Professional Documents

Culture Documents

Risk Assesment - Floor Chasing and Screeding

Risk Assesment - Floor Chasing and Screeding

Uploaded by

Md.Imtayaj AhmadCopyright:

Available Formats

You might also like

- AHA Excavation and Backfill 030922-BDocument3 pagesAHA Excavation and Backfill 030922-BYug Dobariya75% (4)

- 5-Pole Erection & Stringing PDFDocument2 pages5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- RA For Installation & Dismantling of Loading Platform A69Document15 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- Worksheet On Accounting For Partnership - Admission of A Partner Board QuestionsDocument16 pagesWorksheet On Accounting For Partnership - Admission of A Partner Board QuestionsCfa Deepti Bindal100% (1)

- L Risk Assessment Code (RAC) MatrixDocument6 pagesL Risk Assessment Code (RAC) MatrixMario Marasigan50% (2)

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287No ratings yet

- 05 - RISK ASSESSMENT-Winch MechineDocument3 pages05 - RISK ASSESSMENT-Winch Mechine287100% (1)

- 04 - RISK ASSESSMENT CradleDocument5 pages04 - RISK ASSESSMENT Cradle287100% (4)

- Job Market Overview and Salary Survey 2021 enDocument163 pagesJob Market Overview and Salary Survey 2021 enMax EvseevNo ratings yet

- 1 MobilizationDocument8 pages1 MobilizationAnthony Macatangay100% (1)

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 pagesHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- RA for Floor Chasing and ScreedingDocument3 pagesRA for Floor Chasing and Screedingabdelghafour megaacheNo ratings yet

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- Ra - Acoustic Wall Panel - Rev 01Document3 pagesRa - Acoustic Wall Panel - Rev 01ameen jouharNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. RevisedDocument6 pages1.ooreedoo - RA For Maintenance of Chillers. RevisedstarwingsNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. Rev.02 20.11.2023Document6 pages1.ooreedoo - RA For Maintenance of Chillers. Rev.02 20.11.2023starwingsNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. Rev.0322.11.23Document8 pages1.ooreedoo - RA For Maintenance of Chillers. Rev.0322.11.23starwingsNo ratings yet

- Generator Installation - AHADocument9 pagesGenerator Installation - AHATravis PhillipsNo ratings yet

- Gadzoom Sample Activity Hazard Analysis TemplateDocument8 pagesGadzoom Sample Activity Hazard Analysis TemplateΝικολιδάκης ΒαγγέληςNo ratings yet

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- Hse Hra FF 02Document8 pagesHse Hra FF 02R. Ayyanuperumal AyyanuperumalNo ratings yet

- Updated - Risk Assessment - Preventive Maintenance at REMELT AREADocument13 pagesUpdated - Risk Assessment - Preventive Maintenance at REMELT AREAKareem MohamedNo ratings yet

- Deluge Foam System: Task Risk Assessment WorksheetDocument7 pagesDeluge Foam System: Task Risk Assessment WorksheetnathisonsNo ratings yet

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document9 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay50% (2)

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document14 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay100% (2)

- RA Installation of Air Distribution Ducts Rev. 00Document14 pagesRA Installation of Air Distribution Ducts Rev. 00M AzharNo ratings yet

- RA For Builders Work A59Document11 pagesRA For Builders Work A59Sajid ShahNo ratings yet

- AHA Ductbank InstallationDocument5 pagesAHA Ductbank InstallationYug DobariyaNo ratings yet

- Activity Hazards Analysis (AHA) : Severity ProbabilityDocument8 pagesActivity Hazards Analysis (AHA) : Severity ProbabilitySAsaNo ratings yet

- Rebar Lifting Jha 001Document4 pagesRebar Lifting Jha 001Justin JuniorNo ratings yet

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Logo Food Safety Management System Doc No: Subject: Risk Assessment Compiled By: Approved By: Date: Rev No: 00Document2 pagesLogo Food Safety Management System Doc No: Subject: Risk Assessment Compiled By: Approved By: Date: Rev No: 00Abhishek Kumar SinghNo ratings yet

- AHA - Lead and Asbestos WorkDocument3 pagesAHA - Lead and Asbestos Workdg6xkzxsc9No ratings yet

- 01-Risk Assessment For Survey WorkDocument7 pages01-Risk Assessment For Survey Work287100% (3)

