Professional Documents

Culture Documents

The Terminology of PV

The Terminology of PV

Uploaded by

Elie Al-Hallak0 ratings0% found this document useful (0 votes)

0 views7 pagessolar 2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsolar 2

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

0 views7 pagesThe Terminology of PV

The Terminology of PV

Uploaded by

Elie Al-Hallaksolar 2

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 7

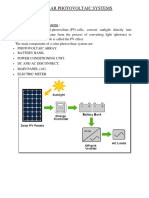

In this video, we will look at the various components making up

a photovoltaic system. For the sake of clarity, we need to get

acquainted with the terminology used in the field as well as the

necessity of each component. Later in the course we will

elaborate on the working principles of the individual

technologies, their roles in a photovoltaic power plant and how

to model and design an entire photovoltaic system. The term

photovoltaic, which is often abbreviated PV, is a combination of

the Greek word phōtós, that means light, and the last name of

the Italian physicist Alessandro Volta, who discovered the first

functional electrochemical battery. A direct translation of the

word would be "light battery", but it refers to the direct

conversion of sunlight into electrical energy. A solar cell is the

most basic component that converts light into electricity. In

most cases, solar cells are made of the semiconducting material

silicon, and deliver voltages of approximately 0.5 volts. The

current depends on the cell area as well as the level of

radiation. So it varies between 0 and 10 amps. Solar cells are

connected in series to achieve more usable voltages in the

range of 20 to 50 volts. This is done in a solar module where the

cells are protected against mechanical damage as well as

environmental factors such as moisture. Now let us consider a

residential building with domestic loads such as a washing

machine and some lighting. We want to build a photovoltaic

system. So let's start out by introducing photovoltaic modules

onto the rooftop. To build up the voltage, several modules must

be connected in series into a string. In this case we have

multiple strings in parallel which is also known as a solar array.

However, our domestic loads require an alternating current

(AC) and the solar panels deliver direct current (DC). Therefore

we need an inverter to convert the DC into AC. At the end of

the 19th century, the invention of the transformer allowed

converting alternating currents to higher voltages which

facilitated the transport of electric power over long distances

with significantly reduced losses. Combined with the invention

of the AC motor the public grid settled for AC power lines, and

we can therefore only feed power into the public grid after

converting DC into AC. However, the power distribution

company needs to know how much electricity we fed into and

out of the public grid and at what time. We therefore install a

meter which comes in various configurations, but nowadays

most meters are bidirectional, meaning that they cannot only

read the current flowing but the direction as well. There are,

however, many components which we have not considered in

this very simple example and a very important one is the

mounting structures which of course varies significantly from

installing a solar array on a rooftop compared to the ground or

on water, or even on a satellite in space. Another common

component is a combiner box that brings the DC output of

multiple strings together into a single set of cables. As we only

had two strings in our example, a combiner box wasn't really

necessary, but in larger projects where we may have thousands

of strings, distributed combiner boxes reduce the length of the

very expensive DC cables we would need. To figure out how

many modules we would need in our solar system, we would

need to know how well the individual module performs.

However, the performance of a solar cell and therefore also of

a solar module varies with varying conditions. Therefore, a set

of standard testing conditions have been agreed upon to

properly compare different solar cells or modules from

different manufacturers. The standard test conditions often

abbreviated STC, consist of three specifications. The first is that

the level of irradiance must be 1000 watts per square meter.

This irradiance level is also known as 1 Sun. The second

condition is that the spectrum of the light we use to illuminate

the solar cell or a module must correspond to the solar

spectrum known as air mass 1.5 global (AM1.5G). The spectrum

of the Sun will be elaborated in course module two. The third

and final condition is that the temperature of the solar cells

must be 25 degrees Celsius. However, the standard for testing

PV performance does not reflect typical operating conditions as

the solar spectrum and level of irradiance change throughout

the day, and the temperature of a solar panel is typically much

higher than 25 degrees Celsius. Nevertheless, these conditions

are used to evaluate how efficiently solar cells and modules

convert optical power from the Sun into electrical power. We

may write the optical power from the Sun as the irradiance

level multiplied by the area of the module. The electric power

delivered by the module at these conditions is also known as

the rated power of the module and is given in watt-Peak, where

peaks simply specifies that these conditions are optimal. There

are many other PV system components that we have not

covered so far. Trackers are an example of a performance

enhancing component as they serve to reposition the

photovoltaic modules to maximize the incident optical power

from the Sun. Tracking systems are usually classified by the

number of rotational axes and the single axis tracker is usually

configured to rotate the solar array from east to west. One

could also go in and actually tilt the mounting structure itself

while still having the east-west tracker rotating the array, such

a configuration is known as a one and a half axis tracker. The

two-axis tracking system is able to reposition the photovoltaic

modules to be directly facing the Sun at all times. However,

such tracking systems are usually rather expensive and not

necessarily compatible with the photovoltaic system that

you're trying to build. Another performance enhancing

component is the maximum power point tracker, also

abbreviated MPPT. Solar cells and modules have a continuous

range of operating points that has to do with the voltage

output of the device. By resistively loading the module, the

voltage at which we operate shifts. The maximum power point

tracker finds the operating point that gives the highest electric

power output of the module and loads the module accordingly.

