Professional Documents

Culture Documents

Simulation of Growth and Detachment in Biofilm Systems Under Defined Hydrodynamic Conditions

Simulation of Growth and Detachment in Biofilm Systems Under Defined Hydrodynamic Conditions

Uploaded by

Hana HanounaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation of Growth and Detachment in Biofilm Systems Under Defined Hydrodynamic Conditions

Simulation of Growth and Detachment in Biofilm Systems Under Defined Hydrodynamic Conditions

Uploaded by

Hana HanounaCopyright:

Available Formats

Simulation of Growth and Detachment in

Biofilm Systems Under Defined

Hydrodynamic Conditions

Harald Horn,1,* Helmut Reiff,2 Eberhard Morgenroth1,3

1

Department of Civil and Environmental Engineering, University of Illinois

at Urbana-Champaign, Urbana, Illinois 61801

2

Ingenieurgesellschaft für Bauwesen und Umwelttechnik mbH, D-76137

Karlsruhe, Germany

3

Department of Animal Sciences, University of Illinois at

Urbana-Champaign, Urbana, Illinois 61801

Received 14 March 2002; accepted 22 July 2002

DOI: 10.1002/bit.10503

Abstract: Detachment from biofilms was evaluated using internal strength of the matrix that is holding the biofilm

a mixed culture biofilm grown on primary wastewater in together. Thus, in principle there are two mechanisms that

a tube reactor. The growth of biofilms and the detach-

ment of biomass from biofilms are strongly influenced can lead to detachment: i) increase of the external shear

by hydrodynamic conditions. In a long-term study, three forces (e.g., during backwashing), or ii) decrease of the

biofilms were cultivated in a biofilm tube reactor. The internal strength (e.g., through hydrolysis of the polymeric

conducted experiments of biofilm growth and detach- biofilm matrix). The discussion of what biological, chemi-

ment can be divided into three phases: 1) an exponential

phase with a rapid increase of the biofilm thickness, 2) a cal, or physical mechanism is the dominating factor in de-

quasi-steady-state with spontaneous fluctuation of the tachment is ongoing (Bakke, 1986; Peyton and Characklis,

biofilm thickness between 500 and 1,200 µm in the in- 1993; Bryers, 2000; Stewart et al., 2000).

vestigated biofilm systems, and 3) a washout experiment Understanding mechanisms and rates of detachment is

with increased shear stress in three to four steps after

necessary to evaluate biofilm development and persistence.

several weeks of quasi-steady-state. Whereas the biofilm

thickness during the homogeneous growth phase can be Biofilm formation and the microbial ecology within the bio-

regarded constant throughout the reactor, it was found film are determined by the balance of growth and detach-

to be very heterogeneous during the quasi-steady-state ment processes. Efficient detachment plays a central role for

and the washout experiments. Growth and detachment the removal of unwanted biofilms in systems such as heat

during all three phases was simulated with the same

one-dimensional biofilm model. For each of the three exchangers (Flemming et al., 1996), dental hygiene (Wilson

phases, a different detachment rate model was used. et al., 1998), biomaterial implants (Dankert et al., 1986),

During the homogeneous growth phase, detachment and on ship hulls (Cooksey and Wigglesworth-Cooksey,

was modeled proportional to the biofilm growth rate. 1995). In drinking water distribution systems, removal of

During the quasi-steady-state phase, detachment was

described by random detachment events assuming a

biofilms is desired; however, detachment of biofilm can

base biofilm thickness. Finally, the washout experiment result in a secondary contamination of the drinking water.

was simulated with detachment being a function of the For beneficial biofilms in ethanol production (Tzeng et al.,

biofilm thickness before the increase of the shear stress. 1991), water purification (Lee and Rittmann, 2000), waste-

© 2003 Wiley Periodicals, Inc. Biotechnol Bioeng 81: 607–617,

2003.

water treatment (Morgenroth and Wilderer, 1999), and soil

Keywords: biofilm; tube reactor; detachment; model remediation (Bouwer and Zehnder, 1993) a balance be-

tween accumulation of sufficient active biomass, on the one

hand, and physical clogging of the system, on the other, has

INTRODUCTION

to be achieved. As shown by Morgenroth and Wilderer

Detachment from biofilms is caused by a combination of (2000), in mixed culture biofilms the rate and dynamics of

processes, including 1) abrasion, 2) erosion, 3) sloughing, detachment also has a significant impact on bacterial com-

and 4) predator grazing (Bryers, 1988). Detachment occurs petition within the biofilm.

when external forces (e.g., through shear) are larger than the Despite the central importance of detachment in biofilm

development, very little is known about the biological,

chemical, and physical mechanisms of detachment (Stewart

*Current address and correspondence to: Harald Horn, Hydrochemis-

try, Hochschule Magdeburg-Stendal (FH), Breitscheidstr. 2, D-39114

et al., 2000). As a result, most mathematical models to

Magdeburg, Germany; telephone: +49391 8864238; fax: +49391 8864234; describe biofilm development are based on simplified as-

e-mail: harald.horn@chemie.hs-magdeburg.de sumptions by either completely neglecting detachment (Kis-

© 2003 Wiley Periodicals, Inc.

sel et al., 1984; Fruhen et al., 1991; Kreft et al., 2001; ment rate over a wide range of conditions (Peyton and Char-

Picioreanu et al., 1998) or by assuming a constant biofilm acklis, 1993).

thickness (Wanner and Gujer, 1984; Eberl et al., 2000). Many laboratory studies under controlled hydrodynamic

Experimental approaches to quantify overall detachment conditions (e.g., in flow channels or annular reactors) have

rates are based on macroscopic mass balances for biofilm been restricted to measurements lasting less than a week

reactors, relating the mass of effluent suspended solids re- (Trulear and Characklis, 1982). Within this restricted time

moved per time to the total mass of biofilm in the system frame it cannot be expected that the biofilm has reached

(Rittmann, 1989). To evaluate local detachment, microscale steady-state conditions and these young and thin biofilms

flow channels have been used in combination with image (<50 m) may not be representative for biofilms observed

analysis (Murga et al., 1995; Sawyer and Hermanowicz, in engineering applications. Most of these studies evaluate

1998; Stoodley et al., 1999). However, for these microscale biofilm detachment only under constant shear conditions.

experiments it is generally not possible to relate local phe- However, in natural and engineered biofilm systems, bio-

nomena with an overall mass balance for suspended solids. film properties change over time and external forces can

Resulting detachment rates have been introduced into math- also change significantly. Only limited information on de-

ematical biofilm models based on biofilm thickness (Bryers, tachment under changing conditions are available (Bakke,

1984; Chang and Rittmann, 1987; Kreikenbohm and 1986). The purpose of this study was to evaluate biofilm

Stephan, 1985; Rittmann, 1989; Tijhuis et al., 1995; Trulear development and detachment over extended periods

and Characklis, 1982; Wanner and Gujer, 1986), shear (weeks) and with dynamic variations of shear stress. Then it

stress (Bakke et al., 1984; Rittmann, 1982; Wang and Bry- was evaluated whether measured biofilm growth and de-

ers, 1997), change of shear stress (Peyton and Characklis, tachment during different stages of the experiments could

1993), growth rate (Peyton and Characklis, 1992, 1993; be represented using a mathematical model.

