Professional Documents

Culture Documents

AB ShaftSealKits

AB ShaftSealKits

Uploaded by

Carlos PCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AB ShaftSealKits

AB ShaftSealKits

Uploaded by

Carlos PCopyright:

Available Formats

Installation Instructions

Shaft Seal Kits

Catalog Numbers VPL-SSN, VPF-SSN, MPL-SSN, MPF-SST, MPS-SST, TL-SSN

Topic Page

About Shaft Seals 1

Required Tools 2

Install a Shaft Seal 2

Shaft Seal Kit Catalog Numbers 4

Additional Resources 6

About Shaft Seals

A shaft seal is recommended if the motor shaft and end bell are exposed to significant amounts of

containments, such as oil, fluids, or fine dust. Use a shaft seal in these environments to prolong

the life of the motor. A shaft seal and Bulletin 2090 cables with environmentally sealed

connectors are required for an IP66 rating or greater.

See Kinetix® Motion Accessories Specifications Technical Data, publication GMC-TD004, to

find Bulletin 2090 cables with environmentally sealed connectors for your motor.

IMPORTANT The shaft seal is not recommended in applications where the motor shaft and end bell are free of oil, fluids, or

fine dust, and a lower IP rating is sufficient.

Shaft seals are subject to wear and require periodic inspection and replacement. Replacement is recommended

every 3 months, not to exceed 12 months, depending on use.

If you paint the motor, do not get paint on the shaft seal area or the shaft. This can decrease the life of the shaft

seal.

Oil, Fluids, and Fine Dust Oil, Fluids, and Fine Dust

Motor Shaft and Motor Shaft and

End Bell are Exposed End Bell are Protected

to Containments From Containments

Shaft Seal Installation Shaft Seal Installation

is Recommended is Not Recommended

Sealant between Motor

and Machine (optional)

2 Shaft Seal Kits

Required Tools

Use these tools to install a shaft seal:

• Rubber/wooden mallet, or a metal hammer and wooden work piece

• Socket, pipe, or tubing (various sizes)

• Abrasive cloth (to remove any nicks or burrs from the motor shaft)

Install a Shaft Seal

ATTENTION: To avoid injury or damage to the equipment, remove power from the motor before installing the

shaft seal.

Follow these steps to install the shaft seal.

1. Verify that power is removed from the motor.

2. Remove the shaft key (if installed).

3. Remove the old shaft seal (if installed).

4. Remove any dirt or grease from the motor shaft and the area around the front end bell of

the motor near the bearing.

5. Use an abrasive cloth to remove any nicks or burrs from the motor shaft.

6. Cover the sharp edges of the keyway with tape to protect the seal lip from damage.

7. Lubricate the inner and outer lip of the shaft seal with the lubricant in the kit.

IMPORTANT Shaft seals must be lubricated. Lubricant is supplied with the shaft seal kits.

8. Position the shaft seal so that the sealing lip faces outward on the shaft.

9. Slide the shaft seal onto the motor shaft.

10. See Shaft Seal Installation Clearances on page 3 for the correct installation clearance of

the shaft seal.

11. Use one of the Shaft Seal Installation Methods on page 4 to gently press the outer

diameter of the shaft seal into the motor.

IMPORTANT Verify that the shaft seal is installed to the correct installation clearance.

If the shaft seal is installed too deep, it can be subject to excessive wear and require frequent

replacement.

If the shaft seal is installed too shallow, it can reduce the effectiveness of the protective seal.

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Shaft Seal Kits 3

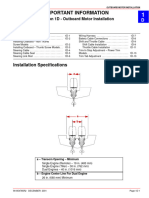

Shaft Seal Installation Clearances

Nom

Front Surface Front Surface

of Motor of Motor

Shaft Seal Pressed

Below Front

Surface of Motor

Shaft Seal Pressed

Min Flush with Front

Max

Surface of Motor

Nom

Motor Cat. No. Shaft Seal Installation Clearance

Min, mm (in.) Nom, mm (in.) Max, mm (in.)

VPL-A/Bxxx Press the shaft seal so that the seal is flush or below the front surface of the motor.

