Professional Documents

Culture Documents

154 201 4091

154 201 4091

Uploaded by

walevishal1980Copyright:

Available Formats

You might also like

- LENGTH .010 D E: Bombardier Standards ManualDocument4 pagesLENGTH .010 D E: Bombardier Standards ManualJohn CollinsNo ratings yet

- HS CFG "A", .90H, X-FLOW, Low Flow, ThreadedDocument3 pagesHS CFG "A", .90H, X-FLOW, Low Flow, ThreadedjmescalanteNo ratings yet

- Notes:: ThermxDocument1 pageNotes:: ThermxTruong CaoNo ratings yet

- 625 24 Unef 2aDocument1 page625 24 Unef 2amacsen.malacaiNo ratings yet

- Umpco: CAGE CODE No. 18076 Part NumberDocument4 pagesUmpco: CAGE CODE No. 18076 Part NumberFredNo ratings yet

- Z RZCZZZSZZN-RC, ST, 11635-BDocument1 pageZ RZCZZZSZZN-RC, ST, 11635-BGilbertoAndresDuarteNo ratings yet

- Bill of Materials: RevisionsDocument1 pageBill of Materials: RevisionsPeter Rhoads100% (1)

- Customer Outline Drawing: Amphenol RFDocument1 pageCustomer Outline Drawing: Amphenol RFamreshjha22No ratings yet

- Tc.v1.am - Lahr V1 R1Document1 pageTc.v1.am - Lahr V1 R1almedin_hecimov8494No ratings yet

- Ag GroupDocument1 pageAg GroupTonyTzuNo ratings yet

- Grayhill JoystickDocument3 pagesGrayhill JoystickЮрий ЧиженкоNo ratings yet

- Sealtron MIL-C-81703 CatalogDocument3 pagesSealtron MIL-C-81703 CatalogJi Zhong MengNo ratings yet

- Raft For 145 146 149 150Document33 pagesRaft For 145 146 149 150Dharnendra P Bhavsar100% (4)

- Ied 211 ConduitBracketDrawingDocument1 pageIed 211 ConduitBracketDrawing836616477No ratings yet

- Red Is Etch For Assembly: Bend Line See Bend Table & Table AboveDocument1 pageRed Is Etch For Assembly: Bend Line See Bend Table & Table AboveGurdeep Singh. 2209No ratings yet

- Lower Plate - A2 PDFDocument2 pagesLower Plate - A2 PDFAliRazaNo ratings yet

- Cavidad Hydraforce 9-108-1Document5 pagesCavidad Hydraforce 9-108-1Taller PahrNo ratings yet

- Section A-A: 00 Drawn Into Solidworks DL 11/14/2007Document1 pageSection A-A: 00 Drawn Into Solidworks DL 11/14/2007Nguyễn Thanh TùngNo ratings yet

- Pillar B - Instruction ManualDocument8 pagesPillar B - Instruction ManualDmitriiȘtirbuNo ratings yet

- Ag GroupDocument1 pageAg GroupTonyTzuNo ratings yet

- 5/8-18 UNF-2A: Sheet 1 of 1Document1 page5/8-18 UNF-2A: Sheet 1 of 1seanNo ratings yet

- Basic GDT EDocument1 pageBasic GDT Evjd5wzx92xNo ratings yet

- Ssi Ar15 LR V3.0Document2 pagesSsi Ar15 LR V3.0aybnk01No ratings yet

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Document8 pagesSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNo ratings yet

- BACB28ATDocument10 pagesBACB28ATKonstantin TroyanovNo ratings yet

- Nyab Same - 779311-0592Document1 pageNyab Same - 779311-0592Gopi NadhanNo ratings yet

- Act 1 Perforacion DireccionalDocument7 pagesAct 1 Perforacion Direccionalfabricio cabreraNo ratings yet

- 9311-60214 PDDDocument1 page9311-60214 PDDsathis13me44No ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Crack Width - Moment - Circular SectionDocument16 pagesCrack Width - Moment - Circular Sectiontaha abu el hanaNo ratings yet

