Professional Documents

Culture Documents

SIGA-IM2 Isolator Module Installation Sheet: Description

SIGA-IM2 Isolator Module Installation Sheet: Description

Uploaded by

Rohan KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIGA-IM2 Isolator Module Installation Sheet: Description

SIGA-IM2 Isolator Module Installation Sheet: Description

Uploaded by

Rohan KumarCopyright:

Available Formats

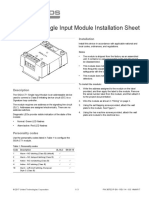

3.

Using the self-tapping screw provided, attach the wall plate to the

module. See Figure 1.

4. Using the four machine screws provided, attach the wall plate and

module to the electrical box.

SIGA-IM2 Isolator Module Figure 1: Installation diagram

Installation Sheet (1)

(2)

(3)

(4)

(5)

Description (1) Compatible electrical box (4) #6-32 × 5/8 machine screws (4X)

The SIGA-IM2 Isolator Module is an addressable device that protects a (2) SIGA-IM2 module (5) #4 × 1/2 self-tapping screw

(3) Wall plate

signaling line circuit (SLC) from a wire-to-wire short. The SIGA-IM2

module monitors line voltages and opens the SLC when a short is

detected, effectively isolating the short between the two isolator Wiring

modules located electrically closest to the short.

Wire this device in accordance with applicable national and local

The SIGA-IM2 module requires one detector address on the SLC. codes, ordinances, and regulations.

Addresses are assigned electronically. There are no address switches.

Notes

An LED provides visible indication of the status of the module:

• Refer to the Signature loop controller installation sheet for SLC

• Normal: Green LED flashes wiring specifications for additional details.

• All wiring is power-limited and supervised.

Installation

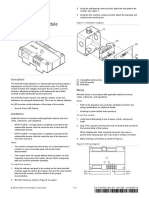

To wire the module:

Install this device in accordance with applicable national and local

1. Verify that all field wiring is free of opens, shorts, and ground

codes, ordinances, and regulations.

faults.

• NFPA 72 2013 – A single fault on a pathway connected to the

2. Strip 1/4 in. (about 6 mm) from the ends of all wires that connect to

addressable devices shall not cause the loss of more than 50

the terminal block of the module.

addressable devices.

• NFPA 72 2016 and later – A single fault on a pathway connected When stripping wire ends, exposing more wire may cause a

to the addressable devices shall not cause the loss of the devices ground fault; exposing less wire may result in a faulty connection.

in more than one zone. 3. Make all wiring connections as shown in Figure 2.

Notes

Figure 2: Wiring diagram

• The module is shipped from the factory as an assembled unit; it

contains no user-serviceable parts and should not be

disassembled.

• This module does not operate without electrical power. As fires

frequently cause power interruption, discuss further safeguards

with your local fire protection specialist.

To install the module:

1. Write the address assigned to the module on the label provided,

and then apply the label to the module. Remove the serial number

SLC SLC

label from the module, and then attach it to the project SLC SLC

documentation.

2. Wire the module as shown in Figure 2 on page 2.

© 2020 Carrier 1/3 P/N 3102697-EN • REV 001 • ISS 24AUG20

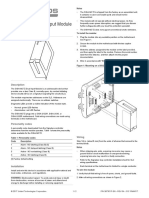

Application Figure 4: Typical Class A with isolators

(1)

For Class A pathways, install SIGA-IM2 modules to segment the SLC

as required (e.g., by zone or by number of devices) to prevent a wire-

to-wire short from taking down the entire circuit. See Figure 3 and IM2 IM2

Figure 4.

(2)

For Class X pathways (see Figure 5):

• Install a SIGA-IM2 module on the Class B out and Class A return

wiring inside the control unit, or in the same room, within 20 ft.

(6.1 m), and wiring enclosed in conduit or equivalently protected

against mechanical injury.

IM2 IM2

• Install a SIGA-IM2 module on both sides of one or more standard

mount modules contained in a common enclosure.

