Professional Documents

Culture Documents

JPegd GR 11 Answer Book (2016) PDF Screw Applied and Interdisciplinary Physics 2

JPegd GR 11 Answer Book (2016) PDF Screw Applied and Interdisciplinary Physics 2

Uploaded by

5yj9h82xjpCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JPegd GR 11 Answer Book (2016) PDF Screw Applied and Interdisciplinary Physics 2

JPegd GR 11 Answer Book (2016) PDF Screw Applied and Interdisciplinary Physics 2

Uploaded by

5yj9h82xjpCopyright:

Available Formats

JPegd GR 11 Answer

Book (2016)

Uploaded by Gugulethu

79% (29) · 39K views · 169 pages

AI-enhanced title

Document Information

Original Title

JPegd GrDownload now

11 Answer Book (2016)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Facebook

Twitter

Email

COPYRIGHT © JP

KOPIEREG © JP

Did you find this document useful?

AD Download to read ad-free.

Is this content inappropriate? Report this Document

D

ir D

k e ir G p

R te ec S ee u

ep S o b

u o to m d n N

ro re m ils

C C C C C C C C C C C

rs e eu g o

d h

H H H H H H H H H H H

v m o r ed p

u a o f re. rat

A A A A A A A A A A A

ce n ig f t e e

h n

let

P P P P P P P P P P P

d d e h t e ig T o

T T T T T T T T T T T

u ie v e q e e h f

a is

E E E E E E E E E E E

n O n In u m v h t

R R R R R R R R R R R

d n d d es id n a in is

re ep

/ / / / / / / / / / /

a ie ito d h lcu w

H H H H H H H H H H H

G fh ie

v e n le d o

O O O O O O O O O O O

o n a ra n s rd es rk

v d w

O O O O O O O O O O O

e k e et in e ie b

li o

lee

F F F F F F F F F F F

rm in

k E t reg w o

S S S S S S S S S S S

e e h x h k

is c

T T T T T T T T T T T

n a eg e

E i rk rto m

red U U U U U U U U U U U

t k m b ee ay

sb

K K K K K K K K K K K

P sa in o n

ri ie o w o ic

1 1 9 8 7 6 5 4 3 2 1

n m at k b

A

e

1 0 : : : : : : : : :

t e b io h o k o e

r'e

: :

o rd r

C

n e n av m m re

s ra k s p

K

W ad B e n ag ec ro T D IN S C C P IS M M

is b ie L L R O IV IV E

N

o , v o ee , so h d O O E T R O E E

I

A L

rk D rad h a u UE C C

O

e IL IL M

N

n n

C

ep rv et n ic ce C C N R R ID S H H

s co d I I P E

W

,

D

sy S

O

d DP A

A

rat

at D n re la, o (C H ( IT R E G D A E

C T A

E

u R N R N N

P

ep d

L

t e in ta eu d in r A E IO IN N E A A T IC IC IC

ie

X

h O

Y

m in rat L

E

o v

o rat r s lcu

M

IX N GET M W L IV

A A

R

ri e ed A

D

n ) Y D

/

za n ri m v fo k d s A P IN R E IN E L L

ri ll /

I

R

I

t ) T

G

g e in a to m

in ll L IE GA T D

N

e

G

ito v e n n ft it / R G IC A A A

a k O T R

lie re g L

E

e t p ri C S W S N

H

n in te

H

n k o re o g p g K O & IO Y A A S A

M

N b sa f li p k h d h E / L IN E

O

te U K W

T

a B v g ië e o in ts S ON / S M L

o m io V

ise S U /

E

t ri to v to N IV G Y

U

. a in / IN

/

e isc u n es o a re S S O T & A S S B T

N

1 se co E IE IV

K D

1 n s g g o n s S O WD S G L IC

v sb , te rb y /

e rev E

T

6 E p (N T L S Y

O S

9 o ra d x ew p m e y fo R IK E E IE IS A

n E

S

a la (

O

7 es u h in ed O H G V L / O /

P

d m a m o rm A KE L T P M L

d rew ca

/

g

ria K E

P

t -t E M

IE

in in u IG A /

at lle , © N E L E E

E

ito ) L R M

G

ed e, a n o g © re o IK G L O G K N E G

y r S

R

ito f J

R

g v co IN P E A T E

A

s w n . b a J b P S S A P R A G

0 GM N L

K

P

E

e a n a n rd y T E N

W

3 n at n n a ) U E M IN IT K IE A

p

G

IE

E

S S d ap d d in n K N E IE T S N

m o ie

E

ep y G

N

u S p g K T IE E S IE

te id et o res n u , m E S E

I

-A u a it o E F T S

N

m d h t a m g r ea E S

b ie -A n ew a n T K A A

G

fr d e, n E M N

re ik to y s K E

S

2 aa es fr u v re in w N E A

0 ic se e it E IN S L

1 n te a rm g fo h N T IT

d

4 se m n w ik ree rm o

u

IN G E IE

a K m C it ro p t G E L

n in o h ro a p L S

d m

o

g m

t

fi d ito e E IN

N p h lm u n rm

o p v re e se st G

. re a h p in is

n

1

1 h

e d n e rm e g re ra

o

iso

7 n ie o w

0

6 ise n isv is f

e o g

e

n

in

e n rd

d w o

d A iso ig o n a

w

at e ig ss n e f d ri

ed as e o a in re t

es f n in

2 se U s t d e rit g

0 ss it h n

Ju v

m e re ig

ev fr p p p p p p p p p p p

rie o n e E st e la o 1

0

9

6

8

6 4

7

4

6 4

9

4

4

2

9

1

8

6

-

1

-5

ly n

g ree In

t x

ec les v sy m 4 -

1 -9 -8 -7 -6 -4 -4 -2 1

7

2 s n o t -1 0 5 5 3 3 8 3 8

0 in d s u le rm st

e

h

e 1 3

1

5 s e itt itv m 6

. itt u e o .

te f

COPYRIGHT © JP

u .

u

t.

KOPIEREG © JP

AD Download to read ad-free.

C C

O E

N C N

T

H N

T R A O

I T T H

E N T

N I O

L G :E

L N

I U

P C N O

S

A E U I E

N

E

O

R E

C

R S

S

T

T

R

H N

I

E

IT

S F

O

E C A U

L N

C T L L

Y

F

L

T / L

N

K

I

IO S

E N

O E S

E

N R C E

N S

R T C

IE

/ D

L

T

N

G E E IO

E

O G HV IO

O

K

N

E U

T

ME S P D A E N

O T

D U R N

I D H A R R

A W /

D

L D

R

E

N E O R N ON H /

L D E

E T N

I E

T E WT I L P A Y V IF

G

T

N E :L

L N A

Q

E E L D S Y E O F

T C L

N U

T R T E I E E N N L E

T N O F

IE

N E

IR

O C L D R S S R

E L A T T R N

O IK E N

E

I IL E I R E

D K R O IT

D

N E E IT N

E E N N C T

T S A T S T

AN L O N / S

IL IT IT V E

E C

R T

K I

E O

E N

R

D /

V

E

C R

O

N N

T S

H

T O

I

K

N I T

R R A IL

U E

L N E E L

O :

I V M IG L

N O O N E

E U L V A E N

S V E D D

E D D E

D S

L

E T C S S E S

E

O

N

S U H E E C N

T

E D N

O

R I C C T IT

C IK T

W

C T

T

T L K I T IO

I

E

L O N IO

E

IO O N T

:

Y P L U

L

N E I N N E

:

N N N O A /

/ D E U / -A IN

G E S W -L

E E / Y

W G S

S N N

E T IT G

N A E

T A A R

E A -A

D L N IG

L

E D D T

E

D U E E E

U R T S S S

W

N L N N N

O

E

L P IT IT IT

L

Y E

:

N N

D

E

AD Download to read ad-free.

