Professional Documents

Culture Documents

Cubo Methodology

Cubo Methodology

Uploaded by

Jerzy Claire Zuñiga0 ratings0% found this document useful (0 votes)

1 views4 pagesOriginal Title

CUBO METHODOLOGY

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views4 pagesCubo Methodology

Cubo Methodology

Uploaded by

Jerzy Claire ZuñigaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

METHODOLOGY

CUBO Modular Inc.

79 General Luis St.,

Bagbaguin

1440 Valenzuela,

Philippines

NAME OF PROJECT:

LOCATION:

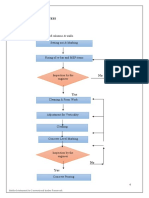

I. Layout and rebar placing

• Ensure that layout of measurements

is accurate as possible +/- 1mm, to

ensure that panels will be correctly

placed and wall footing will not be

out of bounds.

• Use Grade 40 Steel or higher and

follow the proper rebar diameters

that is specified in the structural

plans.

METHODOLOGY

CUBO Modular Inc.

79 General Luis St.,

Bagbaguin

1440 Valenzuela,

Philippines

II. Concreting

• Compact the soil before the laying of

gravel to ensure proper soil bearing

strength

• Ensure correct gravel bedding depth

and follow the plans and specifications

given by the engineer in-charge.

• Use a 1:2:5 Mix Ratio for the footings,

beams and column pedestal. For

mortar and plaster use a cement mix

ratio of 1:3

III. CHB Laying and Anchor Bolt installation

• Once hollow blocks are in-placed

ensure a 7” embedment of anchor

bolt in accordance with design code

for wood frame construction 3.2.1.7.

• Ensure also a reinforced concrete

cap on top of CHB walls to ensure

bearing strength. Follow the spacing

of bolts indicated in the plan.

• Ensure correct level of CHB walls and

squareness of the whole structure

METHODOLOGY

CUBO Modular Inc.

79 General Luis St.,

Bagbaguin

1440 Valenzuela,

Philippines

IV. Water and drainage installation

• Contractor will follow the plumbing

plans given by the Engineer In-Charge.

• All in house plumbing are done by

CUBO Modular the contractor will be

the one to tap the drainage and water

line from the unit to the existing lines

V. Sill Plate Installation

• Check level before installation of Sill

plate, Sill plates should be treated

lumber to ensure bearing plate

strength.

• Attach the polyethylene sheet before

laying the Sill plate to ensure that

moisture will not come up the

structure.

• Counter sink the anchor bolts to

ensure that the bolts are recessed to

have a flat base for the floor panels to

be laid.

• Tighten the bolts and check the level of

each side

METHODOLOGY

CUBO Modular Inc.

79 General Luis St.,

Bagbaguin

1440 Valenzuela,

Philippines

VI. Cubo Kit assembly

• Cubo kit will be assembled per panel

by the Cubo Modular team and the

contractor will assist with the

assembly of the panels. Activities

included here are:

o Assist in Lifting of Panels

o Installation of Bolt Connections

o Provide Scaffold which is good

for a 2 storey height

o Assist in aligning of panels and

others activities not specified

here but will help in assembly

of the Cubo Kit

VII. Tapping of Electrical Lines, Main Sewer Line and Main Water Line

• Once done the contractor will assist

in the energizing of the unit or the

tapping of the main electrical line to

the Cubo unit. The Cubo unit has it’s

own panel box and all electrical lines

are installed inside.

• All outside drainage components and

connection shall be done by the

contractor

• Contractor will be responsible to tap

the cubo unit water line to main line

Prepared By

Engr. Fritz Natividad

You might also like

- Jublie Church - Precast Building Case StudyDocument1 pageJublie Church - Precast Building Case Studypriyadharshini0% (1)

- Method Statement Bored PileDocument9 pagesMethod Statement Bored PileAsma Farah100% (3)

- Loffelstein Installation ManualDocument16 pagesLoffelstein Installation Manuallarushkan100% (3)

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Methodology: CUBO Modular Inc. 79 General Luis ST., Bagbaguin 1440 Valenzuela, PhilippinesDocument5 pagesMethodology: CUBO Modular Inc. 79 General Luis ST., Bagbaguin 1440 Valenzuela, PhilippinesJoshua IlaganNo ratings yet

