Professional Documents

Culture Documents

Axle Identification: Dana (Spicer)

Axle Identification: Dana (Spicer)

Uploaded by

Mayet ManuelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axle Identification: Dana (Spicer)

Axle Identification: Dana (Spicer)

Uploaded by

Mayet ManuelCopyright:

Available Formats

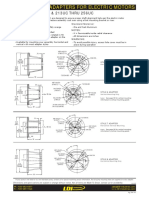

AXLE IDENTIFICATION

DANA (SPICER)

AXLE MODEL Early Models BRAKE SHOE

D= Friction Weld Spindle FC = Fast Change Fabricated,

Axle P= Friction Weld w/ProPar Tapered Riveted Lining

Ident. style spindle & bearings BRAKE SIZE FT = Pivot Type Fabricated,

Charts K,A = Inserted Spindle 123 = 12-1/4" x 3"Hydraulic Tapered Riveted Lining

2 *DD = Friction Weld Spindle

w/drop center (Pusher)

1235 =

1250 =

12-1/4" x 3-1/2" Electric

12-1/4" x 5"

FB

CS

EB

= Fabricated, Bolted Lining

= Cast Shoes

= Electric Brakes

*KD = Inserted Spindle w/drop 1255 = 12-1/4" x 5-1/2"

10 = 10,000# cap 3.5" x .5 1275 = 12-1/4" x 7-1/2" HB = Hydraulic Brakes

14 = 15,000# cap 5" x .5 153 = 15' x 3" Electric NB = No Brakes

21 = 20-22,500# cap 5" x .5 154 = 15" x 4" Electric

or 5" x .625 155 = 15" x 5" Electric

WALL THICKNESS

22 = 20-25,000# cap 5" x .5 165 = 16-1/2" x 5"

5 = 1/2" 7 = 3/4"

or 5" x .625 or 5" x .75 167 = 16-1/2" x 7"

6 = 5/8" S = Solid

25 = 25,000# cap 5" x .75 168 = 16-1/2" x 8-5/8"

30 = 30,000# cap 5.75" x .625 1610 = 16-1/2" x 10"

45 = 45,000# cap 5.75" Solid 187 = 18" x 7" AIR CHAMBER

65 = 65,000# cap 6" Solid 208 = 20" x 8" A = Air chambers mounted on axle

X = No air chamber

D2 2 FC 1 6 7 W NH A 5 7 15

BRAKE SHOE WHEELS

FC = Fast Change Fabricated, NH = No hub or wheel

Tapered Riveted Lining B6 = Six hole hub & drum

FT = Pivot Type Fabricated, B10 = Ten hole hub & drum

Tapered Riveted Lining SW6 = Single wheel six hole

FB = Fabricated, Bolted Lining SW10 = Single wheel ten hole

CS = Cast Shoes SPIDER WD = Cast spoke wheel & drum

EB = Electric Brakes W = Welded H = Heavy duty studs

HB = Hydraulic Brakes B = Bolt-on (EX:B10H)

NB = No Brakes

* The above system is still used for ordering and

specification of new axles.

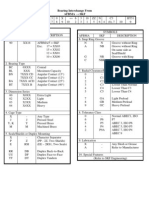

Late Models

Manufacturers Date Code

91 K 5 5 8 7 0

D 2 2 AX 5 0 3 5 2 9

Bill of material/Production number.

AXLE MODEL Must contact manufacturer for specific

D = Friction Weld Spindle AXLE TYPE brake system information.

P = Friction Weld w/ProPar AU = Bent tube, pusher axle

style spindle & bearings AV = Trunnion

K,A = Inserted Spindle AW = Boat drop LEVEL OF COMPLETION

*DD = Friction Weld Spindle AX = Straight 00 - No brakes, wheel ends or spider.

w/drop center (Pusher) 01 - Fully dressed.

*KD = Inserted Spindle w/drop 02 - With hubs, no brakes.