The maximum power point changes with conditions such as

irradiation and temperature, and in this case, the module is

actually partially shaded, which has a significant impact on the

operating points. Finally, we have to consider a few safety

components as well. One of the more common components is a

DC breaker designed to interrupt the DC electricity in case you

for example, need to do maintenance. Another important type

of component is the residual current device that switches off

the electricity automatically if there is a fault. This is a

protective measure against electrocution as well as fires caused

by earth faults. The relevant system components depend on

what kind of PV system you are designing. We may divide

photovoltaics into grid-connected and standalone systems

where product-integrated PV would fall on the stand alone

applications. This includes: outdoor lighting products, vehicles,

solar-driven rescue ladders and harbors, and even pocket

calculators. As you can see, I have also divided the grid-

connected systems into three categories, that is; residential,

commercial, and utility-scale system. The residential and

commercial systems are most often simply installed on

rooftops, whereas utility scale covers the PV power plants and

solar parks. From standalone systems, I have included

microgrids. Grid connection refers to the public distribution

grid, whereas a microgrid often refers to a local distribution

grid, generally not connected to the main grid. A microgrid

produces and distributes electricity independently in a smaller

area. Rooftop installations have historically been realized by

applying photovoltaic modules onto existing roof constructions.

However, PV modules may be integrated into the building and

thus serve two purposes, producing energy and contributing as

a building material for instance, as a cladding material. This

type of system is known as building integrated photovoltaics, or

simply BIPV. Developers of BIPV systems have successfully

created architecturally and aesthetically pleasing systems in a

variety of colors, which enables the conservation of the

building's architectural appearance. On the utility scale, there's

a large variety of PV power plants, and this includes tracking

systems and bifacial modules, where the light is absorbed from

both sides of the module, floating PV, where the modules are

located on water, agrivoltaics, where the agricultural use of

land is combined with the use of land for photovoltaics and the

list goes on. Actually, all the applications marked in red are

examples of optimizing area resources, such as the rooftop

systems, where the photovoltaic system doesn't take up any

additional land area. In this video, we learned that the word

photovoltaic refers to the direct conversion of light into

electrical energy. The solar cell is the most basic component

responsible for this energy conversion process, and several

solar cells are connected in series to obtain usable voltages.

This is done in a solar module that protects the cells from

mechanical impacts as well as the environment. However, a

solar module delivers a direct current, whereas most of our

domestic appliances, as well as the public grid requires an

alternating current. We therefore use an inverter to convert DC

into AC. Furthermore, we also have to monitor the flow of

electricity to and from the grid, which is done using a meter.

Today, most meters are bidirectional. We have also learned

that the performance of a solar cell, as well as a photovoltaic

module varies with varying conditions. Therefore, a set of

standard test conditions known as STC, have been agreed upon

to properly compare devices from different manufacturers. This

includes an irradiance level of 1,000 watts per square meter,

the solar spectrum known as AM1.5G, and a solar cell

temperature of 25 degrees Celsius. A photovoltaic system may

also include performance enhancing components such as

tracking systems and we also need to consider some safety

components, such as DC current breakers and residual current

devices. However, the relevant components depend on the

type of PV system that you're designing. We therefore, looked

into the applications of PV, which included rooftops where we

had building applied and building integrated PV. We also looked

into microgrids, floating PV, agrivoltaics, product integrated PV,

bifacial PV, and the list goes on.