• Install a SIGA-IM2 module on both sides of a single standard

mount module, in the same room, within 20 ft. (6.1 m), and wiring

enclosed in conduit or equivalently protected against mechanical SLC SLC FACU

injury. B+ B- A+ A-

• Install a SIGA-IM2 module on both sides of a common enclosure (3) (4)

containing one or more UIO plug-in modules, in the same room, (1) Non-isolated devices effectively removed from the circuit

within 20 ft. (6.1 m), and wiring enclosed in conduit or equivalently (2) Short circuit

protected against mechanical injury. (3) SLC Class B out

(4) SLC Class A return

Figure 3: Typical Class A with isolated Class B branches

Figure 5: Typical Class X

IM2 (1) (1)

IM2 (2) (2) IM2 IM2 (2) IM2

(2)

IM2 (4) (4)

(1)

(5)

(5)

IM2 (3) IM2

IM2

(4) (4)

IM2

IM2 IM2

SLC SLC FACU

SLC SLC FACU

B+ B- A+ A-

B+ B- A+ A-

(6) (7)

(3) (4)

(1) Common enclosure

(1) Non-isolated devices effectively removed from the circuit (2) Standard mount module

(2) Short circuit

(3) UIO plug-in module

(3) SLC Class B out

(4) Field wiring in the same room, within 20 ft. (6.1 m), and enclosed

(4) SLC Class A return in conduit or equivalently protected against mechanical injury

(5) Automatic fire detectors attached to isolator bases

(6) SLC Class B out

(7) SLC Class A return

2/3 P/N 3102697-EN • REV 001 • ISS 24AUG20

Specifications

Operating voltage 15.20 to 19.95 VDC

Current

Standby 170 µA

Active 427.5 µA

Circuit resistance between 6 Ω max.

isolators

Ground fault impedance 10 kΩ

Circuit designation

Signaling line circuit Class A, Class X

Wire size 12 to 18 AWG (1.0 to 4.0 mm²)

Compatible electrical boxes 2-1/2 in. (64 mm) deep double-gang

box; 4 in. square box, 1-1/2 in. (38 mm)

deep with double-gang cover

Operating environment

Temperature 32 to 120°F (0 to 49°C)

Relative humidity 0 to 93% noncondensing

Storage temperature range −4 to 140°F (−20 to 60°C)

Regulatory information

FCC compliance This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

Contact information

For contact information, see www.edwardsfiresafety.com.

P/N 3102697-EN • REV 001 • ISS 24AUG20 3/3

You might also like

- SIGA CT1 Est Manual Instalacion SH IngenieriaDocument3 pagesSIGA CT1 Est Manual Instalacion SH IngenieriaedgarNo ratings yet

- GSA-IM Isolator Module Installation SheetDocument3 pagesGSA-IM Isolator Module Installation SheetNicolas Leonardo ViqueNo ratings yet

- SIGA MCT2 Dual Input Module Installation Sheet PDFDocument2 pagesSIGA MCT2 Dual Input Module Installation Sheet PDFSofia PeraltaNo ratings yet

- 387351P-EN R04 SIGA-MCT2 Dual Input Module Installation Sheet PDFDocument2 pages387351P-EN R04 SIGA-MCT2 Dual Input Module Installation Sheet PDFErik Alberto FajardoNo ratings yet

- 387037P-EN R13 SIGA-CT2 SheetDocument3 pages387037P-EN R13 SIGA-CT2 SheetJOSENo ratings yet

- 387336P-EN R009 SIGA-CRR Polarity Reversal Relay Module Installation SheetDocument4 pages387336P-EN R009 SIGA-CRR Polarity Reversal Relay Module Installation Sheetpaulchavez34No ratings yet

- SIGA CR Est Manual Instalacion SH Ingenieria - PDF RELAYDocument3 pagesSIGA CR Est Manual Instalacion SH Ingenieria - PDF RELAYFernando TapiaNo ratings yet

- P-047550-1819-En R04 GSA-M278 Double Action Fire Alarm Station Installation SheetDocument2 pagesP-047550-1819-En R04 GSA-M278 Double Action Fire Alarm Station Installation SheetDiego100% (1)

- M85001-0365 - Universal Input-Output Module MotherboardsDocument4 pagesM85001-0365 - Universal Input-Output Module Motherboardsafie pio pioNo ratings yet

