Professional Documents

Culture Documents

Check Bearing & Shear On Bolts

Check Bearing & Shear On Bolts

Uploaded by

Ibrahim HusseinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check Bearing & Shear On Bolts

Check Bearing & Shear On Bolts

Uploaded by

Ibrahim HusseinCopyright:

Available Formats

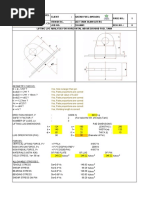

Check Bearing & Shear Out on Lifting Plate

-Design Data

Min ∑ Plate theckness(t)mm 12.00 mm

Dimeter of Bolt(d)mm M 50.00 mm

Plate steel Grade St 44

Bolt Grade 10.90

As for Bolt 15.71 cm2

shear Plans (n) 2.00

P/2

P/2

P P

P/2

P/2

*Check Bearing and shear load.

Table (6.2) Values of α for Different Values of End Distance

End distance in direction of force

≥ 3d ≥ 2.5d ≥ 2.0d ≥ 1.5d

α 1.2 1 0.8 0.6

Table (5.1) Requirements for Properties Affecting Weldability of Steel Shapes, Plates.

Nominal Values of Yield Stress Fy and Ultimate

Strength Fu

Thickness t

Grade of Fy t <40 mm 40 mm < t < 100 mm

Fu Fy Fu

Steel (t/cm2) (t/cm2) (t/cm2) (t/cm2)

St 37 2.4 3.6 2.15 3.4

St 44 2.8 4.4 2.55 4.1

St 52 3.6 5.2 3.35 4.9

Bearing (Rb)=(α Fu for element) d min Σ tmin = 21.12 t

*Check Shear Out.

P

2

P/

2

P/

P

2

P/

2

P/

Applied Force= 19.00 ton

*Allowable Stress =0.58Fy A1 = 6.24 Cm2

St 44 1.62 t/cm2 A2 = 6.24 Cm2

Shear out Stress= Force/Area = 1.52 t/cm2 Safe

*Check Tension.

*Allowable Stress =0.58Fy Applied Force= 32.50 ton

St 52 2.09 t/cm 2

Area = 96.80 Cm2

Tension Stress= Force/Area = 0.34 t/cm2 Safe

You might also like

- Spreader Bar Calculation PDFDocument2 pagesSpreader Bar Calculation PDFFernando Humberto100% (2)

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- TrunnionDocument5 pagesTrunnionTanvirNo ratings yet

- Eccentric and Moment Connections (Fillet Weld) : DATE: 24-SEP-2020 Gurram Vinay (L&T Wet Ic (CMPC)Document6 pagesEccentric and Moment Connections (Fillet Weld) : DATE: 24-SEP-2020 Gurram Vinay (L&T Wet Ic (CMPC)vinayNo ratings yet

- Фланцевые соединения dast v4.3 - EDocument3 pagesФланцевые соединения dast v4.3 - EZdrobau VitalieNo ratings yet

- Tower Crane Pile Foundation - dc2Document4 pagesTower Crane Pile Foundation - dc2venkatram PadalaNo ratings yet

- 6.cantilever Slabs Bakht MuftiDocument8 pages6.cantilever Slabs Bakht MuftiAkarshGowdaNo ratings yet

- Bolt Check: Equipment Tag 179-DS-201: (4404TMBOSG0003T, Clause 5.4)Document6 pagesBolt Check: Equipment Tag 179-DS-201: (4404TMBOSG0003T, Clause 5.4)Dhinesh KalaimaranNo ratings yet

- Water Tank - Is 3370-Sludge TankDocument4 pagesWater Tank - Is 3370-Sludge TankDhayalan PalanisamyNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal Vesselmiteshpatel191100% (2)

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- 4 Allowable StresseDocument26 pages4 Allowable StresseMustafa AbdoNo ratings yet

- ACP-sc-emp-cover Meter 6 InchDocument1 pageACP-sc-emp-cover Meter 6 InchagungNo ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Genset Pad 10ftx2ftDocument7 pagesGenset Pad 10ftx2ftAmmad AlizaiNo ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Design of Moment Connection 2Document2 pagesDesign of Moment Connection 2gops1963No ratings yet

- Test - Pile Report - R2Document4 pagesTest - Pile Report - R2Fahad IqbalNo ratings yet

- Narrow Face Flange - Slip On Hub Type For External PressureDocument23 pagesNarrow Face Flange - Slip On Hub Type For External PressureEng-CalculationsNo ratings yet

