deviation found must be rectified before welding

commence. Dimension taken before welding shall be recorded and

kept for post-welding dimension verification.

Fit-up inspection status must be indicated adjacent to the joint

being inspected, and to indicate date, appropriate weld symbol

where particular weld size is required.

Only a qualified project welder will be used for all tack welding

activity.

6.2.5 Welding Control

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 21 of 32

Before Welding Operation Starts

Fabrication and Welding Supervisor shall be responsible for allocating a

qualified welder that is shown on the register of approved welders list,

before any welding operation starts, and that the below items are closely

followed.

All welding machines are in good operational condition with valid

calibration.

Relevant Welding Procedure Specification is displayed on site and

welders are aware of all welding parameter requirements.

Wind shield is properly set-up to avoid windy or rainy condition.

Pre-Heat Temperature Measurement

Preheat and all subsequent minimum interpass temperatures shall be

maintained during the welding operation for a distance at least equal to the

thickness of the thickest welded part, but not less than 3 in. [75mm] in all

directions from the point of welding.

Appropriate electrodes are deployed as specified.

During Welding Operation

Welding foremen shall monitor all welding activity at the work site.

The QA/QC engineer shall supervise the monitoring team at each

fabrication area, as assigned and randomly check all welding parameters.

For critical welding control, the monitoring team is to monitor the welding

control as per the Welding Engineer’s day-to-day specific work instruction

for welding or repair control and welding sequence.

6.2.6 Inspection and Testing

Weld Inspection

Visual inspection shall be conducted before all NDT.

The QA/QC inspector shall coordinate with welding foremen at work site

to confirm the completed status of all welding activity.

The welding foremen shall be responsible to check all completed welds

that are ready for inspection before confirming the status with QA/QC

inspector.

The welder helper shall clean all completed welds and remove all weld

spatters on adjacent areas in preparation for visual inspection to

commence.

Welders ID, date and time of weld completion shall be indicated adjacent

to the completed welds.

The QA/QC inspector shall visually check and verify the overall condition

of the completed weld. This shall include weld surface appearance

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 22 of 32

dimension profile. Results of inspection and date of acceptance are to be

recorded adjacent to the completed weld.

The QA/QC inspector is responsible for preparing all NDT requisitions and

coordinating with NDT personnel and expediting all of the activities.

Dimensional Check

The QA/QC inspector shall verify the post-welding dimension comparing

with the dimension taken before welding.

Any dimension that found to be out-of tolerance is to be reported and

request for rectification.

The out-off tolerance dimension or distortion will be carried out in

accordance with approved methods.

Fabrication and welder foreman shall ensure that all rectification work is

performed in strict accordance with the owner approved procedures and

work instructions.

The QA/QC inspector will be assigned to monitor all rectification work and

records must be taken to be included in the as built package.

Non-Destructive Testing

All NDT will be performed by suitable approved and qualified personnel.

NDT reports shall be prepared timely upon completion and submitted for

approval to senior QA/QC inspector.

All NDT will be conducted in a sequence method that covers surface or

subsurface examination and the procedure for those requiring internal

examination.

All Weld defect and discontinuity will be recorded before and after repair

is carried out. The NDT technician shall mark-out any defective location.

NDT technician shall mark out the defect location and repair shall be

carried out, strictly as per approved repair welding procedure.

6.2.7 Welds Repair

As low as practicable, welding defect shall be avoided. Where the situation

arises the following shall guides;

Repair work shall not be started until the NDT technician has reported the

defect on the NDT report and owner’s approval is sought.

Any weld containing cracks must be reported to QA/QC engineer and

welding engineer. All welds containing crack shall not be started until

owner has been notified and his approval given to repair same.

Welding on repair shall be as per approved WPQR and shall not exceed

the limit permissible in the code.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 23 of 32

All welds requiring repair will be preheated and excavated as per the

excavation repair procedure.