10 = 10,000# cap 3.5" x .5 WALL THICKNESS 03 - With brakes, no wheel ends.

14 = 15,000# cap 5" x .5 5 = 1/2" 7 = 3/4" 04 - With hubs, no brakes or spiders.

21 = 20-22,500# cap 5" x .5 6 = 5/8" S = Solid 05 - Bare axle, no brakes, hubs, spiders

or 5" x .625 or wheel ends.

22 = 20-25,000# cap 5" x .5

or 5" x .625 or 5" x .75

25 = 25,000# cap 5" x .75

30 = 30,000# cap 5.75" x .625

45 = 45,000# cap 5.75" Solid

65 = 65,000# cap 6" Solid

6 © Copyright 2003 Triangle Suspension Systems, Inc.

AXLE IDENTIFICATION

DEXTER AXLE

Models and Capacities:

Axle

Ident.

10,000 Charts

10,000 lbs. Brake 12-1/4" x 4", Air Brake

2

12,000 & 15,000

12,000 lbs. & 15,000 lbs. Brake 12-1/4" x 5", Air Brake

20,000 - 25,000

Model No.* Beam Brake Beam Capacity

D-2012 5" O.D. x 1/2" wall 12-1/4" x 7-1/2" 20,000 lbs.

D-2212 5" O.D. x 5/8" wall 12-1/4" x 7-1/2" 22,500 lbs.

D-2512 5" O.D. x 3/4" wall 12-1/4" x 7-1/2" 25,000 lbs.

D-2016 5" O.D. x 1/2" wall 16-1/2" x 7" 20,000 lbs.

D-2216 5" O.D. x 5/8" wall 16-1/2" x 7" 22,500 lbs.

D-2516 5" O.D. x 3/4" wall 16-1/2" x 7" 25,000 lbs.

* Located on axle tag, along with serial/manufacturing number.

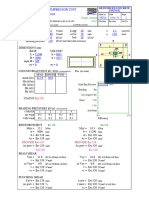

EATON

Model Identification

ES 1 6 5 7L

MANUFACTURER

E = Eaton SHOE/SPIDER TYPE

L = Fabricated Shoe/Fabricated Spider SAP

SERVICE D = Fabricated Shoe/Cast Spider SAP

B = Standard Brake F = Fabricated Shoe/Forged Spider SAP

S = Extended Service Brake M = Fabricated Shoe/Heavy Cast Spider DAP

H = Cast Shoe/Heavy Cast Spider DAP

DRUM DIAMETER R = Cast Shoe/Heavy Cast Spider SAP

150 - 15" (381 mm)

165 - 16.5" (419 mm) SHOE WIDTH

180 - 18" (457 mm) 4 - 4"

5 - 5"

6 - 6"

7 - 7"

8 - 8.63"

Identification Tag Location

*Model Number, Part Number and Serial Number

Model, part and serial numbers are located on a

plate in the middle area of the axle.

* Axles built before 4/1/93 have the serial number

stamped into the beam near the I.D. plate.

© Copyright 2003 Triangle Suspension Systems, Inc. 7

AXLE IDENTIFICATION

EATON

Eaton EST and ESR Series Trailer Axles

Axle EST 2 25 J

Ident.

Charts SPINDLE CODE

MANUFACTURER

2

J = "J" Spindle

E = Eaton

P = "P" Spindle

SERVICE

S = Extended Service Brake TUBE CAPACITY RATING

BRAKE CODE

B = Standard Brake* (x 100 lbs.)