VPF-A/Bxxx

1.40 (0.055) 1.50 (0.060) 1.65 (0.065)

VPS-Bxxx

MPL-A/B15xx

1.50 (0.060) 2.00 (0.080) 3.00 (0.120)

MPL-A/B2xx

All other MPL-A/Bxxx Press the shaft seal so that the seal is flush or below the front surface of the motor.

MPF-A/Bxxx

1.40 (0.055) 1.50 (0.060) 1.65 (0.065)

MPS-A/Bxxx

MPM-xxxx Press the shaft seal so that the seal is flush or below the front surface of the motor.

MDF-SBxxx 1.40 (0.055) 1.50 (0.060) 1.65 (0.065)

TL-Series Press the shaft seal so that the seal is flush or below the front surface of the motor.

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

4 Shaft Seal Kits

Shaft Seal Installation Methods

This section shows the recommended installation methods for the shaft seals.

IMPORTANT Do not hammer directly on the shaft seal. Gently tap the socket, pipe, or tubing evenly around the outer

edge of the shaft seal until the shaft seal is pressed into place.

Socket, Pipe, or Tubing Socket, Pipe, or Tubing

(supplied by the customer) (supplied by the customer)

Motor Motor

Wooden

Or Work

Piece

Metal

Shaft Seal Rubber or Shaft Seal Hammer

Wooden Mallet

Shaft Seal Kit Catalog Numbers

IMPORTANT Third-party shaft seals are not approved for use with these motors. The use of third-party shaft seals voids any

implied or expressed warranties.

Kinetix VP Low Inertia Motors Kinetix VP Food Grade Motors

Motor Cat. No. Shaft Seal Kit Cat. No. Motor Cat. No. Shaft Seal Kit Cat. No.

VPL-A063xx and VPL-B063xx VPF-A063xx and VPF-B063xx

VPL-SSN-F063075 VPF-SSN-F063075

VPL-A075xx and VPL-B075xx VPF-A075xx and VPF-B075xx

VPL-A100xx and VPL-B100xx MPL-SSN-A3B3 VPF-A100xx and VPF-B100xx MPF-SST-A3B3

VPL-A115xx and VPL-B115xx MPL-SSN-A4B4 VPF-A115xx and VPF-B115xx MPF-SST-A4B4

VPL-A130xx and VPL-B130xx MPL-SSN-A5B5 VPF-A130xx and VPF-B130xx MPF-SST-A45B45

VPL-B165xx MPL-SSN-F165 VPF-B165xx MPF-SST-F165

Kinetix VP Stainless Steel Motors

Motor Cat. No. Shaft Seal Kit Cat. No.

VPS-B1304D MPS-SST-A45B45

VPS-B1653D MPS-SST-F165

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Shaft Seal Kits 5

MP-Series Low Inertia Motors MP-Series Medium Inertia Motors

Motor Cat. No. Shaft Seal Kit Cat. No. Motor Cat. No. Shaft Seal Kit Cat. No.

MPL-A15xx and MPL-B15xx MPM-A115xx and MPM-B115xx MPL-SSN-A4B4

MPL-SSN-F63F75

MPL-A2xx and MPL-B2xx MPM-A130xx and MPM-B130xx MPL-SSN-A5B5

MPL-A3xx and MPL-B3xx MPL-SSN-A3B3 MPM-A165xx and MPM-B165xx MPL-SSN-F165

MPL-A4xx and MPL-B4xx MPL-SSN-A4B4 MPM-A215xx and MPM-A215xx MPL-SSN-A6B6

MPL-A45xx and MPL-B45xx MPL-SSN-A5B5

Kinetix 6000M Integrated Drive-Motor

MPL-A520 and MPL-B520

MPL-A540 and MPL-B540 MPL-SSN-F165

MPL-A560 and MPL-B560 Motor Cat. No. Shaft Seal Kit Cat. No.

MPL-B580 MPL-SSN-F165-32MM MDF-SB1003 MPF-SST-A3B3

MPL-B6xx MPL-SSN-A6B6 MDF-SB1153 MPF-SST-A4B4

MPL-B8xx MPL-SSN-A8B8 MDF-SB1304 MPF-SST-A45B45

MPL-B9xx MPL-SSN-A9B9

TL-Series Motors

MP-Series Food Grade Motors Motor Cat. No. Shaft Seal Kit Cat. No.