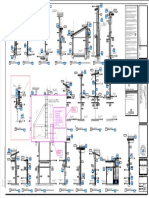

TRUE EXAMPLE CONVENTION TRUE EXAMPLE CONVENTION

FEATURE / EIENSKAP VIEW / AANSIG FEATURE / EIENSKAP VIEW / AANSIG

WARE VOORBEELD KONVENSIE WARE VOORBEELD KONVENSIE

HOLES ON A

CYLINDRICAL HELICAL LINEAR PITCH

COMPRESSION SPRING (REPEATED FEATURES)

SILINDRIESE HELIESE GATE OP 'N

DRUKVEER LINEÊRE STEEK

(HERHAALDE EIENSKAPPE)

STRAIGHT DIAMOND STRAIGHT DIAMOND STRAIGHT DIAMOND

HOLES ON A

CIRCULAR PITCH

KNURLING (REPEATED FEATURES)

KARTELING GATE OP 'N

SIRKELSTEEK

REGUIT DIAMANT / RUIT REGUIT DIAMANT / RUIT REGUIT DIAMANT / RUIT (HERHAALDE EIENSKAPPE)

B AL L B EA RI NG R OL LE R B EA RI NG B ALL B EA RI NG R OL LE R BE AR IN G

DOWEL

BALL & ROLLER

BEARING TAPPEN

SQUARE ON A SHAFT

KOEËL- & ROLLAER

KOEËLLAER ROLLAER KOEËLLAER ROLLAER

VIERKANT OP 'N AS

INTERRUPTED VIEW

ON A ROUND SECTION EXTERNAL SCREW

(S-BREAK) THREAD

ONDERBROKE AANSIG BUITESKROEFDRAAD

OP 'N RONDE SNIT

(S-BREEK)

A A

INTERNAL SCREW

SPUR GEAR THREAD

REGUITTANDRAT BINNESKROEFDRAAD

A A

INTERRUPTED VIEWS SCREW THREADS

SHAFT / AS SHAFT / AS

(S-BREAK) (ASSEMBLY)

ONDERBROKE AANSIGTE PIPE / PYP PIPE / PYP SKROEFDRADE

(S-BREEK) (SAMESTELLING)

SYMMETRY

SYMBOL SPLINED SHAFT

SIMMETRIESE

TREATMENT OF

SYMMETRICAL

SIMBOOL RIB-AS

COMPONENTS

SYMMETRY

SYMBOL

BEHANDELING SIMMETRIESE

VAN SIMBOOL

SIMMETRIESE SERRATED SHAFT

KOMPONENTE

RIFFEL-AS

P P

J J

MECHANICAL DRAWINGS CONVENTIONAL REPRESENTATION

© ©

T

H G

E

IG R

MEGANIESE TEKENINGE KONVENSIONELE VOORSTELLINGS

R E

I

Y P

P

O

O K

C

AD Download to read ad-free.

P

I H GF E D C B A F

G

L

E P

L

U

E

N

S

IN E

N

S

IN

E

N

S

IN S H S T MM

IL S U R

L F O G K G K G K G K B

E

K

R B

E A Q

U L W Y AA

K S

"A N B W T S G C F L A / E L E L E L U V A A A E S X S Y

A IN E GOP S L E L E L E IN E A A K A S L P IM IM R

E IM

R U A E IZ R O T O/ L " " "V S L L D S R D E UU IN V M M

M S IL E O N O U U" J J" "V E MM D E

R L SI R " " " S A C R O

I D T " " " (a (a I V O B B

B C O T - A A W

O

W E W IN

/

S O

R V O H

O 1 1

) )A IN

N T

D I

Y R

DE

A

L P OO F O

GROOVE OR BUTT WELDS / GROEF- OF STUIKLASSE

R T E U S E N A U O E M O B L

E G E S Y D F ND A D I N RO F A P L S

S O A R E S MM N CI V M S E S

ID L P R T M R

O

IN U E W I I D A A O IN V

A I E

N F GA C

E

F D

IN

R T R N

G

S

Y B T

O L

C

U R C N

I IN

M

U

I O

T

I S S V L

T

E S R V U U

"

P

R G

O

C

E

N L M O

L

P

E

N

O D

E

D

S

N

T

I

O

E

L

UU

MM

M V

A

N O

N P P

E C E AO

NF

R

IA

Y

M V IR RF S

O E B IN A S I MM L B L E

M O E G / G

N

G

E N D M ( (

a O F IA A

AA / O A

F J S S T / O A L E A 2 a P S L L T T V 6 L A AC D

E Y G L E S a a ) )2 P U E S E E E /

ME W S H F /

IN A L ME GL a E R OU R IR R 0 B K A

C M W 2 1 RI F ° F

E R / W O

G

E

A V / E M

R

A P R IA A W A T NE

T B / O O K R S N IE N IT

V

L C P FA AL Y A S

IE O

L S E T L T E C D E

E C I O F E O E

L

O S E C S S A E R E L N P S DT

D O W R O T

E

W IP E K R NO E P E R

N L C F N P

E H

I

G V O G O

V

L C IE T R O K U E

GH / E H T K N O

E E GH IR F R U A H P IN N R S

IM S X IN

"P W / I E O IN IN

K

S O G K A T E G O ID T

B S R O G OU F H K R OR

V

G B T

Y A P E G L P R H N E A E M A E X O D

A A E T E S S A A P F E E N C GI

N O U I U

L L S R A K R S A E A ID MT E T V IM N I

IM Y RC S L T L

K D IE O IN S IM S V E' S E E

R R

AD E M

A E A

U GR C

N N A S S S IM B M S N N L R

A K SI A

T

T E T R E A

N B OB E

/ E E W KO E T N R R E V T

T A S B O OO E GU CI IE IA L A

IE C " S E O IE C RG S I

I V A L O L L I OH A

L

Y N O

N W D O L F N

A L HE N

N T E S E S

S A D

A

L S I /

G H G F E D C B A

S A ID S

E L IE P

S

IM R

I E L S

R O S

S O B O A S A P Y IM

S S W O S S P I P E M

J T O P RO R B B

E E O T R R K N C P M D G C L P P P

IM Y I K L E IM Y N RO IR O E IR R O A A O OS

S S A G E G E E M E O E R R L

O B D A X L C X R C U K O N L Y

IE E DI V E IM R D A A

F OA IA V V U IG T L R S D / E M

B M L

A S

T

OCR B M A

L

E

E

IA M O E

L A RE

T MR

L

A

R

A

T

T

IN

G

IO T

N I-

A

U

I

S

S

E

D

R

E

G

I

C

U

L

L

E

L

L

E

S

IM V B

IR O

OB S E G OB R E I E L L L L B

S R L G L A O L

E Y Y R O P S

K

L O T

E

L O L A F

T

E L V

A

E L IN R O

S N S T OR

S 1 E

R

OD

N IR

E 0 P

K R R E

E E I C

R T G

E A T IT

L T IN O

A 5 IO

S

S

(6 5 0 M = N GN

E R C M / (L O

) ° V

E

R Ê F

A A O T R L

P R N T O G I A

QP ON M L K J R D H L Y

Y E E K T

L O R R M IN IN

R S A W M C L " R K W K G G

E IT R E E O O A S A

E ID N T N S A ID )

F E R L D N H O N S M f e d c b a

E -W O D T G T T ID

R W E R T E T E

E E A

L

L

P E H R O E J A S G C

N L / L -T O S P IN C AN OT MA MA PA DI OM SA PR PR GR OR F L L R C

C D P U ID E Y A Y H H M

A N O F N R E

E

L

/

T

Y

L R

O

T

-T C - W E

"

IN E H DE HE SJI CH OTR CE SN MP OD OD OF UG N

S

L

P

P

IN

P IN

WD

E

M M

I

E

T

M

E

IN E

R U O

E

N

E

L

O

F

G R IN GR RR NE INI O TI TE LIN UK UC HE HN Y

P G

E IN

RG

IE

S

C

A O T

/

E R

E

N

D

T

-M

T

R

D

/ W

/

W IN IN OR OU RI GN NR ON RN G SIE OTI IDW SE K L D H

O

N E

V

E

R

IN

-

/

S

W

ID

D S

E L

E

N

E

L

D

O

R

T

G G FH GH GS AL GTI OF EM LEN ME NM AA SV / D

W O

F E E

L

P

A G

T

/ E

L

- & EID NE OT OL GIN LA GIN GT OT ET RD UAL S

IL

B

E

/

T

S Y C "A W

P I

S P E O & S S E A / Y S H D H E E IN H R

WW S

IN E

R R U

N G

IN

V

N

D

P

E OS W

S L

A N L L

E E O RR

, D a a

M D A E

O A A V T C Ê P A M R N A

E EL

G

S

L

S

E

E

N

D S

T

P

O

F

N E

R

N

IN

N

P U AR AL IN E GRI G EH ,T IN IN

B L P

A L S A

J C

IE H

S O

D T

M

IS D Y

N S

L O

M S

A W

E

L

A

S

K

A

N

G P R DE USE G TIN TE AN REA MIK CMI T A

E T

R IN

IN H

E IN

E N

S IN

E

L E

L IN W IË L T E F S G D T O R R IN G R IN L G IN N

( IN G Y T

A G S

E

I

R

IN (P

D "

V

A

R A U(T INB E M MO

L E

IN N E M

G

G P

W

G

S G IT N Q P O N M L K J V C SS RA GT T E T

E

E

S S V

A

C

H

D

IE

L E EN C OO RE R

R

K

IM Y N ) A T H KE F R OS

L L B C F O R G R R

B M A S

A

C

K E AK ST E O GR

D A R

G

R

O

O

U

R O

O U a

S G F G

OB (S

G

E

F

L K O

T X SIE ) E T OR

O

NF

OH

ME

NH

U

MN

H H

E R

I a N

=

MC

U E T K I

N F U M ID BE D

S =

E 1 R

OO T

E

L

Y S ONT

M

E

M

E A K U ) L G

A H

G

E G

RR RG

S

E S Wmµ S

A V

S U A IT

K H N O R H F C G M T T A E S A S

R A A N A E

E ID H

L L )

K T

OU

O

D

H

O

F

WF S R G

S N E

A

D

-

A

D

E

R L

D U

E E

IT T

S R

E IN GS / I

E R E D

R S

T E

U RS

N 12 50

E

E

T O

A N

K C R O I A G

N 11 25

N

O O OR

K H

IN U S A

D R H F O

N 10 12,5

V

N

K

N

C F W GS R Y O

N A

D

E

ID IR F

A A S E S M Y S M ME N9 6,3 =

R

A V

N8 3,2

F E WL IM B B MN GO

S IM O E U µ

E D W R H

L

Y G M S B O R M N7 1,6

m R U

OG

I S H C M S S B

N6 0,8

S A O A V F B P R A A IM Y OL =

V U L L A M L L E H M IN S C B M B L N E 0

F H

K C R

L F S L M M A A

M

IT I

S A D J H O B O OS 1 R N5 0,4 ,0 H N

O O IN IN E M E E S IE IN L T N E E

N4 0,2

V N A A R E E L E O O O1 0

G G R L J R N E L L L 0 I S

D

E V K C IE T T

N3 0,1

1 S

K E N E NO m

N2 0,05

S X E 1 N m

COPYRIGHT © JP

2 1

KOPIEREG © JP

2 N1 0,025

AD Download to read ad-free.