- 12oz Can DrawingDocument1 page12oz Can DrawingTom MyNo ratings yet

- Section B-B Detail E SCALE 10: 16 Section F-F: .03/.05 X 45 Both EndsDocument1 pageSection B-B Detail E SCALE 10: 16 Section F-F: .03/.05 X 45 Both EndsEduardo LópezNo ratings yet

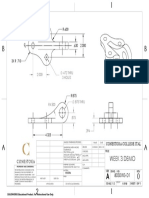

- Week 3 Demo: Conestoga College ItalDocument1 pageWeek 3 Demo: Conestoga College ItalODEH ABU YAHIANo ratings yet

- Torno 1Document1 pageTorno 1anderson santosNo ratings yet

- Atlas RivnutsDocument4 pagesAtlas RivnutsevandropintonetoNo ratings yet

- Stamping Part DimensioningDocument2 pagesStamping Part DimensioningDearRed FrankNo ratings yet

- Two Stage High/Low Hydraulic Pumps: Concentric ABDocument8 pagesTwo Stage High/Low Hydraulic Pumps: Concentric ABZakNo ratings yet

- FLECHADocument1 pageFLECHAnerproci2023No ratings yet

- Specifications Features: 8500 Series Ribbon ConnectorsDocument2 pagesSpecifications Features: 8500 Series Ribbon Connectorshasham nisarNo ratings yet

- 3321-60055 PDDDocument1 page3321-60055 PDDdaniel.rabahdunordNo ratings yet

- CP 01 03Document1 pageCP 01 03Cris ValberdeNo ratings yet

- NAS1677Document2 pagesNAS1677Bogdan RusuNo ratings yet

- Lidkar Samudaya Bavana GFDocument1 pageLidkar Samudaya Bavana GFchandru shekarNo ratings yet

- 750 24 Uns 2aDocument1 page750 24 Uns 2amacsen.malacaiNo ratings yet

- Ssi .308DPMS Ur V3.3Document2 pagesSsi .308DPMS Ur V3.3Ashley MolomoNo ratings yet

- 20008-001-1703 01-12-005-13-A Palanca para Sin FinDocument1 page20008-001-1703 01-12-005-13-A Palanca para Sin FinKarlosdcd WikiNo ratings yet

- Angle BlockDocument1 pageAngle Blockanderson santosNo ratings yet

- 81-03-0074-00 General Assembly, X400-2D With FlangeDocument1 page81-03-0074-00 General Assembly, X400-2D With FlangeMuthukumar RadhakrishnanNo ratings yet

- 523-XXX - Coupling Cut SheetDocument1 page523-XXX - Coupling Cut SheetRavishankarNo ratings yet

- Standing Valve Ball TypeDocument2 pagesStanding Valve Ball TypeNattakorn sangmarkNo ratings yet

- CombineddrawingsDocument20 pagesCombineddrawingsapi-429073519No ratings yet

- Strut and WalingDocument2 pagesStrut and WalingChan Kin CheungNo ratings yet

- Lab 2Document2 pagesLab 2macsen.malacaiNo ratings yet

- 3104 InstallDocument12 pages3104 InstallTim WorkmanNo ratings yet

- Steel Gauge ChartDocument1 pageSteel Gauge Chart성철제No ratings yet

- SLP3 350 200 FDocument5 pagesSLP3 350 200 Fm3y54mNo ratings yet

- Warning !: Revisions Description Ecn No. Date RevDocument3 pagesWarning !: Revisions Description Ecn No. Date Revaw100% (1)

- CS3844Document1 pageCS3844CADTDDNo ratings yet

- Teddy Bear EnglishDocument13 pagesTeddy Bear EnglishSuzettePieterseNo ratings yet

- Saw Blades: Product OverviewDocument34 pagesSaw Blades: Product Overviewhumberto cerda gonzalezNo ratings yet