- Brick CladdingDocument8 pagesBrick CladdingAnonymous PWdOlxYNo ratings yet

- Good Construction Practices PDFDocument9 pagesGood Construction Practices PDFKrishnan SubraNo ratings yet

- Concreting SopDocument9 pagesConcreting SopvivekNo ratings yet

- A4 - Datasheet Weber Blokfix - Renamed SmallDocument2 pagesA4 - Datasheet Weber Blokfix - Renamed Smallzuber shaikhNo ratings yet

- Connolly Dowel Cradles Installation GuideDocument1 pageConnolly Dowel Cradles Installation Guidem_mahfuz118187No ratings yet

- UnderpinningDocument17 pagesUnderpinningBharani MadamanchiNo ratings yet

- CES525 - Assignment 2Document13 pagesCES525 - Assignment 2Alif AkhmizanNo ratings yet

- The Views Tangent Pile-Method StatementDocument5 pagesThe Views Tangent Pile-Method Statementaliengineer953No ratings yet

- Preparatory Works: 5.1 Approved Shop Drawing, Method Statement, Material and SampleDocument6 pagesPreparatory Works: 5.1 Approved Shop Drawing, Method Statement, Material and SampleJasonTeeNo ratings yet

- ConstructionDocument2 pagesConstructionSubash PoudelNo ratings yet

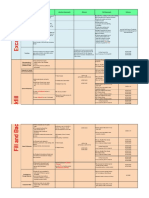

- Contractor's Scope of WorksDocument8 pagesContractor's Scope of WorksJerzy Claire ZuñigaNo ratings yet

- Selecting Right JointDocument5 pagesSelecting Right Joints mNo ratings yet

- Chapter 26 - Batter BoardsDocument8 pagesChapter 26 - Batter Boardsfelipe.moliveira18No ratings yet

- Water For The World: Table 1. Sample Materials List For A Reinforced Concrete CisternDocument7 pagesWater For The World: Table 1. Sample Materials List For A Reinforced Concrete CisternGreen Action Sustainable Technology GroupNo ratings yet

- Silo PresentationDocument21 pagesSilo PresentationCrislynNo ratings yet

- Roof Slab: Maithray BhavanaDocument11 pagesRoof Slab: Maithray BhavanaMaithrayNo ratings yet

- Construction ProcessDocument12 pagesConstruction ProcessChaitanya SinghNo ratings yet

- Wood FlooringDocument5 pagesWood FlooringYunitaNo ratings yet

- Good Construction Practice: Mfar Construction Sriramshankari Project - Ph-3 ChennaiDocument49 pagesGood Construction Practice: Mfar Construction Sriramshankari Project - Ph-3 ChennaiPon Malai KrishNo ratings yet

- VBA Box Gutter DesignDocument2 pagesVBA Box Gutter DesignbradleyrobinsonNo ratings yet

- Product Description Directions For Use: Surface PreparationDocument1 pageProduct Description Directions For Use: Surface Preparationrajeshji_000No ratings yet

- UnderpinDocument5 pagesUnderpinNur AlyaNo ratings yet

- QC Guidelines No. 3 - PPVC Carcass Production Rev0 (May 2020)Document1 pageQC Guidelines No. 3 - PPVC Carcass Production Rev0 (May 2020)Fitri Karim100% (1)

- Soil Nails As Per RDSO-204-212Document9 pagesSoil Nails As Per RDSO-204-212Kishore KumarNo ratings yet

- Residential Amenities Implementation Guide & Checklist Select & Premium HotelsDocument13 pagesResidential Amenities Implementation Guide & Checklist Select & Premium HotelsEstefania BlandonNo ratings yet

- A4 Datasheet Weber Blokset - Renamed SmallDocument2 pagesA4 Datasheet Weber Blokset - Renamed SmallKishore Nayak kNo ratings yet

- WMS 027-SEWERAGE WORKSDocument5 pagesWMS 027-SEWERAGE WORKSAzzam IdrisNo ratings yet

- Guide Specifications (Pci Hcs Manual)Document3 pagesGuide Specifications (Pci Hcs Manual)KhaleelNo ratings yet