260 E QUESTION: ANALYTICAL (MECHANICAL)

+0.25

50 160 -0.30

Given:

A front view, top view and right view of a box and gland assembly, detailed drawing of the flange, a title block and

Ø88 Ø20 a table of questions. The drawings have not been prepared to the indicated scale.

Instructions:

Complete the table below by neatly answering the questions, which all refer to the accompanying drawings and

the title block. [30]

Ø88 Ø76 0

0

1

Ø12

QUESTIONS ANSWERS

0

0

1 On what date was the drawing approved? 2015-03-03 1

2

2 What is the title of the assembly? BOX AND GLAND 1

126

3 What scale is indicated for the drawing? SCALE 1 : 2 1

A

2

4 What material is used to manufacture the bush? RUBBER 1

3

0

2

5 On what date was the revision done? 2015-02-03 1

R75 150° 6 What is the drawing number? LF-15/4 1

DETAILED VIEW OF FLANGE 7 What would VIEW 3 be called? RIGHT VIEW 1

Ø12 HOLE

A Ø26 x 5 SPOT FACE

VIEW 2 A 8 What type of section is shown in VIEW 1? HALF SECTION 1

M12

R What part is used to protect the flange surface when the nut

9 WASHER 1

is being tightened?

2

1

10 Name the part at R. STUD 1

8

11 Name the feature at S. SPOT FACE 1

0

12 Name the feature at T. S-BREAK 1

2

D 13 How many surfaces need to be machined? 7 1

4

6

S

14 Give the complete dimensions at: A 100 B Ø12 2

1

2 C 15 Determine the complete dimensions at: C 21 - 3 = 18 D 64 + (32-8) = 88 4

With reference to the tolerance, determine the maximum

B 16 160.25 2

dimension at E.

Ø58 With reference to the tolerance, determine the minimum

T Ø50 17 159.7 2

dimension at E.

VIEW 1 VIEW 3

18 Insert the cutting plane on VIEW 2 and label it A-A. 3

ALL DIMENSIONS ARE IN MILLIMETRES QUANTITY: 512 UNITS

19 In the space provided below, draw, in neat freehand, the symbol for the projection system used. 4

DRAWING PROGRAM: TURBOCAD 2015 MACHINING: MILLING

FI LE NA ME: L UL U1 5. dwg FI NI SH: PO LI SHED PARTS LIST TOTAL 30

DRAWING No: LF-15/4 SCALE: 1 : 2 PART QUANTITY MATERIAL

1 BASE 1 CAST IRON

UNLESS OTHERWISE SPECIFIED, ALL TOLERANCES ON

DIMENSIONS ARE ±0,15. ALL UNSPECIFIED RADII ARE R3.

2 FLANGE 1 MILD STEEL 2.

7 Angus Street 3 STUD 2 MILD STEEL 1. INSERT SPOT FACE 2015-02-03 ANSWER 19

Pretoria

4 SHAFT 1 HARDENED STEEL REVISIONS DATE

www.jpegd.co.za

012 345 6789 5 BUSH 1 RUBBER DRAWN: HENDRIK 2015-01-01

TITLE 6 WASHER 2 MILD STEEL CHECKED: ANEMIE 2015-02-02

7 NUT 2 MILD STEEL APPROVED: ANDRE 2015-03-03 SYMBOL

P P

J J

NAME: ANALYTICAL (MECHANICAL) ©

T

©

ENGINEERING GRAPHICS & DESIGN H G

E

IG R

R IE

GRADE 11: DATE: Y

P

O

P

O

K

C

AD Download to read ad-free.

260 E VRAAG: ANALITIES (MEGANIES)

+0.25

50 160 -0.30

Gegee:

'n Vooraansig, bo-aansig en regteraansig van 'n pakbus- en drukstuksamestelling, 'n gedetailleerde tekening van

Ø88 Ø20 die flens, 'n titelblok en 'n tabel met vrae. Die tekeninge is nie volgens die aangetoonde skaal voorberei nie.

Instruksies:

Voltooi die tabel hieronder deur die vrae, wat almal na die bygaande tekeninge en titelblok verwys, netjies te

Ø88 Ø76 0

0 beantwoord. [30]

1

Ø12

VRAE ANTWOORDE

0

0

1 Op watter datum is die tekening goedgekeur? 2015-03-03 1

2

2 Wat is die titel van die samestelling? PAKBUS EN DRUKSTUK 1

126

3 Watter skaal word vir die tekening aangetoon? SKAAL 1 : 2 1

A

2

4 Van watter materiaal is die bus vervaardig? RUBBER 1

3

0

2

5 Op watter datum is die hersiening gedoen? 2015-02-03 1

R75 150° 6 Wat is die tekeningnommer? LF-15/4 1

GEDETAILLEERDE AANSIG VAN FLENS 7 Wat sal AANSIG 3 genoem word? REGTERAANSIG 1

A Ø12 GAT

Ø26 x 5 KOLVLAK 8 Watter soort snit word in AANSIG 1 getoon? HALFDEURSNEE 1

AANSIG 2 A

M12

R Watter onderdeel word gebruik om die flensoppervlakte te

9 beskerm wanneer die moer vasgedraai word?

WASTER 1

2

1

10 Benoem die onderdeel by R. TAPBOUT 1

8

11 Benoem die kenmerk by S. KOLVLAK 1

0

12 Benoem die kenmerk by T. S-BREEK 1

2

D 13 Hoeveel vlakke moet gemasjineer word? 7 1

4

6

S

14 Gee die volledige afmetings by: A 100 B Ø12 2

1

2 C 15 Bepaal die volledige afmetings by: C 21 - 3 = 18 D 64 + (32-8) = 88 4

Met verwysing na die toleransie, bepaal die maksimum

B 16 afmeting by E? 160.25 2

Ø58 Met verwysing na die toleransie, bepaal die minimum

T Ø50 17 afmeting by E? 159.7 2

AANSIG 1 AANSIG 3

18 Voeg die snyvlak op AANSIG 2 in en benoem dit A-A. 3

ALLE AFMETINGS IS IN MILLIMETER HOEVEELHEID: 512 EENHEDE

In die spasie voorsien hieronder, teken, in netjiese vryhand, die simbool vir die projeksiesisteem

TEKENPROGRAM: TURBOCAD 2015 MASJINERING: FREESWERK 19 wat gebruik word. 4

LÊERNAAM: LULU15.dwg AFWERKING: GEPOLEER LYS VAN ONDERDELE

TOTAAL 30

TEKENING Nr: LF-15/4 SKAAL: 1 : 2 ONDERDEEL HOEVEELHEID MATERIAAL

TENSY ANDERS VERMELD IS ALLE TOLERANSIES OP AFMETINGS ±0,15. 1 BASIS 1 GIETYSTER

ALLE ONGESPESIFISEERDE RADIUSSE IS R3. 2 FLENS 1 SAGTE STAAL 2.

Angusstraat 7 3 TAPBOUT 2 SAGTE STAAL 1. VOEG KOLVLAK BY 2015-02-03 ANTWOORD 19

Pretoria 4 AS 1 VERHARDE STAAL HERSIENINGS DATUM

www.jpegd.co.za

012 345 6789 5 BUS 1 RUBBER GETEKEN: HENDRIK 2015-01-01

TITEL 6 WASTER 2 SAGTE STAAL NASIENER: ANEMIE 2015-02-02

7 MOER 2 SAGTE STAAL GOEDGEKEUR: ANDRE 2015-03-03 SIMBOOL

P P

J J

NAAM: ANALITIES (MEGANIES) © ©

INGENIEURSGRAFIKA & ONTWERP

T

H G

E

IG R

GRAAD 11: DATUM: R

Y

P

O

IE

P

O

K

C

AD Download to read ad-free.