Robinson et al., 1984; Speitel and DiGiano, 1987; Stewart,

1993), time-dependent detachment events (Benefield and

Molz, 1985; Morgenroth and Wilderer, 1998, 1999, 2000), MATERIALS AND METHODS

or using dimensionless analysis of parameter combinations

(Chang et al., 1991; Nicolella et al., 1996). Recently, a Reactor

mathematical model was presented that combines modeling

of heterogeneous biofilms with a mechanistic model of bio- The investigated heterotrophic biofilms were grown in a

film detachment assuming that the biofilm can be approxi- biofilm tube reactor shown in Figure 1. The experimental

mated as a homogeneous elastic material and that biofilm setup consisted of the tube reactor, a mixing tank, a flow

detachment results from the combined effect of liquid shear meter, and an eccentric screw recirculation pump (Reiff,

and biofilm strength (Picioreanu et al., 2001). The abun- 1992). The pump capacity allowed for flow velocities up to

dance of available detachment rate equations partially re- 4.8 m/s in the tube reactor. The tube reactor was built out of

flects the failure of any one expression to model the detach- Plexiglas (PMMA) and was divided into five segments

Figure 1. Experimental setup with biofilm tube reactor, mixing tank, and recirculation pump.

608 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 81, NO. 5, MARCH 5, 2003

which could be weighed separately. The tube was fixed at vertically for 20 min, the wet biofilm mass was determined

an angle of 30° to avoid the collection of gas bubbles in the by weighing each drained segment individually. The mean

reactor. The technical specifications of the biofilm tube re- biofilm thickness was then calculated from the mass of the

actor are listed in Figure 1. Biofilms were grown using wet biofilm assuming a density of the wet biofilm of W ⳱

primary settled wastewater from a wastewater treatment 1 g/cm3. The mean biofilm density F (g DM/m3) was de-

plant (Kassel, Germany). For practical reasons the system termined by collecting samples of biofilm from the tubes

was operated in a sequencing batch mode where the entire after the draining procedure. The wet mass of the samples

wastewater was exchanged daily causing some fluctuations (mWM) was measured to calculate the biofilm volume VF (⳱

of organic substrate concentration over a day (Table I). mWM / W). Afterwards, the biofilm samples were dried at

Aeration was achieved through recirculation and gas trans- 105°C and weighed again (mDM). The mean biofilm density

fer within the mixing tank, resulting in a mean oxygen of the cultivated biofilm was then estimated from:

concentration >0.5 g/m3 in all experiments. Due to the high

mDM

concentration of microorganisms in the wastewater, a sepa- F = (2)

rate inoculation was not necessary. mWM

W

Growth Conditions With the exception of Experiment I (Table II), biofilms

were cultivated until they reached a quasi-steady-state with

Three experiments were carried out to investigate the

respect to the biofilm thickness. This quasi-steady-state

growth and detachment in the biofilm system under defined

phase or plateau phase can be described by a fluctuation of

hydrodynamic conditions. Organic substrate concentrations

the thickness in a certain range. After several weeks of

in the primary wastewater were high and, as a result, oxygen operation, washout experiments were performed. The flow

was the limiting component in all three experiments. The velocity in the tube reactor during the washout experiment

COD and oxygen concentration in the mixing tank were depended on the flow velocity during the growth of the

measured 2–3 times per week. The samples were taken from biofilm. The washout experiments were conducted in the

the mixing tank before the wastewater was exchanged. In following manner: Water from bank filtration was used for

addition, pH, total nitrogen concentration, and phosphorus the washout experiments. The bank filtration water obtained

concentrations were determined according to the DEV was pumped next to the river Fulda. This water was used

(1981). The biofilms were grown under three different shear because it contained only negligible amounts of COD (<10

conditions where wall shear stress () was calculated for

g/m3) and suspended solids (<1 g/m3), while maintaining an

turbulent flow using the Blasius equation (Chadwick and

ionic composition close to the growth conditions of the

Morfett, 1993):

biofilm. Compared to the batch mode during biofilm culti-

= 0.0395 Re−0.25 Waterw2 (1) vation, the washout experiments were carried out in a con-

tinuous mode. COD and suspended solids were measured in

where Re is the Reynolds numbers, w is the mean flow the effluent during the washout experiments. Each washout

velocity in the tube, and Water is the density of the water. event was monitored using multiple samples. During Ex-

The principal growth conditions, including Re, , COD, and periment I, five samples were taken during the following

oxygen are shown in Table II. time intervals: 0–0.5 min, 0.5–1.5 min, 1.5–3.5 min, 3.5–6.5

min, and 6.5–15 min. During Experiments II and III, nine

samples were taken in the time intervals: 0–0.17 min, 0.17–

Biofilm Thickness and Washout Experiments

.33 min, 0.33–0.5 min, 0.5–0.83 min, 0.83–1.17 min, 1.17–

The biofilm thickness was estimated using the method of 1.5 min, 1.5–3.5 min, 3.5–6.5 min, and 6.5–15 min.

Horn and Hempel (1997). After draining the five segments Between each increase of the flow velocity, the biofilm

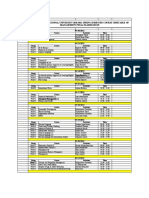

Table I. Hydraulic conditions and substrate loading during the experiments.

Experiment I Experiment II Experiment III

Procedure w [m/s] w [m/s] W [m/s]

Previous growth conditions 0.15 0.3 0.6

15-min 2-fold flow velocity compared

to growth condition 0.3 0.6 1.2

→ Determination of biofilm thickness

15-min 4-fold flow velocity 0.6 1.2 2.4

→ Determination of biofilm thickness

15-min 8-fold flow velocity 1.2 2.4 4.8

→ Determination of biofilm thickness

15-min 16-fold flow velocity 2.4 4.8 —

→ Determination of biofilm thickness

HORN ET AL.: SIMULATION OF GROWTH AND DETACHMENT IN BIOFILM SYSTEMS 609

Table II. Hydraulic conditions and substrate loading during the experiments.

Duration of Mean flow Reynolds Shear stress Mean COD Mean oxygen Biofilm density

experiment velocity w number concentration concentration

Experiment days [m/s] Re [N/m2] [g/m3] [g/m3] [kg DM/m3]

I 30 0.15 6,600 0.10 250 ± 103 0.7 55 ± 15

II 45 0.3 13,200 0.33 146 ± 68 1.3 51 ± 15

III 81 0.6 26,400 1.12 268 ± 128 1.5 64 ± 24

thickness was measured as described above. Due to biomass IV. The presented mass transfer coefficients were estimated

that had accumulated in the tubes and pump, a mass balance on the basis of Wäsche et al. (2000). Bulk phase concen-

of the detached biomass could not be done. After an in- trations for organic substrate and oxygen were taken from

crease of the flow velocity during a washout experiment, the experiments (Table II). Both the kinetic model and the

effluent suspended solids were derived from detachment in detachment model were integrated into a biofilm compart-

the tubular reactor but also from the tubes and pump. Thus, ment in the software package AQUASIM (Reichert, 1994).

the mass of effluent suspended solids could not be directly

correlated with the change in biofilm thickness in the reac-

tor. However, normalized effluent suspended solids concen- Detachment

trations could be used to calibrate the dynamics of detach- Three different approaches to model detachment were re-

ment in the mathematical model. quired to describe distinctly different phases of the experi-

ments (see, for example, Fig. 4): 1) homogeneous growth

Model Considerations with a homogeneous biofilm morphology and steadily in-

creasing biofilm thickness, 2) quasi-steady-state with spon-

taneous detachment events and an approximately constant

Kinetic and Stoichiometry mean biofilm thickness, and 3) washout conditions in an

experiment with an incremental increase of shear forces.