- Micrologix™ Analog Input/Output: Installation InstructionsDocument24 pagesMicrologix™ Analog Input/Output: Installation InstructionsDavid LucioNo ratings yet

- 1732e-In004 - En-E (Dual Port Enet)Document20 pages1732e-In004 - En-E (Dual Port Enet)MarcosNo ratings yet

- 037 Siga-Cc1Document6 pages037 Siga-Cc1zezohomeNo ratings yet

- P-047550-1802-En R04 GSA-CC1 Single Input Signal Module Installation SheetDocument7 pagesP-047550-1802-En R04 GSA-CC1 Single Input Signal Module Installation SheetDiegoNo ratings yet

- Módulos SIGA CC1 e CC2Document6 pagesMódulos SIGA CC1 e CC2leomsilveiraNo ratings yet

- Simatic S5 318-3UA11 Central Controller Interface Module: ManualDocument37 pagesSimatic S5 318-3UA11 Central Controller Interface Module: ManualAutomacao16No ratings yet

- Installation and Assembly: 4. Manual SpongeDocument3 pagesInstallation and Assembly: 4. Manual SpongeJennifer Eszter SárközyNo ratings yet

- Compact 1769-ASCII Module: Installation InstructionsDocument40 pagesCompact 1769-ASCII Module: Installation InstructionsMaximilianoAlvarezNo ratings yet

- Siga CC1SDocument4 pagesSiga CC1SMarceloNo ratings yet

- 1 Safety Instructions: Bluetooth Low Energy Radio TransmitterDocument4 pages1 Safety Instructions: Bluetooth Low Energy Radio TransmitterMohamed Tahar BoussahaNo ratings yet

- Manual Controle Central CE52Document45 pagesManual Controle Central CE52Vitor SilvaNo ratings yet

- 1762 Ob16Document16 pages1762 Ob16SANKPLYNo ratings yet

- E85001-0365 - Universal Input-Output Module MotherboardsDocument4 pagesE85001-0365 - Universal Input-Output Module MotherboardsEduardo LópezNo ratings yet

- E85001-0543 - Synchronization Output ModuleDocument4 pagesE85001-0543 - Synchronization Output ModuleCoordinador TecnicoNo ratings yet

- Input Modules: Siga-Mm1 & Siga-WtmDocument4 pagesInput Modules: Siga-Mm1 & Siga-WtmLuis PárragaNo ratings yet

- Devicenet 1732 Armorblock I/O, Series A: Installation InstructionsDocument16 pagesDevicenet 1732 Armorblock I/O, Series A: Installation InstructionsMariano DavicoNo ratings yet

- 1734 Oe2cDocument16 pages1734 Oe2ctony.pearce1No ratings yet

- Armorblock 2-Port Ethernet/Ip Module: Installation InstructionsDocument20 pagesArmorblock 2-Port Ethernet/Ip Module: Installation InstructionsJulio EcheverríaNo ratings yet

- TYWE3S Module Tuya Smart DocsDocument7 pagesTYWE3S Module Tuya Smart DocsMadhusudanan AshokNo ratings yet

- Input Modules: Siga-Mm1 & Siga-WtmDocument4 pagesInput Modules: Siga-Mm1 & Siga-Wtmarun RajannaNo ratings yet

- GuardPLC Digital Input Output Module PDFDocument20 pagesGuardPLC Digital Input Output Module PDFTarun BharadwajNo ratings yet

- Micrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsDocument24 pagesMicrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsRexNo ratings yet

- Installation Instructions For Flm-325-2I4 Dual Input Monitor ModuleDocument1 pageInstallation Instructions For Flm-325-2I4 Dual Input Monitor ModuleLuiyi Lazcano MontalvoNo ratings yet

- Product Description Sectos NXB..24kV W. Current and and Voltage Sensors (135NX1A)Document33 pagesProduct Description Sectos NXB..24kV W. Current and and Voltage Sensors (135NX1A)Anonymous hRePlgdOFrNo ratings yet

- Class A/B Modules: Intelligent Input/Output SecurityDocument6 pagesClass A/B Modules: Intelligent Input/Output Securitymax_powerNo ratings yet