- HIRA - 04-Construction of Ball Handling Pit Rev-01 - DeepakDocument30 pagesHIRA - 04-Construction of Ball Handling Pit Rev-01 - DeepakBhagat DeepakNo ratings yet

- 02-RA For Panel InstallationDocument5 pages02-RA For Panel Installation287100% (1)

- Aha Crane Lifting InspectionDocument2 pagesAha Crane Lifting InspectionTakiNo ratings yet

- Man Basket HIRA - 04-Construction of Ball Handling Pit Rev-01Document14 pagesMan Basket HIRA - 04-Construction of Ball Handling Pit Rev-01Bhagat DeepakNo ratings yet

- Approved By: ClauseDocument4 pagesApproved By: ClauseMohammed Imran100% (1)

- Risk Assessment - ExcavationDocument6 pagesRisk Assessment - Excavationganesh gbNo ratings yet

- RA-Repair The Damage Concrete at Berth 6Document5 pagesRA-Repair The Damage Concrete at Berth 6faisalkhanmlm2No ratings yet

- RISK ASSESSMENT - 031 - Personnel Transfer - Boat To BoatDocument5 pagesRISK ASSESSMENT - 031 - Personnel Transfer - Boat To Boatasritokkong980No ratings yet

- RISK ASSESSMENT-RevantaDocument4 pagesRISK ASSESSMENT-RevantaMehboob ChoudharyNo ratings yet

- RA For Summer Heat Stress Management A71Document4 pagesRA For Summer Heat Stress Management A71Sajid Shah100% (3)

- ADA Ramp Installation 061322-BDocument11 pagesADA Ramp Installation 061322-BYug Dobariya0% (1)

- RA For Installation & Dismantling of Loading Platform A69Document8 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- HIRA - Construction of Ball Handling Pit Rev-00 - TILL EXCAVATIONDocument28 pagesHIRA - Construction of Ball Handling Pit Rev-00 - TILL EXCAVATIONBhagat DeepakNo ratings yet

- X.9.1.a - Light Framed Steel Framing AHA - AnswerDocument7 pagesX.9.1.a - Light Framed Steel Framing AHA - AnswerBunyamin SelimogluNo ratings yet

- Rev-01-Mariner WorkDocument40 pagesRev-01-Mariner Workrohit kumarNo ratings yet

- P-985-SH-AHA-003. AHA For Outage Lock Our Tag OutDocument3 pagesP-985-SH-AHA-003. AHA For Outage Lock Our Tag OutPatrick Bibila NdansiNo ratings yet

- KCF1-27 Activity Hazard METHOD STATEMENT FOR ABORTIVE WORK (DEMOLISHING)Document3 pagesKCF1-27 Activity Hazard METHOD STATEMENT FOR ABORTIVE WORK (DEMOLISHING)ansarabdul773No ratings yet

- P-985-SH-AHA-008, AHA For Demolision WorksDocument4 pagesP-985-SH-AHA-008, AHA For Demolision WorksPatrick Bibila NdansiNo ratings yet

- RA Excavation Near Overhead Electrical Live LinesDocument2 pagesRA Excavation Near Overhead Electrical Live LinesSn AhsanNo ratings yet

- 13-MS & RA Rotor Poles InstallationDocument4 pages13-MS & RA Rotor Poles Installationimran hassan bangashNo ratings yet

- Hiradc Form - TemplateDocument5 pagesHiradc Form - TemplateMuhammad ZulkarnainNo ratings yet

- Activity Hazard AnalysisDocument2 pagesActivity Hazard Analysisadalacse2016No ratings yet

- Quiz 1 Midterm Bac100Document12 pagesQuiz 1 Midterm Bac100G Rosal, Denice Angela A.No ratings yet

- Principles of Economics Australia and New Zealand 6Th Edition Gans Test Bank Full Chapter PDFDocument61 pagesPrinciples of Economics Australia and New Zealand 6Th Edition Gans Test Bank Full Chapter PDFamandabinh1j6100% (10)

- Dataware House Doc3Document2 pagesDataware House Doc3UmERNo ratings yet

- Iso 31030 2021Document15 pagesIso 31030 2021Kevin MudiNo ratings yet

- Weekly Assignment 4 - Mohit Sharma - 55Document2 pagesWeekly Assignment 4 - Mohit Sharma - 55amyna abhavaniNo ratings yet