Biofilm growth was described using a simple model includ-

During the homogeneous growth phase the detachment

ing growth, maintenance, and inactivation of heterotrophic

rate coefficient kd of biomass was considered to be depen-

bacteria (Table III). The model includes the two dissolved

dent on the advective velocity uF by which the biofilm

components for organic matter cS and oxygen cO2 and the

surface moves perpendicular to the substratum (Wanner and

two particulate components for heterotrophic biomass XH

Reichert, 1996). The detachment was described as follows:

and inactive biomass XI. Growth and maintenance describe

the substrate uptake and growth of the heterotrophic bio- dLF

mass. Inactivation describes the formation of inactive or- = uF * kd,hom (3)

dt

ganic material, for example, EPS, out of heterotrophic bio-

mass. Because of the low oxygen concentrations, it was where kd,hom can range between 0 and 1 and couples the

assumed that maintenance was a main process in the de- detachment velocity to the current growth rate. This proce-

scribed biofilm systems, which translated into lower KS- dure allows the description of a continuous detachment rate

values in the Monod terms of the process maintenance com- during the homogeneous growth phase of the biofilm.

pared to the KS-values for the process growth (Horn and Following the homogeneous growth phase, the biofilm

Hempel, 1997). The kinetic parameters are shown in Table thickness LF in Experiments II and III reached quasi-steady-

Table III. Process matrix for the heterotrophic biofilm (for kinetic parameters, see Table IV).

Dissolved Solid

components components

Process cS cO2 XH XI Process rate

Growth of heterotrophic bacteria −1 1−YH 1 — cs c02

− H X

YH YH Ks + cs KO2 + cO2 H

Maintenance of heterotrophic −1 −1 — — cs c02

bacteria km X

KSmain + cs KO2main + cO2 H

Inactivation of heterotrophic — — −1 1 Ks K02

bacteria k1 X

Ks + cs KO2 + cO2 H

610 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 81, NO. 5, MARCH 5, 2003

Table IV. Model parameters for the heterotrophic biofilm.

Parameter Model Values

1

Kinetic

Mean maxium growth rate:

heterotroph H 5 d−1

Yield coefficient:

heterotroph YH 0.5 gX g−1COD

Monod constant:

COD Ks 10 g m−3

Oxygen KO2 0.5 g m−3

Maintenance coefficient km 1.95 d−1

Monod constant:

COD KSmain 1 g m−3

Oxygen KO2main 0.2 g m−3

Reaction rate constant for the process inactivation

heterotroph bacteria kI 0.028 d−1

Diffusion coefficient:

oxygen DO2 2.1 cm2 d−1

glucose Ds 0.58 cm2 d−1

Mass transfer coefficients2:

experiment I  3 m/d

experiment II  6 m/d

experiment III  10 m/d

Density of solid phase:

heterotroph H 110 kg m−3

inert I 110 kg m−3

Initial condition for volume fraction of the

heterotroph bacteria ⑀H ini 0.01 —

inert material ⑀I ini 0.49

Initial biofilm thickness Lfini 1 m

Detachment3

Coefficient for the detachment velocity kd,hom 0.1

Mean base biofilm thickness LF,buse 600 m

Detachment rate constant for forced

detachment kd,detach 800000 d−1

1

Kinetic data were taken from Horn and Hempel (1997).

2

Mass transfer cefficients were estimated using Wäsche et al. (2000).

3

Data fitted using the experimental results.

state conditions with fluctuations of the biofilm thickness ment was initiated in washout experiments by incrementally

between 500 and 1,200 m. Frequent sloughing events re- increasing the shear forces acting on the biofilm surface.

sulted in a very heterogeneous biofilm thickness and the Different modeling approaches had to be evaluated to de-

reported biofilm thickness describes an overall mean bio- scribe the change in measured mean biofilm thickness dur-

film thickness. Fluctuations of the biofilm thickness were ing washout. First, the amount of detached biomass (⌬LF)

usually spontaneous and started after approximately 20 days was correlated with the increased flow velocity correspond-

of growth. In the mathematical model, these spontaneous ing to increased shear stress during washout conditions (Fig.

events were modeled using a fixed base biofilm thickness 2a). Second, ⌬LF was correlated with the ratio of the shear

(Morgenroth and Wilderer, 2000) combined with a random stress during the washout experiment to the shear stress

detachment process: during the growth phase (Fig. 2b). This approach was based

dLF on the idea that biofilm strength will be a function of shear

= kd,random 共LF − LF,base兲 (4) conditions during biofilm development. Third, the biofilm

dt

thickness after detachment (LF,detach) was correlated with

where kd,random is a time-dependent detachment rate that the biofilm thickness before each washout event (Fig. 2c).

was modeled in AQUASIM by using a real list variable. The Surprisingly, both the flow velocity during detachment

dynamics of detachment during the quasi-steady-state phase and the shear stress ratios did not correlate well with the

resulted on average in one detachment event every 6 days. detached biomass. Correlating the mean biofilm thickness

LF,base is the mean base biofilm thickness. LF,base was esti- LF,detach after the washout experiment with the mean biofilm

mated based on measured biofilm thickness in Experiments thickness LF before the detachment resulted in an acceptable

II and III. linear fit and this approach was subsequently used in the

At the end of each growth experiment increased detach- described mathematical model:

HORN ET AL.: SIMULATION OF GROWTH AND DETACHMENT IN BIOFILM SYSTEMS 611

where kd,detach is the detachment rate constant for the wash-

out experiments. The detachment rate was estimated based

on dynamics of effluent suspended solids during the wash-

out experiments. This approach of using a base biofilm

thickness after detachment is based on Morgenroth and

Wilderer (2000). A similar approach to model periodic de-

tachment where biofilm is removed only in the outer layers

but bacteria below a base thickness were protected from

detachment was used by Rittmann et al. (2002).

RESULTS AND DISCUSSION

The results of the biofilm growth and washout experiments

are shown in Figures 3–5. All three biofilms grew within

2–3 weeks to a maximum biofilm thickness ranging from

500–1,200 m. In Experiment I, a washout experiment was

performed at the end of the homogeneous growth phase. In

Experiments II and III the biofilm was maintained for sev-

eral weeks at quasi-steady-state conditions where biofilm

thickness varied in the range of 500–1,200 m. It should be

noted that detachment during this quasi-steady-state oc-

curred both spontaneously during normal operation and also

during the determination of the biofilm thickness. The pro-

cedure for determining the biofilm thickness required drain-

ing of all water from the tube reactor. Draining was done in

Figure 2. Dependence of the detached biomass ⌬LF (a) on flow velocity

during the washout experiment and (b) on the shear stress ratio. (c) De-

pendence of the mean biofilm thickness after detachment LF,detach on the

biofilm thickness LF before the washout experiment.