144

Ø76 PARTS LIST QUESTION 1: ANALYTICAL (MECHANICAL)

16 A R16 PART QUANTITY MATERIAL Given:

Six parts of a crank handle with a title block and a table of questions.

1. HANDLE 1 MILD STEEL

0 8

1 4 2. SPINDLE 1 MILD STEEL Instructions:

B B 3. WOODRUFF KEY 1 HARDENED STEEL Complete the table below by neatly answering the questions, which

Ø13

4. CASTLE NUT 1 HARDENED STEEL all refer to the accompanying drawings and the title block.

A

SECTION A-A 34 5. WASHER 1 MILD STEEL

[25]

VIEW 1 VIEW 2 6. SPILT PIN 1 SPRING STEEL

1 6

1

R10

G

6

1

6

1

D QUESTION ANSWERS

4

4

E 1 On what date was the drawing drawn? 05/10/2011 1

5 8 2 What is the file name of the drawing? CRANK_003 1

C 3 In which street is the manufacturing company situated? GOVAN MBEKI DRIVE 1

VIEW 3

M24 9

1 4 Who made changes to the drawing? ARNO 1

4

Ø5 5 What scale is indicated for the drawing? SCALE 1:2 1

4

7

3

6 What is the tolerance allowed on the dimensions? ± 0.15 1

R16 x 10

3 7 If a scale of 1:5 were used, what would a dimension of 10mm read? 10 mm 1

F 8 What would VIEW 3 be called? SECTIONAL FRONT VIEW 1

° 4

0

1

0 4

2

9 How many surfaces must be machined on VIEW 4? SIX 1

10 What is the thickness of the woodruff key? 10 mm 1

Ø48

11 Determine the dimensions at C and D. C: 198 mm D: 76 mm 2

2 Ø160

5

6

4

12 What isthe sizeof the arc at E? R3 1

Ø28

13 What is the angle / gradient of feature F? 10˚ = (100° - 90°) 1

5

Ø24 6 14 What is the feature at G called? Keyway 1

9

1

Ø48

Ø16 15 What is the purpose of the castle nut? To secure the handle to the spindle 1

R4 1

2 To secure the castle nut to the spindle /

16 What is the purpose of the split pin? To prevent the castle nut from unwinding 1

Ø44 17 What type of section is indicated on VIEW 4? Partional section / Part Section 1

Ø120 So that the handle and spindle will turn

18 What is the purpose of the woodruff key in the crank handle assembly? together 1

VIEW 4 19 Draw the arrows for the cutting plane located on VIEW 2 and label it B-B. DRAW ON THE VIEW 2

Inthe box below (ANSWER 20), draw, in neat freehand, the symbol for the

20 DRAW IN THE GIVEN SPACE 4

projection system used.

MACHINING AND SURFACE TEXTURE SYMBOL 23/10/2011 ARNO INSERT KEY AND KEYWAY A

TOTAL (11) C: 198 mm (38+144+16) D: 76 mm (44+16+16) 25

ALL DIMENSIONS ARE IN MILLIMETRES DATE CHANGED BY REVISION DESCRIPTION Nr ANSWER 20 ANSWER 19

DRAWN BY: JOHAN DRAWING NO. 2 MATERIAL: MILD, HARDENED AND SPRING STEEL

UNLESS OTHERWISE

SPECIFIED TOLERANCES DATE: 05/10/2011 FILE NAME: CRANK_003 HEAT TREATMENT: NORMALISE

ON DIMENSIONS ARE

± 0,15

CHECKED BY: LUHAN

GOVAN MBEKI DRIVE

PORT ELIZABETH

DATE:10/10/2011

ALL UNSPECIFIED RADII 6001

ARE R3

APPROVED BY: PIETER www.maxsteel.co.za B B

DRAWING PROGRAM: DATE: 20/10/2011

TurboCAD Pro 17.2

SCALE 1:2

CRANK HANDLE SYMBOL

P P

J J

NAME: ANALYTICAL (MECHANICAL) ©

T

©

ENGINEERING GRAPHICS & DESIGN H G

E

IG R

R IE

GRADE 11: DATE: Y

P

O

P

O

K

C

AD Download to read ad-free.

144

VRAAG: ANALITIES (MEGANIES)

Ø76

ONDERDELELYS

Gegee:

16 A ONDERDELE HOEVEELHEID MATERIAAL

R16 Ses onderdele van 'n slinger met 'n titelblok en 'n tabel met vrae.

1. HANDVATSEL 1 SAGTE STAAL

2. SPIL 1 SAGTE STAAL Instruksies:

0 8

1 4 Voltooi die onderstaande tabel deur die vrae, wat almal na die

3. WOODRUFF-SPY 1 VERHARDE STAAL

B B bygaande tekene en titelblok verwys, netjies te

Ø13 4. KROONMOER 1 VERHARDE STAAL beantwoord.

A 5. WASTER 1 SAGTE STAAL [25]

SNIT A-A 34

6. SPILPEN 1 VEERSTAAL

AANSIG 1 AANSIG 2

1 6

1

G R10

6

1

6 D

VRAAG ANTWOORDE

1

4

4

1 Op watter datum is die tekening geteken? 05/10/2011 1

E

2 Wat is die lêernaam van die tekening? SLINGER_003 1

5 8

C 3 In watter straat is die vervaardigingsmaatskappy geleë? GOVAN MBEKIRYLAAN 1

M24

AANSIG 3 9

4 Wie het veranderinge aan die tekening aangebring? ARNO 1

1

4

5 Wat is die skaal wat vir die tekening aangedui word? SKAAL 1:2 1

Ø5

4 6 Wat is die toelaatbare toleransie op die afmetings? ± 0.15 1

7

3

R16 x 10 7 Indien 'n skaal van 1:5 gebruik word, wat sal 'n afmeting van 10mm lees? 10 mm 1

3

8 Wat sal AANSIG 3 genoem word? DEURSNEE VOORAANSIG 1

F

0

° 4

9 Hoeveel vlakke moet op AANSIG 4 gemasjineer word? SES 1

0 4

1

2

10 Wat is die dikte van die woodruff-spy? 10 mm 1

Ø48 11 Bereken die afmetings by C en D. C: 198 mm D: 76 mm 2

2 Ø160

5 12 Wat is die grootte van die boog by E? R3 1

6

4

Ø28 13 Wat is die skuinste / helling van kenmerk by F ? 10˚ = (100° - 90°) 1

6 14 Wat word die kenmerk by G genoem? Spygleuf 1

9

Ø24

5

1

Ø48 15 Wat is die doel van die kroonmoer? Om die handvatsel aan die spil te vestig 1

Ø16 Om die kroonmoer aan die spil te vestig /

R4 1

2

16 Wat is die doel van die splitpen? Om te verhoed dat die kroonmoer losdraai 1

17 Watter tipe snit word op AANSIG 4 getoon? Gedeeltelike snit 1

Ø44

18 Wat is die doel van die woodruff-spy in die slingersamestelling? Sodat die handvatsel en spil saam sal draai 1

Ø120

AANSIG 4 19 Teken die pylpunte vir die snyvlak op AANSIG 2 en benoem dit B-B. TEKEN OP DIE AANSIG 2

In die blok hieronder ( ANTWOORD 20), teken, in netjiese vryhand, die

20 simbool vir die projeksiesisteem wat gebruik word.

TEKEN IN DIE GEGEWE SPASIE 4

MASJINERINGS EN OPPERVLAKTE-TEKSTUUR SIMBOOL 23/10/2011 ARNO VOEG SPY EN SPYGLEUF IN A

TOTAAL (11) C: 198 mm (38+144+16) D: 76 mm (44+16+16) 25

ALLE AFMETINGS IS IN MILLIMETER DATUM VERANDER DEUR BESKRYWING VAN HERSIENING Nr ANTWOORD 20 ANTWOORD 19

TEKENAAR: JOHAN TEKENING NR. 2 MATERIAAL: SAGTE, VERHARDE EN VEER STAAL

TENSY ANDERS VERMELD,

IS ALLE TOLERANSIES OP DATUM: 05/10/2011 LÊERNAAM: SLINGER_003 HITTEBEHANDELING: NORMALISEER

AFMETINGS ± 0,15

NASIENER: LUHAN GOVAN MBEKIRYLAAN

DATUM:10/10/2011

PORT ELIZABETH

ALLE ONGESPESIFISEERDE 6001

RADIUSSE IS R3

GOEDGEKEUR: PIETER www.maxsteel.co.za B B

TEKENPROGRAM: DATUM: 20/10/2011

TurboCAD Pro 17.2

SKAAL 1:2

SLINGER SIMBOOL

P P

J J

NAAM: ANALITIES (MEGANIES) © ©

INGENIEURSGRAFIKA & ONTWERP

T

H G

E

IG R

GRAAD 11: DATUM:

R E

I

Y P

P

OO

C K

AD Download to read ad-free.