- Conventional Timber FormworksDocument6 pagesConventional Timber FormworksLasantha WeerasekaraNo ratings yet

- Presentation1 160110103317Document19 pagesPresentation1 160110103317Tilak BodduNo ratings yet

- Critical Inspections and Quality ChecksDocument8 pagesCritical Inspections and Quality ChecksalfieNo ratings yet

- Critical Inspections and Quality ChecksDocument8 pagesCritical Inspections and Quality ChecksalfieNo ratings yet

- Critical Inspections and Quality ChecksDocument8 pagesCritical Inspections and Quality ChecksalfieNo ratings yet

- Helibar: Applications FeaturesDocument2 pagesHelibar: Applications FeaturesRomeu Branco SimõesNo ratings yet

- SruthiDocument34 pagesSruthiSRUTHI RAJNo ratings yet

- LN 2 IbsDocument68 pagesLN 2 IbsthamilNo ratings yet

- MsDocument2 pagesMsVarsha PrakashNo ratings yet

- Tech Seminar On Recent Developments in Geotechnical Site Investigation - Presentation 2 by DR PoDocument88 pagesTech Seminar On Recent Developments in Geotechnical Site Investigation - Presentation 2 by DR PoSewGuanNo ratings yet

- Method Statement For Construction of Precast Concrete Pipe CulvertDocument4 pagesMethod Statement For Construction of Precast Concrete Pipe CulvertDanny NguNo ratings yet

- 2316-A00.00 (B) - Cover SheetDocument1 page2316-A00.00 (B) - Cover SheetLuiz JuniorNo ratings yet

- Precast Concrete Catch Basins and Inlets: Unmatched Strength and DurabilityDocument3 pagesPrecast Concrete Catch Basins and Inlets: Unmatched Strength and DurabilityAhmadNo ratings yet

- Bangladesh-Method of Statement Using Geotubes-17th Feb. 2021Document4 pagesBangladesh-Method of Statement Using Geotubes-17th Feb. 2021Sukmana IndrawanNo ratings yet

- Control of RC WorksDocument47 pagesControl of RC Workskimura takuyaNo ratings yet

- Work Instruction Page 1 of 2 Contiguous Bored Piles InstallationDocument7 pagesWork Instruction Page 1 of 2 Contiguous Bored Piles InstallationMuhammad Syahmi Adli SamNo ratings yet

- R V Underpinning en v02 FreysinnetDocument4 pagesR V Underpinning en v02 FreysinnetXXX XXXNo ratings yet

- Ground Reinforcement MethodsDocument55 pagesGround Reinforcement MethodsVidya SagarNo ratings yet

- E Brochure Technique 210 BoredPiles InteractiveDocument5 pagesE Brochure Technique 210 BoredPiles Interactiveamirulardhian1996No ratings yet

- Safety Precautions: ACI 347R Safety ProvisionsDocument8 pagesSafety Precautions: ACI 347R Safety ProvisionsvisvisvisvisNo ratings yet

- Saes A 114Document2 pagesSaes A 114Nino Celso AstilleroNo ratings yet

- Method Statement For Bored Pile: Nam Fatt Construction Sdn. BHDDocument5 pagesMethod Statement For Bored Pile: Nam Fatt Construction Sdn. BHDMohamad Syafiq Bin A.Rashid100% (1)

- Pbuc 3Document30 pagesPbuc 3ZXCvincentNo ratings yet

- Installation of Timber CladdingDocument4 pagesInstallation of Timber CladdingKNo ratings yet

- Control of RC WorksDocument52 pagesControl of RC WorksSyerifaizal Hj. MustaphaNo ratings yet

- Cable Bolt Installation ProcedureDocument7 pagesCable Bolt Installation ProcedureAgung k100% (1)

- Method of Construction for Administration Building مسودةDocument7 pagesMethod of Construction for Administration Building مسودةM.ZEKEBA50% (2)

- Timber GrowthDocument17 pagesTimber GrowthAbdul Sukur Kamsir100% (3)

- PCMP (Guzman, Renz N. Bped Ep21)Document4 pagesPCMP (Guzman, Renz N. Bped Ep21)Renz N. GuzmanNo ratings yet