- RCBC Appform Editable AUTOLOANDocument4 pagesRCBC Appform Editable AUTOLOANglennmarkpaltaoNo ratings yet

- Trainers Training Invitation LetterDocument1 pageTrainers Training Invitation LetterJonathan RicablancaNo ratings yet

- SC21 Manufacturing Excellence Process Overview Dec 2013Document11 pagesSC21 Manufacturing Excellence Process Overview Dec 2013Sanjeev Kumar JhaNo ratings yet

- Shipping Business Examiners Report May 2019 RevDocument5 pagesShipping Business Examiners Report May 2019 RevdiablolcNo ratings yet

- ACCT6174-Tugas Personal 1-W2-S3-R1Document3 pagesACCT6174-Tugas Personal 1-W2-S3-R1Raisul Ma'arifNo ratings yet

- 16705190652022-12-08 22 34 25 Fi-MmDocument9 pages16705190652022-12-08 22 34 25 Fi-MmAyan SahaNo ratings yet

- ENTREPRENEURSHIP Module 1-First SemDocument24 pagesENTREPRENEURSHIP Module 1-First SemKarla CarbonelNo ratings yet

- 1-Accounting EquationDocument4 pages1-Accounting EquationNoraNo ratings yet

- Oswal and It's OperationsDocument22 pagesOswal and It's Operationskanikagoel1No ratings yet

- The Role of Free Zones in International StrategyDocument9 pagesThe Role of Free Zones in International StrategyErfanNo ratings yet

- Cheat Sheet Chapter 11Document7 pagesCheat Sheet Chapter 11richard mathengeNo ratings yet

- Pahang Cement SDN BHD: Hazards Identification AnalysisDocument5 pagesPahang Cement SDN BHD: Hazards Identification AnalysisMahendren JayapalanNo ratings yet

- Six Theories About How 3D Printing Will Change Logistics: White PaperDocument14 pagesSix Theories About How 3D Printing Will Change Logistics: White Paperyourpartner wireframetechnologyNo ratings yet

- FS in Market ViabilityDocument7 pagesFS in Market Viabilityrobelyn veranoNo ratings yet

- 2.1 HSE PolicyDocument1 page2.1 HSE Policybilo1984No ratings yet

- Kaushal Kumar Agarwal: The Manager The ManagerDocument33 pagesKaushal Kumar Agarwal: The Manager The ManagerGurjeevNo ratings yet

- Order Letter Writing TipsDocument11 pagesOrder Letter Writing TipsFatimahNo ratings yet

- Business EnglishDocument91 pagesBusiness EnglishPriscila LopesNo ratings yet

- Additional Questions-7Document8 pagesAdditional Questions-7Ak AgarwalNo ratings yet

- Syllabus TaxDocument23 pagesSyllabus TaxMark M. MabalayNo ratings yet

- AP Inventories 1stsetDocument8 pagesAP Inventories 1stsetMaritessNo ratings yet

- IALA Complementary Lighthouse Use Manual Ed2 92pp WebDocument92 pagesIALA Complementary Lighthouse Use Manual Ed2 92pp Websandeep bagulNo ratings yet

- ComplanDocument7 pagesComplanjango fettNo ratings yet

Risk Assesment - Floor Chasing and Screeding

Risk Assesment - Floor Chasing and Screeding

Uploaded by

Md.Imtayaj AhmadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assesment - Floor Chasing and Screeding

Risk Assesment - Floor Chasing and Screeding

Uploaded by

Md.Imtayaj AhmadCopyright:

Available Formats

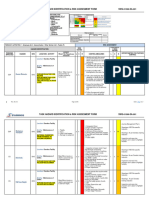

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM

RISK ANALYSIS Risk Level Matrix ( R ) Hierarchy of Controls

CONSEQUENCE (C) of Results

Consequence Eliminate

Contract Project: QATAR COOL, WESTBAY 1 - Insignificant

2 - Minor 1 2 3 4 5 Substitute

Download HSE Docs hseprof.com

3 - Moderate 5 H H E E E Engineer

Likelihood

4 - Major 4 M H H E E Administrative Control

Site Name: QATAR COOL, WESTBAY 5 - Catastrophic 3 L M H E E PPE

Nominated Work Floor chipping LIKELIHOOD (L) of Occurrence 2 L L M H E

1 - Rare Risk Acceptance

1 L L M H H Name of Employee Accepting

Date Develop: 21-02-2023 2 - Unlikely Controls should be selected based

Risk Level

Risk Level

Signature

3 - Moderate E = Extreme H = High on the Hierarchy of Controls Extreme (Contract Manager