Motor Cat. No. Shaft Seal Kit Cat. No. TLY-A1xx and TL-A1xx TL-SSN-1

MPF-A3xx and MPF-B3xx MPF-SST-A3B3 TLY-A2xx and TL-A2xx TL-SSN-2

MPF-A4xx and MPF-B4xx MPF-SST-A4B4 TLY-A25xx and TL-A25xx

TL-SSN-3

MPF-A45xx and MPF-B45xx MPF-SST-A45B45 TLY-A3xx

MPF-A5xx and MPF-B5xx MPF-SST-F165 TL-A4xx TL-SSN-4

MP-Series Stainless Steel Motors

Motor Cat. No. Shaft Seal Kit Cat. No.

MPS-A3xx and MPS-B3xx MPS-SST-A3B3

MPS-A45xx and MPS-B45xx MPS-SST-A45B45

MPS-B5xx MPS-SST-F165

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

6 Shaft Seal Kits

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

Resource Description

Kinetix Motion Control Selection Guide, Overview of Kinetix servo drives, motors, actuators, and motion

accessories designed to help make initial decisions for the motion control

publication GMC-SG001 products best suited for your system requirements.

Product specifications for Kinetix VP (Bulletin VPL, VPF, VPS), MP-Series™

Kinetix Rotary Motion Specifications,

publication GMC-TD001 (Bulletin MPL, MPM, MPF, MPS), Kinetix 6000M (Bulletin MDF),

TL-Series™, RDD-Series™, and HPK-Series™ rotary motors.

Product specifications for Bulletin 2090 motor and interface cables,

Kinetix Motion Accessories Specifications, low-profile connector kits, drive power components, and other servo drive

publication GMC-TD004

accessory items.

Industrial Automation Wiring and Grounding Provides general guidelines for installing a Rockwell Automation industrial

Guidelines, publication 1770-4.1 system.

Provides declarations of conformity, certificates, and other certification

Product Certifications website, http://www.ab.com details.

You can view or download publications at http://www.rockwellautomation.com/literature/. To

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Shaft Seal Kits 7

Notes:

Rockwell Automation Publication 2090-IN012C-EN-P - February 2014

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support you can find technical and application notes, sample code, and links to software

service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/ for software updates, support chats

and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact

your local distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/services/online-phone.

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Use the Worldwide Locator at

Outside United States or

http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your

Canada

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

Contact your distributor. You must provide a Customer Support case number (call the phone number

United States

above to obtain one) to your distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002, available at http://www.rockwellautomation.com/literature/.

Allen-Bradley, Rockwell Software, Rockwell Automation, Kinetix, MP-Series, RDD-Series, HPK-Series, and TL-Series are trademarks of

Rockwell Automation, Inc.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 2090-IN012C-EN-P - February 2014 PN-237636

Supersedes Publication 2090-IN012B-EN-P - January 2007 Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

You might also like

- Pokémon Unbound Mission List+ v2.1.0Document8 pagesPokémon Unbound Mission List+ v2.1.0Kokot100% (3)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- Swot AnalysisDocument3 pagesSwot AnalysisJasmin Celedonio Laurente100% (8)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- TMVW Orbital Motor Repair InstructionDocument28 pagesTMVW Orbital Motor Repair InstructionServicio TLMNo ratings yet

- Cooler MOORE PDFDocument22 pagesCooler MOORE PDFhugo peñaNo ratings yet

- 205-00 Drive Shaft System - General InformationDocument12 pages205-00 Drive Shaft System - General InformationPor PenglengNo ratings yet

- Classroom Observation ToolDocument1 pageClassroom Observation ToolRyan Edem100% (2)

- Behaviorally Anchored Rating ScalesDocument5 pagesBehaviorally Anchored Rating ScalesAarti Bhoria100% (2)

- Metodo Elevacion F350aDocument2 pagesMetodo Elevacion F350arocavero8No ratings yet

- Rod BearingsDocument29 pagesRod BearingsDaniel SarmientoNo ratings yet

- MP8 - D13 Injector Cup Info 45-sb211007-1Document6 pagesMP8 - D13 Injector Cup Info 45-sb211007-1ONE SOURCE DIESELNo ratings yet

- Rear AxleDocument23 pagesRear Axlemika DataNo ratings yet

- Motor B411 Turbo MitsubishiDocument1 pageMotor B411 Turbo MitsubishiCarlos Alberto Lau SosaNo ratings yet