- Moment Conn-FlDocument2 pagesMoment Conn-Flmahmoud Ibrahem100% (1)

- Total DataDocument61 pagesTotal DataGANDRETI RAMU (N160267)No ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal VesselshaishavNo ratings yet

- Reference BS 449 Part 2: Design of Moment Connection Flush End Plate Moment ConnectionDocument2 pagesReference BS 449 Part 2: Design of Moment Connection Flush End Plate Moment ConnectionMazenMowafyNo ratings yet

- Design of Raft ThicknessDocument4 pagesDesign of Raft Thicknessvel suriyaNo ratings yet

- Chapter4 Allowable StresseDocument26 pagesChapter4 Allowable StresseDevendra BangarNo ratings yet

- Crash AbsorbersDocument31 pagesCrash AbsorbersMarcos CampolinaNo ratings yet

- Flange Design Tablated FormDocument4 pagesFlange Design Tablated Formmukesh100% (1)

- Design of Field SpliceDocument5 pagesDesign of Field Splicemai mamdouhNo ratings yet

- Water Tank - Is 3370-Mbbr Tank - 1 & 2Document4 pagesWater Tank - Is 3370-Mbbr Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Water Tank - Is 3370-MBBR Tank - 1 & 2Document4 pagesWater Tank - Is 3370-MBBR Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Beam Design (SSB)Document7 pagesBeam Design (SSB)SaiSowmithGoudNaramalaNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- ESR ST - DesignDocument33 pagesESR ST - DesignTarkeshwar Lal SrivastavaNo ratings yet

- Lifting Lug CalculationsDocument1 pageLifting Lug CalculationsshazanNo ratings yet

- General Data: Bending StessesDocument8 pagesGeneral Data: Bending Stessesprajakt_pieNo ratings yet

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument11 pagesEngineering Calculation Sheet Consulting EngineersJONAS NGNo ratings yet

- Design Dharmanagar 14.03.18Document38 pagesDesign Dharmanagar 14.03.18Anindit MajumderNo ratings yet

- Full Face Flanges With Metal To Metal ContactDocument6 pagesFull Face Flanges With Metal To Metal ContactEng-CalculationsNo ratings yet

- Lifting - Lug (Modification)Document11 pagesLifting - Lug (Modification)Sam LowNo ratings yet

- Mẫu Thiết Kế Tính ToánDocument2 pagesMẫu Thiết Kế Tính ToánNhật NguyễnNo ratings yet

- TENSION MEMBER (Compatibility Mode)Document44 pagesTENSION MEMBER (Compatibility Mode)fadhlanNo ratings yet

- PCA TIME SAVING DESIGN AIDS - Two-Way SlabsDocument7 pagesPCA TIME SAVING DESIGN AIDS - Two-Way SlabsvNo ratings yet

- Hydrotest CalculationDocument1 pageHydrotest CalculationkiranNo ratings yet

- Calc. Fillet Weld Transverse Load-Jacket ClosureDocument6 pagesCalc. Fillet Weld Transverse Load-Jacket ClosureAsep MulyadiNo ratings yet

- Padeye CalcDocument11 pagesPadeye CalcShridhar AmatiNo ratings yet

- Plinth Beam Design For Pb1: Safe Extra TopDocument2 pagesPlinth Beam Design For Pb1: Safe Extra TopNAYAN RANPURANo ratings yet

- Two Way SlabDocument88 pagesTwo Way SlabSushil KumarNo ratings yet

- Truss To Column Connection: 10 MM 22mmDocument2 pagesTruss To Column Connection: 10 MM 22mmMe Kang He Kodos We Kang And KodosNo ratings yet

- Blast Resistance Design WallDocument8 pagesBlast Resistance Design WalljatinNo ratings yet

- Calculation Curvature HDDDocument1 pageCalculation Curvature HDDSeng HeangNo ratings yet

- Stress Analysis of Flange Bolted JointsDocument3 pagesStress Analysis of Flange Bolted Jointsudaykumar8995No ratings yet

- Stress Analysis of Flange Bolted JointsDocument3 pagesStress Analysis of Flange Bolted Jointsudaykumar8995No ratings yet

- Pin StressesDocument5 pagesPin Stressesprajakt_pieNo ratings yet

- Tension MemDocument19 pagesTension MemNick AvisNo ratings yet

- Pile Design - CUP BLDG P6Document9 pagesPile Design - CUP BLDG P6fanta calcioNo ratings yet