- Installation Manual: JY997D33501DDocument3 pagesInstallation Manual: JY997D33501DDon Rodo Delgallagher100% (1)

- 1756 in 034 CenpDocument20 pages1756 in 034 CenpGuillermo LIZZANONo ratings yet

- A1SD75P 1 2 3 S3 UserManual Hardware IB 66732 EDocument16 pagesA1SD75P 1 2 3 S3 UserManual Hardware IB 66732 EJuliana BertonNo ratings yet

- Gsa UmDocument6 pagesGsa Umafie pio pioNo ratings yet

- 1732e In004 - en eDocument20 pages1732e In004 - en eisaacsavioNo ratings yet

- (Preview) Notifier - MMX-1 (A) Monitor Module CMX-2 (A) Control Module and ISO-XDocument1 page(Preview) Notifier - MMX-1 (A) Monitor Module CMX-2 (A) Control Module and ISO-XAul BachaeNo ratings yet

- Siga CRH PDFDocument4 pagesSiga CRH PDFAngel DuarteNo ratings yet

- 85001-0239 - Control Relay ModulesDocument6 pages85001-0239 - Control Relay Modulesjed_poliNo ratings yet

- PLC IO Modules Part1 PDFDocument22 pagesPLC IO Modules Part1 PDFReda NariNo ratings yet

- K85001-0272 - Isolator Module GSA-IM2Document4 pagesK85001-0272 - Isolator Module GSA-IM2Rafael AraújoNo ratings yet

- E85010-0061 - EST3 Hardwired Module PDFDocument4 pagesE85010-0061 - EST3 Hardwired Module PDFOmar Andres Novoa MartinezNo ratings yet

- LIM800 Line Isolator Module - Installation Instruction: Technical SpecificationsDocument8 pagesLIM800 Line Isolator Module - Installation Instruction: Technical SpecificationsICEMANNo ratings yet

- Micrologix™ Analog Input/Output: Installation InstructionsDocument24 pagesMicrologix™ Analog Input/Output: Installation Instructionscamus1125No ratings yet

- Selection GuideDocument1 pageSelection GuideF. PratomoNo ratings yet

- Trina Solar - Installation ManualDocument6 pagesTrina Solar - Installation Manualimrozkhan1No ratings yet

- 036 Siga-UmDocument6 pages036 Siga-UmzezohomeNo ratings yet

- Trinasolar Module Installation Manual Iec-V2 2011Document6 pagesTrinasolar Module Installation Manual Iec-V2 2011rony zea lazoNo ratings yet

- 13 - SIGA IM - Isolator Module PDFDocument2 pages13 - SIGA IM - Isolator Module PDFPrakash SelvarajNo ratings yet

- SEL Input ModuleDocument8 pagesSEL Input ModuleMahdi BOUANZOULNo ratings yet

- Siga Io ModulesDocument6 pagesSiga Io ModulesAnonymous s6f1tisKjSNo ratings yet

- SIGA WTM Input ModulesDocument4 pagesSIGA WTM Input ModulesMark SalvadorNo ratings yet

- Siga CC1S PDFDocument4 pagesSiga CC1S PDFAngel Duarte100% (1)

- 62 0467 PDFDocument4 pages62 0467 PDFNgọc Thanh VũNo ratings yet

- 1756 Ib32Document16 pages1756 Ib32Daniel BacicNo ratings yet

- M85001 0297 Input ModulesDocument4 pagesM85001 0297 Input Modulesafie pio pioNo ratings yet

- Modeling Tube Circuits With Altium DesignerDocument17 pagesModeling Tube Circuits With Altium DesignerAndrus AaslaidNo ratings yet

- Irf3805Pbf Irf3805Spbf Irf3805Lpbf: FeaturesDocument14 pagesIrf3805Pbf Irf3805Spbf Irf3805Lpbf: Featurescarmel asentistaNo ratings yet

- Basic Electronics Lab ManualsDocument31 pagesBasic Electronics Lab ManualsMirza Umar Farooq BaigNo ratings yet

- GE FKG1NWE-brochure-enDocument2 pagesGE FKG1NWE-brochure-enHassan_haNo ratings yet

