Professional Documents

Culture Documents

EF612 Westlake

EF612 Westlake

Uploaded by

Yefrain J. ArzolayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EF612 Westlake

EF612 Westlake

Uploaded by

Yefrain J. ArzolayCopyright:

Available Formats

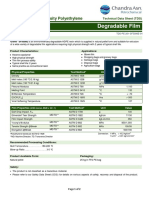

EF612

Low Density Polyethylene

Technical Data Sheet

Applications

Clarity films

Product Description

Westlake EF612 is an LDPE resin suggested for use in films requiring good clarity and toughness. It has excellent

processability, and is an excellent choice as a blend resin with LLDPE in general-purpose clarity packaging applications.

Typical Physical Properties

Property a Test Method b Typical Value, Units c

Melt Index (Condition 190°C/2.16 kg) D 1238 2.50 g/10 min

Density (Base Formulation) D 1505 920 kg/m3 (0.920 g/cm3)

Dart Impact D 1709 75 g

Haze (Formulated Version) D 1003 5.3 %

Tensile Strength @ Break M.D. D 882 22.8 MPa (3,300 psi)

T.D. D 882 15.9 MPa (2,300 psi)

Elongation @ Break M.D. D 882 350 %

T.D. D 882 680 %

1% Secant Modulus M.D. D 882 172.4 MPa (25,000 psi)

T.D. D 882 193 MPa (28,000 psi)

a Unless noted otherwise, all tests are run at 23°C (73°F) and 50% relative humidity.

b Unless noted otherwise, the test method is ASTM.

c Units are in SI or US customary units.

Notes

Test specimens for blown film: nominal thickness 1.25 mils; blow up ratio 2.5:1, die gap 35 mils.

Processing

Melt temperatures of 360°F – 400°F are recommended for Westlake EF612 with blow-up ratios of 1.5:1 or higher.

Regulatory Compliance

This product has some 21 CFR clearances. Please contact your Westlake Sales Representative for food contact statements.

Properties reported here are based on limited testing. Westlake makes no representation that the material in any particular shipment will conform

exactly to the values given. Westlake and its marketing affiliates shall not be responsible for the use of this information, or of any product, method, or

apparatus mentioned, and you must make your own determination of its suitability and completeness for your own use, for the protection of the

environment, and for the health and safety of your employees and purchasers of your products. No warranty is made of the merchantability of fitness

of any product, and nothing herein waives any of the Seller's conditions of sale.

Westlake Polymers LLC

2801 Post Oak Boulevard, Suite 600

Houston, Texas 77056

1.800.545.9577

www.westlake.com 07/07/22

You might also like

- LLBF 122FDocument1 pageLLBF 122FYefrain J. ArzolayNo ratings yet

- Lab Report First Law of ThermodynamicsDocument19 pagesLab Report First Law of Thermodynamicshanif yoo67% (6)

- ABAQUS Explicit SlidesDocument14 pagesABAQUS Explicit SlidesHarpreet SinghNo ratings yet

- Low Density Polyethylene LD7000A: DescriptionDocument1 pageLow Density Polyethylene LD7000A: DescriptionJaime222No ratings yet

- PP - Braskem - CP 442 XP PDFDocument1 pagePP - Braskem - CP 442 XP PDFAdemilson Alves Dos SantosNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Qatofin Lotrene Q2018Document2 pagesQatofin Lotrene Q2018HichamSalamaNo ratings yet

- Equate EGDA 6888Document2 pagesEquate EGDA 6888akshayNo ratings yet

- ALATHON L5005 y CERTENE 122DDocument4 pagesALATHON L5005 y CERTENE 122DJuan Carlos Otero JaramilloNo ratings yet

- Petrothene: Low Density Polyethylene Film Extrusion GradeDocument1 pagePetrothene: Low Density Polyethylene Film Extrusion GradeGabriela Lopez MunozNo ratings yet

- TDS - LD 2023 CC PDFDocument1 pageTDS - LD 2023 CC PDFYasir SiddiquiNo ratings yet

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocument1 pageCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaNo ratings yet

- LDF201FG R01Document1 pageLDF201FG R01Oscar Tan IIINo ratings yet

- High Density Polyethylene GF4950: DescriptionDocument1 pageHigh Density Polyethylene GF4950: Descriptioncesar1scribdNo ratings yet

- Ficha Tecnica HIFOR LF2020Document1 pageFicha Tecnica HIFOR LF2020alnair coronaNo ratings yet