T = 16-1/2" x 7"

*No longer current production. R = 15" x 8-5/8"

FRUEHAUF (DELPHOS)

Trailer Axle Description and Designation

P P 3 2 B 3 B CAM LENGTHS,

SPLINE TYPE

A = STD 16-1/8" 37 spline

SPINDLE DESIGN B = Long 21-1/8" 37 spline

P = Parallel TYPE BRAKE RATING C = X-Long 23-7/8" 37 spline

D = Trade D = 5" Round 1 - 18,000 # D = STD 16-1/8" 28 spline

P = 5" Square TRACK

E = Euro 2 - 20,000 # E = Long 21-1/8" 28 spline

1 - 71-1/2"

2 - 77-1/2" 3 - 23,000 #

BEAM RATING* 3 - Other 4 - 25,000 #

1 - 22,000 # (10MT)

2 - 22,500 # BRAKE TYPE & SIZE

3 - 25,000 # A = "XEM", 16-1/2" x 7"

4 - 28,600 # (13 MT) B = "XEM", 16-1/2" x 8-5/8"

C = "Q", 16-1/2" x 7"

D = "P", 12-1/4" x 8"

* Rating based on approved installation and normal highway conditions.

Denotes specifications are not applicable.

HENDRICKSON "INTRAAX"

Model Number Description

A . A 1 A A N 0 N 0 0 0 NN

HANGER STYLE

A = Weld On ABS READY

UP TRAVEL BRAKE SIZE N = No

B = Bolt On A = Standard A = 16.5" x 7.0"

C = Weldable Bolt On Y = Yes

D = Weld On w/Slot

AIR SPRING BRAKE LINING HUB, DUST SHIELD, DRUM

1 - Standard & TYPE 000 - None

SEQUENTIAL #

Assigned by 001 - HT1 Standard

Hendrickson SHOCK OPTIONS 003 - HT3 BEARING, SEAL,

A = Standard LUBE OPTIONS

B = Heavy Duty SLACK ADJUSTER NN = None

RIDE HEIGHT

C = Heavy Duty, N = None

13 - 13.5"

High control

14 - 14"

15 - 15" BRAKE CHAMBER

16 - 16" TRACK & SPINDLE 0 - None

17 - 17" 01 - 71.5" HN 35.0" Beam Center

02 - 77.5" HN 41.0" Beam Center

06 - 71.5" HP 35.0" Beam Center The Intraax System Air Axle (AA) has a rating of 23,000

07 - 77.5" HP 41.0" Beam Center lbs (230). The suspension is the first in a series of top-

mount configurations (TA).

8 © Copyright 2003 Triangle Suspension Systems, Inc.

AXLE IDENTIFICATION

INGERSOLL

Axle

A 2 2 T T I ME W / O 8 Ident.

Charts

BRAKE TYPE/SIZE* 2

SERIES CAPACITY 12-1/2" X 7-1/2" BRAKE WIDTH

A = Std. 5" Rd. LBS. GAWR FS75 = 7-1/2" "P" 8 = 8-5/8" "Q"

w/Inserted Spindle 19 22,500 FS75-HD = 7-1/2" "P" w/HD Return Sprg. (only)

DC = Drop Center 19S 22,500 FS75-U = 7-1/2" "Q" w/HD Return Sprg.

w/Inserted Spindle 22 22,500 16 1/2" Dia.

SPIDER TYPE

F = Light Weight 24S 22,500 TIME = 7" "Q"

W/O = Weld On

FrictionWelded 24H 25,000 F7R = 7" "P"

B/O = Bolt On

24T 26,000 F8R = 8-5/8" "P"

26S 30,000 FCT7R = 7" "P"

FCT8R = 8-5/8" "P"

* Brakes listed use fabricated pressed steel shoes.

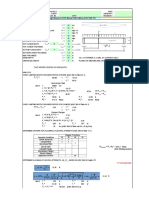

ROCKWELL

Front Non-Drive Axles

F F 9 6 1 LX 00 0

FRONT AXLE SPECIFICATION

NUMBER

BASIC CAPACITY lbs. (kg) BASIC SERIES

C = 7-8,000 (3,175-3,629) BRAKE TYPE

D = 10,000 (4,536) CA - Air Disc Brake

F = 12-13,200 (5,443-5,988) L - "Q Plus" Cam Brake

MAJOR VARIATION

G = 14,600 (6,623) N - None

2 - Upgraded design

L = 16-20,000 (7,258-9,072) P - "P" Series Cam Brake

4 - Easy Steer® bushing

U = 28-30,000 (12,701-13,608) Q - "Q" Series Cam Brake

construction

T - "T" Series Cam Brake

5 - Tubular center

W - "W" Series Cam Brake

6 - Light weight beam

RDA - Wedge Brake (Dual Air Chambers)