- 7B ReportDocument12 pages7B ReportRowena A. TomalabcadNo ratings yet

- SDM-v1 0Document32 pagesSDM-v1 0Franz NussmannNo ratings yet

- Effective Assessment of Crude Oil Sourness For The MaterialDocument7 pagesEffective Assessment of Crude Oil Sourness For The MaterialRenanLacanaNo ratings yet

- Basic Facts About ESOPs2Document20 pagesBasic Facts About ESOPs2Quant TradingNo ratings yet

- Bacteria ProfileDocument18 pagesBacteria ProfileNOR-FATIMAH BARATNo ratings yet

- SZ Sales ProgramDocument28 pagesSZ Sales ProgramrossifrancescoNo ratings yet

- Science Journalism ReviewerDocument15 pagesScience Journalism ReviewerHiyami ChanNo ratings yet

- Variable Pay & Executive Compensation Submmitted BY Shweta Nayak SuchitraDocument63 pagesVariable Pay & Executive Compensation Submmitted BY Shweta Nayak SuchitrabsbhavaniNo ratings yet

- All About StarDocument9 pagesAll About StarRukanuzzaman RaselNo ratings yet

- Jetlax's CNS Pharmacology Cheat Sheet For The Philippines v6.0 at Bit - Ly - CNSPcol - See Bit - Ly - CNSHandouts For 5.0 CorrectionsDocument61 pagesJetlax's CNS Pharmacology Cheat Sheet For The Philippines v6.0 at Bit - Ly - CNSPcol - See Bit - Ly - CNSHandouts For 5.0 CorrectionsShalimar BasmanNo ratings yet

- How To MentorDocument54 pagesHow To Mentorgetahun esubalewNo ratings yet

- Makro Chef Ingredients For Your PassionDocument62 pagesMakro Chef Ingredients For Your PassionCarina LopesNo ratings yet

- Hunna I. Lipke v. City of New York, Et Al.Document21 pagesHunna I. Lipke v. City of New York, Et Al.Eric SandersNo ratings yet

- Certificate of Compliance CSA For Fluke 113 - 114 - 115-116-117Document2 pagesCertificate of Compliance CSA For Fluke 113 - 114 - 115-116-117CHARLES BARRAZA100% (1)

- Case Study Sickle CellDocument2 pagesCase Study Sickle CellAweGooseTreeNo ratings yet

- Edl What Is A TestDocument18 pagesEdl What Is A TestEric Tipton100% (1)

- Essay C DraftDocument7 pagesEssay C Draftapi-242837115No ratings yet

- The Internet Addiction and The Academic Productivity of Grade 12 Students in Aclc OrmocDocument43 pagesThe Internet Addiction and The Academic Productivity of Grade 12 Students in Aclc OrmocKenberly DingleNo ratings yet

- Last Six Months Current AffairsDocument102 pagesLast Six Months Current Affairschoudharysiya8580409398No ratings yet

- Hotel Majestic Kuala Lumpur Press ReleaseDocument3 pagesHotel Majestic Kuala Lumpur Press Releasesam07rocksNo ratings yet

- Annex 3 - 5-Revised EMFDocument3 pagesAnnex 3 - 5-Revised EMFVholts Villa VitugNo ratings yet

- Standard Muster List: NYK SMS Manual (Rev:2020/01/01)Document2 pagesStandard Muster List: NYK SMS Manual (Rev:2020/01/01)Cleanard HidalgoNo ratings yet

- Infinix Hot 10: Best Gaming Smartphone Under 20k in Nepal, LaunchedDocument7 pagesInfinix Hot 10: Best Gaming Smartphone Under 20k in Nepal, LaunchedSulavNo ratings yet

- CreamsDocument17 pagesCreamsSolomonNo ratings yet

- Chapter - 10: Reaching The Age of AdolescenceDocument11 pagesChapter - 10: Reaching The Age of AdolescenceDestroy YtNo ratings yet

- LV Panel ReportDocument71 pagesLV Panel ReportMudassirNo ratings yet

- Yokogawa RAGN ManualDocument46 pagesYokogawa RAGN ManualJohn AdewaleNo ratings yet

- International StandardDocument8 pagesInternational Standardnazrul islamNo ratings yet