- Lldpe 22501aa22501kjDocument2 pagesLldpe 22501aa22501kj李万福No ratings yet

- TDS Dfda 7042 AstmDocument2 pagesTDS Dfda 7042 AstmLeductoan LeNo ratings yet

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraNo ratings yet

- LLBF 218aDocument1 pageLLBF 218aYefrain J. ArzolayNo ratings yet

- 219ZJDocument2 pages219ZJAziz AlaghbariNo ratings yet

- Q2018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ2018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverNo ratings yet

- Q1018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ1018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- CG 210NA-enUS-ASTMDocument1 pageCG 210NA-enUS-ASTMCristian Tomas Del Solar EspoueysNo ratings yet

- Lotrene LLDPE Datasheet PDFDocument6 pagesLotrene LLDPE Datasheet PDFThụy Thảo LinhNo ratings yet

- 400 00285139en Innate st50 Precision Packaging Resin TdsDocument3 pages400 00285139en Innate st50 Precision Packaging Resin Tdsteguh.budi.uNo ratings yet

- TDS DGDZ 6097 ASTM HexeneDocument2 pagesTDS DGDZ 6097 ASTM HexenegauravmishraanalystNo ratings yet

- Tds DGDX 6097 Astm ButeneDocument2 pagesTds DGDX 6097 Astm ButeneLakshay UniplarNo ratings yet

- Formolene fl2202c 1Document1 pageFormolene fl2202c 1armandoestavanquitoNo ratings yet

- LL0220CADocument2 pagesLL0220CAmohamad mostafaviNo ratings yet

- Tricolene LLB1918ADocument1 pageTricolene LLB1918ARoberto De Mesa PNo ratings yet

- Hdpe LTL 2130Document4 pagesHdpe LTL 2130mohamad mostafaviNo ratings yet

- High Density Polyethylene HC7260LS-L: DescriptionDocument1 pageHigh Density Polyethylene HC7260LS-L: DescriptionJaime222No ratings yet

- LTL 2130Document4 pagesLTL 2130mohamad mostafaviNo ratings yet

- TDS Pe 002 Uf1810t 03Document2 pagesTDS Pe 002 Uf1810t 03qc jrpNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- Ldpe 2404TC47Document3 pagesLdpe 2404TC47mohamad mostafaviNo ratings yet

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetJosiola MariledoNo ratings yet

- Ldpe 2602TH00Document4 pagesLdpe 2602TH00mohamad mostafaviNo ratings yet

- Lldpe - Sabic® Lldpe - 118NJ PDFDocument2 pagesLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverNo ratings yet

- HDI2061 enUS ASTMDocument1 pageHDI2061 enUS ASTMWendy WilchesNo ratings yet

- LDPE L2AS Data SheetDocument1 pageLDPE L2AS Data SheetGabriela Lopez MunozNo ratings yet

- Surat Jastifikasi - (SANFAB PE - ST)Document5 pagesSurat Jastifikasi - (SANFAB PE - ST)arungrifqy putraaditNo ratings yet

- ExxonMobil HTA 001HDDocument1 pageExxonMobil HTA 001HDakshayNo ratings yet

- Exceed™ S 9272ML: Performance PolymerDocument2 pagesExceed™ S 9272ML: Performance PolymerMaram YasserNo ratings yet

- Tds Dfda 7047 AstmDocument2 pagesTds Dfda 7047 Astmhafidz 35No ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetnadaelbeltagy4No ratings yet

- Lotrène FE8000 2014 04 16Document2 pagesLotrène FE8000 2014 04 16aman.chaudhary3663No ratings yet

- Ldpe 2004TX37 - 2004TC37Document4 pagesLdpe 2004TX37 - 2004TC37mohamad mostafaviNo ratings yet

- PRB 0131-enUS-ASTMDocument1 pagePRB 0131-enUS-ASTMquanghoang10986No ratings yet

- Ldpe HP4025ZN TDSDocument2 pagesLdpe HP4025ZN TDSmittalplaschemNo ratings yet

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilNo ratings yet

- Product Sheet Petlin LD N125y - 0Document2 pagesProduct Sheet Petlin LD N125y - 0Manufaktur Sinar JoyoboyoNo ratings yet

- SABIC® LLDPE - 218WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 218WJA - Americas - Technical - Data - Sheetdiana sarmientoNo ratings yet

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaNo ratings yet

- Exceed™ XP 8346PA: Performance PolymerDocument2 pagesExceed™ XP 8346PA: Performance PolymerMaram YasserNo ratings yet