RSA - Wedge Brake (Single Air Chambers)

NUMBER DESIGN VARIATION RDH- Wedge Brake (Dual Hydraulic

1 - straight knuckle pin Chambers)

2 - Larger diameter cross-tube RSH - Wedge Brake (Single Hydraulic

3 - 5" drop from spindle intersection to pad Chambers)

4 - 5" drop and larger diameter cross-tube

5 - Special spindle and wheel end

© Copyright 2003 Triangle Suspension Systems, Inc. 9

AXLE IDENTIFICATION

ROCKWELL

Front Drive Axles

ROCKWELL

Axle

Ident.

Charts

RF 1 6 1 4 5 N F Q F* 1 2 3

2 FRONT DRIVE Nominal Axle Load Rating AXLE SPECIFICATION NUMBER

STEER AXLE (GAWR) in Thousands Identifies variations from the original

of Pounds base axle design. Refer to the manu-

facturer for specification details.

GEARING TYPE

1 - Single Speed HUB TYPE

2 - Hypoid-Planetary 2-Speed A - Aluminum

3 - Helical-Hypoid Double Reduction C - Cast Spoke Wheel

5 - Planetary Double Reduction F - Ferrous

6 - Hub Reduction N - None

CARRIER TYPE BRAKE TYPE

Carrier size. Larger numbers indicate a higher B - Hydraulic Disc Brake

GCW rated carrier, i.e., larger ring gear, etc. D - Wedge Brake (Dual Air Chambers)

MAIN DIFFERENTIAL E - Wedge Brake (Dual Hydraulic

NEST TYPE Chambers)

AXLE DESIGN VARIATION

B - Special Differential F - Wedge Brake (Single Hydraulic

Indicates axle design level or variation. Refer to

C - Driver Controlled Chambers)

Bill of Materials for details

Differential Lock H - Hydraulic Drum Brake

F - Standard Differential L - "Q Plus" Cam Brake

MANUFACTURING LOCATION

H - High Traction Diff. N - None

B - Brazil

N - No-Spin Differential Q - "Q" Series Cam Brake

E - Europe (CVC)

M - Europe (Maudslay) S - Wedge Brake (Single Air Chambers)

N - U.S.A.

ROCKWELL

Rear Drive Axles AXLE

SPECIFICATION

NUMBER

RR 2 0 1 4 5 N C Q F* 1 2 3 Identifies varia-

tions from original

base axle design.

AXLE TYPE Refer to manufac-

C - Single Rear Drive, Coach GEARING TYPE turer for specifica-

D - Forward-Rear of a Drive Tandem 1 - Single Speed tion details.

w/Inter-Axle Differential 2 - 2-Speed MANUFACTURING

N - Forward-Rear of a Drive Tandem 3 - Helical Double LOCATION HUB TYPE

or Tridem w/o Inter-Axle of a Reduction A - Australia A - Aluminum

DriveTandem 4 - Salisbury B - Brazil C - Cast Spoke Wheel

P - Forward-Rear of a Drive Tandem Single Speed (Braseixos) F - Ferrous

w/Inter-Axle of a Drive Tandem 5 - Planetary Dbl C - India N - None

S - Single Rear Drive Reduction D - Mexico (Dirona)

BRAKE TYPE

T - Tandem Drive Axle Set 6 - Hub Reduction E - Europe (CVC)

C - Air Disc Brake

Z - Tridem Drive Axle Set M - Europe

D - Wedge Brake (Dual Air Chambers)

(Maudslay)

Nominal Axle Load Rating (GAWR): E - Wedge Brake (Dual Hydraulic

N - U.S.A.