LF,det ach = 0.61 LF − 30 (5)

It should be noted that each incremental increase of the

water velocity was exactly doubling the previous flow rate.

LF,detach was then used as the new base biofilm thickness in

the kinetic expression to simulate the next subsequent wash-

out experiment:

dLF

= kd,det ach 共LF − LF,det ach兲 (6) Figure 3. Experiments and simulation of the mean biofilm thickness LF

dt (a) during growth phase and (b) the washout experiment in Experiment I.

612 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 81, NO. 5, MARCH 5, 2003

Figure 4. Experiments and simulation of the mean biofilm thickness LF Figure 5. Experiments and simulation of the mean biofilm thickness LF

(a) during growth phase, steady-state phase, and (b) the washout experi- (a) during growth phase, steady-state phase, and (b) the washout experi-

ment in Experiment II. ment in Experiment III.

following detachment parameters were estimated based on

reverse flow direction to normal operating conditions and experimental results—but all three experiments were de-

resulted in an increased stress for the biofilm. scribed using the same set of parameters:

Biofilm densities were measured to characterize biofilm ● kd,hom: During the homogeneous growth phase

structure. Biofilm densities in all three experiments were in ● kd,random, LF,base: During the quasi-steady-state phase

the same range but had a high standard deviation that can be ● kd,detach, LF,detach: During the washout experiment

explained by the method used to determinate the dry bio-

mass (Table II). Low bulk phase oxygen concentrations in Detachment during the homogeneous growth phase was

Experiment I resulted in slower biofilm growth compared to based on Eq. [3]. The simulated biofilm thickness in Figures

Experiments II and III. Thus, it could have been expected 3–5 fits best with a value of 0.1 for kd,hom. Thus, 90% of the

that the densities in Experiment I are higher compared to net biomass production accumulated during the homoge-

Experiments II and III. Overall the densities are high, which neous growth phase in the biofilm, while only 10% were

can be explained by high shear stress during the growth removed through detachment.

phase (Table II). Biofilm densities are within the range of The detachment during the quasi-steady-state phase of

densities reported in the literature. Zhang and Bishop (1994) Experiments II and III was described based on Eq. [4]. The

reported average biofilm densities of 40 kg/m3 that was mean base biofilm thickness, LF,base, was set to 600 m for

shown to vary over the thickness of the biofilm. Tanyolac the presented simulations. The mean base biofilm thickness

and Beyenal (1997) reported higher biofilm densities for a is not constant and is dependent on the growth conditions of

fluidized bed reactor ranging from 34–76 kg/m3. In tube the biofilm. Under very high shear stress and low substrate

reactors operated at a wall shear stress below 0.05 N/m2 supply, the biofilm might never reach a thickness of 600

biofilm densities ranged between 5–15 kg/m3 (Wäsche et m. So the mean base biofilm thickness is a function of:

al., 2000). ● hydrodynamic conditions and reactor design

A single set of kinetic parameters (Table IV) was used to ● substrate load

simulate all experiments. Growth kinetics and stoichiometry ● involved bacteria

were mainly based on default values from the literature. The ● grazing organisms

HORN ET AL.: SIMULATION OF GROWTH AND DETACHMENT IN BIOFILM SYSTEMS 613

The random detachment coefficient, kd,random, is a time-

dependent constant and was provided as a real list variable

in AQUASIM. The real list consisted of two values, which

were randomly distributed using a frequency of 0.16 d-1 for

detachment events:

kd,random 再 0 d−1 without detachment

4 d−1 during detachment event

Obviously, such a statistical detachment approach will not

be able to describe individual detachment events correctly.

However, the general dynamics of randomly distributed de-

tachment events are well represented (Figs. 4, 5). In general,

the biofilm thickness during the homogenous growth and

quasi-steady-state phase in Experiments I and III was over-

estimated by the model. On the other hand, the biofilm Figure 7. Simulation of the suspended solids at the outlet of the tube

thickness in Experiment II was underestimated. reactor during the first stage of the detachment in Experiment I.

The washout experiments are presented in the expanded

Figures 3b–5b. The mean biofilm thickness LF,detach after a had been observed in reported experiments. All used de-

washout experiment was calculated using Eq. [5]. The de- tachment coefficients are summarized in Table IV.

tachment coefficient kd,detach describing the dynamics of de- The driving force for detachment in the washout experi-

tachment in Eq. [6] was fitted with the measured response ments was the increase in shear stress during the experi-

curves of suspended solids at the outlet of the tube reactor ments. After the first detachment of biomass, no significant

during the washout experiment. These response curves further detachment was observed during the ongoing ex-

were, independent from the biofilm, very similar throughout periment. However, it cannot be predicted how the biofilm

all experiments. Fifty to 70% of the detached biomass was might have behaved if the period with higher shear stress

found in the first sample. Figure 6 shows the results of had been extended to more than 15 min. Washout was per-

Experiment III for the first 4 min of the washout experi- formed using river bank filtrate with a low COD. It has been

ments. Due to the fixed biomass inside the pump and on the shown that reduced substrate concentrations resulting in

tube walls the total suspended solids in the effluent were lower growth rates can lead to lower detachment rates

approximately twice what could be balanced by the mass (Speitel and DiGiano, 1987; Peyton and Characklis, 1993;

calculated using measured ⌬LF and biofilm densities in the Tijhuis et al., 1995). However, the response time of detach-

reactor. ment rates to changes in growth rates is on the order of

In Figure 7, modeled and measured biomass concentra- hours. For the washout experiment described in this study,

tions are shown, where effluent suspended solids are nor- the influence of a reduced COD is assumed to be negligible.

malized with the maximum effluent concentration. The de- Another factor that can lead to detachment is a change of

tachment coefficient kd,detach for these washout experiments ionic strength and the ionic composition (Turakhia et al.,

was 800,000 d-1 to achieve rapid detachment of biomass, as 1983; Keiding and Nielsen, 1997). However, the ionic com-

position of the river bank filtrate was similar to the primary

wastewater used during biofilm growth. As shown in Figure

6, detachment occurred within seconds after the increase of

shear stress and most of the detached biomass was removed

within the first minute of the washout experiment. It is

concluded that the main mechanism leading to the rapid

detachment during the washout experiments is the increase

of the shear stress. Our findings are in line with Bakke

(1986), who reported a significant increase of detachment

rates during the transient increase of shear stress, while

shear stress did not have a significant influence on steady-

state detachment rates.

The simulated detachment curves in Figures 4b and 5b fit

well with the measured mean biofilm thickness after the

washout experiment. On the other hand, the simulated re-

sults of washout in Experiment I do not fit very well with

Figure 6. Measurement of suspended solids at the outlet of the tube the measured data. The simulated decrease of the mean

reactor during washout in Experiment III. biofilm thickness is much higher than the measured value.