- Chemical Engineering Journal 294 (2016) 176-184Document9 pagesChemical Engineering Journal 294 (2016) 176-184Yoneibis Donado RodriguezNo ratings yet

- DataDocument4 pagesDataCesar MoraNo ratings yet

- Matter - SOL 5.4 - Science Study GuideDocument4 pagesMatter - SOL 5.4 - Science Study GuideTegan HutchinsonNo ratings yet

- Experiment No. 7: The Conical PendulumDocument6 pagesExperiment No. 7: The Conical PendulumTrina Rose AutidaNo ratings yet

- Physics Lab 3Document11 pagesPhysics Lab 3omario normanNo ratings yet

- Nonlinear Dynamic Analysis Procedureand Ground Motion ScalingDocument4 pagesNonlinear Dynamic Analysis Procedureand Ground Motion ScalingAnita KartikaNo ratings yet

- IGCSE 15 TheTurningEffectOfForcesDocument29 pagesIGCSE 15 TheTurningEffectOfForcessalmanNo ratings yet

- Solved Problem 04Document8 pagesSolved Problem 04Abdullah SimpsonNo ratings yet

- A Study On Response Reduction Factor of RC Wter TankDocument61 pagesA Study On Response Reduction Factor of RC Wter TankMILANNo ratings yet

- Evoscgr Katalogs 2011 en Ispitivanje 82stDocument116 pagesEvoscgr Katalogs 2011 en Ispitivanje 82stvladomilanNo ratings yet

- Tpro - CIP Data QuestionnaireDocument4 pagesTpro - CIP Data QuestionnaireUgur TucNo ratings yet

- Bio MagnetismDocument36 pagesBio MagnetismSinan Erol Tektaş100% (5)

- CEE 541. Structural Dynamics: Fall 2014Document4 pagesCEE 541. Structural Dynamics: Fall 2014praveennagarajanNo ratings yet

- Ventilator FL Ktwoods Centripal Eu Brochure PDFDocument64 pagesVentilator FL Ktwoods Centripal Eu Brochure PDFgabisaNo ratings yet

- High Temperature SuperconductorsDocument5 pagesHigh Temperature SuperconductorsROJA MACHERLANo ratings yet

- Giga - GS01U10B03 00EN R - 006 1Document100 pagesGiga - GS01U10B03 00EN R - 006 1Sofiyan AliNo ratings yet

- Short Fiber Reinforced Composites For Fused Deposition ModelingDocument6 pagesShort Fiber Reinforced Composites For Fused Deposition ModelingGourav MithareNo ratings yet

- Gold Brochure PDFDocument12 pagesGold Brochure PDFmushava nyokaNo ratings yet

- Shear Stress PDFDocument6 pagesShear Stress PDFengineer bilalNo ratings yet

- Electrodynamic Withstand and Effects of Short-Circuit CurrentsDocument6 pagesElectrodynamic Withstand and Effects of Short-Circuit CurrentsTriều Nguyễn NgọcNo ratings yet

- AWS Welding Journal October 2014 PDFDocument265 pagesAWS Welding Journal October 2014 PDFmaurya21No ratings yet

- Solutions - : Solute SolventDocument4 pagesSolutions - : Solute SolventLawn94No ratings yet

- Laser: Recent Advances in OtorhinolaryngologyDocument65 pagesLaser: Recent Advances in OtorhinolaryngologyAnkushJainNo ratings yet

- Lesson Plan ME-102 Thermodynamics (EE)Document3 pagesLesson Plan ME-102 Thermodynamics (EE)fida khanNo ratings yet

- Filipovic Double-Slot Antennas On Extended HemisphericalDocument12 pagesFilipovic Double-Slot Antennas On Extended HemisphericalbiglcloverNo ratings yet

- Homework (Lecture 4)Document31 pagesHomework (Lecture 4)anh anhNo ratings yet

- Portals and Trussed Frame StructuresDocument5 pagesPortals and Trussed Frame StructuresMichael SandersNo ratings yet

- Recommended For You: Deflection of Slab With StepDocument8 pagesRecommended For You: Deflection of Slab With StepMahindaNo ratings yet

- Mind Map Physical ChemDocument1 pageMind Map Physical ChemhusnaNo ratings yet

- Chemical Equilibrium McqsDocument3 pagesChemical Equilibrium Mcqssadaf yousafzaiNo ratings yet