- Selection of Surge Protective Device (SPD) - (Part 1)Document5 pagesSelection of Surge Protective Device (SPD) - (Part 1)supermannonNo ratings yet

- ABB Compact SubstationDocument24 pagesABB Compact SubstationMichael Parohinog GregasNo ratings yet

- PR G61CBD DatasheetDocument2 pagesPR G61CBD DatasheetvidotrNo ratings yet

- Selection of Main & Branch CB As Per NEC-210 (1.1.17)Document7 pagesSelection of Main & Branch CB As Per NEC-210 (1.1.17)kisan singhNo ratings yet

- Om 436Document258 pagesOm 436Georgian CrantaNo ratings yet

- PV776 TSP23760 1Document100 pagesPV776 TSP23760 1Registr Registr100% (1)

- Capacitor ESR MeterDocument7 pagesCapacitor ESR MeterrubemllNo ratings yet

- Eaton 171890 Emt62 DB en GBDocument3 pagesEaton 171890 Emt62 DB en GBAriel TorresNo ratings yet

- EE121 Power System ProtectionDocument2 pagesEE121 Power System Protection9782279059No ratings yet

- CT Dimensioning Master FileDocument10 pagesCT Dimensioning Master FileCm Tham (Facebook)No ratings yet

- West 6170-2Document2 pagesWest 6170-2stev_zoranNo ratings yet

- IMG - 0001 EE Past Board Problem MRC 3Document1 pageIMG - 0001 EE Past Board Problem MRC 3let ramNo ratings yet

- Detector Llama Lg1093 HoneywellDocument2 pagesDetector Llama Lg1093 Honeywellkuro lucirufurNo ratings yet

- Code Part Name Description Detail Specification: PXR-321B/401B/501B/322B/502BDocument3 pagesCode Part Name Description Detail Specification: PXR-321B/401B/501B/322B/502Beng5mostafa5humaid100% (1)

- SQ D-Elect Aapp'n GuideDocument156 pagesSQ D-Elect Aapp'n GuideRahul SinganiaNo ratings yet

- General Electrical Notes Legends: Detail of PanelDocument1 pageGeneral Electrical Notes Legends: Detail of PanelJAN WESLEY MORIDONo ratings yet

- Ael1037b-I Power Electronics Trainer v1.2014Document2 pagesAel1037b-I Power Electronics Trainer v1.2014Carbon Nano TubeNo ratings yet

- Sanyo Repair Tips CollectionDocument24 pagesSanyo Repair Tips CollectionH3liax90% (10)

- D50Xxpv-G/10Kt1: Type 1+2 PV Surge ProtectorDocument1 pageD50Xxpv-G/10Kt1: Type 1+2 PV Surge ProtectorCamilo Andres Bayona AguileraNo ratings yet

- 2CF2SYDocument121 pages2CF2SYAzro Marin Pavešković33% (3)

- Basic Electronics (Report)Document20 pagesBasic Electronics (Report)Jayson Jugan MangubatNo ratings yet

- Document (17) PHILIPPINE ELECTRICAL CODE 2017 - ARTICLE 1.3 ELECTRICAL PLANS AND SPECIFICATIONSDocument10 pagesDocument (17) PHILIPPINE ELECTRICAL CODE 2017 - ARTICLE 1.3 ELECTRICAL PLANS AND SPECIFICATIONSJeff CayetanoNo ratings yet

- Building Electrification Big Question - 26428013 - 202 - 231211 - 182225Document5 pagesBuilding Electrification Big Question - 26428013 - 202 - 231211 - 182225Krish ChakrabortyNo ratings yet

- 2N2102 Silicon NPN Transistor General Purpose Amplifier and Switch TO 39 Type PackageDocument2 pages2N2102 Silicon NPN Transistor General Purpose Amplifier and Switch TO 39 Type PackageNaelectronic UONo ratings yet

- Trafoindo Catalogue Oil Immersed TransformersDocument2 pagesTrafoindo Catalogue Oil Immersed TransformersRidwan HabibieNo ratings yet

- Enerzio Product Catalog 2019-2020 New PDFDocument16 pagesEnerzio Product Catalog 2019-2020 New PDFHarvinder Singh HarryNo ratings yet