Professional Documents

Culture Documents

Eaton Vickers KFDG4V-3, KFTG4V-3, BFDG4V-3, KBFTG4V-3

Eaton Vickers KFDG4V-3, KFTG4V-3, BFDG4V-3, KBFTG4V-3

Uploaded by

Kamil Gökberk ErginOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eaton Vickers KFDG4V-3, KFTG4V-3, BFDG4V-3, KBFTG4V-3

Eaton Vickers KFDG4V-3, KFTG4V-3, BFDG4V-3, KBFTG4V-3

Uploaded by

Kamil Gökberk ErginCopyright:

Available Formats

Vickers® Proportional Valves

K(B)FD/TG4V-3, 1*/2* Series

Proportional Directional Valves with Feedback Pressures to 350 bar (5000 psi)

Eaton Vickers KFDG4V-3

www: www.salushydraulics.pl

Eaton Vickers KFTG4V-3

e-mail: pl@salushydraulics.pl

Eaton Vickers BFDG4V-3

shop/sklep: www.sklep.salushydraulics.pl

Eaton Vickers KBFTG4V-3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Typical Section View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Model Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Spool Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operating Data

Valves with Amplifier, KBFD/TG4V-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valves without Amplifier,KFD/TG4V-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

KBFD/TG4V-3 & KFD/TG4V-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pressure and Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance Curves

Power Capacity Envelopes, Single Solenoid Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Capacity Envelopes, Double Solenoid Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flow Gain Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation Dimensions

KFDG4V-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

KFTG4V-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

KBFDG4V-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

KBFTG4V-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Subplates and Mounting Surfaces

Parallel Path Flow Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Subplate Functional Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Interface with Additional Drain Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation Dimensions, KDGVM-3-1*-R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation Dimensions, KDGVM-3-676803-1* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting Surface Interface to ISO 4401 (Size 03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Information

Block Diagram Voltage Input (M1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Block Diagram Current Input (M2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring Connection Voltage Input (M1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring Connections Current Input (M2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

Introduction

General Description

Eaton’s Vickers® K(B)FD/ KFD/TG4V-3 KBFD/TG4V-3 • Installation wiring reduced

TG4V proportional valves This version is supplied A range of proportional and simplified

are designed to provide a without the integral directional and throttle • Standard 7-pin connector

controlled oil flow in direct amplifier. valves with integral control

proportion to a command • Standard 24V DC supply

electronics. Factory-set with wide tolerance band

signal. They are available Features and Benefits adjustments of gain, spool

in two types; a double deadband compensation • Optional ± 10V DC or

• Wide range of spool and

solenoid version that will and offset ensure consistent 4-20 mA command

flow rate options

provide reversible flow to repeatability valve-to-valve. signals

an actuator and a single • Electronic feedback LVDT

The only electrical inputs • Valve with integrated

solenoid throttle version that ensures accurate spool

required are power supply amplifier selected,

provides a single direction of position control

(24V) and a voltage ordered, delivered and

flow. Hydrostats are available • Vibration and shock installed as one perfor-

for load compensation and command signal of ± 10V

tested or 4-20 mA. The amplifier mance-tested package

parallel flow path modules

are available that will boost • Supported by a broad is housed in a robust metal • Spool position monitor

the flow capacity of single range of amplifiers and enclosure, sealed against pin to help with trouble-

solenoid throttle versions auxiliary function modules ingress of water and other shooting

to nearly twice that of the • Full CE electromagnetic fluids. Electrical connections

• Simple valve removal and

standard valve. compatibility are via a standard 7-pin plug.

replacement for service

Additionally, both of these A spool position monitor (plug and play)

valve types can be supplied pin allows the function of

• Vibration and shock tested

with or without an integral the valve to be electrically

monitored. Ramp functions, • Auxiliary DIN rail mounted

amplifier built directly onto

if required, can be generated electronic function mod-

the valve.