- Dremel Catalogue 2014-2015Document132 pagesDremel Catalogue 2014-2015azukickNo ratings yet

- Botosei CrosetatiDocument2 pagesBotosei CrosetatidaniellioanaNo ratings yet

- Basic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDocument34 pagesBasic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDeepti KanadeNo ratings yet

- Grade 7 CarpentryDocument3 pagesGrade 7 Carpentrychricyl mae leganadNo ratings yet

- 6000+ Woodworking Projects PagesDocument1,079 pages6000+ Woodworking Projects Pagesmnboks100% (6)

- Production Technology - Ii: Metal CuttingDocument58 pagesProduction Technology - Ii: Metal CuttingVaibhav BirlaNo ratings yet

- F2 Dolly The Sheep English v14 SmallDocument11 pagesF2 Dolly The Sheep English v14 SmallJosé Eduardo Gonzalez100% (2)

- Darning Embroidery PDFDocument1 pageDarning Embroidery PDFJohn DoverNo ratings yet

- Joseph Nicephore Niepce Inventor of The Photograph: BiographyDocument3 pagesJoseph Nicephore Niepce Inventor of The Photograph: BiographyNick ZhangNo ratings yet

- M - Shravan Kumar: Educational QualificationDocument4 pagesM - Shravan Kumar: Educational QualificationShravan MandaNo ratings yet

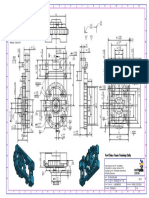

- 第46届世界技能大赛数控铣项目湖北省选拔赛样题2 091801Document1 page第46届世界技能大赛数控铣项目湖北省选拔赛样题2 091801omarNo ratings yet

- Fun and Easy Amigurumi Book SpecialDocument59 pagesFun and Easy Amigurumi Book SpecialTrang Lê100% (2)

- Veritas® Dovetail Saw HandleDocument3 pagesVeritas® Dovetail Saw HandleBíró Balázs MátéNo ratings yet

- Microsoft PowerPoint - 5-Sheet MetalworkingDocument26 pagesMicrosoft PowerPoint - 5-Sheet MetalworkingRama SatriotamaNo ratings yet

- Free Abstract Ink PPT Templates: Insert The Subtitle of Your PresentationDocument48 pagesFree Abstract Ink PPT Templates: Insert The Subtitle of Your PresentationWindha Sari TawilNo ratings yet

- The Liner-Lock Folder Part 1 of 4Document61 pagesThe Liner-Lock Folder Part 1 of 4Chris ParsonNo ratings yet

- Difference Between Floor Tiles and Wall TilesDocument2 pagesDifference Between Floor Tiles and Wall TilesDira AzmanNo ratings yet

- Canadian Woodworking 015 (December 2001-January 2002) PDFDocument44 pagesCanadian Woodworking 015 (December 2001-January 2002) PDFluis murilloNo ratings yet

- CrochetDocument9 pagesCrochetNela Djokic Tankosic33% (3)

- Complete: HandbookDocument776 pagesComplete: HandbookLuis Torres GalmesNo ratings yet

- IIT Hyderabad Workshop ManualDocument37 pagesIIT Hyderabad Workshop ManualMadhu PunjalaNo ratings yet

- Amigurumi BambolaDocument19 pagesAmigurumi BambolaSara SchepisNo ratings yet

- Machine Tools PDFDocument57 pagesMachine Tools PDFnikhil tiwariNo ratings yet

- Grade 9 TLE-Needlecraft (ADM Template) WEEK ADocument20 pagesGrade 9 TLE-Needlecraft (ADM Template) WEEK AMonique Elegarco82% (34)

- Modern Cable Hat in Paintbox Yarns Downloadable PDF 2Document4 pagesModern Cable Hat in Paintbox Yarns Downloadable PDF 2Viktor del campoNo ratings yet

- 51-42-00 - 2 Chapter ManualDocument18 pages51-42-00 - 2 Chapter ManualRobert KrižanovićNo ratings yet