614 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 81, NO. 5, MARCH 5, 2003

Two explanations are possible: 1) Significant detachment Different approaches can be used to include these hetero-

had already occurred during measurements of the biofilm geneous biofilm thickness distributions in mathematical

thickness. The measured value was lower than the precedent models. Multidimensional models could be used to explic-

value. 2) The doubling of the flow velocity was not the only itly describe these heterogeneous biofilm morphologies

parameter which influenced the detachment rate, but also (Noguera et al., 1999; Hermanowicz, 1999; Eberl et al.,

the value of the shear stress during the growth phase, which 2000; Picioreanu et al., 2001). However, studies that are

was the lowest during Experiment I. based on macroscopic mass balances usually provide suffi-

While the simulation results are not fully satisfying, the ciently detailed experimental data to justify the use of these

applied detachment model is able to describe the two main complex multidimensional models. Based on one-

detachment processes investigated: random detachment in a dimensional modeling some effects related to the heteroge-

fully developed biofilm; and forced detachment by in- neous biofilm thickness distribution can be predicted. Mor-

creased shear stress. The presented model is based on a genroth and Wilderer (2000) evaluated the influence of lo-

discussion of the mean biofilm thickness, LF. As was shown cal dynamic detachment on competition within a biofilm by

by Bakke (1986), the heterogeneity of a biofilm increases integrating over time results from a one-dimensional model

over cultivation time. In the current study the biofilm het- with dynamic detachment in different intervals. Morgenroth

erogeneity was evaluated by comparing the average biofilm et al. (2000) used multiple one-dimensional biofilm com-

thickness in different sections of the reactor and by visual partments where mass transport in the heterogeneous bio-

observations (data not shown). During the initial growth film structure was modeled using convective links between

phase the biofilm was homogeneously distributed through- the one-dimensional biofilm compartments. Results of this

out the reactor. Random sloughing during quasi-steady-state modified one-dimensional model were compared with

operation and the washout experiments resulted in a patchy three-dimensional modeling results. The main question will

biofilm. Thus, detachment during the quasi-steady-state be to evaluate how far biofilm heterogeneity will determine

phase and the washout experiments were not homoge- competition between different groups of microorganisms

neously distributed over the substratum area and the re- within a biofilm (Morgenroth and Wilderer, 2000). In the

ported values of ⌬LF represent detachment averaged over present study, the biofilm was based mainly on heterotro-

the substratum area. Only during the homogeneous growth phic growth, and competition between different groups of

phase can the biofilm thickness be regarded as nearly con- organisms was beyond the scope of this study.

stant along the reactor axis. In Figure 8, a conceptual model

is shown of the biofilm thickness development during the

three periods of Experiments II and III. CONCLUSIONS

The investigation and simulation of growth and detachment

in biofilm tube reactors show four main results: 1) At a

certain time during biofilm development the biofilm thick-

ness switched from a homogeneous growth phase to a quasi-

steady-state phase with a base biofilm thickness. 2) When

an increase in shear stress was applied to the biofilm, de-

tachment occurred in the first few seconds of the washout

experiment. The amount of detached biomass was found to

depend mainly on the biofilm thickness before the detach-

ment event. 3) During the quasi-steady-state and the wash-

out experiments, detachment resulted in a heterogeneous

patchy biofilm. 4) Due to similar biofilm densities and

growth rates in the conducted experiments, correlation with

these parameters are not detectable.

References

Bakke R. 1986. Biofilm detachment. Ph.D. thesis. Missoula: Montana State

University.

Bakke R, Trulear MG, Robinson JA, Characklis WG. 1984. Activity of

Pseudomonas aeruginosa in biofilms: steady state. Biotechnol Bioeng

26:1418–1424.

Benefield L, Molz F. 1985. Mathematical simulation of a biofilm process.

Figure 8. Detachment model for three phases of biofilm development. Biotechnol Bioeng 27:921–931.

Biofilm thickness is in the range of micrometers, the distance along the Bouwer EJ, Zehnder AJB. 1993. Bioremediation of organic-compounds —

substratum represents millimeters. LF,base and LF,detach are average thick- putting microbial-metabolism to work. Trends Biotechnol 11:

nesses used in the presented mathematical model. 360–367.

HORN ET AL.: SIMULATION OF GROWTH AND DETACHMENT IN BIOFILM SYSTEMS 615

Bryers JD. 1984. Biofilm formation and chemostat dynamics: pure and Morgenroth E, Eberl HJ, van Loosdrecht MCM. 2000. Evaluating 3-D and

mixed culture considerations. Biotechnol Bioeng 26:948. 1-D mathematical models for mass transport in heterogeneous bio-

Bryers JD. 1988. Modeling biofilm accumulation. In: Bazin M, Prosser JI, films. Water Sci Technol 41:347–356.

editors. Physiological models in microbiology. Boca Raton, FL: CRC Murga R, Stewart PS, Daly D. 1995. Quantitative analysis of biofilm

Press. p 109–144. thickness variability. Biotechnol Bioeng 45:503–510.

Bryers JD. 2000. Biofilm formation and persistence. In: Bryers JD, editor. Nicolella C, Felice RD, Rovatti M. 1996. An experimental model of bio-

Biofilms II: process analysis and application. New York: Wiley-Liss. film detachment in liquid fluidized bed biological reactors. Biotechnol

p 45–88. Bioeng 51:713–719.

Chadwick AJ, Morfett JC. 1993. Hydraulics in civil and environmental Noguera DR, Pizarro G, Stahl DA, Rittmann BE. 1999. Simulation of

engineering, 2nd ed. London: E & FN Spon. multispecies biofilm development in three dimensions. Water Sci

Chang HT, Rittmann BE. 1987. Mathematical modeling of biofilm on Technol 39:123–130.

activated carbon. Environ Sci Technol 21:273–280. Peyton BM, Characklis WG. 1992. Kinetics of biofilm detachment. Water

Chang HT, Rittmann BE, Amar D, Heim R, Ehlinger O, Lesty Y. 1991. Sci Technol 26:1995–1998.

Biofilm detachment mechanisms in a liquid-fluidized bed. Biotechnol

Peyton BM, Characklis WG. 1993. A statistical-analysis of the effect of

Bioeng 38:499–506.

substrate utilization and shear-stress on the kinetics of biofilm detach-

Cooksey KE, Wigglesworth-Cooksey B. 1995. Adhesion of bacteria ment. Biotechnol Bioeng 41:728–735.

and diatoms surfaces in the sea: a review. Aquat Microb Ecol 9:

Picioreanu C, van Loosdrecht MCM, Heijnen JJ. 1998. A new combined

87–96.

differential-discrete cellular automaton approach for biofilm model-

Dankert J, Hogt AH, Feijen J. 1986. Biomedical polymers, bacterial ad- ing: application for growth in gel beads. Biotechnol Bioeng 57:

hesion, colonization and infection. CRC Crit Rev Biocompat 2: 718–731.

219–301.