- Bolt Torque Sequence PDFDocument2 pagesBolt Torque Sequence PDFmil100% (1)

- Drive ShaftDocument9 pagesDrive ShaftSteven AmadorNo ratings yet

- T-SB-0088-10 Transmission Fluid Leak Through Drive Shaft YokeDocument4 pagesT-SB-0088-10 Transmission Fluid Leak Through Drive Shaft YokeFrank Logan100% (1)

- Breakage of The Tightening Stud of Cyl - CoverDocument5 pagesBreakage of The Tightening Stud of Cyl - Coverstergios meletisNo ratings yet

- Nissan Frontier Vq40 v6 Despiece MotorDocument210 pagesNissan Frontier Vq40 v6 Despiece Motorerik rojasNo ratings yet

- Unit Injector - InstallDocument4 pagesUnit Injector - InstallJose PichinteNo ratings yet

- Identification: Drive Axle Noise DiagnosisDocument48 pagesIdentification: Drive Axle Noise DiagnosisRoberto Ortega MicalizziNo ratings yet

- Installation Instructions: Yamaha 10-300C: Confirm Measurements Prior To InstallationDocument2 pagesInstallation Instructions: Yamaha 10-300C: Confirm Measurements Prior To InstallationBob MillerNo ratings yet

- Basic Block: Systems OperationDocument3 pagesBasic Block: Systems OperationFrezgi BirhanuNo ratings yet

- Rear Axle ShaftsDocument4 pagesRear Axle ShaftsMaria AparecidaNo ratings yet

- Wif.00003-B Piston Ring End Gap Guidelines 06-23-2021Document1 pageWif.00003-B Piston Ring End Gap Guidelines 06-23-2021mokhtarzahrezaNo ratings yet

- Sumitomo Cyclo 6000 Quick StartDocument16 pagesSumitomo Cyclo 6000 Quick StartJulver Goyzueta Arce100% (1)

- 205-00 Drive Shaft System - General Information PICKUP JMCDocument12 pages205-00 Drive Shaft System - General Information PICKUP JMCRusonegroNo ratings yet

- Calibracion Cilindros Liner MackDocument6 pagesCalibracion Cilindros Liner MackHamilton MirandaNo ratings yet

- 4032 Installation Tips: Piston To Cylinder Wall ClearanceDocument2 pages4032 Installation Tips: Piston To Cylinder Wall ClearanceMihneaStefanNo ratings yet

- Brute IV ExtremeDocument8 pagesBrute IV Extremejarrodjohns927No ratings yet

- Manual Generador KatoDocument160 pagesManual Generador Katomass72100% (4)

- Fiat Lanac Chain TB - VKML - 82000 - en - 0915Document3 pagesFiat Lanac Chain TB - VKML - 82000 - en - 0915Aleksandar ZivkovicNo ratings yet

- Toyota Automatic Transmission A340 Series. Repair Instruction - Page 14Document11 pagesToyota Automatic Transmission A340 Series. Repair Instruction - Page 14Carlos André BodybuilderNo ratings yet

- PSI 262 - 1012-1013-2012-2013 Crankshaft Sealing Rings in Free End CoverDocument7 pagesPSI 262 - 1012-1013-2012-2013 Crankshaft Sealing Rings in Free End CoverJKLUISJRNo ratings yet

- T SB 0274 09Document5 pagesT SB 0274 09goombaNo ratings yet

- 3 - DrivelineDocument247 pages3 - DrivelineTracy CarverNo ratings yet

- ReplacementDocument8 pagesReplacementEdson CRNo ratings yet

- Anhängerkupplung - Hayman Reese 03379RW Installationsanleitung 03379rwDocument10 pagesAnhängerkupplung - Hayman Reese 03379RW Installationsanleitung 03379rwnorbert xyNo ratings yet

- ENGIMAX Komatsu Liner KitDocument24 pagesENGIMAX Komatsu Liner KitahmedalgaloNo ratings yet

- SS395R Land Rover Dicovery All Engines Snorkel InstallDocument5 pagesSS395R Land Rover Dicovery All Engines Snorkel InstallMario LopesNo ratings yet

