Professional Documents

Culture Documents

BB6 BB7 BB8 BEF 1 ElecAxialFeedAssy LgBoringBars

BB6 BB7 BB8 BEF 1 ElecAxialFeedAssy LgBoringBars

Uploaded by

azharzeb0 ratings0% found this document useful (0 votes)

5 views2 pagesLine Boring

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLine Boring

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views2 pagesBB6 BB7 BB8 BEF 1 ElecAxialFeedAssy LgBoringBars

BB6 BB7 BB8 BEF 1 ElecAxialFeedAssy LgBoringBars

Uploaded by

azharzebLine Boring

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

ELECTRIC AXIAL FEED ASSEMBLY 06 2BEF1

023

Electric Axial Feed Assembly

For CLIMAX BB6100, BB7100 and BB8100 Boring Machines

The CLIMAX Electric Axial Feed Assembly is

Electric drive engage/

designed for use on CLIMAX BB6100,

disengage lever

BB7100 and BB8100 boring systems. This

feed unit can be easily adapted to boring

machines utilizing 3.5, 5, 6, and 8 inch (88.9,

Mechanical gear box

127, 152.4, and 203.2 mm) diameter bars.

assembly

Our electric feed unit not only provides you

with a feed rate that is infinitely adjustable

and reversible from 0.0 to 0.664 inches (0.0

to 17 mm) per minute (critical when machin- Main boring

ing large diameter bores) but also provides bar assembly

you with the capability to quickly position (or

reposition) the tool carrier directly to the site Safety-activated drill

where your machining needs to be done. motor rapid

advance port

This capability will save you a considerable

High precision

amount of time when repositioning the tool electric drive motor

carrier and enable you to complete your bor-

ing operations much faster. The feed unit has

a remote pendant with a 3.5 foot (107 cm) Order inexpensive adapter plates to use on Technical Information

cord, which allows the user to control the more than one size boring bar! • The feed rate is infinitely adjustable and

feed rate, feed direction and feed stop/start. Please contact your CLIMAX Sales reversible from 0.0 to 0.664 inches (0.0 to

17 mm)/minute.

The CLIMAX Electric Axial Feed Assembly is Representative for ordering information.

made up of the following components: Ordering Information • Rapid Advance is available using your

hand drill and a 7/16 inch (11 mm) drive

• A compact, precision electric motor that will PN Description

socket (included). Typical rapid feed rates

provide you with infinitely adjustable (and 43735 Electric Feed Assembly For B6100, using your 0 - 400 RPM drill is 0.0 - 32

reversible) boring feed rate from 0.0 to 0.48 3.5 inch (88.9 mm) diameter bar inches (0.0 - 813 mm)/min.

inches (0.0 to 12.2 mm) per minute. 43736 Electric Feed Assembly For BB7100

• Power requirements: 120/240V, 4A,

• A unique mechanical gearbox assembly or BB8100, 5 or 6 inch (127 or 152.4

mm) diameter bar 50/60Hz.

allows you to engage and disengage the

electric drive to the boring bar assembly. 43734 Electric Feed Assembly For BB8100, • The CLIMAX Electric Axial Feed is also

With the electric drive disengaged, a con- 8 inch (203.2 mm) diameter bar available to fit competitive boring systems.

venient port is revealed that allows a hand

drill to be attached for the purpose of rap- End mount support

idly advancing the machine’s tool carrier to assembly

Tools head assembly

the location to be machined. As a safety (manual assembly shown)

factor, this drill access port is blocked ID mount bearing support assembly

when the electric drive is engaged to the

boring bar assembly. Rotational drive assembly

• A special adaptor plate allows you to eas-

ily connect the electric feed/ mechanical Boring bar/lead screw assembly

gearbox assembly to CLIMAX 3.5, 5, 6,

Tool carrier assembly

and 8 inch (88.9, 127, 152.4, and 203.2

mm) boring bars. Adapters are also avail- Hydraulic motor CLIMAX Electric Axial Feed

able for competitive boring systems. Adaptor feed axial assembly Assembly shown mounted to a

Feed axial assembly CLIMAX BB8100 Boring Machine

OEM OPERATIONAL TRAINING

Backed by Over 50 Years of Experience

CLIMAX pioneered the concept of portable machine tools in 1964. Since that time, CLIMAX has grown to become the world’s

largest provider of innovative on-site machining solutions.