All weld repair area will be re-examined by the approved NDT method. All

repair welds will be initiated with (R) prefix and record will be provided to

the discipline engineer and owner representative.

6.2.8 Inspection and Test Status

Outstanding Work Punch List

Any outstanding work, pending inspection or test, intended to be

continued later are to be captured on an “Outstanding Work Punch List”.

QA/QC engineer shall be responsible to prepare Punch list for any

outstanding work, inspection or test, and he shall follow up expediting with

the outstanding parties.

Final Inspection

The QA/QC Inspector shall carry out a final check verifying

Visual inspection

Dimensional check

QA/QC records

Mill certificates

To confirm the completed product is acceptable before issuing the, “Inspection

Release Note”.

Inspection Release Note

The inspection release note is a final inspection control document that checks all

the process control requirements and is inherent to the fabrication process

within design drawing and owners specifications. Once all fabrication and final

inspection is completed, the Senior QA/QC shall compile the quality inspection

and NDT reports to verify that all process control requirements are met. The

senior QA/QC inspector shall issue the inspection release note for the review

and acceptance of the owner representative. Any outstanding work, pending

inspection or tests intended shall be noted on the Inspection release note. On

issue of Inspection release note the item shall proceed with the next stage of

operation that is blasting and painting activity, or installation.

QA/QC Inspection Reports

The following are mandatory reports that the QA/QC inspector must generate

after each inspection.

Material Verification Record

Fit-up Inspection Report

Welding Visual Inspection Report

Final Dimension Report

Weld Repair Excavation Record (if required)

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 24 of 32

Inspection Release Note

NDT Inspection Reports

The following are mandatory NDT reports that NDT Technician must generate

after each test.

Radiography Testing Report

Ultrasonic Testing Report

Magnetic Particle Inspecting Report

Issue Inspection Release Notes

Senior QA/QC inspector shall issue Final Inspection Release note duly signed

after confirming all inspection and test, including any repair pertaining to the

work that has been completed and accepted.

Outstanding Punch list

Any outstanding work, pending inspection or tests intended to be

continued later are to be captured on an “Outstanding Work Punch List”.

QA/QC engineer shall be responsible to prepare a Punch list for any

outstanding works, inspection and test; He shall also follow up with

expediting the outstanding parties.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 25 of 32

7 LOGISTICS

CONTRACTOR shall be responsible for Handling, load out and transportation of

WORKS equipment and materials, and all other temporary equipment and

materials to and from all locations necessary for the performance of the WORK,

including test locations. This shall include all haulage, customs clearance, origin

documentation charges and port handling charges as required for

CONTRACTOR to perform the WORK.

CONTRACTOR shall be responsible for producing all relevant handling, storage

and preservation procedures relating to the WORKS equipment and materials.

CONTRACTOR shall provide damage and environmental protection, including

preservation, for all WORKS equipment and materials against internal and

external corrosion so that WORKS equipment and materials can be put into

storage, without deterioration for a period of not less than 24 (twenty-four)

months.

CONTRACTOR shall supply, fabricate and install all temporary works necessary

for the load out and transportation activities associated with the WORK.

CONTRACTOR shall liaise with its SUPPLIERS to ensure that the integrity of

the WORKS equipment and materials are not compromised during the handling,

load out, sea-fastening, transportation and storage phases.

Load out and transportation of WORKS materials and equipment shall include,

but not be limited to:

Provision of a pre-mobilisation schedule covering all checking, testing and

calibration activities;

Checking, testing and calibration of major items of equipment;

Supply of grillage, sea fastenings, lifting equipment, slings and craneage;

Provision of spare parts.

CONTRACTOR load-out of WORKS shall only take place upon confirmation that

WORKS materials and equipment has met the requirements of COMPANY.

CONTRACTOR shall ensure that all lifting equipment, including slings, lifting

lugs, padeyes, etc. are re-certified immediately prior to use. CONTRACTOR

shall comply with any requirements of the COMPANY as applicable to

preparation for load out, transport and installation.