externally. ules available

• Full CE electromagnetic

Features and Benefits compatibility

• Factory-sealed adjust- • IP65 and IP67 valve

ments ensure valve-to- environmental protection

valve reproducibility rating

• Optional valve enable

function

Typical Section View

KBFD/TG4V-3-*PE7, 1* Design

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 3

Model Codes

K (B) F * G 4 V -3- ** * ** * * * - Z - (V) - (M) -(U1) - (* * *) - H - * - *

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

1 Valve Type 10 Spool/Spring 14 Manual Overrides 18 Electrical Connection

K Proportional valve Arrangement Z No manual overrides (KBF valves only)

B Spring centered single PC7 7-pin connector without

Integral Amplifier

2 solenoid valve (solenoid “B” 15 Solenoids Energization plug

B Integral amplifier “B” only) Solenoid “A” for “V” Identity PE7 7-pin electrical plug

series. Omit for models version, Throttle valve (non-integral amplifier types with mating half

without integral amplifier C Spring centered, dual KF only, omit for valves with PH7 As PE7 but with pin

solenoid, Direction valve integral amplifier) “C” used for enable

3 Feedback Arrangement V Solenoid “A” is at signal

11 Spool Flow Rating

F Spool position port “A” end and Solenoid PR7 As PC7 but with pin

∆ p = 5 bar (75 psi) per “B” is at port “B” end “C” used for enable

4 Control Type metering flow path, e.g. B independent of spool type signal

D Directional valve to T. (For actual maximum Blank US ANSI B93.9

flow refer to power capacity 19

standard (energize solenoid Coil Rating

T Throttle valve envelope curves. “A”, flow symbol is (P→A) H 24 VDC amplifier supply

03 3 L/min (0.79 USgpm) ∆

Mounting

5

Command Input

16

07 7 L/min (1.85 USgpm) ▲ 20 Port T Pressure Limit

G Subplate mounted M Electrical feature flag Code

13 13 L/min (3.43 USgpm) ▲

20 20 L/min (5.28 USgpm) ▲ (KF only) 6 For 2C**S spools

6 Operation

28 28 L/min (7.40 USgpm) ❑ M1 ± 10VDC (KBF only) 7 For all other spools

4 Solenoid operation

30 30 L/min (7.92 USgpm) ■ M2 4-20 mA (KBF only)

▲ Meter-in/meter-out

21 Design Number

Pressure Rating

7

❑ Meter-out only; type 2 17 Solenoid Connector 1* & 2* Series

V 350 bar (5000 psi) on

ports P, A & B spool only Omit for valves with integral Subject to change

∆ Fine meter-in/meter-out amplifier KBF

8 Interface U1 ISO 4400/DIN 43650,

■ 5C Spool only

non-integral amplifier

3 ISO 4401, size 03-02-0-

type KF only (mating

94 ANSI/B93.7M-D03 Spool Metering Type

12

plug supplied)

N Meter-in and meter-out

9 Spool Type (center

F Fine meter-in and meter-

condition) (see spool

out (only 03 spool)

data, page 5)

S Meter-out only

2 All ports closed

WARNING

5 All ports closed (zero lap) 13 Flow Rating (“B” port Valves with integral

33 P port closed, bleed A & flow for asymmetric amplifier are

B to T spools) K(B)FDG supplied with or without the

Valves only metal 7-pin plug. The Eaton

10 10 L/min (2.64 USgpm) plug, part no. 934939, must

(20N10 only) be correctly fitted to ensure

Omit for symmetrical spools that the EMC rating and

IP67 rating are achieved. The

plug retaining nut must be

tightened with a torque of

2-2,5 Nm (1.5-2.0 lbf ft) to

effect a proper a proper seal)

4 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

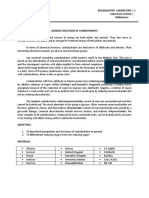

Spool Data

Spool Symbols Spool Type and Flow Rating

Available Spools for Symmetric Spools

K(B)FDG4V-3 Base line starting at ∆ p = 5 bar (75 psi) per metering flow pat, e.g. B to T. For actual

Spool type 2C**N, maximum flow refer to power capacity envelope curves.

meter-in/meter-out

For K(B)FDG4V-3 Valves

Spool Code Spool Symbol Flow Rating

2C03F 2C 3 L/min (0.79 USgpm)