- Tra 026Document7 pagesTra 026Trọng Nghĩa VõNo ratings yet

- Installation For Dodge Charger / Chrysler 300 PN-140685, 140686Document4 pagesInstallation For Dodge Charger / Chrysler 300 PN-140685, 140686Ricardo López HernandezNo ratings yet

- Bolts and Bolt TorqueDocument1 pageBolts and Bolt TorqueRichard ChuaNo ratings yet

- 001-008 Camshaft: InstallDocument6 pages001-008 Camshaft: InstallNaing Min HtunNo ratings yet

- Disc BrakesDocument17 pagesDisc BrakesBenz Aio Calachua AraujoNo ratings yet

- Subaru Manley - Piston and Ring InstallationDocument2 pagesSubaru Manley - Piston and Ring Installationgreg monroeNo ratings yet

- Fis148 en A4Document8 pagesFis148 en A4Mayur PattanshettiNo ratings yet

- Corksport Install Instr For Axleback Muffler CX5!6!102-10-WEBDocument9 pagesCorksport Install Instr For Axleback Muffler CX5!6!102-10-WEBhutz5000No ratings yet

- Komatsu Liner KitDocument34 pagesKomatsu Liner KitMANCHING MOKNo ratings yet

- Class 10000 Fans Owners ManualDocument19 pagesClass 10000 Fans Owners Manualshivakumar bairojuNo ratings yet

- CBN Series 2000 Emerson BrowningDocument20 pagesCBN Series 2000 Emerson BrowningLuis Ramón Argüello RealNo ratings yet

- Brute IV Extreme For 1990-05 Dyna ModelsDocument8 pagesBrute IV Extreme For 1990-05 Dyna Modelsjarrodjohns927No ratings yet

- 001-012 Camshaft Gear (Camshaft Installed) : InstallDocument3 pages001-012 Camshaft Gear (Camshaft Installed) : InstallNaing Min HtunNo ratings yet

- Catalogo Engimax Motores IsuzuDocument38 pagesCatalogo Engimax Motores IsuzuAlexis SanchezNo ratings yet

- KIC e-CATALOG - 2018 PDFDocument60 pagesKIC e-CATALOG - 2018 PDFjONATHAN100% (1)

- SM-BB80: General Safety InformationDocument1 pageSM-BB80: General Safety InformationVIRAL WORLD IDNo ratings yet

- Meritor Brake Training 2019培训材料Document107 pagesMeritor Brake Training 2019培训材料maverickyogiNo ratings yet

- Stem Installation Instructions: Top View Top Cap 5mm Spacer Steere Tube 2mm Above The Stem ClampDocument2 pagesStem Installation Instructions: Top View Top Cap 5mm Spacer Steere Tube 2mm Above The Stem ClampHugoMSTNo ratings yet

- Power Steering GearsDocument5 pagesPower Steering GearsDarren ANo ratings yet

- Service Bulletins - Maounting SD110Document3 pagesService Bulletins - Maounting SD110Imam MuhhudaNo ratings yet

- Important Information: Section 1D - Outboard Motor InstallationDocument13 pagesImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaNo ratings yet

- Manley Rod-Sportsmaster Torque SpecDocument1 pageManley Rod-Sportsmaster Torque SpecHernan SeilikovichNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Equipment - Manual - For - Control - Units - GH1 - 102008 - Eng - en-US - Old VersionDocument272 pagesEquipment - Manual - For - Control - Units - GH1 - 102008 - Eng - en-US - Old VersionCarlos PNo ratings yet

- 3HAC021395 001RevBDocument140 pages3HAC021395 001RevBCarlos PNo ratings yet

- SRS - SRM Sick StegmannDocument28 pagesSRS - SRM Sick StegmannCarlos P0% (1)

- Q&A Webinar - Detecting Misalignment Using Vibration Analysis - LudecaDocument6 pagesQ&A Webinar - Detecting Misalignment Using Vibration Analysis - LudecaCarlos PNo ratings yet

- Tly Servos PDFDocument24 pagesTly Servos PDFGuillermo Jimenez Camarena100% (1)

- Carlos Gavazzi RVCF Drive Advanced User ManualDocument122 pagesCarlos Gavazzi RVCF Drive Advanced User ManualCarlos P100% (1)