In thousands of pounds. Individual forward and Chambers)

rear axles of a tandem set (D, N, P, R) are rated AXLE DESIGN VARIATION F - Wedge Brake (Single Hydraulic

as single axles. A tandem set (T) is rated as the Identifies axle design level or variation, Chambers)

combination of the two axles and a tridem set (Z)

(e.g., RS 23 161 has a thicker wall L - "Q Plus" Cam Brake

as the combination of the three axles. N - None

housing than the RS 23 160). Refer to

manufacturer for specific axle model. P - "P" Series Cam Brake

CARRIER TYPE Q - "Q" Series Cam Brake

Carrier size. Larger numbers indicate a (Also see Tridem Axle Note 2.)

S - Wedge Brake (Single Air Chambers)

higher GCW rated carrier, i.e., larger ring T - Cam-Master® "T" Series Cam Brake

gear, etc. (Also see Tridem Axle Note 2.) MAIN DIFFERENTIAL

NEST TYPE W - Cam-Master® "W" Series Cam Brake

B - Special Differential

NOTE 2: FOR TRIDEM AXLES ONLY: C- Driver Controlled

For a Tridem Drive Axle Set (RZ), the number in the Differential Lock

sixth position designates the carrier in the first axle. F - Standard Differential

The number in the seventh position designates the H- High Traction® Differential

carriers in the second and third axles. N- NoSPIN

10 © Copyright 2003 Triangle Suspension Systems, Inc.

AXLE IDENTIFICATION

ROCKWELL

Trailer Axle

BRAKE TYPE Axle

D = Air Disc Ident.

DESIGN Charts

DH = Air Disc w/Hub

VARIATION

C = Crank MISCELLANEOUS installed

DW = Air Disc w/Wheel

2

D = Drop 0 =FMVSS121 Brake

Certification installed

(Blank) = Straight

1 =Equipped for ABS L = "Q Plus" Brake

N = No Brake

P = Cam

CAPACITY (LBS.) Q = "Q" Brake

K = 22,500 QH = "Q" w/Hub installed

N = 22,500 BRAKE QW = "Q" w/Wheel installed

P = 22,500/25,000 WIDTH RDA = "Stopmaster" Wedge

Q = 25,000 1 =10" QR = Aftermarket "Q" Brake

R = 22,500/25,000 6 =6" w/o locator hole

T = 30,000 7 =7" or 7.5" LR = Aftermarket "Q Plus"

8 =8.625" cam brake service

beam w/o locator hole

BEAM TYPE NR = Aftermarket service

T=Tubular beam w/o brake and

R =Rectangular locator hole

T N 4 6 7 0 QR 1 2 0 0*

MODIFICATION TRACK SLACK

1 =Single Wheel 1 =71.50 ADJUSTER

2 =Intermodal 7 =77.50 0 =None

BRAKE

3 =Bolted on brakes 1 =5-1/2" manual

DIAMETER

4 =Manual Brg. 2 =6" manual

2 =12.25"

Adjustment 3 =5" auto

5 =15"

6 =Positive Brg. 4 =5-1/2" auto

6 =16.5"

Adjustment (Not 5 =6" auto

8 =18"

available on Crank or

Drop Center Axles)

8 =Heavy Wall Tube CAM LENGTH/SPLINE

0= No cams

1= Short 17-1/4" 28T

2= Int. 20-3/8" 28T

3= Long 24-1/16" 28T

4= Short 17-1/4" 10T LINING MIX

5= Int. 20-3/8" 10T 0 = No brake

6= Long 24-1/16" 10T 1+ = Lining manufacturer

* NOTE: The last four digit designations apply to

aftermarket "BRAKE TYPES" QR, LR and NR only

(without locator hole).