4 - Likely High (Site Manager)

Date Reviewed: NA M = Moderate L = Low

5- Almost Certain Moderate (Deputy Manager / Supervisor

Low (Supervisor)

ECM RA NO

PERSON’S AFFECTED: 1. Employee (E) 2. Subcontractor / Other Worker (S) 3. Public (P) RISK ASSESSMENT

CONTROLLE

RISK

HAZARD IDENTIFICATION D RISK

RATING

RATING

EFFECT

PERSONS OPPORTUNITIES FOR FUTHER

HAZARD OHS LOCATION / ACTIVITY What if the Hazard was L C R CONTROL MEASURES L C R

AFFECTED CONTROL

released?

1. Identify and verify the correct

equipment’s / facilities / services

where maintenance to be carried

out.

2. Engage the right person ( trained

and skilled )who can be capable to

carry out job safely

Location; QATAR COOL, ECM – HSE Site specific Induction

Minor / Major injury to

Human Behavior WESTBAY personal due to incident 3. Conduct toolbox talk (briefing)

ESP OHS 2 3 M 2 2 L

caused by human error before start of work Emergency awareness training

Activity: Floor chipping Emergency evacuation

4. Talk to the employees on their

capability to handle the job,

knowledge and understanding of

work to be carried out

5. Ensure that members of workforce

had not worked prolong hours in

the previous shift

Rev. No: 0 Page 1 of 3 Date: 01-09-19

Download HSE Docs hseprof.com

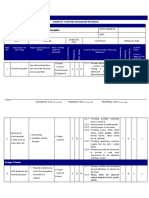

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM

1. Barricade and provide signage to

warns about the hazards

2. Clean spillage if any area around

the to avoid slip and fall

Download HSE Docs hseprof.com

3.Maintain good housekeeping around

the manhole to avoid trip and fall

Location; QATAR COOL, PPE talk and awareness training

ESP OHS 1.Minor/major injuries to 3 3 H 4.Ensure minimum man power 1 2 L

WESTBAY daily basis

Slip, trip & fall personal available as required the job. Do not

allow other stand or watch.

Activity: floor chipping General safety training frequent

5.Inspect the safety shoes to identify

basis

the slippery sole

6.Use proper tools for lifting of

manhole cover

7.Tools must be in good condition

8.Appropriate PPE

# Ergonomics - 1. PTW

Manual Handling 2. Avoid lifting where possible use

Tool box talk and

- Excessive pushing, - Health effects lifting aids and trucks

Location; QATAR COOL,

ESP pulling, lifting, OHS - Body pain 3 4 E 3. Proper Posture / Body Positioning 1 3 M

WESTBAY PPE talk and awareness training

bending, twisting - Asphyxiation 4. Lifting Technique

daily basis

- Repetitive motion - Fatality 5. Risk Assessment

Activity: Floor chipping

- Body position and 6. Recommended first aid measures

General safety training frequent

placement 7. PPE (Back Support belt)

basis

Fatalities/fractures

Prepare lift plans and ensure safe

Location; QATAR COOL, Property/material

ESP OHS 2 5 E 1 5 H operations accordingly, H&S Six

Working exposed to WESTBAY damage PPE's-safety helmet, dust mask,

Pack Training, Trained and

dust - Equipment Damage safety harness, safety shoes

competent employees.

Activity: Floor chipping - Injuries to the

public/personal injury

Rev. No: 0 Page 2 of 3 Date: 01-09-19

Download HSE Docs hseprof.com

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM

1.Engineers to isolate electrical Tool box talk and

supply and confirm using

Download HSE Docs hseprof.com

appropriate test equipment. PPE talk and awareness training

daily basis

Working with Location; QATAR COOL,

ESP OHS Electrical shock, Fatal 2 4 E 2.Permit to work system to be used, 1 3 M

WESTBAY

electrical equipment Injury otherwise for lamp changing only, Electrical safety and hazards

Death engineers to confirm light unit fitted training

Activity: Floor chipping

with MCB/RCD prior to work Conduct

work out of hours if no MCB/RCD General safety training frequent

fitted and isolate electrical supply basis

Use non-conductive stepladder

1.