- 2022 11 01CreativeKnittingDocument72 pages2022 11 01CreativeKnittingAdriana ChicaizaNo ratings yet

- Barbie Giselle Dress Pattern EngDocument6 pagesBarbie Giselle Dress Pattern EngMadelene100% (1)

154 201 4091

154 201 4091

Uploaded by

walevishal1980Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

154 201 4091

154 201 4091

Uploaded by

walevishal1980Copyright:

Available Formats

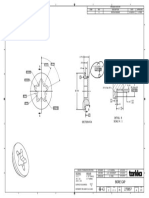

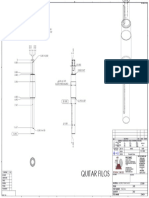

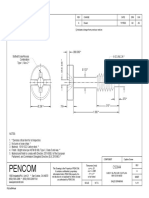

NO DEVIATIONS WITHOUT ENG. DEPT.

APPROVAL

ECN NO. REV. DESCRIPTION BY DATE

18424 B HEAT TREAT AREA CLARIFICATION MM 28MAY14

20821 C SEAL Ø WAS .4998/.4965 ND 02MAY18

Ø.505/.504 WAS .507/.505 DIA, REDRAWN IN

22140 D MJK 12JUN20

SOLIDWORKS, 1.570/1.560 WAS 1.570/1.460

8.362±.003

D

1.570

.578±.003 5.785±.003 1.560 SEAL GRIND LENGTH

.25 H.T. TRANSITION AREA

#10-32 UNF-2B .500 +.003 1.21 MIN H.T. LENGTH

FULL THREAD DEPTH 2X .046-.000

D

.07 X 10°

.002 A .399

2X Ø.505/.504 OVER (4) SPLINES R.005

.396 5.29 .13 LONG

.004 A-B R.03 B

85° TO 90° APART

#2 CENTER DRILL

TO Ø.140

(OPTIONAL)

B

.410

4X R.005 MAX .5003 FULL TOOTH

A .5000 CF 1.065

CHAMFER USING #3 .402

CENTER DRILL .78 .5003 .398 BEFORE HOBBING

TO Ø.234 .5000 BEFORE H.T. .001 A-B

.03 X 45° .001

.3951

.3931 AFTER HOBBING & H.T.

.001 A-B

20

C .001

10

.4980

.4965 AFTER H.T. & SEAL GRIND

NOTES: .001 A-B

1. MADE FROM 700-050-1144GPR.

2. HOB PER 300-154-1136.

3. INDUCTION HARDEN, QUENCH AND TEMPER TO 48-52 Rc STRESS RELIEVE AND DESCALE

AFTER HARDENING TO DIMENSIONS SHOWN. MATERIAL REMOVE ALL BURRS AND

1144 STEEL SHARP CORNERS.

4. STRAIGHTEN SHAFT AS REQUIRED. DO NOT SCALE DRAWING.

5. GRIND SEAL AREA PER WP-04-014. Gear & Engineering Corp. UNLESS OTHERWISE SPECIFIED SCALE: 1:1

TOLERANCE TO BE:

DRN. BY DATE

6. SCRATCHES, ABRASIONS, NICKS, DENTS AND GOUGES ARE NOT ALLOWED ON EITHER 3850 Ohio Avenue ALL FRACTIONS

ALL TWO PLACE DECIMAL

1/32

.010

BFC 19SEP00

PINION OR SEAL AREAS. St. Charles. IL 60174 ALL THREE PLACE DECIMAL

ALL ANGLES

.005 CKD. BY

1

DATE

630-377-4327 FAX 630-377-6777 CONCENTRICITY .005 T.I.R.

SQUARENESS .001 T.I.R./IN. OF DIA. NUR # EP #

7. IF DIMENSION OVER SWAGE TAPPERS TOWARD ON END OF SHAFT, SMALLEST DIMENSION

DESCRIPTION 154-201-4091 REV.

MUST BE OPPOSITE THE PINION END.