You might also like

- Final Year Project ProposalDocument14 pagesFinal Year Project ProposalBilalHassan100% (1)

- Effect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IDocument6 pagesEffect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IM VetriselviNo ratings yet

- Solar Water PumpsDocument15 pagesSolar Water Pumpsmakaliza2005100% (1)

- Projectreport REDocument15 pagesProjectreport REUnzillahNo ratings yet

- Solar Home System - BasicDocument6 pagesSolar Home System - BasicShamim MollaNo ratings yet

- 1.1 Water Pumping Systems and Photovoltaic PowerDocument54 pages1.1 Water Pumping Systems and Photovoltaic Powerthawpeek2006100% (1)

- How A PV System Works - pdf-20200211100803465Document9 pagesHow A PV System Works - pdf-20200211100803465ahmed abusnoubarNo ratings yet

- SOLARDocument5 pagesSOLARKim CanilloNo ratings yet

- ChaptersDocument47 pagesChaptersAitha DeepakNo ratings yet

- Solar Energy ReportDocument13 pagesSolar Energy ReportScribdTranslationsNo ratings yet

- EsquivelVilchisA TermoApl 36 PhotovoltaicSystem Nov152014Document9 pagesEsquivelVilchisA TermoApl 36 PhotovoltaicSystem Nov152014EsquivelAndiieNo ratings yet

- Solar Inverter and Tracking SystemDocument20 pagesSolar Inverter and Tracking SystemGANDE SAI KIRANNo ratings yet

- Solar Technology: Seminar ContentsDocument19 pagesSolar Technology: Seminar ContentsObichere OnyekachiNo ratings yet

- Solar Power Plant: Government Engineering College BharatpurDocument29 pagesSolar Power Plant: Government Engineering College BharatpurHinduja KumarasamyNo ratings yet

- Parts of Solar System:: 1. What Is A Solar Cable?Document6 pagesParts of Solar System:: 1. What Is A Solar Cable?muhammad umairNo ratings yet

- Chapter-1 IntroductionDocument24 pagesChapter-1 IntroductionNaveenNo ratings yet

- Report 3 D Solar Cell...Document15 pagesReport 3 D Solar Cell...Pankaj DeshmukhNo ratings yet

- MainDocument25 pagesMainDurgaprasadNo ratings yet

- 22661-RET Notes-UNIT 02Document25 pages22661-RET Notes-UNIT 02jayeshdeore398No ratings yet

- A Project Report ON Solar Street LightDocument27 pagesA Project Report ON Solar Street LightVinod JadavNo ratings yet

- Solar Panel PDFDocument3 pagesSolar Panel PDFArnab DeyNo ratings yet

- Solar Panel: Jump To Navigation Jump To SearchDocument18 pagesSolar Panel: Jump To Navigation Jump To SearchEr Dinesh TambeNo ratings yet

- A10020115 KTI AJER InternasionalDocument15 pagesA10020115 KTI AJER Internasionalarief ndartoNo ratings yet

- Report On Different Accessories of The Solar Power Plant 46-50Document5 pagesReport On Different Accessories of The Solar Power Plant 46-50pagal noobNo ratings yet

- History of Solar PowerDocument3 pagesHistory of Solar PowersmshivaNo ratings yet

- Solar Power For Beginners - The Ultimate Guide On Mastering The Basics Designs and InstallationsDocument78 pagesSolar Power For Beginners - The Ultimate Guide On Mastering The Basics Designs and InstallationsC. A.100% (1)

- Efficient Use of Solar Power Energy: Ruby Vij, Research Scholar D.A.V Institute of Tech. JalandharDocument3 pagesEfficient Use of Solar Power Energy: Ruby Vij, Research Scholar D.A.V Institute of Tech. JalandharPramod KumarNo ratings yet

- Chapter One 1.0Document37 pagesChapter One 1.0martinsNo ratings yet

- The Roof SystemDocument36 pagesThe Roof SystemAbhay UpadhyayNo ratings yet

- A Project Report OnDocument17 pagesA Project Report OnAshok GadhwalNo ratings yet

- Project Report On Maximum Power Point Tracking of PV Arrays in SimulinkDocument7 pagesProject Report On Maximum Power Point Tracking of PV Arrays in SimulinkPriyanshu SinghNo ratings yet

- Chapter:-1: 1.1 Introduction To Solar EnergyDocument15 pagesChapter:-1: 1.1 Introduction To Solar EnergySwaroopNo ratings yet

- ContentDocument38 pagesContentSowmya SivasriNo ratings yet

- InverterDocument23 pagesInverterBittu Kumar SinhaNo ratings yet

- Solar InverterDocument28 pagesSolar InverterVishnu Nayak100% (2)

- CHAPTER II Solar-Powered Automatic Lighting SystemDocument32 pagesCHAPTER II Solar-Powered Automatic Lighting SystemJo Sofia Delos SantosNo ratings yet

- Solar Integration - Inverters and Grid Services Basics - Department of EnergyDocument7 pagesSolar Integration - Inverters and Grid Services Basics - Department of EnergyPop Ideas inc.No ratings yet