Picioreanu C, van Loosdrecht MCM, Heijnen JJ. 2001. Two-dimensional

DEV. 1981. Deutsche Einheitsverfahren zur Wasser-, Abwasser- und

model of biofilm detachment caused by internal stress from liquid

Schlammuntersuchung, Wasserchemische Gesellschaft. Fachgruppe in

flow. Biotechnol Bioeng 72:205–218.

der GDCh / in Gemeinschaft mit dem Normenausschu Wasserwesen

(NAW) im DIN Deutsches Institut für Normung (Eds.). Weinheim: Reichert P. 1994. Concepts underlying a computer program for the iden-

Wiley-VCH. (German standard methods for examination of water, tification and simulation of aquatic systems (AQUASIM 1.0). Düben-

wastewater and sludge.) dorf: Schriftenreihe der EAWAG.

Eberl HJ, Picioreanu C, Heijnen JJ, van Loosdrecht MCM. 2000. A three- Reiff H. 1992. Wachstum und Abtrag der Sielhaut in Mischwasserkanälen

dimensional numerical study on the correlation of spatial structure, [Growth and detachment of biofilms in sewers]. Ph.D. thesis. Univer-

hydrodynamic conditions, and mass transfer and conversion in bio- sity of Kassel.

films. Chem Eng Sci 55:6209–6222. Rittmann B. 1982. The effect of shear stress on biofilm loss rate. Biotech-

Flemming H-C, Griebe T, Schaule G. 1996. Antifouling strategies in tech- nol Bioeng 24:501–506.

nical systems — a short review. Water Sci Technol 34:517–524. Rittmann BE. 1989. Detachment from biofilms. In: Characklis WG,

Fruhen M, Christan E, Gujer W, Wanner O. 1991. Significance of spatial Wilderer PA, editors. Structure and function of biofilms. New York:

distribution of microbial species in mixed culture biofilms. Water Sci Wiley. p 49–58.

Technol 23:1365–1374. Rittmann BE, Stilwell D, Ohashi A. 2002. The transient-state, multiple-

Hermanowicz SW. 1999. Two-dimensional simulations of biofilm devel- species biofilm model for biofitration processes. Water Res 36:

opment: effects of external environmental conditions. Water Sci Tech- 2342–2356.

nol 39:107–114.

Robinson JA, Trulear MG, Characklis WG. 1984. Cellular reproduction

Horn H, Hempel DC. 1997. Growth and decay in an auto-/heterotrophic and extracellular polymer formation by Pseudomonas aeruginosa in

biofilm. Water Res 31:2243–2252. continuous culture. Biotechnol Bioeng 26:1409–1417.

Keiding K, Nielsen PH. 1997. Desorption of organic macromolecules from Sawyer LK, Hermanowicz SW. 1998. Detachment of biofilm bacteria due

activated sludge: effect of ionic composition. Water Res 31: to variations in nutrient supply. Water Sci Technol 37:211–214.

1665–1672.

Speitel GE, DiGiano FA. 1987. Biofilm shearing under dynamic condi-

Kissel JC, McCarty PL, Street RL. 1984. Numerical simulation of mixed- tions. J Environ Eng ASCE 113:464–475.

culture biofilm. J Environ Eng ASCE 110:393–411.

Stewart PS. 1993. A model of biofilm detachment. Biotechnol Bioeng

Kreft JU, Picioreanu C, Wimpenny JWT, van Loosdrecht MCM. 2001.

41:111–117.

Individual-based modelling of biofilms. Microbiol Sgm 147:

2897–2912. Stewart PS, McFeters GA, Huang CT. 2000. Biofilm formation and per-

sistence. In: Bryers JD. editor. Biofilms II: process analysis and ap-

Kreikenbohm R, Stephan W. 1985. Application of a two-compartment

plication. New York: Wiley-Liss. p 373–405.

model to the wall growth of Pelobacter acidigallici under continuous

culture conditions. Biotechnol Bioeng 27:296–301. Stoodley P, Dodds I, Boyle JD, Lappin-Scott HM. 1999. Influence of

hydrodynamics and nutrients on biofilm structure. J Appl Microbiol

Lee KC, Rittmann BE. 2000. A novel hollow-fibre membrane biofilm

reactor for autohydrogenotrophic denitrification of drinking water. 85:19S–28S.

Water Sci Technol 41:219–226. Tanyolac A, Beyenal H. 1997. Prediction of average biofilm density and

Morgenroth E, Wilderer PA. 1998. Modeling of enhanced biological phos- performance of a spherical bioparticle under substrate inhibition. Bio-

phorus removal in a sequencing batch biofilm reactor. Water Sci Tech- technol Bioeng 56:319–329.

nol 37:583–587. Tijhuis L, van Loosdrecht MCM, Heijnen JJ. 1995. Dynamics of biofilm

Morgenroth E, Wilderer PA. 1999. Controlled biomass removal — the key detachment in biofilm airlift suspension reactors. Biotechnol Bioeng

parameter to achieve enhanced biological phosphorus removal in bio- 45:481–487.

film systems. Water Sci Technol 39:33–40. Trulear MG, Characklis WG. 1982. Dynamics of biofilm processes. J

Morgenroth E, Wilderer PA. 2000. Influence of detachment mechanisms Water Pollut Control Fed 54:1288–1301.

on competition in biofilms. Water Res 34:417–426. Turakhia MH, Cooksey KE, Characklis WG. 1983: Influence of a calcium-

616 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 81, NO. 5, MARCH 5, 2003

specific chelant on biofilm removal. Appl Environ Microbiol 46: Wanner O, Gujer W. 1986. A multispecies biofilm model. Biotechnol

1236–1238. Bioeng 28:314–328.

Tzeng JW, Fan LS, Gan YR, Hu TT. 1991. Ethanol fermentation using Wanner O, Reichert P. 1996: Mathematical-modeling of mixed-culture

immobilized cells in a multistage fluidized-bed bioreactor. Biotechnol biofilms. Biotechnol Bioeng 49:172–184.

Bioeng 38:1253–1258. Wäsche S, Horn H, Hempel DC. 2000. Mass transfer phenomena in Bio-

Wang GTY, Bryers JD. 1997. A dynamic model for receptor-mediated film Systems. Water Sci Technol 41:57–360.

specific adhesion of bacteria under uniform shear flow. Biofouling Wilson M, Patel H, Noar JH. 1998. Effect of chlorhexidine on multi-

11:227–252. species biofilms. Curr Microbiol 36:13–18.

Wanner O, Gujer W. 1984. Competition in biofilms. Water Sci Technol Zhang TC, Bishop PL. 1994. Density, porosity, and pore structure of

17:27–44. biofilms. Water Res 28:2267–2277.