MOTOR SHAFT - PINION DRIVE, 11T 36P B

15 DEG HEL D

SHEET: 1 OF 1

You might also like

- LENGTH .010 D E: Bombardier Standards ManualDocument4 pagesLENGTH .010 D E: Bombardier Standards ManualJohn CollinsNo ratings yet

- HS CFG "A", .90H, X-FLOW, Low Flow, ThreadedDocument3 pagesHS CFG "A", .90H, X-FLOW, Low Flow, ThreadedjmescalanteNo ratings yet

- Notes:: ThermxDocument1 pageNotes:: ThermxTruong CaoNo ratings yet

- 625 24 Unef 2aDocument1 page625 24 Unef 2amacsen.malacaiNo ratings yet

- Umpco: CAGE CODE No. 18076 Part NumberDocument4 pagesUmpco: CAGE CODE No. 18076 Part NumberFredNo ratings yet

- Z RZCZZZSZZN-RC, ST, 11635-BDocument1 pageZ RZCZZZSZZN-RC, ST, 11635-BGilbertoAndresDuarteNo ratings yet

- Bill of Materials: RevisionsDocument1 pageBill of Materials: RevisionsPeter Rhoads100% (1)

- Customer Outline Drawing: Amphenol RFDocument1 pageCustomer Outline Drawing: Amphenol RFamreshjha22No ratings yet

- Tc.v1.am - Lahr V1 R1Document1 pageTc.v1.am - Lahr V1 R1almedin_hecimov8494No ratings yet

- Ag GroupDocument1 pageAg GroupTonyTzuNo ratings yet

- Grayhill JoystickDocument3 pagesGrayhill JoystickЮрий ЧиженкоNo ratings yet

- Sealtron MIL-C-81703 CatalogDocument3 pagesSealtron MIL-C-81703 CatalogJi Zhong MengNo ratings yet

- Raft For 145 146 149 150Document33 pagesRaft For 145 146 149 150Dharnendra P Bhavsar100% (4)

- Ied 211 ConduitBracketDrawingDocument1 pageIed 211 ConduitBracketDrawing836616477No ratings yet

- Red Is Etch For Assembly: Bend Line See Bend Table & Table AboveDocument1 pageRed Is Etch For Assembly: Bend Line See Bend Table & Table AboveGurdeep Singh. 2209No ratings yet

- Lower Plate - A2 PDFDocument2 pagesLower Plate - A2 PDFAliRazaNo ratings yet

- Cavidad Hydraforce 9-108-1Document5 pagesCavidad Hydraforce 9-108-1Taller PahrNo ratings yet

- Section A-A: 00 Drawn Into Solidworks DL 11/14/2007Document1 pageSection A-A: 00 Drawn Into Solidworks DL 11/14/2007Nguyễn Thanh TùngNo ratings yet

- Pillar B - Instruction ManualDocument8 pagesPillar B - Instruction ManualDmitriiȘtirbuNo ratings yet

- Ag GroupDocument1 pageAg GroupTonyTzuNo ratings yet

- 5/8-18 UNF-2A: Sheet 1 of 1Document1 page5/8-18 UNF-2A: Sheet 1 of 1seanNo ratings yet

- Basic GDT EDocument1 pageBasic GDT Evjd5wzx92xNo ratings yet

- Ssi Ar15 LR V3.0Document2 pagesSsi Ar15 LR V3.0aybnk01No ratings yet

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Document8 pagesSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNo ratings yet

- BACB28ATDocument10 pagesBACB28ATKonstantin TroyanovNo ratings yet

- Nyab Same - 779311-0592Document1 pageNyab Same - 779311-0592Gopi NadhanNo ratings yet

- Act 1 Perforacion DireccionalDocument7 pagesAct 1 Perforacion Direccionalfabricio cabreraNo ratings yet

- 9311-60214 PDDDocument1 page9311-60214 PDDsathis13me44No ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Crack Width - Moment - Circular SectionDocument16 pagesCrack Width - Moment - Circular Sectiontaha abu el hanaNo ratings yet