- Solar PV ParametersDocument39 pagesSolar PV ParametersAlbert PaulNo ratings yet

- Photo Voltaic CellsDocument3 pagesPhoto Voltaic CellsApurva AnandNo ratings yet

- Chapter-2 Mathematical Modeling of Photovoltaic SystemDocument21 pagesChapter-2 Mathematical Modeling of Photovoltaic SystemSorinNo ratings yet

- How Do Solar Panel WorkDocument34 pagesHow Do Solar Panel Worklambanaveen123No ratings yet

- Solar TrackerDocument50 pagesSolar TrackerzizoNo ratings yet

- Solar Power PlantDocument3 pagesSolar Power PlantgirishNo ratings yet

- Case Study-Solar EnergyDocument24 pagesCase Study-Solar Energyadam0611No ratings yet

- Report On Visit To Solar Power PlantDocument16 pagesReport On Visit To Solar Power Plantsm4513848No ratings yet

- Design of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiDocument5 pagesDesign of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiHypnotic KnightNo ratings yet

- Ems ResearchDocument8 pagesEms ResearchalinsasaguinjoyNo ratings yet

- Solar Inverter - Wikipedia, The Free EncyclopediaDocument6 pagesSolar Inverter - Wikipedia, The Free EncyclopediaronniedakingpouNo ratings yet

- Design and Construction of A Solar Powered Streetlight SystemDocument7 pagesDesign and Construction of A Solar Powered Streetlight Systemsamuel mechNo ratings yet

- Solar Power Monitoring Using IoT (Report Book)Document41 pagesSolar Power Monitoring Using IoT (Report Book)Moin NordenNo ratings yet

- Tarun Jadhav - WONDERS OF SOLAR - Solar PV Guide - Design, Installation - MaintenanceDocument93 pagesTarun Jadhav - WONDERS OF SOLAR - Solar PV Guide - Design, Installation - MaintenanceRAFAEL CAISIPNo ratings yet

- Emma ProjectDocument48 pagesEmma ProjectChristianNo ratings yet

- Effect. The Most Common Types of Solar Cells Are Based On The PhotovoltaicDocument4 pagesEffect. The Most Common Types of Solar Cells Are Based On The PhotovoltaicAbdullah Al MamunNo ratings yet

- What Is A Solar Power Plant? How Does It Work?Document2 pagesWhat Is A Solar Power Plant? How Does It Work?Sumon ShariarNo ratings yet

- Module 2Document33 pagesModule 2Vibin NivasNo ratings yet

- Manu PDFDocument4 pagesManu PDFVipin palNo ratings yet

- Photovoltaics | 101: The hands-on beginner's guide for designing an on-grid or off-grid PV systemFrom EverandPhotovoltaics | 101: The hands-on beginner's guide for designing an on-grid or off-grid PV systemNo ratings yet

- Solar Electricity Generation System with a DIY Sun-Tracking PropositionFrom EverandSolar Electricity Generation System with a DIY Sun-Tracking PropositionNo ratings yet

- Off Grid Solar Power: The Ultimate Step by Step Guide to Install Solar Energy Systems. Cut Down on Expensive Bills and Make Your House Completely Self-SustainableFrom EverandOff Grid Solar Power: The Ultimate Step by Step Guide to Install Solar Energy Systems. Cut Down on Expensive Bills and Make Your House Completely Self-SustainableNo ratings yet

- Guide To The Installation of Photovoltaic Systems - DocsLibDocument124 pagesGuide To The Installation of Photovoltaic Systems - DocsLibPedro AranaNo ratings yet

- Week 2 Assignment 2Document3 pagesWeek 2 Assignment 2Pedro AranaNo ratings yet

- Week 1 Assignment 1Document5 pagesWeek 1 Assignment 1Pedro AranaNo ratings yet

- Ebr - Matemática-1Document4 pagesEbr - Matemática-1Pedro AranaNo ratings yet

- English English: Curso de Sensibilización A La PAEPDocument9 pagesEnglish English: Curso de Sensibilización A La PAEPPedro AranaNo ratings yet

- 02 Aei 200302Document4 pages02 Aei 200302ciudiNo ratings yet

- ATLAS 560 580W TOPCON DOUBLE GLASS English CompressedDocument2 pagesATLAS 560 580W TOPCON DOUBLE GLASS English Compressedanes1skiiilNo ratings yet

- AssignmentDocument5 pagesAssignmentG.M. Sifat IqbalNo ratings yet

- Terrafarm Racking SystemDocument12 pagesTerrafarm Racking SystemmiguelpaltinoNo ratings yet