Ø64

A Ø30

Ø44 QUESTION: ANALYTICAL (MECHANICAL)

Given:

The working drawing of a diaphragm regulator with a title block

1 0

2 2 and a table of questions.

M Ø

Instructions:

S S Complete the table below by neatly printing the answers to the

1 questions, which all refer to the accompanying drawings and title

Ø70 block.

[30]

AF 32

VIEW 2 Ø14

QUESTIONS ANSWERS

6 2

1 1 On what date was the revision completed? 12/05/2011 1

2

2 Who checked the drawing? ARNO 1

M12 x 1,5

4 3 What is the title of the drawing? DIAPHRAGM REGULATOR 1

4 6

E

3

4 What scale is indicated for the drawing? 1:2 1

3

5 From what material are the metal components of the regulator made? BRASS 1

SPH Ø10 8 6 How many internal screw threads are there in the assembly? 5 1

4

7

B 5

7 How many parts make up the assembly? 10 1

3rd ANGLE ORTHOGRAPHIC

8 What orthographic projection system has been used? PROJECTION 1

Ø60 RUBBER DIAPHRAGM 9 What would VIEW 3 be called? RIGHT VIEW 1

F

C 2

10 What would VIEW 2 be called? TOP VIEW 1

1

0

2 11 What is the outer diameter of the rubber diaphragm? Ø60 1

12 What is the diameter of the sphere? Ø10 1

Ø3

8 13 Determine the dimensions at:(A) (B) (C) (D) (E) (F) 6

4 3

3 0

3

2

2 7 14 What drawing feature is shown at 1? CUTTING PLANE 1

1

D 15 What drawing feature is shown at 2? DIMENSION / LENGTH 1

23 34

16 What type of section is shown at 3? PART SECTION 1

M14 x 1,5 x 11 DEEP M20 x 1,5 x 10 DEEP

17 What does the machining symbol mean? NO MACHINING PERMITTED 2

VIEW 1 VIEW 3

18 What is the permissible tolerance on the components of the regulator? 0,25 mm 1

19 Determine the upper limit of tolerance for a dimension of 34 mm. 34,25 mm 2

In the block below, draw, in neat freehand, the simplified SANS 0111

20 4

convention for a spring!

12/05/11 MARIE DIAMETER OF INLET A TOTAL (13) Ø14 ,Ø30 , Ø64 ,Ø20, M 12, 107 30

DATE CHANGED BY REVISION OF DESCRIPTION No: DRAWING SYSTEM: TurboCAD Prof v17.2 DRAWN: LUHAN 20/03/11 20.

DRAWING No: LFN/304/2010 CHECKED: ARNO 29/03/11

FILE NAME: D5Y2 APPROVED: ANNA 03/04/11

188 SCHOEMAN STREET UNLESS OTHERWISE SPECIFIED ALL MATERIAL: BRASS

PRETORIA DIMENSIONS ARE IN MILLIMETRES

WITH A TOLERANCE OF 0,25. HEAT TREATMENT: NORMALISE

0001

www.egdengineering.co.za UNLESS OTHERWISE SPECIFIED, ALL SCALE: 1:2

(SA) (PTY) LTD

012 555 2345 SURFACE TEXTURE FINISHES ARE Convention for the spring

P P

J J

NAME: ANALYTICAL (MECHANICAL) ©

T

©

ENGINEERING GRAPHICS & DESIGN H G

E

IG R

R IE

GRADE 11: DATE: Y

P

O

P

O

K

C

AD Download to read ad-free.

Ø64

A Ø30

Ø44 VRAAG: ANALITIES (MEGANIES)

Gegee:

1 0

Die werkstekening van 'n diafragmareguleerder met 'n titelblok

2 2 en 'n tabel met vrae.

M Ø

Instruksies:

S S Voltooi die tabel hieronder deur die antwoorde van die vrae, wat

1 almal na die bygaande tekeninge en titelblok verwys, netjies te

Ø70 drukskryf.

[30]

OK 32

AANSIG 2 Ø14

VRAE ANTWOORDE

6 2

1 1 Op watter datum is die hersienin g voltooi? 12/05/2011 1

2

2 Wie het die tekening nagesien? ARNO 1

M12 x 1,5

4 3 Wat is die titel van die tekening ? DIAFRAGMAREGULEERDER 1

4 6

E

3

4 Wat is die skaal wat vir die tekening aangetoon word? 1:2 1

3 Van watter materiaal is die metaalonderdele van die reguleerder

5 GEELKOPER 1

vervaardig?

SPH Ø10 8 6 Hoeveel interne skroefdrade is daar in die samestelling? 5 1

4

7

B 5

7 Uit hoeveel onderdele bestaan die samestelling? 10 1

8 Watter ortografiese projeksiesisteem is gebruik? DERDEHOEKS 1

Ø60 RUBBERDIAFRAGMA 9 Wat sal AANSIG 3 genoem word? REGTERAANSIG 1

F

C 2

10 Wat sal AANSIG 2 genoem word? BO-AANSIG 1

1

0

2 11 Wat is die buite-diameter van die rubberdiafragma? Ø60 1

Ø3

12 Wat is die diameter van die sfeer? Ø10 1

4

8

3 13 Bepaal die afmetings by:(A) (B) (C) (D) (E) (F) 6

3 0

3

2

2 7

1

14 Watter tekenkenmerk word by 1 getoon? SNYVLAK 1

D 15 Watter tekenkenmerk word by 2 getoon? AFMETING / LENGTE 1

23 34

16 Watter tipe snit word by 3 getoon? GEDEELTELIKE SNIT 1

M14 x 1,5 x 11 DIEP M20 x 1,5 x 10 DIEP

17 Wat word met die masjineringsimbool bedoel? GEEN MASJINERING 2

AANSIG 1 AANSIG 3

18 Wat is die toelaatbare toleransie op die onderdele van die reguleerder? 0,25 mm 1

19 Bepaal die boonste toleransiebeperking vir die afmeting van 34 mm. 34,25 mm 2

20 Teken, in netjiese vryhand, die eenvoudige SANS 0111- konvensie

van 'n veer in die onderstaande blok. 4

12/05/11 MARIE DIAMETER VAN INVOERE A TOTAAL (13) Ø14 ,Ø30 , Ø64 ,Ø20, M 12, 107 30

DATUM VERANDER DEUR BEKRYWING VAN HERSIENING Nr: TEKENPROGRAM: TurboCAD Prof v17.2 TEKENAAR: LUHAN 20/03/11 20.

TEKENING Nr: LFN/304/2010 NASIENER: ARNO 29/03/11

LEÊRNAAM: D5Y2 GOEDGEKEUR: ANNA 03/04/11

SCHOEMANSTRAAT 188 TENSY ANDERS VERMELD, IS ALLE MATERIAAL: GEELKOPER

PRETORIA AFMETINGS IN MILLIMETER MET 'N

TOLERANSIE VAN 0,25. HITTEBEHANDELING: NORMALISEER

0001

(SA) (Edms.) Bpk. www.igoingenieurs.co.za TENSY ANDERS VERMELD, IS ALLE SKAAL: 1:2

012 555 2345 OPPERVLAKTEKSTUURAFWERING Konvensies vir die veer

P P

J J

NAAM: ANALITIES (MEGANIES) © ©

INGENIEURSGRAFIKA & ONTWERP

T

H G

E

IG R

GRAAD 11: DATUM: R

Y

P

O

IE

P

O

K

C

AD Download to read ad-free.

1 2 QUESTION: ANALYTICAL (MECHANICAL)

E

Given:

0

3

1

1 The views of an adaptor plate with a title block and a table of

questions.

6 4

1 1

1 3

B

Instructions:

7

3 2 5 2

4

Complete the table below by neatly printing the answers to the

3 1

6

questions, which all refer to the accompanying drawings and title

block.

[31]

C D

6 QUESTIONS ANSWERS

VIEW 2

14,47 1 What is the title of the drawing? ADAPTOR PLATE 1

REAM

41 14,27

2 On what date was the drawing checked? 10/01/11 1

Ø30

3 Who approved the drawing? L STEYN 1

4 What is the drawing number? Q1/ERCO/11 1

5 If a scale of 1:5 were used, what would a dimension of 10 mm read? 10 1

6 How many surfaces of the component require machining? 9 1

2

6 R9

15 7 What process must be applied to achieve the required finish? GRINDING 1

5 Ø5 22 3

As what type of mechanical drawing can the views of the adaptor plate be

8 DETAILED DRAWING 1

1

8

classified?

5

1

9 What would VIEW 2 be called? TOP VIEW 1

4 10 What is the thickness of the rib marked A? 11 1

5 Ø22

11 Determine the dimension at: B 52 C 60 D Ø22 E M4 4

R15 12 What is the linear distance between holes 1 and 2? 73 1

4

5 13 What type of symbol is shown at 3? WELDING SYMBOL 1

Ø30

14 What does the circle on the symbol at 4 mean? WELDING ALL AROUND 1

Ø37

A R51 15 What type of section is shown at 5? REVOLVED SECTION 2

5

16 What is the permissible tolerance on the dimensions of the components? 0,3 1

63

17 Determine the tolerance for the dimension at 6. 0,2 2

16,10

REAM

16,02 M4 32 In the box below, draw, in neat freehand, the symbol for the projection

18 4

system used.