HORN ET AL.: SIMULATION OF GROWTH AND DETACHMENT IN BIOFILM SYSTEMS 617

You might also like

- Present Perfect SlidesDocument22 pagesPresent Perfect SlidesKinanti Ithuww VeraNo ratings yet

- IWE SubjectsDocument2 pagesIWE SubjectsAdnan Rana100% (4)

- Bifurcacion 1Document9 pagesBifurcacion 1monica2061No ratings yet

- Pintelon 2011Document12 pagesPintelon 2011Adriana GomezNo ratings yet

- InTech-Scanning Electron Microscopy Sem and Environmental Sem Suitable Tools For Study of Adhesion Stage and Biofilm FormationDocument15 pagesInTech-Scanning Electron Microscopy Sem and Environmental Sem Suitable Tools For Study of Adhesion Stage and Biofilm FormationJose Manuel Oliveira PereiraNo ratings yet

- DisposableDocument9 pagesDisposableSuzanne TaylorNo ratings yet

- Properties of Chitosan Films Prepared Under Different Drying ConditionsDocument7 pagesProperties of Chitosan Films Prepared Under Different Drying ConditionsMelidy Eided Hinostroza MitaccNo ratings yet

- Biofilm BioreactorDocument5 pagesBiofilm BioreactorWhite SpireNo ratings yet

- Using Flow Cytometry For Counting Natural Planktonic Bacteria and Understanding The Structure of Planktonic Bacterial CommunitiesDocument28 pagesUsing Flow Cytometry For Counting Natural Planktonic Bacteria and Understanding The Structure of Planktonic Bacterial CommunitiesClaudia MaturanaNo ratings yet

- Chan Et Al 2016Document8 pagesChan Et Al 2016Fernando LimaNo ratings yet

- Bib8 2018 Propiedades Mecanicas AGS OpticalDocument11 pagesBib8 2018 Propiedades Mecanicas AGS OpticalKaren RosasNo ratings yet

- Algal ApplicationsDocument12 pagesAlgal ApplicationsnithitheyellowstarNo ratings yet

- Exploiting A New Electrochemical Sensor For Biofilm Monitoring and Water Treatment Optimization (Pavanello Et Al 2011)Document10 pagesExploiting A New Electrochemical Sensor For Biofilm Monitoring and Water Treatment Optimization (Pavanello Et Al 2011)Leo EspositoNo ratings yet

- A Macrokinetic Model For Dimensioning of Biofilters For VOC and Odour TreatmentDocument10 pagesA Macrokinetic Model For Dimensioning of Biofilters For VOC and Odour TreatmentrichardNo ratings yet

- I J C R E: Modelling A Biochemical Reaction With Computational Fluid DynamicsDocument21 pagesI J C R E: Modelling A Biochemical Reaction With Computational Fluid Dynamics9ona3No ratings yet

- Biofilm Fixed Film SystemsDocument26 pagesBiofilm Fixed Film SystemsAlvaro HueteNo ratings yet

- Resistance of Bacterial Biofilms To Disinfectants A ReviewDocument17 pagesResistance of Bacterial Biofilms To Disinfectants A ReviewGianinna Zegarra QuevedoNo ratings yet

- Listeria Monocytogenes Biofilms: Numerical Spatio-Temporal Characterization ofDocument17 pagesListeria Monocytogenes Biofilms: Numerical Spatio-Temporal Characterization ofNunuh SulaemanNo ratings yet

- Limnology Ocean Methods - 2008 - Seymour - A Microfluidic Chemotaxis Assay To Study Microbial Behavior in DiffusingDocument12 pagesLimnology Ocean Methods - 2008 - Seymour - A Microfluidic Chemotaxis Assay To Study Microbial Behavior in Diffusingsamsinghhello1234No ratings yet

- Dolbeth Et Al CanJFishAquaSc 2012 CompletDocument67 pagesDolbeth Et Al CanJFishAquaSc 2012 Completmei mulyaNo ratings yet

- BioreactorsDocument9 pagesBioreactorsnurul9535No ratings yet

- Biofilm Growth and Control in Cooling Water Industrial SystemsDocument13 pagesBiofilm Growth and Control in Cooling Water Industrial SystemsMAI_AAN_KURNIAWANNo ratings yet

- Effect of Wall Shear Rate On Biofilm Deposition andDocument12 pagesEffect of Wall Shear Rate On Biofilm Deposition andHana HanounaNo ratings yet

- Gutirrez 2016Document13 pagesGutirrez 2016Lina Maria RodriguezNo ratings yet

- Biodegradable Polymers For Bone Tissue Engineering: M. Susana Cortizo and M. Soledad BelluzoDocument29 pagesBiodegradable Polymers For Bone Tissue Engineering: M. Susana Cortizo and M. Soledad BelluzoRajeshwari MalliNo ratings yet

- Explicacion Fisica de Los Coeficientes de Gas y Liquido de Transferencia de MasaDocument16 pagesExplicacion Fisica de Los Coeficientes de Gas y Liquido de Transferencia de MasaKevin Diego Hernandez MenaNo ratings yet

- Controle Dual ReleaseDocument7 pagesControle Dual ReleasedtninfocellNo ratings yet

- A Survey of Bacteria and Fungi Occurring During CompostingDocument62 pagesA Survey of Bacteria and Fungi Occurring During CompostingMadelaine Quiroz EspinozaNo ratings yet

- Bio FilmsDocument33 pagesBio FilmsALisaNo ratings yet

- Bharti2017 Phototrophic BiofilmsDocument16 pagesBharti2017 Phototrophic BiofilmsSacra PsyntergiaNo ratings yet

- Biovolume Determination of Phytoplankton Guilds in Transitional Water Ecosystems of Mediterranean EcoregionDocument20 pagesBiovolume Determination of Phytoplankton Guilds in Transitional Water Ecosystems of Mediterranean Ecoregionoanaoana2427No ratings yet

- Kim 2011Document8 pagesKim 2011Muriel GonzálezNo ratings yet

- Temporary Immersion Systems in Plant MicropropagationDocument17 pagesTemporary Immersion Systems in Plant MicropropagationaguilaquecaeNo ratings yet

- 5 Estructura de Poros en Filtros PercoladoresDocument9 pages5 Estructura de Poros en Filtros PercoladoresPerfecto Chagua RodriguezNo ratings yet

- Integrating Microbial Ecology in Bioprocess Understanding - The Case of Gas BiofiltrationDocument13 pagesIntegrating Microbial Ecology in Bioprocess Understanding - The Case of Gas BiofiltrationPhuong NguyenNo ratings yet

- Comparisons of The Growth of Six Diatom Species Between Two Configurations of PhotobioreactorsDocument10 pagesComparisons of The Growth of Six Diatom Species Between Two Configurations of PhotobioreactorsJordan IsmaelNo ratings yet

- Microbial Growth and Substrate Utilization Kinetics PDFDocument13 pagesMicrobial Growth and Substrate Utilization Kinetics PDFLucio Rodriguez SifuentesNo ratings yet

- Microbiological Deterioration and Degradation of Synthetic Polymeric Materials - Recent Research AdvancesDocument23 pagesMicrobiological Deterioration and Degradation of Synthetic Polymeric Materials - Recent Research AdvancesMarisela BelloNo ratings yet

- Air Dan GliserolDocument6 pagesAir Dan GliserolMuhammad FajriNo ratings yet

- Characterization of Anaerobic Biomass Immobilized in Polyurethane Foam MatricesDocument6 pagesCharacterization of Anaerobic Biomass Immobilized in Polyurethane Foam MatricesmirgytooNo ratings yet

- Methods To Isolate Culturable Bacteria Colonising MicroplasticsDocument10 pagesMethods To Isolate Culturable Bacteria Colonising MicroplasticsadelgenomicsbengaluruNo ratings yet

- Microplastics in Sediments: A Review of Techniques, Occurrence and EffectsDocument36 pagesMicroplastics in Sediments: A Review of Techniques, Occurrence and EffectsLeonny MustikaNo ratings yet