Professional, Experienced Instructors

All training programs are taught by experienced OEM CLIMAX

trainers. Your instructor will provide valuable information on

operator safety, tool set-up, mounting, and operation that will

help you complete your on-site machining tasks quickly and to

the highest quality standards. Part number 00042

Sign up today for training at one of our eight Global CLIMAX

training centers.

• Portland, Oregon • Manchester, United Kingdom

• Houston, Texas • Düren, Germany

• Baton Rouge, Louisiana • Dubai, United Arab Emirates

• Cleveland, Ohio • Dammam, Saudi Arabia

Call CLIMAX for:

RENTALS

On selected models. With 20+ worldwide

rental depot locations, you are never far

away from CLIMAX.

OEM TRAINING

If you need training or on-site consultation,

we’re famous for it!

SPARES, REPAIR & MAINTENANCE

Call us for anything you need to keep your

system running in top condition.

CUSTOM PROJECTS

Custom turn-key system design services

from the most experienced engineers in the

business! Follow us on:

World Headquarters European United Kingdom

Address: 2712 E. 2nd St, Newberg, Oregon 97132 Address: Am Langen Graben 8, 52353 Düren, Address: Unit 3 Martel Court, S.Park Business Park,

Tel: +1 503 538 2185 Germany Stockport SK1 2AF

Fax: +1 503 538 7600 Tel: (+49) (0) 2421 9177 0 Tel: +44 (0) 161 406 1720

Email: info@cpmt.com Fax: (+49) (0) 2421 9177 29 Email: ClimaxUK@cpmt.com

Email: ClimaxEurope@cpmt.com

Asia Pacific

Address: 10, Raeburn Park, #02-08, Singapore Middle East

088702 Address: C9, Phase 5, Light Industrial Units, DSO,

Tel: +65 6801 0662 Dubai, UAE

Fax: +65 6801 0699 Tel: +971 4 321 0328

Email: ClimaxAsia@cpmt.com Email: ClimaxUAE@cpmt.com

Copyright © 2023 CLIMAX Portable Machining & Welding Systems. All Rights Re-

served. CLIMAX has taken reasonable measures to ensure the accuracy of the

information contained in this document. However, CLIMAX makes no warranties

or representations with respect to the information contained herein; and CLIMAX

shall not be held liable for damages resulting from any errors or omissions herein,

or from the use of the information contained in this document.

You might also like

- Consulting Service Proposal TemplateDocument12 pagesConsulting Service Proposal TemplateAmos Korme50% (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Connectra 28 HP Butt Fusion MAchineDocument1 pageConnectra 28 HP Butt Fusion MAchineDesli MunarsaNo ratings yet

- AGW TrainingDocument23 pagesAGW TraininglimasmildredNo ratings yet

- Fluids Lab ReportDocument19 pagesFluids Lab Reportdhruv100% (3)

- Dystopian Wars FluffDocument13 pagesDystopian Wars FluffFinin Chisholm100% (2)

- SP94 03 PDFDocument24 pagesSP94 03 PDFgooseNo ratings yet

- Understanding The Graphics PipelineDocument35 pagesUnderstanding The Graphics PipelineskalmariNo ratings yet

- Solution Manual For Principles of Engineering Thermodynamics 1st Edition by ReiselDocument22 pagesSolution Manual For Principles of Engineering Thermodynamics 1st Edition by Reisela21311553067% (3)

- Automated System For Arcing of Sugar Mill Crusher RollsDocument3 pagesAutomated System For Arcing of Sugar Mill Crusher RollsIfzal MirNo ratings yet

- Esab 400i XCDocument2 pagesEsab 400i XCcuervocrdNo ratings yet

- KAT Gouging System - Arcair N7500Document2 pagesKAT Gouging System - Arcair N7500Th NattapongNo ratings yet

- Gates MachineryDocument27 pagesGates MachineryAlex PeñaNo ratings yet

- DocLib - 8654 - Victor Thermal Dynamics Cutmaster A-Series Bro - (63-2809) - August2013Document6 pagesDocLib - 8654 - Victor Thermal Dynamics Cutmaster A-Series Bro - (63-2809) - August2013Federico MarzulloNo ratings yet

- Catalogo Protecciones Termicas ALLEN BRADLEY - 193-Pp016 - En-PDocument8 pagesCatalogo Protecciones Termicas ALLEN BRADLEY - 193-Pp016 - En-PbolasalazarNo ratings yet