- Hdpe LTL 2185Document4 pagesHdpe LTL 2185mohamad mostafaviNo ratings yet

- Novapol TF 0338 e NovaDocument2 pagesNovapol TF 0338 e NovaJulio GarcíaNo ratings yet

- Luban DFDC-7080: Linear Low Density PolyethyleneDocument2 pagesLuban DFDC-7080: Linear Low Density PolyethyleneNazmul - Polymet SANo ratings yet

- Chapter 3Document18 pagesChapter 3mohammed emadNo ratings yet

- As 1012.17-1997 Methods of Testing Concrete Determination of The Static Chord Modulus of Elasticity and PoissDocument3 pagesAs 1012.17-1997 Methods of Testing Concrete Determination of The Static Chord Modulus of Elasticity and PoissSAI Global - APACNo ratings yet

- JEE Compendium Solutions Chemistry 1Document163 pagesJEE Compendium Solutions Chemistry 101sehwagNo ratings yet

- Omnirad 1870 EN PDS 2Document3 pagesOmnirad 1870 EN PDS 2brausenpaulNo ratings yet

- Answer and Solutions JEE Main 2023 PH 1-29-01 2023 Morning Shift 1Document23 pagesAnswer and Solutions JEE Main 2023 PH 1-29-01 2023 Morning Shift 1Ayan JainNo ratings yet

- Procedure 1Document9 pagesProcedure 1Siphesihle NkosiNo ratings yet

- 30A Speaker Protector Technical MrigankaDocument2 pages30A Speaker Protector Technical Mrigankakingcooldued1234No ratings yet

- ECT362-Jan 2024Document2 pagesECT362-Jan 2024rijovskNo ratings yet

- IACSDocument65 pagesIACSbhavin183100% (2)

- A New Role For Microalloyed SteelsDocument11 pagesA New Role For Microalloyed SteelsMuhammed SulfeekNo ratings yet

- Any Aircraft Showing The Locations of The Composite Part 2. Advantages and Disadvantages of Using A CompositeDocument13 pagesAny Aircraft Showing The Locations of The Composite Part 2. Advantages and Disadvantages of Using A CompositeQueen CryNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentAjay EadakeNo ratings yet

- INOTEK 2024 - Category ET (Nurul Aqila Razali)Document1 pageINOTEK 2024 - Category ET (Nurul Aqila Razali)qilayooNo ratings yet

- The Colloidal Activity of ClaysDocument5 pagesThe Colloidal Activity of ClaysHenrique ApolinarioNo ratings yet

- PH8253-Physics For Electronics EngineeringDocument14 pagesPH8253-Physics For Electronics EngineeringDanush KumarNo ratings yet

- In Situ Soil Testing For Foundation Performance Prediction - Yueyang Zhao 2008 Cambridge PHD ThesisDocument267 pagesIn Situ Soil Testing For Foundation Performance Prediction - Yueyang Zhao 2008 Cambridge PHD Thesisjohn.zhao731180% (5)

- 05 CT Jee-Pc As 29-12-2022Document4 pages05 CT Jee-Pc As 29-12-2022Bolly TubeNo ratings yet

- Quiz 2Document2 pagesQuiz 2Catherine De LunaNo ratings yet

- Basic Gear Terminology and Calculation - KHK Gears PDFDocument8 pagesBasic Gear Terminology and Calculation - KHK Gears PDFMinhas ArshadNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- 1 ph-1Document17 pages1 ph-1soonaNo ratings yet

- Bubbledeck Voided Flat Slab Solutions: June 2008Document91 pagesBubbledeck Voided Flat Slab Solutions: June 2008Gan Chin PhangNo ratings yet

- 2089 340065 Multimeter Mastech Ms8240cDocument11 pages2089 340065 Multimeter Mastech Ms8240cFrancisco Javier GuerraNo ratings yet

- Sa 105 PDFDocument10 pagesSa 105 PDFkumarNo ratings yet

- STAAD-I Section With LTBDocument9 pagesSTAAD-I Section With LTBparishithNo ratings yet

- Metal Nanoparticles ThesisDocument8 pagesMetal Nanoparticles Thesisjum1p0tonip3100% (1)

- 6 PPT f5Document3 pages6 PPT f5Nurul BalkhisNo ratings yet

- QW-483 (Green) PQR No.: Tme 356Document1 pageQW-483 (Green) PQR No.: Tme 356Sudhir KotkarNo ratings yet