© Copyright 2003 Triangle Suspension Systems, Inc. 11

You might also like

- Box Culvert CalculationDocument15 pagesBox Culvert CalculationPetec Claudiu MariusNo ratings yet

- Bomba SPV 25 Manual de ServicioDocument22 pagesBomba SPV 25 Manual de Serviciogustavo rivasNo ratings yet

- AFBMA To SKF PDFDocument1 pageAFBMA To SKF PDFrfriosEPNo ratings yet

- Johnson Evinrude 1 PDFDocument50 pagesJohnson Evinrude 1 PDFJPNo ratings yet

- Baseplate Design AiscDocument20 pagesBaseplate Design AiscShamim Ahsan ZuberyNo ratings yet

- 2004 Nissan Murano 3.5L Localizacion de Componentes ElectricosDocument22 pages2004 Nissan Murano 3.5L Localizacion de Componentes ElectricosAudirwbenz Ruben50% (2)

- Nissan Primastar X83 (2002-2006) Service Manual #13Document67 pagesNissan Primastar X83 (2002-2006) Service Manual #13János Závogyán100% (1)

- 3406E 550hpDocument2 pages3406E 550hpالمهندسوليدالطويلNo ratings yet

- SteelDocument2 pagesSteelabdul khader100% (1)

- HY25-0098-B1 - US - Final 680 - 08.03.10Document2 pagesHY25-0098-B1 - US - Final 680 - 08.03.10MTK2016No ratings yet

- Struktur Kayu Tulang For ContructionDocument30 pagesStruktur Kayu Tulang For ContructionHendro TritatoNo ratings yet

- Beam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 pageBeam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña Velasquez100% (1)

- Chelsea 870 Series: Ten Bolt Powershift P.T.ODocument2 pagesChelsea 870 Series: Ten Bolt Powershift P.T.Oayman akrabNo ratings yet

- Basic Design Data Check Lower Right Brace: Non-Seismic Design BeamDocument1 pageBasic Design Data Check Lower Right Brace: Non-Seismic Design BeamSudipta DashNo ratings yet

- The Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FDocument22 pagesThe Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FBang OchimNo ratings yet

- Chelsea 880 - PTODocument2 pagesChelsea 880 - PTOkaabach80No ratings yet

- 182TC Thru 256TC AND-213UC Thru 256UCDocument3 pages182TC Thru 256TC AND-213UC Thru 256UCCarlos RodriguezNo ratings yet

- Elbows: ECCO™ Is Proud To Be A Member ofDocument14 pagesElbows: ECCO™ Is Proud To Be A Member ofMohamed RaafatNo ratings yet

- HY25-0093-B1 - US - Final 271 Series - 04.12.13 PDFDocument2 pagesHY25-0093-B1 - US - Final 271 Series - 04.12.13 PDFRodolfo Rodriguez VargasNo ratings yet

- MNB AbutmentDocument145 pagesMNB AbutmentSUSHEEL KUMAR KANAUJIYANo ratings yet

- Anchor Bolt - 25Document204 pagesAnchor Bolt - 25M Yazid TrisumaNo ratings yet

- 267series ChelseaDocument2 pages267series ChelseaGustavo CardenasNo ratings yet

- Beam SpliceDocument2 pagesBeam SplicePaoloEduardoCarusid'EmpaireNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsMohit VatsNo ratings yet

- Pricelist Rental Alinco Scaffolding IndonesiaDocument3 pagesPricelist Rental Alinco Scaffolding Indonesiajams rasyidNo ratings yet

- 302Document136 pages302arielbankiNo ratings yet

- Desain Base PlateDocument4 pagesDesain Base PlatesteveassaNo ratings yet

- HSS WF CapacityDocument7 pagesHSS WF CapacitylucianduNo ratings yet

- Design of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Document5 pagesDesign of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Uttam Raj SutraveNo ratings yet

- Part Numbering System For Perma-SeriesDocument3 pagesPart Numbering System For Perma-Seriesazert511No ratings yet