- Matrix 4000 AcdcDocument42 pagesMatrix 4000 Acdcsonnguyen2041996No ratings yet

- Tolomatic IMA 2011 CatalogDocument18 pagesTolomatic IMA 2011 CatalogElectromateNo ratings yet

- Beta Electric WinchesDocument10 pagesBeta Electric Winchesjalali007No ratings yet

- Cable Reeling DrumDocument4 pagesCable Reeling DrumBanamali NaskarNo ratings yet

- Miller MIGDocument12 pagesMiller MIGouterraceNo ratings yet

- Vietz Arcotrac enDocument8 pagesVietz Arcotrac enAlonso Samora ortis100% (1)

- Valve Automation Brochure USDocument8 pagesValve Automation Brochure USprufino2No ratings yet

- Idealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingDocument4 pagesIdealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingmoorthysanmukamNo ratings yet

- Valve Automation BrochureDocument8 pagesValve Automation BrochuresalemNo ratings yet

- Sandvik 311 SoloDocument29 pagesSandvik 311 Solomarco antonio resendiz meloNo ratings yet

- Instruction Manual Cable Reel Type: 10.1 R612-250 K450/1/Fci/Mck 10.1 R612-250 K450/2/Fci/MckDocument27 pagesInstruction Manual Cable Reel Type: 10.1 R612-250 K450/1/Fci/Mck 10.1 R612-250 K450/2/Fci/MckcristianNo ratings yet

- EPM Valve Automation TechnologiesDocument8 pagesEPM Valve Automation TechnologiesWahyu YuliadiNo ratings yet

- Arrancador Con Rele de Sobrecarga Estado SolidoDocument8 pagesArrancador Con Rele de Sobrecarga Estado SolidoedgarlimasNo ratings yet

- DanaherMotion S200 Press ReleaseDocument1 pageDanaherMotion S200 Press ReleaseElectromateNo ratings yet

- Kemppi Kempact-Pulse-3000 en UsDocument6 pagesKemppi Kempact-Pulse-3000 en UsMilenkoBogdanovicNo ratings yet

- 6P BSG Us PDFDocument6 pages6P BSG Us PDFdocrafiNo ratings yet

- LV059Document136 pagesLV059Boris KoganNo ratings yet

- Equipment Catalogue 2014 - ENDocument48 pagesEquipment Catalogue 2014 - ENIonut SaucaNo ratings yet

- Rolling 618 Electric enDocument2 pagesRolling 618 Electric enJuan Felipe Perez VasquezNo ratings yet

- ICM200 Series Ignition Control Module: InstallationDocument13 pagesICM200 Series Ignition Control Module: InstallationHernan RiveraNo ratings yet

- Acs800 Starter Hardware ManualDocument193 pagesAcs800 Starter Hardware Manualویرا محاسب پاسارگادNo ratings yet

- Basics of Motor Control CentersDocument72 pagesBasics of Motor Control CentersRaihanKhan100% (2)

- Application Spotlight - Bb5000 Bucket Repair - Climax PortableDocument4 pagesApplication Spotlight - Bb5000 Bucket Repair - Climax PortableazharzebNo ratings yet

- SS-8003897-1000006023-001 SS Page 1 of 6Document6 pagesSS-8003897-1000006023-001 SS Page 1 of 6Emanuel CondeNo ratings yet

- Idealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingDocument4 pagesIdealarc DC-600: Rugged Multi-Process Power For Industrial Manufacturingmkpasha55mpNo ratings yet

- Technical Catalogue Low Voltage Air Circuit-Breakers: 1SDC200006D0204Document278 pagesTechnical Catalogue Low Voltage Air Circuit-Breakers: 1SDC200006D0204febinjohnNo ratings yet

- May Cat ABBDocument177 pagesMay Cat ABBHùng NguyenNo ratings yet

- Arc Spray Featuring "AVD" Technology Model 57350-1.6: SpecificationsDocument1 pageArc Spray Featuring "AVD" Technology Model 57350-1.6: SpecificationshainguyenbkvhvNo ratings yet

- NA-5 Control and Heads: Flux-Cored, Submerged Arc K356-2Document4 pagesNA-5 Control and Heads: Flux-Cored, Submerged Arc K356-2Cornel NoiaNo ratings yet