VIEW 1 In the block below, draw, in neat freehand, the SANS 0111 convention for

19 5

the given internal screw thread.

TOTAL 31

17/01/11 JOHNNY CHANGE MACHINING SPEC' B

GRINDING

14/01/11 JOHNNY DECREASE RIB THICKNESS A ALL SPECIFIED SURFACE 0,05

DATE CHANGED BY REVISION DESCRIPTION No. FINISHES ARE:

DRAWING No: Q1/ERCO/11 MATERIAL: CAST ALUMINIUM UNLESS OTHERWISE SPECIFIED ALL 18 19

DIMENSIONS ARE IN MILLIMETRES

FILE NAME: ERCO-BL-2011 HEAT TREATMENT: NONE WITH A TOLERANCE OF 0,3.

188 SCHOEMAN STREET DRAWING PROGRAM: TurboCAD Pro 17.2

PRETORIA

0001 DRAWING BY: ARNO BELL 02/01/11

www.egdengineering.co.za

(SA) (PTY) LTD 012 555 2345 CHECKED BY: T MORKEL 10/01/11

TITLE APPROVED BY: L STEYN 14/01/11

SCALE: NTS SYMBOL SANS 0111 - CONVENTION

P P

J J

NAME: ANALYTICAL (MECHANICAL) ©

T

©

ENGINEERING GRAPHICS & DESIGN H G

E

IG R

R IE

GRADE 11: DATE: Y

P

O

P

O

K

C

AD Download to read ad-free.

1 2

E VRAAG: ANALITIES (MEGANIES)

0

Gegee:

3

1

1

Twee aansigte van 'n passtuk met 'n titelblok en 'n tabel met vrae.

6 4

1 1

1 3 Instruksies:

B 7

Voltooi die tabel hieronder deur die antwoorde van die vrae, wat

3 2

3

5

1

2

4 almal na die bygaande tekeninge en titelblok verwys, netjies te

6 drukskryf.

[31]

C D

6 VRAE ANTWOORDE

AANSIG 2 1 Wat is die titel van die tekening? PASSTUK 1

14,47

RUIM

41 14,27 2 Op watter datum is die tekening nagesien? 10/01/11 1

Ø30

3 Wie het die tekening goedgekeur? L STEYN 1

4 Wat is die tekeningnommer? Q1/ERCO/11 1

Indien 'n skaal van 1:5 gebruik sou word, wat sal 'n afmeting van 10 mm

5 lees? 10 1

2 6 Hoeveel oppervlaktes van die komponent moet gemasjineer word? 9 1

R9 15

6

5 Ø5 22 3 7 Watter proses moet aangewend word om die verlangde afwerking te verkry? SLYP 1

1 As watter tipe meganiese tekening kan die aansigte van die passtuk

8 8 geklassifiseer word?

GEDETAILLEERDE TEKENING 1

5

1

4 9 Wat sal die AANSIG 2 genoem word? BO-AANSIG 1

5 Ø22 10 Wat is die dikte van die rib gemerk A ? 11 1

R15 11 Bepaal die afmetings by: B 52 C 60 D Ø22 E M4 4

4

12 Wat is die lineêre afstand tussen gate 1 en 2? 73 1

5

Ø30 13 Watter tipe simbool word by 3 getoon? SWEISLASSIMBOOL 1

Ø37 14 Wat is die betekenis van die sirkel op die simbool by 4 ? SWEIS RONDOM 1

A R51

5 15 Watter tipe snit word by 5 getoon? GEWENTELDESNIT 2

63 16 Wat is die toelaatbare toleransie op die afmetings van die komponente? 0,3 1

16,10 RUIM 17 Bepaal die toleransie vir die afmetings by 6? 0,2 2

16,02 M4 32

18 Teken, in die blok hieronder, in netjiese vryhand, die simbool vir die 4

AANSIG 1

projeksiesisteem wat gebruik is.

19 Teken, in die blok hieronder, in netjiese vryhand, die SANS0111- konvensie 5

vir die gegewe interne skroefdraad.

17/01/11 JOHNNY VERANDER MASJINERING SPES' B

TOTAAL 31

SLYP

14/01/11 JOHNNY VERMINDER DIKTE VAN RIB A ALLE GESPESIFISEERDE 0,05

DATUM VERANDER DEUR BESKRYWING VAN HERSIENING Nr. OPPERVLAKAFWERKING IS:

TEKENINGNR: Q1/ERCO/11 MATERIAAL: GEGOTE ALUMINIUM TENSY ANDERS VERMELD, IS ALLE 18 19

AFMETINGS IN MILLIMETER MET 'N

LÊERNAAM: ERCO-BL-2011 HITTEBEHANDELING: GEEN TOLERANSIE VAN 0,3.

SCHOEMANSTRAAT 188 TEKENPROGRAM: TurboCAD Pro 17.2

PRETORIA

0001 TEKENAAR: ARNO BELL 02/01/11

www.igoingenieurs.co.za

(SA) (Edms.) Bpk. 012 555 2345 NASIENER: T MORKEL 10/01/11

TITEL GOEDGEKEUR: L STEYN 14/01/11

SKAAL: NVS SIMBOOL SANS 0111 - KONVENSIE

P P

J J

NAAM: ANALITIES (MEGANIES) © ©

INGENIEURSGRAFIKA & ONTWERP

T

H G

E

IG R

GRAAD 11: DATUM: R E

P

OO

I

Y P

C K

AD Download to read ad-free.

QUESTION: ANALYTICAL (MECHANICAL)

32 Given:

24 R20 A table of questions and a working drawing.

Ø20

R12 Instructions:

R12 Complete the table below by answer the questions, which all refer to the accompanying drawings

[28]

and the title block.

A R8

R20 QUESTION: ANSWERS:

8

2 1 On what date was the drawing first completed? 20/02/08 1

8 2 What material is used to manufacture the bell crank? CAST IRON 1

P 2 6

5

0

8

92 1 3 What is the drawing number? S8/ED/01 1

F 4 How many revisions have been made to the drawing? 1 1

Ø96

9

8

B 5 Where is the manufacturing company situated? GOODWOOD 1

6 What is the tolerance allowed on the dimensions? ± 0.25 1

S

OUTER Ø 48

INNER Ø 40 7 How many surfaces must be machined? 6 1

TEETH 6 WIDE

12 C 8 What is feature A called? FILLET 1

E 9 What is feature B called? SPLINE (SPLINED SHAFT) 1

12 24 Q

D 10 What is feature C called? RIB/WEB 1

11 What is feature D called? THREADED HOLE 1

2

1 12 Name the type of line shown at E. CENTRE LINE 1

0

7

2

5

0 13 Identify the type of symbol shown at F. WELDING SYMBOL 1

2

1

2

0 14 Name the type of section on VIEW 1. ALIGNED SECTION 1

0

4

15 Determine the dimensions at: ( P) 96 ( Q) 56 (R) 30 3

20

60 16 What is the size of angle S? 150° 1

R

36 17 What orthographic projection system has been used? THIRD-ANGLE 1

60

18 Draw the arrows for the cutting plane located on view 2 and label it A-A. 2

VIEW 1 VIEW 2

19 In the box below and in freehand, neatly draw the symbol for the projection system used. 4

20 In the box below and in freehand, neatly draw the SANS 0111 convention used for the feature at B. 3

15/10/08 KARIN GROOVE ON HUB A

TOTAL (15) P= 96 mm, Q= 56 mm, R=30 mm 28

DATE CHANGED BY DESCRIPTION OF REVISION No

UNLESS OTHERWISE DRAWN: COLEEN DRAWING No: S8/ED/01 MATERIAL: CAST IRON 19 20

SPECIFIED ALL

DIMENSIONS ARE IN DATE: 20/02/08 FILE NAME: S-P2-A2 HEAT TREATMENT: NORMALISE

MILLIMETRES WITH A 18

TOLERANCE OF ±0,25. CHECKED: KARL FORESTRY DRIVE

GOODWOOD

ALL UNSPECIFIED DATE: 26/02/08

5240

RADII ARE R3 www.capesteel.co.za

APPROVED: JAN

DATE: 01/03/08

DRAWING PROGRAM:

TurboCAD Pro v17.2

SCALE: N.T.S

BELL CRANK SYMBOL Convention of feature B

P P

J J

NAME: ANALYTICAL (MECHANICAL) ©

T

©

ENGINEERING GRAPHICS & DESIGN H G

E

IG R

R IE

GRADE 11: DATE: Y

P

O

P

O

K

C

AD Download to read ad-free.