- Connection Design For Column Above Beam, Based On AISC Manual & AISC 360-05Document1 pageConnection Design For Column Above Beam, Based On AISC Manual & AISC 360-05RayodcNo ratings yet

- Plane Bearings: Material Indicator Shape or SeriesDocument4 pagesPlane Bearings: Material Indicator Shape or SeriesJuan LoaizaNo ratings yet

- Column Above BeamDocument1 pageColumn Above Beamjs.from5208No ratings yet

- HSS WF CapacityDocument7 pagesHSS WF CapacityMoe Oo HtunNo ratings yet

- Padeye Design: Input Sling Angle (From X-Z Plane)Document7 pagesPadeye Design: Input Sling Angle (From X-Z Plane)Alexandre FreitasNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - Columnsfeiz asgarNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsNaziemi AhmadNo ratings yet

- Conversion AFBMA - To - SKFDocument1 pageConversion AFBMA - To - SKFGABRIEL MATTOSNo ratings yet

- AFBMA To SKF PDFDocument1 pageAFBMA To SKF PDFaazznovskyNo ratings yet

- AFBMA To SKF PDFDocument1 pageAFBMA To SKF PDFaazznovskyNo ratings yet

- Nomenclatura SKFDocument1 pageNomenclatura SKFJuan José MeroNo ratings yet

- AFBMA To SKFDocument1 pageAFBMA To SKFfahrian05No ratings yet

- Project: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port TrustDocument1 pageProject: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port Trustkeerthivasan_mrvNo ratings yet

- Omc Ob FullDocument65 pagesOmc Ob FullDonna Anne Eberle0% (1)

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsJule LobresNo ratings yet

- Pinned Base Anchor Bolt DesignDocument2 pagesPinned Base Anchor Bolt Designkhan84mind100% (1)

- BoxDocument16 pagesBoxAlfred KameyaNo ratings yet

- Capstone Chapter 4Document108 pagesCapstone Chapter 4Calvin BaraquiaNo ratings yet

- 3 Pile Cap DesignDocument7 pages3 Pile Cap DesignSheikh Mizanur RahmanNo ratings yet

- Perhitungan Kolom Metode SRPMK SNI 2847Document6 pagesPerhitungan Kolom Metode SRPMK SNI 2847michel johnNo ratings yet

- Corbel Raina PDF FreeDocument13 pagesCorbel Raina PDF FreeSudipta HuiNo ratings yet

- Pilecap Design by Bending Theory To B.S 8110 & B.S 8004Document59 pagesPilecap Design by Bending Theory To B.S 8110 & B.S 8004azwanNo ratings yet

- Rekap MaterialDocument106 pagesRekap MaterialPerencanaan RAPNo ratings yet

- Screw Compressor UnitDocument14 pagesScrew Compressor UnitMakinde Musa AdewaleNo ratings yet

- Beam To Column Connection ConnectionDocument1 pageBeam To Column Connection Connection2213644No ratings yet

- Steel ColumnDocument41 pagesSteel Columnchristian abogadoNo ratings yet

- 6er BGF eDocument1 page6er BGF ejostNo ratings yet

- 2.pile - Cap.design ColumnsDocument9 pages2.pile - Cap.design Columnstaha abu el hanaNo ratings yet

- Cantilever Slab Design Calculation & Procedure - Structural GuideDocument1 pageCantilever Slab Design Calculation & Procedure - Structural GuideFrancisco FongNo ratings yet

- 8Document6 pages8Mohan BhalmeNo ratings yet

- Bolt Design and Embedment Length CheckDocument6 pagesBolt Design and Embedment Length CheckHarish M PNo ratings yet

- K Hitch KF22 KF29 Drum Brake Axle PartsDocument7 pagesK Hitch KF22 KF29 Drum Brake Axle PartsSteven FryeNo ratings yet

- Jaguar S-TYPE 2004 Quick GuideDocument2 pagesJaguar S-TYPE 2004 Quick GuideFerexNo ratings yet