PTW

2. Segregate the generated waste

Waste disposal Location; QATAR COOL, (Hazardous or Non Hazardous Metal

Build up on rubbish & Nonmetal) and keep in the HSE Site specific Induction

WESTBAY

ESP on the work OHS Rubbish on track 3 4 E appropriate skip with label in safe 1 3 M

environment and Buildup of rubbish / manner Emergency awareness training

surrounding area 3.Keep suitable capacity and enough Emergency evacuation

Activity: All PPM & CM work

number of skips in appropriate

location to collect the waste

Activity: Floor chipping 4.Ensure there is no chance of

spillage of waste.

Assessed By: Reviewed & Approved By: Approved By:

Name: Muhammed Irfan V.P Name: MHAMED BASHA D V Name: Name:

Date: - 21-02-2023 Date: Date: Date:

Signature: Signature: Signature: Signature:

Rev. No: 0 Page 3 of 3 Date: 01-09-19

Download HSE Docs hseprof.com

You might also like

- AHA Excavation and Backfill 030922-BDocument3 pagesAHA Excavation and Backfill 030922-BYug Dobariya75% (4)

- 5-Pole Erection & Stringing PDFDocument2 pages5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- RA For Installation & Dismantling of Loading Platform A69Document15 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- Worksheet On Accounting For Partnership - Admission of A Partner Board QuestionsDocument16 pagesWorksheet On Accounting For Partnership - Admission of A Partner Board QuestionsCfa Deepti Bindal100% (1)

- L Risk Assessment Code (RAC) MatrixDocument6 pagesL Risk Assessment Code (RAC) MatrixMario Marasigan50% (2)

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287No ratings yet

- 05 - RISK ASSESSMENT-Winch MechineDocument3 pages05 - RISK ASSESSMENT-Winch Mechine287100% (1)

- 04 - RISK ASSESSMENT CradleDocument5 pages04 - RISK ASSESSMENT Cradle287100% (4)

- Job Market Overview and Salary Survey 2021 enDocument163 pagesJob Market Overview and Salary Survey 2021 enMax EvseevNo ratings yet

- 1 MobilizationDocument8 pages1 MobilizationAnthony Macatangay100% (1)

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 pagesHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- RA for Floor Chasing and ScreedingDocument3 pagesRA for Floor Chasing and Screedingabdelghafour megaacheNo ratings yet

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- Ra - Acoustic Wall Panel - Rev 01Document3 pagesRa - Acoustic Wall Panel - Rev 01ameen jouharNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. RevisedDocument6 pages1.ooreedoo - RA For Maintenance of Chillers. RevisedstarwingsNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. Rev.02 20.11.2023Document6 pages1.ooreedoo - RA For Maintenance of Chillers. Rev.02 20.11.2023starwingsNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. Rev.0322.11.23Document8 pages1.ooreedoo - RA For Maintenance of Chillers. Rev.0322.11.23starwingsNo ratings yet

- Generator Installation - AHADocument9 pagesGenerator Installation - AHATravis PhillipsNo ratings yet

- Gadzoom Sample Activity Hazard Analysis TemplateDocument8 pagesGadzoom Sample Activity Hazard Analysis TemplateΝικολιδάκης ΒαγγέληςNo ratings yet

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- Hse Hra FF 02Document8 pagesHse Hra FF 02R. Ayyanuperumal AyyanuperumalNo ratings yet

- Updated - Risk Assessment - Preventive Maintenance at REMELT AREADocument13 pagesUpdated - Risk Assessment - Preventive Maintenance at REMELT AREAKareem MohamedNo ratings yet

- Deluge Foam System: Task Risk Assessment WorksheetDocument7 pagesDeluge Foam System: Task Risk Assessment WorksheetnathisonsNo ratings yet

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document9 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay50% (2)

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document14 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay100% (2)

- RA Installation of Air Distribution Ducts Rev. 00Document14 pagesRA Installation of Air Distribution Ducts Rev. 00M AzharNo ratings yet

- RA For Builders Work A59Document11 pagesRA For Builders Work A59Sajid ShahNo ratings yet