- 40W Solar Panel Specifications: Main FeaturesDocument2 pages40W Solar Panel Specifications: Main FeaturesthoroidNo ratings yet

- Sample Presentation TrikeDocument13 pagesSample Presentation TrikejamboNo ratings yet

- Dual Axis Solar Panel ComponentsDocument11 pagesDual Axis Solar Panel ComponentsRaj Kothari MNo ratings yet

- DissertationDocument100 pagesDissertationnateNo ratings yet

- Pvsyst 5Document219 pagesPvsyst 5nexarsolarNo ratings yet

- GameChange Solar Genius - Tracker 2P Technical - Datasheet 7 13 3022Document2 pagesGameChange Solar Genius - Tracker 2P Technical - Datasheet 7 13 3022ThorstenNo ratings yet

- 325w Poly Solar Panel SpecsDocument4 pages325w Poly Solar Panel SpecsEmmanuel santosNo ratings yet

- A Review of Concentrated Photovoltaic-Thermal (CPVT) Hybrid Solar SystemsDocument40 pagesA Review of Concentrated Photovoltaic-Thermal (CPVT) Hybrid Solar SystemsKatiaPeraltaNo ratings yet

- LG NeON® 2 BiFacial (LG400-405N2T-J5)Document4 pagesLG NeON® 2 BiFacial (LG400-405N2T-J5)Adrian GhermanNo ratings yet

- Monocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ADocument2 pagesMonocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34AsuryarisNo ratings yet

- Telecommunication Power System: Energy Saving, Renewable Sources, Environmental Monitoring and Diesel Consumption ReductionDocument23 pagesTelecommunication Power System: Energy Saving, Renewable Sources, Environmental Monitoring and Diesel Consumption ReductionMd MinhajNo ratings yet

- How To Calculate Size of Solar System in India?Document10 pagesHow To Calculate Size of Solar System in India?olexNo ratings yet

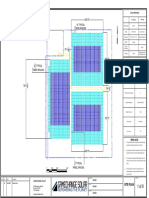

- 630'-5" 16' Typical Row Spacing: LegendDocument9 pages630'-5" 16' Typical Row Spacing: LegendSmile PlzNo ratings yet

- Seguidores para Parques Solares Lorentz - Solarparks - Pi - enDocument4 pagesSeguidores para Parques Solares Lorentz - Solarparks - Pi - enManuel Armindo RibeiroNo ratings yet

- Design and Development of A SOLAR TREEDocument9 pagesDesign and Development of A SOLAR TREETech ManiacNo ratings yet

- UPS System Using PV PanelDocument58 pagesUPS System Using PV PanelRamanan MNo ratings yet

- BLUESUN Lmited Warranty - Solar ModuleDocument6 pagesBLUESUN Lmited Warranty - Solar ModuleAusNo ratings yet

- Delta ManualDocument392 pagesDelta Manualnkapnangluther3099No ratings yet

- EPYK Solar Lights CatalogueDocument12 pagesEPYK Solar Lights CatalogueAman JoshiNo ratings yet

- Canadian-solar-HiKu6 CS6R-MS Black-Frame v1.5W25 EN 395-420WDocument2 pagesCanadian-solar-HiKu6 CS6R-MS Black-Frame v1.5W25 EN 395-420WJoão Lopes0% (1)

- Siemens SM55-SM50 Solar Panel InformationDocument2 pagesSiemens SM55-SM50 Solar Panel InformationUel Le Responsable UefaNo ratings yet

- ELDORA 100P Micro DatasheetDocument2 pagesELDORA 100P Micro DatasheetANURODH YADAVNo ratings yet

- Techno-Economic Analysis of Solar Photovoltaic PowDocument8 pagesTechno-Economic Analysis of Solar Photovoltaic PowrabiNo ratings yet

- Hiku5 Poly Perc: Cs3Y-435 - 440 - 445 - 450 - 455 - 460PDocument2 pagesHiku5 Poly Perc: Cs3Y-435 - 440 - 445 - 450 - 455 - 460PfedaNo ratings yet

- Quotation 30 KW Hybrid - MR UmerDocument1 pageQuotation 30 KW Hybrid - MR UmerMuhammad Furqaa9rsh. e0v22gn v 9No ratings yet

- Presented By: Ifix Green Solutions PVT LTD Address: No 136, St. Sebastian'S Street, Mannar. Contact: 070 50 5000 9Document13 pagesPresented By: Ifix Green Solutions PVT LTD Address: No 136, St. Sebastian'S Street, Mannar. Contact: 070 50 5000 9Sekaram WenitonNo ratings yet