Spool type 5C**N, 2C07N 2C 7 L/min (1.85 USgpm)

meter-in/meter-out (zero lap) 2C13N 2C 13 L/min (3.43 USgpm)

2C20N 2C 20 L/min (5.28 USgpm)

2C30N 2C 30L/min (7.92 USgpm)

2C28S 2C 28 L/min (7.40 USgpm)

Spool type 2C20N10,

asymmetric flow 33C03F 33C 3 L/min (0.79 USgpm)

33C07N 33C 7 L/min (1.85 USgpm)

33C13N 33C 13 L/min (3.43 USgpm)

33C20N 33C 20 L/min (5.28 USgpm)

Spool type 2C28S, 5C30N 5C 30/min (7.92 USgpm)

meter-out only

For K(B)FTG4V-3 Valves

Spool Code Spool Symbol Flow Rating

2B03F 2B 03 L/min (0.79 USgpm)

Spool 33C**N, meter-in/ 2B07N 2B 07 L/min (1.85 USgpm)

meter-out 2B13N 2B 13 L/min (3.43 USgpm)

2B20N 2B 20 L/min (5.28 USgpm)

Spool type 33C20N10, Asymmetric Spools

asymmetric flow Figure preceding metering type designator, “N” (e.g. 2C***N) is flow rating P–A, or A–T

(“A” port flow); figure after “N” (N***) is flow rating P–B, or B–T (“B” port flow).

For K(B)FDG4V-3 Valves

Available Spools for Spool Spool Flow

Code Symbol Rating

K(B)FTG4V-3

2C20N10 2C 20 L/min (5.28 USgpm), “A” port flow

Spool type 2B**N,

10 L/min (2.64 USgpm), “B” port flow

meter-in/meter-out

33C20N10 33C 20 L/min (5.28 USgpm), “A” port flow

10 L/min (2.64 USgpm), “B” port flow

Functional Symbols

Model Types KBFDG4V-3 Model Types KFDG4V-3

proportional directional proportional directional

valve (with integrated 7-pin valve (requires amplifier

electronics) plug card)

P T B A L P T B A L

Model Types KBFTG4V-3 Model Types KFTG4V-3

proportional throttle 7-pin

proportional throttle

valve (with integrated plug valve (requires amplifier

electronics) card)

P T B A L

P T B A L

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 5

Operating Data

K(B)FD/TG4V-3

Valves with Amplifier

KBFD/TG4V-3 Valves with Integral Amplifier

Data is typical with fluid at 36 cSt (168 SUS) and 50° C (122° F).

Power supply 24V DC (21 V to 36V including 10% peak-to-peak max. ripple)

max current 3A

Command signal

Voltage mode M1 0 to +10V DC, or 0 to -10V DC, or -10V to +10V DC

Input impedance 47 Ω

Common mode voltage to pin B 18V (max)

Current mode M2 4-20 mA

Input impedance 100 Ω

Max differential voltage to pin E to pin D 100 mV

Valve enable signal for model codes PH7 & PR7

Enable >8.5V (36V max)

Disable <6.5 V

Input impedance 10 Ω

7-pin plug connector Pin Description

A G

A Power supply positive (+)

View of pins of fixed half F B B Power Supply 0V and current command return

C Not connected (PE7 & PC7)

C Valve enable (PH7 & PR7)

D Command signal (+V or current IN)

E C

E Command signal (–V or current GND)

F Mounting input

D G Protective ground

Electromagnetic compatibility (EMC)

Emmission (10V/m) EN 61326-2

Immunity (10V/m) EN 61326-2

Threshold command voltage

(minimum voltage for minimum flow) 0.25V

Monitor signal (pin F) KBFD valves ± 10V DC for full spool stroke

KBFT valves 0 to -10 V DC for full spool stroke

Output impedance 10 Ω

Power stage PWM frequency 10 kHz nominal

Step input response with flow through P–A–B–T

∆ p=5 bar (75 psi) per metering path, e.g. P–A

Required flow step: Time to reach 90% of required step:

0 – 100% 17 ms

100% – 0 16 ms

+90 – -90% (KBFDG4V-3 only) 25 ms

Reproducibility, valve-to-valve (at factory settings):