- The Biomechanics of Seed Germination: Tina Steinbrecher and Gerhard Leubner-MetzgerDocument19 pagesThe Biomechanics of Seed Germination: Tina Steinbrecher and Gerhard Leubner-Metzgerimellia deviNo ratings yet

- Wang 2018Document17 pagesWang 2018Taxman HarrisonNo ratings yet

- Trends in Food Science & TechnologyDocument8 pagesTrends in Food Science & TechnologyRoxana StanculescuNo ratings yet

- Deshusses1995 ParteDocument10 pagesDeshusses1995 ParteVANESANo ratings yet

- Mass Transfer in Bioreactors PDFDocument48 pagesMass Transfer in Bioreactors PDFGiovanniNo ratings yet

- Radiation Physics and ChemistryDocument4 pagesRadiation Physics and ChemistrySilvia AningtyasNo ratings yet

- PC PDFDocument17 pagesPC PDFAtul SharmaNo ratings yet

- Carneiro Et Al 2020bDocument10 pagesCarneiro Et Al 2020bsara.alves9402No ratings yet

- Bioprocess Intensification For Production of NovelDocument13 pagesBioprocess Intensification For Production of NovelNedita Putri BandaroNo ratings yet

- Analysis of Bacterial Communities Responsible For Carbon Removal Through A Reactor Cascade Treating WastewaterDocument13 pagesAnalysis of Bacterial Communities Responsible For Carbon Removal Through A Reactor Cascade Treating WastewaterTibor BenedekNo ratings yet

- Biofilms in Food IndustryDocument11 pagesBiofilms in Food IndustryKaleem UllahNo ratings yet

- Mckenna 2009Document9 pagesMckenna 2009Wayan ArnataNo ratings yet

- Heliyon: Sohail Ahmad, Muhammad Ashraf, Kashif AliDocument9 pagesHeliyon: Sohail Ahmad, Muhammad Ashraf, Kashif Alikiran batoolNo ratings yet

- Rolland2016 Article QuorumSensingAndQuorumQuenchinDocument11 pagesRolland2016 Article QuorumSensingAndQuorumQuenchinlunitajoaNo ratings yet

- Modeling Nutrient Consumptions in Large Flow-Through Bioreactors For Tissue EngineeringDocument13 pagesModeling Nutrient Consumptions in Large Flow-Through Bioreactors For Tissue Engineeringkomal_93No ratings yet

- Biological Fixed Film: Md. Shahinoor Islam, Geelsu Hwang, Yang LiuDocument33 pagesBiological Fixed Film: Md. Shahinoor Islam, Geelsu Hwang, Yang Liusong1088No ratings yet

- Molecular Microbiology - 2008 - Ojha - Growth of Mycobacterium Tuberculosis Biofilms Containing Free Mycolic Acids andDocument11 pagesMolecular Microbiology - 2008 - Ojha - Growth of Mycobacterium Tuberculosis Biofilms Containing Free Mycolic Acids andrupalraibplNo ratings yet

- Microwave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDocument28 pagesMicrowave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDominico Delven YapinskiNo ratings yet

- Microbiology of AerosolsFrom EverandMicrobiology of AerosolsAnne-Marie DelortNo ratings yet

- Fen4702 Project 2019Document18 pagesFen4702 Project 2019Molebogeng MathibediNo ratings yet

- Cost TypesDocument3 pagesCost TypesAsif IqbalNo ratings yet

- Ala-Too International University 2020-2021 Spring Semester Course Timetable of Management Final ExaminationDocument8 pagesAla-Too International University 2020-2021 Spring Semester Course Timetable of Management Final ExaminationKunduz IbraevaNo ratings yet

- YANG, Y.-E., Reading Mark 11,12-25 From A Korean PerspectiveDocument11 pagesYANG, Y.-E., Reading Mark 11,12-25 From A Korean PerspectiveJoaquín MestreNo ratings yet

- Concept Art Tutorial PDFDocument5 pagesConcept Art Tutorial PDFArc AngleNo ratings yet

- Thanksgiving 2010Document15 pagesThanksgiving 2010Joyce TorresNo ratings yet

- TSPSC Vro Vra Exam Pattern 2017Document7 pagesTSPSC Vro Vra Exam Pattern 2017Sk HarrshadNo ratings yet

- Syllabus - PAPER 1 - Application of Computer in MediaDocument39 pagesSyllabus - PAPER 1 - Application of Computer in MediaAbubakar shomarNo ratings yet

- History of VaccinesDocument1 pageHistory of VaccinesjordanNo ratings yet

- Grant Noble - The Trader's EdgeDocument128 pagesGrant Noble - The Trader's EdgeneerajmattaNo ratings yet

- 000 - S4H Certification Courses ListDocument3 pages000 - S4H Certification Courses ListVempati NaveenNo ratings yet

- Christmas Fruit Cake - Kerala Plum CakeDocument2 pagesChristmas Fruit Cake - Kerala Plum Cakekevinkevz1No ratings yet

- IDOC Testing: You Can Test The Idoc Using Idoc Test Tool. Just Follow The Steps AboveDocument3 pagesIDOC Testing: You Can Test The Idoc Using Idoc Test Tool. Just Follow The Steps AboveaximeNo ratings yet

- Lab Report Fine Aggregate A13 PDFDocument10 pagesLab Report Fine Aggregate A13 PDFNur NabilahNo ratings yet

- DeforestationDocument2 pagesDeforestationSoumya SNo ratings yet

- AN-066B-EN IS31FL3733B vs. IS31FL3733 Rev.ADocument9 pagesAN-066B-EN IS31FL3733B vs. IS31FL3733 Rev.ALászló MondaNo ratings yet

- SSP MonitoringDocument2 pagesSSP MonitoringcolosseusdNo ratings yet

- Theory of Indicator BehaviourDocument12 pagesTheory of Indicator BehaviourPavoNo ratings yet

- 4D Printing: Self-Assembly & Programmable MatterDocument18 pages4D Printing: Self-Assembly & Programmable MatterAnonymous iI88LtNo ratings yet

- 4 Porifera Spicules & Canal SystemDocument34 pages4 Porifera Spicules & Canal Systemapi-3732735100% (2)

- Boiling - WikipediaDocument6 pagesBoiling - WikipediaTinidoorNo ratings yet

- Self MonitoringDocument16 pagesSelf MonitoringMaroofa YounusNo ratings yet

- English NotesDocument16 pagesEnglish NotesNerin MichaelNo ratings yet

- Samsung TV ManualDocument61 pagesSamsung TV ManualAnders MåsanNo ratings yet

- BLDP Fuel Cell TelecomDocument2 pagesBLDP Fuel Cell TelecomWallStreetMannaNo ratings yet

- PulpPaper PDFDocument57 pagesPulpPaper PDFNavaganesh KannappenNo ratings yet

- Giao An Mon Tieng Anh 7 Hoc Ki 2Document95 pagesGiao An Mon Tieng Anh 7 Hoc Ki 2Vũ Nguyễn ĐứcNo ratings yet

- Msedcl Grid Connectivity ProcedureDocument29 pagesMsedcl Grid Connectivity ProcedureSubra GorthiNo ratings yet