- AHA Ductbank InstallationDocument5 pagesAHA Ductbank InstallationYug DobariyaNo ratings yet

- Activity Hazards Analysis (AHA) : Severity ProbabilityDocument8 pagesActivity Hazards Analysis (AHA) : Severity ProbabilitySAsaNo ratings yet

- Rebar Lifting Jha 001Document4 pagesRebar Lifting Jha 001Justin JuniorNo ratings yet

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Logo Food Safety Management System Doc No: Subject: Risk Assessment Compiled By: Approved By: Date: Rev No: 00Document2 pagesLogo Food Safety Management System Doc No: Subject: Risk Assessment Compiled By: Approved By: Date: Rev No: 00Abhishek Kumar SinghNo ratings yet

- AHA - Lead and Asbestos WorkDocument3 pagesAHA - Lead and Asbestos Workdg6xkzxsc9No ratings yet

- 01-Risk Assessment For Survey WorkDocument7 pages01-Risk Assessment For Survey Work287100% (3)

- HIRA - 04-Construction of Ball Handling Pit Rev-01 - DeepakDocument30 pagesHIRA - 04-Construction of Ball Handling Pit Rev-01 - DeepakBhagat DeepakNo ratings yet

- 02-RA For Panel InstallationDocument5 pages02-RA For Panel Installation287100% (1)

- Aha Crane Lifting InspectionDocument2 pagesAha Crane Lifting InspectionTakiNo ratings yet

- Man Basket HIRA - 04-Construction of Ball Handling Pit Rev-01Document14 pagesMan Basket HIRA - 04-Construction of Ball Handling Pit Rev-01Bhagat DeepakNo ratings yet

- Approved By: ClauseDocument4 pagesApproved By: ClauseMohammed Imran100% (1)

- Risk Assessment - ExcavationDocument6 pagesRisk Assessment - Excavationganesh gbNo ratings yet

- RA-Repair The Damage Concrete at Berth 6Document5 pagesRA-Repair The Damage Concrete at Berth 6faisalkhanmlm2No ratings yet

- RISK ASSESSMENT - 031 - Personnel Transfer - Boat To BoatDocument5 pagesRISK ASSESSMENT - 031 - Personnel Transfer - Boat To Boatasritokkong980No ratings yet

- RISK ASSESSMENT-RevantaDocument4 pagesRISK ASSESSMENT-RevantaMehboob ChoudharyNo ratings yet

- RA For Summer Heat Stress Management A71Document4 pagesRA For Summer Heat Stress Management A71Sajid Shah100% (3)

- ADA Ramp Installation 061322-BDocument11 pagesADA Ramp Installation 061322-BYug Dobariya0% (1)

- RA For Installation & Dismantling of Loading Platform A69Document8 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- HIRA - Construction of Ball Handling Pit Rev-00 - TILL EXCAVATIONDocument28 pagesHIRA - Construction of Ball Handling Pit Rev-00 - TILL EXCAVATIONBhagat DeepakNo ratings yet

- X.9.1.a - Light Framed Steel Framing AHA - AnswerDocument7 pagesX.9.1.a - Light Framed Steel Framing AHA - AnswerBunyamin SelimogluNo ratings yet

- Rev-01-Mariner WorkDocument40 pagesRev-01-Mariner Workrohit kumarNo ratings yet

- P-985-SH-AHA-003. AHA For Outage Lock Our Tag OutDocument3 pagesP-985-SH-AHA-003. AHA For Outage Lock Our Tag OutPatrick Bibila NdansiNo ratings yet

- KCF1-27 Activity Hazard METHOD STATEMENT FOR ABORTIVE WORK (DEMOLISHING)Document3 pagesKCF1-27 Activity Hazard METHOD STATEMENT FOR ABORTIVE WORK (DEMOLISHING)ansarabdul773No ratings yet

- P-985-SH-AHA-008, AHA For Demolision WorksDocument4 pagesP-985-SH-AHA-008, AHA For Demolision WorksPatrick Bibila NdansiNo ratings yet

- RA Excavation Near Overhead Electrical Live LinesDocument2 pagesRA Excavation Near Overhead Electrical Live LinesSn AhsanNo ratings yet