Flow at 100% command signal ≤ 5%

Protection

Electrical Reverse polarity protected

Environmental I EC 60529, Class IP65 and IP67

Ambient air temperature range for full performance 0° C to 70° C (32° F to 158° F)

Oil temperature range for full performance 0° C to 70° C (32° F to 158° F)

Minimum temperature at which -20° C (-4° F)

valves will work at reduced performance

Storage temperature range -25° C to +85° C (-13° F to +185° F)

Supporting products

Auxiliary electronic modules (DIN -rail mounting):

EHD-DSG-201-A-1* command signal generator See catalog GB 2470

EHA-RMP-201-A-2* Ramp generator See catalog GB 2410A

EHA-PID-201-A-2* PID controller See catalog GB 2427

EHA-PSU-201-A-10 Power supply See catalog GB 2410A

6 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

Operating Data

KFD/TG4V-3

Valves without

Amplifier

KFD/TG4V-3 Valves without Integral Amplifier (requires a Eurocard amplifier, refer to Supporting Products)

Data is typical with fluid at 36 cSt (168 SUS) and 50° C (122° F).

Max current, at 50° C (122° F) 2,7 A

Coil resistance, at 20° C (68° F) 1,87 Ω

Step response

Step size (% of max spool stroke) Time to reach 90% of required step:

0 – 100% 18 ms

100% – 0 19 ms

+90 – -90% (KBFDG4V3-3 only) 30 ms

Type of protection, with electrical plugs fitted correctly IEC60529, Class IP65

Electromagnetic compatibility (EMC)

Emmision (10V/m) EN 50081-2

Immunity (10V/m) EN 50082-2

Maximum allowable ambient air temperature 60° C (140° F)

Maximum allowable oil temperature 60° C (140° F)

Supporting products:

Eurocard amplifiers

EEA PAM 533 A/B/C/D/E/F See catalog GB-2464

KFD/TG4V-3 and KBFD/4V-3 Valves (All Valves)

Relative duty factor Continuous rating (ED = 100%)

Hysteresis with flow through P–A–B–T <1% of max stroke (center-to-offset)

Mass: KFDG4V-3 2,7 kg (5.9 lb) approx.

KBFDG4V-3 3,1 kg (6.8 lb) approx.

KFTG4V-3 2,1 kg (4.6 lb) approx.

KBFTG4V-3 2,5 kg (5.5 lb) approx.

Portable test equipment

EBA TEQ 460 A 10 See catalog V-ELAC-TM001-E

Pressure and Flow Rates

Maximum pressures, bar (psi)

Model Port L Condition Ports P, A, B T L

All models for normal usage Normally blocked by 315 (4500) 160 (2300) 160 (2300)

(L port not connected) mounting surface 350 (5000) 105 (1500)

105 (1500)

For K(B)FDG4V-3**C**N/F-Z models only Drained directly to tank 350 (5000) 210 (3000) 10 (150)

a higher “T” port pressure is allowed if the

“L” port is connected directly to tank.

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 7

Performance

Curves

Power Capacity

Envelopes

Single Solenoid Models:

K(B)FTG4V-3

Spool types as noted

Double Solenoid Models:

K(B)FDG4V-3

Spool types as noted

8 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

Performance When using the single

solenoid throttle valves

the effect of spool overlap.

Curves shown include

Curves version (K*FT) a parallel

flowpath module (page 12)

deadband compensation

provided for the KF valve

can used to approximately by Eaton’s Vickers Eurocard

Flow Gain Curves double the flow rate. Amplifier EEA-PAM-533-*-32

KBF valves are preset at the (user adjustable).

factory to compensate for

K(B)FD/TG4V-3

Spool types as noted

USgpm L/min USgpm L/min

8 8 30

20

7

25

7N

6 6

1.5 C0

S

28

**

5 20

2C

N,

N

20

07

C

4 **

2B

1.0 15 ,

4 0N

2

3 2B

03F 10 3N

*C C1

0.5 2 03 F, * * *

2B 2 N,

5 13

2B

1

0 0

0 20 40 60 80 100 0 20 40 60 80 100

Command signal (% of max.) Command signal (% of max.)