VRAAG: ANALITIES (MEGANIES)

32 Gegee:

24 R20 'n Tabel met vrae en 'n werkstekening.

Ø20

R12 Instruksies:

R12 Voltooi die tabel hieronder deur die vrae, wat almal na die bygaande tekeninge en titelblok verwys,

netjies te beantwoord. [28]

A R8 R20 VRAE: ANTWOORDE:

8

2 1 Op watter datum is die tekening die eerste keer voltooi? 20/02/08 1

8 2 Watter materiaal is gebruik om die klokkruk te vervaardig? GIETYSTER 1

P 2 6

5

0

8

92 1 3 Wat is die tekeningnommer? S8/ED/01 1

F 4 Hoeveel keer is die tekening verander? 1 1

Ø96

9

8

B 5 Waar is die vervaardigingsmaatskappy geleë? GOODWOOD 1

6 Wat is die toleransie wat op die maatskrywings toegelaat word? ± 0.25 1

S

BUITE Ø 48

BINNE Ø 40 7 Hoeveel oppervlaktes moet gemasjineer word? 6 1

TANDWYDTE 6

12 C 8 Wat word kenmerk A genoem? BINNERONDING 1

E 9 Wat word kenmerk B genoem? RIBRAT 1

12 24 Q

D 10 Wat word kenmerk C genoem? RIB/WEB 1

11 Wat word kenmerk D genoem? SKROEFDRAAD 1

2

1 12 Benoem die tipe lyn by E? SENTERLYN 1

0

7

2

5

0 13 Identifiseer die tipe simbool by F? SWEISSIMBOOL 1

2

1

2

0 14 Benoem die tipe snit op AANSIG 1. LYNGERIGTE SNIT 1

0

4

15 Bepaal die afmetings by: (P) 96 (Q) 56 (R) 30 3

20

60 16 Hoe groot is die hoek by S? 150° 1

R

36 17 Watter ortografiese projeksiestelsel word gebruik? DERDEHOEKSE 1

60

18 Teken die pyle vir die snyvlak op AANSIG 2 en benoem dit A-A. 2

AANSIG 1 AANSIG 2

19 Teken in die blok hieronder 'n netjiese vryhandtekening van die simbool vir die projeksiestelsel

wat gebruik word. 4

20 Teken in die blok hieronder 'n netjiese vryhandtekening van die SANS0111-konvensie van 3

die kenmerk by B.

15/10/08 KARIN GROEF OP NAAF A

TOTAAL (15) P= 96 mm, Q= 56 mm, R=30 mm 28

DATUM VERANDER DEUR BESKRYWING VAN VERANDERING Nr

TENSY ANDERS VERMELD, TEKENAAR: COLEEN TEKENING Nr: S8/ED/01 MATERIAAL: GIETYSTER 19 20

IS ALLE AFMETINGS IN

MILLIMETER MET 'N DATUM: 20/02/08 LÊERNAAM: S-P2-A2 HITTEBEHANDELING: NORMALISEER

18

TOLERANSIE VAN ±0,25. NAGESIEN: KARL FORESTRYLAAN

ALLE DATUM: 26/02/08 GOODWOOD

ONGESPESIFISEERDE 5240

www.capesteel.co.za

RADIUSSE IS R3 GOEDGEKEUR: JAN

DATUM: 01/03/08

TEKENPROGRAM:

TurboCAD PRO v17.2 SKAAL: N.V.S

KLOKKRUK SIMBOOL Konvensie van kenmerk B

P P

J J

NAAM: ANALITIES (MEGANIES) © ©

INGENIEURSGRAFIKA & ONTWERP

T

H G

G E

I R

GRAAD 11: DATUM: R

Y

P

O

IE

P

O

K

C

You might also like

- Teen Mega Emotions Super BundleDocument234 pagesTeen Mega Emotions Super Bundlewilliamtheallenkid100% (2)

- Lonely Planet - TuscanyDocument139 pagesLonely Planet - TuscanyMarc Rubio Campàs100% (1)

- Amore E MorteDocument5 pagesAmore E MorteAnastassia IvanovaNo ratings yet

- Feedback Control Systems 5Th Edition Phillips Solutions Manual Full Chapter PDFDocument46 pagesFeedback Control Systems 5Th Edition Phillips Solutions Manual Full Chapter PDFDeborahWestwdzt100% (15)

- Uchiage Hanabi: Fireworks (2017) EDDocument7 pagesUchiage Hanabi: Fireworks (2017) EDAlan MaNo ratings yet

- Chart - Poster - PMBOK 6th Ed Data Flow DiagramDocument1 pageChart - Poster - PMBOK 6th Ed Data Flow DiagramPatelVKNo ratings yet

- Read Perfect Selling PDF Online: Book DetailsDocument1 pageRead Perfect Selling PDF Online: Book DetailsyousefNo ratings yet

- No. 1637Document282 pagesNo. 1637benjaminNo ratings yet

- (PDF) The MMPI-2/MMPI-2-RF: An Interpretive Manual (3rd Edition) Popular OnlineDocument1 page(PDF) The MMPI-2/MMPI-2-RF: An Interpretive Manual (3rd Edition) Popular OnlineSana SajidNo ratings yet

- LAYOUT CONVERTED FEETS-Model PDFDocument1 pageLAYOUT CONVERTED FEETS-Model PDFmanindrajust4uNo ratings yet

- Plinth Area Rates (From 1977 - 78 To 2020 - 21) Download Free PDF Tile Foundation (Engineering)Document1 pagePlinth Area Rates (From 1977 - 78 To 2020 - 21) Download Free PDF Tile Foundation (Engineering)Dinesh Babu SelvarajNo ratings yet

- PMBOK Six Edition Data Flow Diagram by English: Project Life Cycle Description. Development ApproachDocument1 pagePMBOK Six Edition Data Flow Diagram by English: Project Life Cycle Description. Development ApproachErick Reyna ChirinosNo ratings yet

- PMBOK Six Edition Data Flow Diagram by English Planning ProcessDocument3 pagesPMBOK Six Edition Data Flow Diagram by English Planning ProcesssegoooNo ratings yet

- تلخيص شامل لجميع دروس الفلسفة لسنة التانية بكالوريا - PDFDocument1 pageتلخيص شامل لجميع دروس الفلسفة لسنة التانية بكالوريا - PDFhajarlbrahmi611No ratings yet

- Read Clinical Biochemistry: An Illustrated Colour Text, 5e Full Ebook FreeDocument1 pageRead Clinical Biochemistry: An Illustrated Colour Text, 5e Full Ebook FreeHisham GhanemNo ratings yet

- 3412E-3408E Engine Electrical Schematics: Compartir Este DocumentoDocument1 page3412E-3408E Engine Electrical Schematics: Compartir Este DocumentoAxel ValenciaNo ratings yet

- 02 Bid Docs Caticlan Jetty Port Final W Pcg-2 PDF PDF Deep Foundation 3Document1 page02 Bid Docs Caticlan Jetty Port Final W Pcg-2 PDF PDF Deep Foundation 3c755p6jmm7No ratings yet

- MSLP PDFDocument1 pageMSLP PDFLuis AldanaNo ratings yet

- As Long As It Gonna PayDocument6 pagesAs Long As It Gonna PayWollepykNo ratings yet

- Canon imagePROGRAF TM Series BrochureDocument8 pagesCanon imagePROGRAF TM Series BrochureMohammad Farooq Khan Jehan Zeb KhanNo ratings yet

- Mphasis Digital Use Go for System ProgrammingDocument13 pagesMphasis Digital Use Go for System Programming0253 CSE C.HarshaVardhanNo ratings yet

- (PDF) Best of Goan Cooking Free Online: Book DetailsDocument1 page(PDF) Best of Goan Cooking Free Online: Book DetailsJhon0% (1)

- (PDF) FLORA Y VEGETACIÓN DE LA COMPAÑÍA PIKYSYRY, CAACUPÉ, DEPARTAMENTO DE CORDILLERA, PARAGUAY - (Flora and Vegetation of The CDocument1 page(PDF) FLORA Y VEGETACIÓN DE LA COMPAÑÍA PIKYSYRY, CAACUPÉ, DEPARTAMENTO DE CORDILLERA, PARAGUAY - (Flora and Vegetation of The Cgj5sgwp4hzNo ratings yet

- LakeviewDocument1 pageLakeviewrafaeldeboerNo ratings yet

- Free English For Everyone: Level 1: Beginner, Course Book Read Full PDF Unlimited-PaperbackDocument1 pageFree English For Everyone: Level 1: Beginner, Course Book Read Full PDF Unlimited-PaperbackCindy Huerta Castillo100% (1)

- Soil Mechanics and FoundationsDocument1 pageSoil Mechanics and FoundationsSuryansh SinghNo ratings yet

- 22 06 24 Deep Q LearningDocument20 pages22 06 24 Deep Q LearningAsif RazaNo ratings yet

- Prepare 2 SB PDF Language Mechanics GrammarDocument7 pagesPrepare 2 SB PDF Language Mechanics GrammarВиктория КопаNo ratings yet