CONTRACTOR shall perform all monitoring and testing of equipment before,

during and after loadout and transportation in accordance with GOOD

INDUSTRY PRACTICE, the Technical Information and CONTRACTOR’s

engineering.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 26 of 32

8 INSTALLATION AND CONSTRUCTION

8.1 General

Construction work shall be performed by CONTRACTOR in accordance with

COMPANY approved Construction Execution Plan.

CONTRACTOR shall be responsible for providing all plant, equipment,

materials, tools, labour and supervision required to install, fabricate (on and off-

site), erect, test, pre-commission, commission and start-up the new and

upgraded facilities required for the WORKs.

CONTRACTOR shall ensure all personnel have required certification and

permits to work and that all equipment is in good condition with up to date

certification.

CONTRACTOR shall be responsible for preparing all working procedures,

including welding, NDT, painting, hydro-testing etc. for submission to

COMPANY for approval.

CONTRACTOR shall carry out risk assessments, lifting studies and any other

assessments or studies required to understand and mitigate risks associated

with construction activities and submit these for COMPANY approval prior to

starting the activity concerned.

CONTRACTOR shall provide a method statement for COMPANY approval prior

to starting a construction activity.

CONTRACTOR shall be responsible for supplying, treating, and disposing of

hydro-test water

8.2 Pre-Installation Activities

CONTRACTOR shall develop and submit a Master Documents Register (MDR)

containing all procedures, plans, Installation drawings and documents for the

project to COMPANY for approval.

CONTRACTOR will then be required to prepare the requisite procedures and

drawings (where they don’t exist) as defined in the deliverables register for

approval prior to commencement of installation works. The PMT anticipates that

COMPANY will have personnel in CONTRACTOR’s office location to facilitate

the development and approval of these drawings and documents.

All engineering activities will be conducted in accordance with COMPANY

Specifications ensuring quality and traceability of documents and any proposed

design changes.

Installation Scope includes but not limited to the following:

Installation procedures

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 27 of 32

WPS, PQR, WQT

Preparation of detailed installation design

Preparation of MTO

Preparation of all relevant installation procedures

Lifting plans/Analysis/Drawings

Pre-construction and installation Survey

All relevant drawings –Lifting/ installation

Welding procedures

Field joint coating procedures

Bolting Procedures- Torqueing or Tensioning

Investigation and Testing Plans

Plans – HSE, QA/QC, Logistics, Security & Emergency Response,

In addition to the Plans and Procedures, the PMT shall submit a detailed

Transportation Plan of each phase of the equipment haulage to COMPANY and

agree on the Inspections Schedule. The inspections are to assure regulatory,

integrity and functionality of all the materials and equipment.

Material handling and haulage shall be executed following satisfactory

COMPANY inspections.

8.3 Heavy Lifting

No lifting activity will be performed without the COMPANY’s approval. A

checklist of all pre- lift activities will be prepared and signed off by the field

engineer. The following activities shall form the basis of the pre-lift activities on

site: Lifting Analysis Approval, Rigging Aid Verification, Padeye check result,

Anchor bolt position check, Crane position foundation checks, Crane lifting chart

confirmation, Radio communication equipment check.

The Rigger foreman shall be the sole coordinator of all heavy lift activities giving

instruction to the crane operator using standard equipment and hand signals.

Hand signals are usable when the sole signaler is in a clear view of the crane

operator, and have a clear view of the load and the equipment

Lifting will not be done during heavy rainfall or extreme gust wind. This is to

minimize the risk involved in this operation.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 28 of 32

8.4 Hydrotest and Pre-commissioning

PPSL will mobilize third party Subcontractors to carry out these activities. These

Subcontractors shall prepare the Hydrotest and pre-commissioning procedure

for COMPANY’s approval, at least thirty (30) Days prior to start of hydrotesting

activities and at least ninety (90) Days prior to start of pre-commissioning

activities. All gauging, cleaning and hydrotesting activities shall be carried out by

the Tenderer upon approval of the procedures by the COMPANY.