- Miller Spectrum 875 XtremeDocument4 pagesMiller Spectrum 875 XtremeomaralihasNo ratings yet

- Technical Instructions: Document No. 155-517P25Document28 pagesTechnical Instructions: Document No. 155-517P25chiita123No ratings yet

- MultiCam 3000-Series CNC PlasmaDocument9 pagesMultiCam 3000-Series CNC PlasmaDaniel AustinNo ratings yet

- SubSea Group PresentationDocument21 pagesSubSea Group PresentationandhikabpNo ratings yet

- BB5500 Turbine Coupling Boring Machine EDocument8 pagesBB5500 Turbine Coupling Boring Machine EazharzebNo ratings yet

- Pages From Simoreg - DCM 6ra70 p3Document10 pagesPages From Simoreg - DCM 6ra70 p3AhmadNo ratings yet

- Siemens Motor - Control - CentersDocument80 pagesSiemens Motor - Control - Centersmarf123No ratings yet

- JSL LTSB OneDocument8 pagesJSL LTSB Oneerkamlakar2234No ratings yet

- Alwasy Step Ahead in TechnologyDocument4 pagesAlwasy Step Ahead in TechnologyDxFxNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Magnetic Back Travel Dial Indicator 1Document2 pagesMagnetic Back Travel Dial Indicator 1azharzebNo ratings yet

- BB8100 Line Boring Machine E 2Document8 pagesBB8100 Line Boring Machine E 2azharzebNo ratings yet

- Km4000 Keymill: Designed To Cut Extra-Wide Keyways, Stress Relief Pockets, Motor Mounts Slots, and MoreDocument8 pagesKm4000 Keymill: Designed To Cut Extra-Wide Keyways, Stress Relief Pockets, Motor Mounts Slots, and MoreazharzebNo ratings yet

- Brunson Climax Boring Alignment Kit CPMWS1Document2 pagesBrunson Climax Boring Alignment Kit CPMWS1azharzebNo ratings yet

- BB7100 Boring Machine E 1Document8 pagesBB7100 Boring Machine E 1azharzebNo ratings yet

- Mitutoyo Caliper General CatalogDocument35 pagesMitutoyo Caliper General CatalogazharzebNo ratings yet

- Climax BB5V Technical Data EDocument2 pagesClimax BB5V Technical Data EazharzebNo ratings yet

- Investigation of Microstructure and Mechanical ProDocument8 pagesInvestigation of Microstructure and Mechanical ProazharzebNo ratings yet

- Cm6200 Milling Machine: Portable, On-Site Machining Solutions For Large Flange MachiningDocument10 pagesCm6200 Milling Machine: Portable, On-Site Machining Solutions For Large Flange MachiningazharzebNo ratings yet

- An Obituary Printed in The London TimesDocument3 pagesAn Obituary Printed in The London TimesazharzebNo ratings yet

- BMT Bore Measuring Tool 79159 and 79151Document2 pagesBMT Bore Measuring Tool 79159 and 79151azharzebNo ratings yet

- 9.small Part Machining ENGDocument58 pages9.small Part Machining ENGazharzebNo ratings yet

- Description: JIK Precision Tools StoreDocument13 pagesDescription: JIK Precision Tools StoreazharzebNo ratings yet

- Lazy RulesDocument1 pageLazy RulesazharzebNo ratings yet

- Surface Finish Code - Steel Flat Bars - Tianjin Co. ChinaDocument1 pageSurface Finish Code - Steel Flat Bars - Tianjin Co. ChinaazharzebNo ratings yet

- TMR T Slot Milling Cutter Round Nose R2.5 R3 R5 R5 R6 T Grooving Cutter RDMW RCMT RPMT 1204 CNC Carbide Inserts - AliExpressDocument13 pagesTMR T Slot Milling Cutter Round Nose R2.5 R3 R5 R5 R6 T Grooving Cutter RDMW RCMT RPMT 1204 CNC Carbide Inserts - AliExpressazharzebNo ratings yet

- Flat Steel BarDocument14 pagesFlat Steel BarazharzebNo ratings yet

- Kyocera KPK CT 3 en CompressedDocument16 pagesKyocera KPK CT 3 en CompressedazharzebNo ratings yet

- Linear Guideways: WWW - Hiwin.deDocument152 pagesLinear Guideways: WWW - Hiwin.deazharzebNo ratings yet