- 13-MS & RA Rotor Poles InstallationDocument4 pages13-MS & RA Rotor Poles Installationimran hassan bangashNo ratings yet

- Hiradc Form - TemplateDocument5 pagesHiradc Form - TemplateMuhammad ZulkarnainNo ratings yet

- Activity Hazard AnalysisDocument2 pagesActivity Hazard Analysisadalacse2016No ratings yet

- Quiz 1 Midterm Bac100Document12 pagesQuiz 1 Midterm Bac100G Rosal, Denice Angela A.No ratings yet

- Principles of Economics Australia and New Zealand 6Th Edition Gans Test Bank Full Chapter PDFDocument61 pagesPrinciples of Economics Australia and New Zealand 6Th Edition Gans Test Bank Full Chapter PDFamandabinh1j6100% (10)

- Dataware House Doc3Document2 pagesDataware House Doc3UmERNo ratings yet

- Iso 31030 2021Document15 pagesIso 31030 2021Kevin MudiNo ratings yet

- Weekly Assignment 4 - Mohit Sharma - 55Document2 pagesWeekly Assignment 4 - Mohit Sharma - 55amyna abhavaniNo ratings yet

- RCBC Appform Editable AUTOLOANDocument4 pagesRCBC Appform Editable AUTOLOANglennmarkpaltaoNo ratings yet

- Trainers Training Invitation LetterDocument1 pageTrainers Training Invitation LetterJonathan RicablancaNo ratings yet

- SC21 Manufacturing Excellence Process Overview Dec 2013Document11 pagesSC21 Manufacturing Excellence Process Overview Dec 2013Sanjeev Kumar JhaNo ratings yet

- Shipping Business Examiners Report May 2019 RevDocument5 pagesShipping Business Examiners Report May 2019 RevdiablolcNo ratings yet

- ACCT6174-Tugas Personal 1-W2-S3-R1Document3 pagesACCT6174-Tugas Personal 1-W2-S3-R1Raisul Ma'arifNo ratings yet

- 16705190652022-12-08 22 34 25 Fi-MmDocument9 pages16705190652022-12-08 22 34 25 Fi-MmAyan SahaNo ratings yet

- ENTREPRENEURSHIP Module 1-First SemDocument24 pagesENTREPRENEURSHIP Module 1-First SemKarla CarbonelNo ratings yet

- 1-Accounting EquationDocument4 pages1-Accounting EquationNoraNo ratings yet

- Oswal and It's OperationsDocument22 pagesOswal and It's Operationskanikagoel1No ratings yet

- The Role of Free Zones in International StrategyDocument9 pagesThe Role of Free Zones in International StrategyErfanNo ratings yet

- Cheat Sheet Chapter 11Document7 pagesCheat Sheet Chapter 11richard mathengeNo ratings yet

- Pahang Cement SDN BHD: Hazards Identification AnalysisDocument5 pagesPahang Cement SDN BHD: Hazards Identification AnalysisMahendren JayapalanNo ratings yet

- Six Theories About How 3D Printing Will Change Logistics: White PaperDocument14 pagesSix Theories About How 3D Printing Will Change Logistics: White Paperyourpartner wireframetechnologyNo ratings yet

- FS in Market ViabilityDocument7 pagesFS in Market Viabilityrobelyn veranoNo ratings yet

- 2.1 HSE PolicyDocument1 page2.1 HSE Policybilo1984No ratings yet

- Kaushal Kumar Agarwal: The Manager The ManagerDocument33 pagesKaushal Kumar Agarwal: The Manager The ManagerGurjeevNo ratings yet

- Order Letter Writing TipsDocument11 pagesOrder Letter Writing TipsFatimahNo ratings yet

- Business EnglishDocument91 pagesBusiness EnglishPriscila LopesNo ratings yet

- Additional Questions-7Document8 pagesAdditional Questions-7Ak AgarwalNo ratings yet

- Syllabus TaxDocument23 pagesSyllabus TaxMark M. MabalayNo ratings yet

- AP Inventories 1stsetDocument8 pagesAP Inventories 1stsetMaritessNo ratings yet

- IALA Complementary Lighthouse Use Manual Ed2 92pp WebDocument92 pagesIALA Complementary Lighthouse Use Manual Ed2 92pp Websandeep bagulNo ratings yet

- ComplanDocument7 pagesComplanjango fettNo ratings yet