8.5 Field Joint Coating (FJC)

FJC procedure shall be prepared and submitted to the COMPANY for approval.

The approved document shall form the basis of putting finishing touches on field

welded pipe joints on the site.

8.6 Painting

All painting works shall be done by CONTRACTOR using experienced painters

and paints specified by the COMPANY. Painting Procedure shall be prepared

and submitted to COMPANY for approval.

The approved document shall form the basis of all painting activities to be

embarked upon on the site.

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 29 of 32

9. COMMISSIONING, PERFORMANCE TESTING

9.1 Commissioning

Commissioning shall commence when the Pre-Start up Technical Safety Audit

has been completed and all recommendations have been addressed by

CONTRACTOR and COMPANY is satisfied that all systems are fit and safe for

energising and/or introducing hydrocarbons.

Equipment packages shall be mechanically run tested and care must be taken

to comply with the Vendors requirements.

All commissioning activities shall be carried out strictly in accordance with

CONTRACTOR prepared procedures approved by COMPANY.

Construction and pre-commissioning of different systems may be completed at

different times and commissioning of these systems may also take place at

different times. CONTRACTOR has ultimate responsibility for defining the

sequence in which the systems are commissioned.

CONTRACTOR shall also be responsible for identifying all of the temporary and

permanent facilities that need to be made available for commissioning, together

with their timing and who shall be providing them. This shall be presented for

COMPANY approval in the form of an Interface Matrix, at least 3 (three) months

prior to commencement of any commissioning activities.

CONTRACTOR shall also prepare and submit a Commissioning Manual to

COMPANY for approval at least 3 (three) months prior to commencement of any

Pre-commissioning activities.

9.2 Performance Testing

The overall philosophy for performance testing is to demonstrate that the new

equipment and systems function reliably, and function satisfactorily in

conjunction with each other.

CONTRACTOR shall develop a Performance Test Procedure, which

demonstrates that all units operate smoothly and meet COMPANY

specifications but not necessarily at design throughput conditions. This shall be

submitted to COMPANY for approval at least 3 (three) months prior to any

performance testing

Petro Pride Subsea Limited

Response to: TENDTR REFERENCE NO C W 8 0 9 6 5 5

PROVISION OF INTEGRATED PIPELINE REPAIR AND

MAINTENANCE SERVICES

TECHNICAL PROPOSAL

PROJECT EXECUTION PLAN Page 30 of 32

10.CLEANING AND RESTORATION

The WORKSITE(s) and surrounding area are to be cleared of all debris, rubbish

and unused materials before Final Acceptance and disposed of in a manner to

be proposed by CONTRACTOR for COMPANY approval, prior to disposal.

On completion of the WORK and demobilization, the site should be returned by

CONTRACTOR to a condition agreed with COMPANY.

CONTRACTOR shall be responsible for removing all plant, facilities and excess

materials from the WORKSITE(s) prior to handover.

CONTRACTOR shall fix all damage to equipment, structures, finishes, etc.,

caused during the performance of the WORK.

CONTRACTOR shall reinstate any areas disturbed during the WORKs including

any temporary access ways, roads, etc.

CONTRACTOR shall clear and make good the construction / laydown areas and

then landscape as specified by COMPANY within 2 (two) months of Final

Acceptance.

Any demolished materials are property of COMPANY and CONTRACTOR

should obtain COMPANY approval prior to removal from Site. Any materials

required by COMPANY shall be packaged, documented and stored or

dispatched in accordance with COMPANY instructions.

11. PLANNING REPORTING AND CONTROL

Planning and project controls shall be in accordance with CONTRACTOR’s

Project Controls Procedure. The project key dates will be as indicated in the