- 12oz Can DrawingDocument1 page12oz Can DrawingTom MyNo ratings yet

- Section B-B Detail E SCALE 10: 16 Section F-F: .03/.05 X 45 Both EndsDocument1 pageSection B-B Detail E SCALE 10: 16 Section F-F: .03/.05 X 45 Both EndsEduardo LópezNo ratings yet

- Week 3 Demo: Conestoga College ItalDocument1 pageWeek 3 Demo: Conestoga College ItalODEH ABU YAHIANo ratings yet

- Torno 1Document1 pageTorno 1anderson santosNo ratings yet

- Atlas RivnutsDocument4 pagesAtlas RivnutsevandropintonetoNo ratings yet

- Stamping Part DimensioningDocument2 pagesStamping Part DimensioningDearRed FrankNo ratings yet

- Two Stage High/Low Hydraulic Pumps: Concentric ABDocument8 pagesTwo Stage High/Low Hydraulic Pumps: Concentric ABZakNo ratings yet

- FLECHADocument1 pageFLECHAnerproci2023No ratings yet

- Specifications Features: 8500 Series Ribbon ConnectorsDocument2 pagesSpecifications Features: 8500 Series Ribbon Connectorshasham nisarNo ratings yet

- 3321-60055 PDDDocument1 page3321-60055 PDDdaniel.rabahdunordNo ratings yet

- CP 01 03Document1 pageCP 01 03Cris ValberdeNo ratings yet

- NAS1677Document2 pagesNAS1677Bogdan RusuNo ratings yet

- Lidkar Samudaya Bavana GFDocument1 pageLidkar Samudaya Bavana GFchandru shekarNo ratings yet

- 750 24 Uns 2aDocument1 page750 24 Uns 2amacsen.malacaiNo ratings yet

- Ssi .308DPMS Ur V3.3Document2 pagesSsi .308DPMS Ur V3.3Ashley MolomoNo ratings yet

- 20008-001-1703 01-12-005-13-A Palanca para Sin FinDocument1 page20008-001-1703 01-12-005-13-A Palanca para Sin FinKarlosdcd WikiNo ratings yet

- Angle BlockDocument1 pageAngle Blockanderson santosNo ratings yet

- 81-03-0074-00 General Assembly, X400-2D With FlangeDocument1 page81-03-0074-00 General Assembly, X400-2D With FlangeMuthukumar RadhakrishnanNo ratings yet

- 523-XXX - Coupling Cut SheetDocument1 page523-XXX - Coupling Cut SheetRavishankarNo ratings yet

- Standing Valve Ball TypeDocument2 pagesStanding Valve Ball TypeNattakorn sangmarkNo ratings yet

- CombineddrawingsDocument20 pagesCombineddrawingsapi-429073519No ratings yet

- Strut and WalingDocument2 pagesStrut and WalingChan Kin CheungNo ratings yet

- Lab 2Document2 pagesLab 2macsen.malacaiNo ratings yet

- 3104 InstallDocument12 pages3104 InstallTim WorkmanNo ratings yet

- Steel Gauge ChartDocument1 pageSteel Gauge Chart성철제No ratings yet

- SLP3 350 200 FDocument5 pagesSLP3 350 200 Fm3y54mNo ratings yet

- Warning !: Revisions Description Ecn No. Date RevDocument3 pagesWarning !: Revisions Description Ecn No. Date Revaw100% (1)

- CS3844Document1 pageCS3844CADTDDNo ratings yet

- Teddy Bear EnglishDocument13 pagesTeddy Bear EnglishSuzettePieterseNo ratings yet

- Saw Blades: Product OverviewDocument34 pagesSaw Blades: Product Overviewhumberto cerda gonzalezNo ratings yet

- Dremel Catalogue 2014-2015Document132 pagesDremel Catalogue 2014-2015azukickNo ratings yet