- B-65152e 03Document236 pagesB-65152e 03Carlos PNo ratings yet

- Jakub Józef Orliński: Il Pomo D'Oro Maxim EmelyanychevDocument26 pagesJakub Józef Orliński: Il Pomo D'Oro Maxim EmelyanychevMarco Antônio RibasNo ratings yet

- A Discourse of Amanat Galunggung TerjemahkanDocument10 pagesA Discourse of Amanat Galunggung TerjemahkanGelar T. KusumawardhanaNo ratings yet

- Mechanics of Deformable Bodies: Mapúa Institute of TechnologyDocument16 pagesMechanics of Deformable Bodies: Mapúa Institute of TechnologyAhsan AliNo ratings yet

- Periodic Answer Key (Editable)Document44 pagesPeriodic Answer Key (Editable)coleenmaem.04No ratings yet

- Handbook of Digestive DiseasesDocument561 pagesHandbook of Digestive DiseasesOdiet RevenderNo ratings yet

- Regular Income Tax: Exclusions From Gross IncomeDocument11 pagesRegular Income Tax: Exclusions From Gross IncomeAngelica PagaduanNo ratings yet

- Proy. Final p2Document2 pagesProy. Final p2Antuan ButabiNo ratings yet

- Lec 9-Compatibility of Polymer BlendsDocument7 pagesLec 9-Compatibility of Polymer BlendsMua ban linh tinh100% (1)

- Days of Wine and Roses - For SymphonyDocument1 pageDays of Wine and Roses - For SymphonyEmmett Amitai WolbergerNo ratings yet

- Chapter 3Document36 pagesChapter 3刘伟康No ratings yet

- A Selection of Games at Chess Actually PDocument311 pagesA Selection of Games at Chess Actually PYandy Rojas BarriosNo ratings yet

- Percakapan Bahasa Inggris SMP Negeri 1 MaduranDocument2 pagesPercakapan Bahasa Inggris SMP Negeri 1 MaduranDevi WulansariNo ratings yet

- Haptik - WhatsApp KitDocument30 pagesHaptik - WhatsApp KitAditya ChakravartyNo ratings yet

- Injury Report FormDocument2 pagesInjury Report FormFrank Abuda100% (2)

- Gambaran Self-Compassion Dalam Relasi Berpacaran Pada Mahasiswa Fakultas Psikologi PadjadjaranDocument16 pagesGambaran Self-Compassion Dalam Relasi Berpacaran Pada Mahasiswa Fakultas Psikologi PadjadjaranNestyNo ratings yet

- Mti and Pulsed DopplerDocument33 pagesMti and Pulsed DopplerWaqar Shaikh67% (3)

- Female Psychology A-Z FREE GuideDocument37 pagesFemale Psychology A-Z FREE Guideklaus Beck100% (8)

- Non Classical Gung FuDocument19 pagesNon Classical Gung Fuxtygerx0% (1)

- 3 PTSD Checklist and ScoringDocument2 pages3 PTSD Checklist and ScoringAnchita KhuranaNo ratings yet

- People v. Sy Pio, G.R. No. L-5848. April 30, 1954Document3 pagesPeople v. Sy Pio, G.R. No. L-5848. April 30, 1954Anna BarbadilloNo ratings yet

- Solid Triangle Sales Corp. v. Sheriff of RTC QC, G. R. No. 144309, November 23,2001Document14 pagesSolid Triangle Sales Corp. v. Sheriff of RTC QC, G. R. No. 144309, November 23,2001Cza PeñaNo ratings yet

- Case StudyDocument5 pagesCase StudyRushabh AjmeraNo ratings yet

- Life and Works of Rizal - Jose Rizal's Family TreeDocument1 pageLife and Works of Rizal - Jose Rizal's Family Treeangela roperezNo ratings yet

- Persuasive Essay - Project 4Document6 pagesPersuasive Essay - Project 4api-302893696No ratings yet

- Spouting Lore - Playing Stonetop (And Other PbtA Games)Document30 pagesSpouting Lore - Playing Stonetop (And Other PbtA Games)Gabriel KerrNo ratings yet

- BEP 359 - Virtual Teams 1: Video Conference MeetingsDocument12 pagesBEP 359 - Virtual Teams 1: Video Conference MeetingsPatrickNo ratings yet