- GV250 Parts Cross ReferenceDocument4 pagesGV250 Parts Cross Referenceben100% (1)

- Unit 4 - Load Distribution and Vehicle StabilityDocument25 pagesUnit 4 - Load Distribution and Vehicle StabilityMOHAMMED SAQLAINNo ratings yet

- Suspension Development On Daihatsu TaftDocument4 pagesSuspension Development On Daihatsu Taftkendhie100% (1)

- Modsurplus Specsheet 50365Document3 pagesModsurplus Specsheet 50365MOTER321No ratings yet

- System Wiring Diagrams SorrentoDocument99 pagesSystem Wiring Diagrams SorrentoIván Luis Guerra Serrano100% (1)

- New Creta BrochureDocument13 pagesNew Creta BrochureNitinNo ratings yet

- VianoBrochure 2015Document60 pagesVianoBrochure 2015Тимченко ИванNo ratings yet

- Changan Parts List Jan 2020Document4 pagesChangan Parts List Jan 2020samisabakNo ratings yet

- Contoh BrosurDocument4 pagesContoh BrosurTomy AkhrizaNo ratings yet

- Flyer Omoda 5Document2 pagesFlyer Omoda 5MABL ChannelNo ratings yet

- Inspection Report: Wheel LoadersDocument5 pagesInspection Report: Wheel LoadersLacatusu MirceaNo ratings yet

- General Catalog: The Specialized RangeDocument16 pagesGeneral Catalog: The Specialized RangeiokuNo ratings yet

- September '96: 709 CARRARO AXLES REF. 122634-122146 For "CASE" IH P100 Spare Parts ListDocument9 pagesSeptember '96: 709 CARRARO AXLES REF. 122634-122146 For "CASE" IH P100 Spare Parts Listmarc danielNo ratings yet

- 1569 e G 2101 en Viab 2014-05 ScreenDocument4 pages1569 e G 2101 en Viab 2014-05 ScreenJorge AlbertoNo ratings yet

- Volkswagen Beetle Spotter's Guide: How To Tell The Age of A Volkswagen, From Small Wonder: The Amazing Story of The Volkswagen Beetle by Walter Henry NelsonDocument16 pagesVolkswagen Beetle Spotter's Guide: How To Tell The Age of A Volkswagen, From Small Wonder: The Amazing Story of The Volkswagen Beetle by Walter Henry NelsonBentley Publishers50% (2)

- Price List Kaze Series As Dated 08-08-2011Document49 pagesPrice List Kaze Series As Dated 08-08-2011kzxe100% (2)

- Actividad 2 Ingles Sena Ignition SystemDocument4 pagesActividad 2 Ingles Sena Ignition SystemDiego CuadradoNo ratings yet

- Design Report SuspensionDocument5 pagesDesign Report SuspensionMaharshi Vipulbhai PatelNo ratings yet

- Referencia Inyectores FordDocument15 pagesReferencia Inyectores Forddixon gonzalezNo ratings yet

- SSP 423 Golf '09Document72 pagesSSP 423 Golf '09mohhizbarNo ratings yet

- Modelling and Simulation of Automatic TransmissionDocument7 pagesModelling and Simulation of Automatic TransmissionIJRASETPublicationsNo ratings yet

- Msa5p1476c 1406-Cvt Transmission g2 Tr580Document74 pagesMsa5p1476c 1406-Cvt Transmission g2 Tr580cristobal astudilloNo ratings yet

- Donaldson EAFM MRP Price (Market) New 01-09Document52 pagesDonaldson EAFM MRP Price (Market) New 01-09BANSAL BROTHERSNo ratings yet

- 24M - Vol I.Document764 pages24M - Vol I.Lewis OlivoNo ratings yet

- Toyota Diagnostic Trouble Codes Full List Obdii365Document2 pagesToyota Diagnostic Trouble Codes Full List Obdii365kabuye NicholasNo ratings yet