- Python The Complete ReferenceDocument1 pagePython The Complete Referencepdkonline0% (1)

- The C Programming LanguageDocument1 pageThe C Programming LanguageYash Verma0% (1)

- PMBOK 6 Data Flow DiagramDocument2 pagesPMBOK 6 Data Flow Diagram小瀬 淳一No ratings yet

- Fire Extinguisher Monthly Inspection RegisterDocument1 pageFire Extinguisher Monthly Inspection RegisterMd. Ashraful IslamaNo ratings yet

- Fire Extinguisher Monthly Inspection RegisterDocument1 pageFire Extinguisher Monthly Inspection RegisterMd. Ashraful IslamaNo ratings yet

- Nelson Vectors 12 Supplement PDF Force Eucl 3Document17 pagesNelson Vectors 12 Supplement PDF Force Eucl 3Darie MitulescuNo ratings yet

- تلخيص شامل لجميع دروس الفلسفة لسنة التانية بكالوريا PDFDocument1 pageتلخيص شامل لجميع دروس الفلسفة لسنة التانية بكالوريا PDFsalahouardiNo ratings yet

- Calgary Transit - 2019 - 2020 MAPDocument1 pageCalgary Transit - 2019 - 2020 MAPcamilleleleNo ratings yet

- Kent Kennan - ContrapontoDocument219 pagesKent Kennan - ContrapontoBackerrrNo ratings yet

- Peer-e-Kamil - Umera AhmedDocument550 pagesPeer-e-Kamil - Umera AhmedsaraNo ratings yet

- Interconnection Diagram XL-200 - 110V PDFDocument1 pageInterconnection Diagram XL-200 - 110V PDFOluas OlivNo ratings yet

- Cross Worlds Transcultural PDFDocument1 pageCross Worlds Transcultural PDFPalin WonNo ratings yet

- Selection RegisterDocument1 pageSelection RegisterOMERNo ratings yet

- Keep On Rocking in The Free World: Neil YoungDocument4 pagesKeep On Rocking in The Free World: Neil YoungthierryNo ratings yet

- Full District - Rev April 21Document1 pageFull District - Rev April 21Rrsc RamsNo ratings yet

- (PDF) Steel Structures Design: ASD/LRFD - All Ebook DownloadsDocument1 page(PDF) Steel Structures Design: ASD/LRFD - All Ebook DownloadsSourNo ratings yet

- (PDF) Books Toxic Parents Epub Popular Download - by Susan ForwardDocument1 page(PDF) Books Toxic Parents Epub Popular Download - by Susan Forwardmartagonzalezbordonaba0% (3)

- M.P.M.N. Mercadillo Municipal: Entidad Prestadora de Servicios de Saneamiento Eps Moquegua S.ADocument1 pageM.P.M.N. Mercadillo Municipal: Entidad Prestadora de Servicios de Saneamiento Eps Moquegua S.Adoctor psiquiatraNo ratings yet

- FCE - Listening Internal Exam - FillableDocument7 pagesFCE - Listening Internal Exam - FillableLoo WeiNo ratings yet

- ItsDocument1 pageItsYimer MesheshaNo ratings yet

- 20210104-L-AS-COMM-WOODLAKE - porto-SPDocument1 page20210104-L-AS-COMM-WOODLAKE - porto-SPPutri ApriliaNo ratings yet

- A6.01 - Wall Sections Rev.2 MarkupDocument1 pageA6.01 - Wall Sections Rev.2 MarkupIMPRESIONESNo ratings yet

- Connect2 0Document7 pagesConnect2 0hachi m.hNo ratings yet

- DesktopDocument1 pageDesktopmegafightNo ratings yet

- Calgary-Transit - 2022 System MapDocument1 pageCalgary-Transit - 2022 System MapThei12No ratings yet

- Parking Key: School of Food Science Is Located HereDocument1 pageParking Key: School of Food Science Is Located Herecloudman81No ratings yet

- Caterpillar 320 DLDocument1 pageCaterpillar 320 DLAhmedNo ratings yet

- Cause EffectDocument1 pageCause Effectariawan habibi.abNo ratings yet

- Connect: Mahou Shoujo Madoka Magica OPDocument9 pagesConnect: Mahou Shoujo Madoka Magica OPtijmen visser100% (1)

- 03 o Suplicio Do Papa Mel de Helio PolvoraDocument10 pages03 o Suplicio Do Papa Mel de Helio Polvoraeliteles1No ratings yet

- Auditorium Seating Plan PDFDocument1 pageAuditorium Seating Plan PDFAravindNo ratings yet

- Convenciones: ColegioDocument1 pageConvenciones: ColegioCristina MedinaNo ratings yet

- P01 e P02 - Coberta e TerreoDocument1 pageP01 e P02 - Coberta e TerreoWachelo TchaikovskyNo ratings yet

- S-Curve For Jayapura (3.20) RevDocument1 pageS-Curve For Jayapura (3.20) RevFauzan TriandiNo ratings yet

- The Standard Definition of Creativity: Creativity Research Journal January 2012Document7 pagesThe Standard Definition of Creativity: Creativity Research Journal January 2012Ria Paula PacuanNo ratings yet

- Giant Friends: by Liza CharlesworthDocument10 pagesGiant Friends: by Liza CharlesworthLivegreen 360No ratings yet

- Roshan Deen V. Preeti LalDocument9 pagesRoshan Deen V. Preeti Lalmegha singlaNo ratings yet

- ExcerptDocument4 pagesExcerptmay wint htelNo ratings yet

- Urogenital SystemDocument8 pagesUrogenital SystemB JYOTHSNANo ratings yet

- Book 20231105190902161400 Pythagorean Triples Practice NDocument3 pagesBook 20231105190902161400 Pythagorean Triples Practice NCyril Danica LimareNo ratings yet

- UADocument76 pagesUAKaigoCitronNo ratings yet

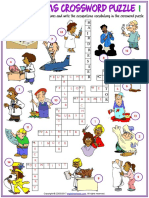

- Occupations Crossword PuzzleDocument10 pagesOccupations Crossword Puzzlegerardo ordoñez cardenasNo ratings yet

- Introducing Public Administration 8th Edition Shafritz Test BankDocument25 pagesIntroducing Public Administration 8th Edition Shafritz Test BankMichelleBrownfxmk100% (64)

- اعتذار سقراط وكريتو 2Document261 pagesاعتذار سقراط وكريتو 2بيان أكاديمي-bayan academyNo ratings yet

- Shrink-Wrap AgreementDocument2 pagesShrink-Wrap Agreementcw99zxfngrNo ratings yet

- Telma 继电器盒Document3 pagesTelma 继电器盒MapleNo ratings yet

- Adel Tawil - LiederDocument2 pagesAdel Tawil - Liedermarcello_37No ratings yet

- الدراما المصرية والتركية وتأثيرها على الشباب - دراسة مقارنةDocument474 pagesالدراما المصرية والتركية وتأثيرها على الشباب - دراسة مقارنةanf bilalNo ratings yet

- TR 6af1Document245 pagesTR 6af1pedroNo ratings yet

- A Guide To Copyright in Kenya 2018 2PRESS0Document12 pagesA Guide To Copyright in Kenya 2018 2PRESS0Kemei JamesNo ratings yet

- EMV 3DS SB255 SpecVersConfig v3 20231221 2Document5 pagesEMV 3DS SB255 SpecVersConfig v3 20231221 2lainey.sebastienNo ratings yet

- The Ontology of Alethic Modalities in Aquinas Suarez and Leibniz Amy Debra Karofsky PDFDocument269 pagesThe Ontology of Alethic Modalities in Aquinas Suarez and Leibniz Amy Debra Karofsky PDFAmbrosiusNo ratings yet

- Indonesia Property Market Report Q3 2023Document18 pagesIndonesia Property Market Report Q3 2023fandrian.ramadhaniNo ratings yet

- Sae J107-2019Document3 pagesSae J107-2019tiramisuweitaoNo ratings yet

- Intake Interview MSE - chp78Document94 pagesIntake Interview MSE - chp78yingying9811No ratings yet

- Dosh-Sirim PPEDocument9 pagesDosh-Sirim PPERoy IsmyleNo ratings yet

- HINO DA IGREJA DO EVANGELHO QUADRANGULAR - EdfDocument45 pagesHINO DA IGREJA DO EVANGELHO QUADRANGULAR - EdfAikido MarabaNo ratings yet

- GalopDocument11 pagesGalopRenan SantosNo ratings yet

- Lord For Thy Tender Mercies Sake - Tye PDFDocument3 pagesLord For Thy Tender Mercies Sake - Tye PDFManado Chamber SingersNo ratings yet

- AWS Welding Symbol Chart 2007Document3 pagesAWS Welding Symbol Chart 2007EmrE GöktuĞNo ratings yet

- Zxur 9000 gsmv65020 BSC Commissioning Guide r11 - Compress PDFDocument206 pagesZxur 9000 gsmv65020 BSC Commissioning Guide r11 - Compress PDFnazilaNo ratings yet