- A Safety Guide To CNC Milling MachineDocument2 pagesA Safety Guide To CNC Milling MachineazharzebNo ratings yet

- Upgrade Upgrade Upgrade Upgrade Record Record Record RecordDocument65 pagesUpgrade Upgrade Upgrade Upgrade Record Record Record RecordazharzebNo ratings yet

- Differences Between Stepper Motors and Servo MotorsDocument1 pageDifferences Between Stepper Motors and Servo MotorsazharzebNo ratings yet

- 1624R Router S5Document2 pages1624R Router S5azharzebNo ratings yet

- 61992e PDFDocument177 pages61992e PDFGilson BaldoNo ratings yet

- Synchronous Servo Motors: AutomationDocument32 pagesSynchronous Servo Motors: AutomationAllison GallowayNo ratings yet

- Division 3 Specs WrittingDocument16 pagesDivision 3 Specs WrittingJaymar Palomares OrilloNo ratings yet

- Amplificador 20W RMS TDA2003 Con Placa PCBDocument15 pagesAmplificador 20W RMS TDA2003 Con Placa PCBEnya Andrea Ribba Hernandez100% (5)

- Basic Principles of Engineeing For Diploma Food TechnologyDocument14 pagesBasic Principles of Engineeing For Diploma Food TechnologypokhralikanchhaNo ratings yet

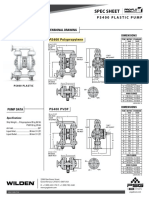

- Spec Sheet: Ps400 Plastic Pump 38 MM (1-1/2") Pump Maximum Flow Rate: 458 LPM (121 GPM)Document2 pagesSpec Sheet: Ps400 Plastic Pump 38 MM (1-1/2") Pump Maximum Flow Rate: 458 LPM (121 GPM)Flavio MedranoNo ratings yet

- Pa 24 Service ManualDocument689 pagesPa 24 Service ManualJohnWelling100% (7)

- E Waste Management and Recycling Mechanism in Japan Sugimoto San PDFDocument17 pagesE Waste Management and Recycling Mechanism in Japan Sugimoto San PDFNadia KamaNo ratings yet

- Autocad CommandsDocument17 pagesAutocad CommandsMuhammad AdibNo ratings yet

- Anticipated Failure DeterminationDocument19 pagesAnticipated Failure Determinationangelesmtz69927No ratings yet

- Astra HD9 Sheet Chassis Euro3 6x4 GB PDFDocument4 pagesAstra HD9 Sheet Chassis Euro3 6x4 GB PDFRajkumarNo ratings yet

- 2 MW Containerised Diesel GenDocument13 pages2 MW Containerised Diesel Genhermit44535No ratings yet

- Resume: Aman SrivastavaDocument3 pagesResume: Aman SrivastavaAman SrivastavaNo ratings yet

- FSA Stat Cards V2-Zenian LeagueDocument18 pagesFSA Stat Cards V2-Zenian LeagueAndrew English LewisNo ratings yet

- Solar PumpDocument16 pagesSolar PumpPIYUSH KULKARNINo ratings yet

- NTE955MC Integrated Circuit CMOS Timing Circuit: DescriptionDocument7 pagesNTE955MC Integrated Circuit CMOS Timing Circuit: DescriptionManuel ReynosoNo ratings yet

- Alstom Technical FlyerDocument2 pagesAlstom Technical Flyerram_kisna007No ratings yet

- Nanomaterial PDFDocument5 pagesNanomaterial PDFSetya AdjieNo ratings yet

- 3Document6 pages3Jose F. Ramirez MendozaNo ratings yet

- ChhhhheeerDocument2 pagesChhhhheeerapi-407075083No ratings yet

- Input SLD Datablock: One-Line Diagram - OLV1 (Edit Mode)Document4 pagesInput SLD Datablock: One-Line Diagram - OLV1 (Edit Mode)Tosikur RahmanNo ratings yet

- 16.04.2022 - Description of CSSDocument2 pages16.04.2022 - Description of CSSYazhisai SelviNo ratings yet

- En Connectors TableDocument1 pageEn Connectors TableluisNo ratings yet

- 7 OrderReshop 18.1 Implementation GuideDocument295 pages7 OrderReshop 18.1 Implementation Guidesubhayan.nittNo ratings yet