- Botosei CrosetatiDocument2 pagesBotosei CrosetatidaniellioanaNo ratings yet

- Basic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDocument34 pagesBasic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDeepti KanadeNo ratings yet

- Grade 7 CarpentryDocument3 pagesGrade 7 Carpentrychricyl mae leganadNo ratings yet

- 6000+ Woodworking Projects PagesDocument1,079 pages6000+ Woodworking Projects Pagesmnboks100% (6)

- Production Technology - Ii: Metal CuttingDocument58 pagesProduction Technology - Ii: Metal CuttingVaibhav BirlaNo ratings yet

- F2 Dolly The Sheep English v14 SmallDocument11 pagesF2 Dolly The Sheep English v14 SmallJosé Eduardo Gonzalez100% (2)

- Darning Embroidery PDFDocument1 pageDarning Embroidery PDFJohn DoverNo ratings yet

- Joseph Nicephore Niepce Inventor of The Photograph: BiographyDocument3 pagesJoseph Nicephore Niepce Inventor of The Photograph: BiographyNick ZhangNo ratings yet

- M - Shravan Kumar: Educational QualificationDocument4 pagesM - Shravan Kumar: Educational QualificationShravan MandaNo ratings yet

- 第46届世界技能大赛数控铣项目湖北省选拔赛样题2 091801Document1 page第46届世界技能大赛数控铣项目湖北省选拔赛样题2 091801omarNo ratings yet

- Fun and Easy Amigurumi Book SpecialDocument59 pagesFun and Easy Amigurumi Book SpecialTrang Lê100% (2)

- Veritas® Dovetail Saw HandleDocument3 pagesVeritas® Dovetail Saw HandleBíró Balázs MátéNo ratings yet

- Microsoft PowerPoint - 5-Sheet MetalworkingDocument26 pagesMicrosoft PowerPoint - 5-Sheet MetalworkingRama SatriotamaNo ratings yet

- Free Abstract Ink PPT Templates: Insert The Subtitle of Your PresentationDocument48 pagesFree Abstract Ink PPT Templates: Insert The Subtitle of Your PresentationWindha Sari TawilNo ratings yet

- The Liner-Lock Folder Part 1 of 4Document61 pagesThe Liner-Lock Folder Part 1 of 4Chris ParsonNo ratings yet

- Difference Between Floor Tiles and Wall TilesDocument2 pagesDifference Between Floor Tiles and Wall TilesDira AzmanNo ratings yet

- Canadian Woodworking 015 (December 2001-January 2002) PDFDocument44 pagesCanadian Woodworking 015 (December 2001-January 2002) PDFluis murilloNo ratings yet

- CrochetDocument9 pagesCrochetNela Djokic Tankosic33% (3)

- Complete: HandbookDocument776 pagesComplete: HandbookLuis Torres GalmesNo ratings yet

- IIT Hyderabad Workshop ManualDocument37 pagesIIT Hyderabad Workshop ManualMadhu PunjalaNo ratings yet

- Amigurumi BambolaDocument19 pagesAmigurumi BambolaSara SchepisNo ratings yet

- Machine Tools PDFDocument57 pagesMachine Tools PDFnikhil tiwariNo ratings yet

- Grade 9 TLE-Needlecraft (ADM Template) WEEK ADocument20 pagesGrade 9 TLE-Needlecraft (ADM Template) WEEK AMonique Elegarco82% (34)

- Modern Cable Hat in Paintbox Yarns Downloadable PDF 2Document4 pagesModern Cable Hat in Paintbox Yarns Downloadable PDF 2Viktor del campoNo ratings yet

- 51-42-00 - 2 Chapter ManualDocument18 pages51-42-00 - 2 Chapter ManualRobert KrižanovićNo ratings yet

- 2022 11 01CreativeKnittingDocument72 pages2022 11 01CreativeKnittingAdriana ChicaizaNo ratings yet

- Barbie Giselle Dress Pattern EngDocument6 pagesBarbie Giselle Dress Pattern EngMadelene100% (1)