Single flowpath (e.g. P–A) ■ At other ∆ p values and within the

pressure drop, ∆ p = 5 bar power capacity envelopes, flow rates

(72 psi) ■. approximate to:

∆ px where Qd = Datum flow rate

Qx = Qd

∆ pd ∆ pd = Pressure drop at datum flow rate

∆ px = Required ∆p

Frequency Response

(Typical)

For an amplitude of ± 25%

max. flow about the 50% flow,

at ∆ p (P–B) = 5 bar (72 psi)

KBFD/TG4V-3 KFD/TG4V-3

+3 +3

0 0

Amplitude ration (dB)

Amplitude ration (dB)

Phase lag (degrees)

Phase lag (degrees)

–3 –3

–6 135° –6 135°

90° 90°

45° 45°

0 0

1 2 3 4 5 10 20 30 40 60 80 1 2 3 4 5 10 20 30 40 60 80

Frequency (Hz) Frequency (Hz)

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 9

Installation

Dimensions

3rd angle

projection

KFDG4V-3 Solenoid plug (ISO 4400/DIN 43650); Solenoid plug (ISO 4400/DIN 43650);

mm (inch) gray, marked A, for V models, or black, marked B, for V models, or

black, marked B, for non-V models; gray, marked A, for non-V models;

see 15 in “Model Code” see 15 in “Model Code”

13 (0.52)

clearance

for

removal

KFTG4V-3

mm (inch)

▲ Mounting surface seals supplied

NOTE: For optimum valve • Remove both bleed be prevented by installing a

operation, bleed the air from screws, and use a stan- check valve in the tank line.

the proportional solenoids at dard oil can nozzle to The cracking pressure of the

initial start-up. This may be pump fluid in one side check valve should be in the

done as follows: until it flows, free of air range of 22 - 45 psi (1.5 - 3

• The valve may be pres- bubbles, out the other bar).

surized by removing the side. Reinstall screws.

bleed screws until no If there is no inherent back

bubbles appear and then pressure in the tank port of

reinstalling bleed screws, the circuit do not allow the

or... tank line to empty. This may

10 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

Installation

Dimensions

KBFDG4V-3

mm (inch)

KBFTG4V-3

mm (inch)

Amplifier and solenoid may

be rotated 90° as shown by

removing 4 screws shown X.

Re-torque to 7-9 Nm (6-7 lbf ft)

Warning * Bleed screw locations Air

Valves with integral bleed, Socket Head Cap

amplifiers are Screw.

supplied with or without the Torque to 2,5-3,0 Nm (2.0-

metal 7-pin plug. The Eaton 2.5 lbf ft)

plug, part no. 934939, must

be correctly fitted to ensure

that the EMC rating and

IP67 rating are achieved. The

plug retaining nut must be

tightened with a torque of 2,0-

2,5 Nm (1.5-2.0 lbf ft) to effect

a proper seal.

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 11

Parallel Path Flow

Module

Size 03

Parallel-Flow-Path Module

KDGMA-3-616265-1*

4 holes 5,6 (0.22 dia).

counterbored to 9,5 (0.374 dia.)

P T B A

A Nameplate

P 65.0

(2.6)

P T B A T

B

Typically used for doubling effective flow capability

of single solenoid proportional valves (throttle

valves), as illustrated in "Typical Applications'. 47.6

(1.9)

▲ A, TA and TB ports at subplate face are blind 50.0 20,0 (0.78)

holes fitted with O-seals. (1.97)

Subplates and

Mounting Surfaces

General Description Dimensional Tolerances Mounting Bolt Tapping that customer’s own

If a subplate is not used, Dimensional tolerance on ISO 4401 gives metric manifold blocks for UNC

a machined pad must be interface drawings is ±0.2 thread tappings. Alternate bolts should be tapped to

provided for valve mounting. mm (±0.008”) except where UNC tapping are Eaton’s the minimum depths given

Pad must be flat within otherwise stated. ISO 4401 recommendations that allow in the footnotes.

0,0127 mm (.0005 inch) and specifies inch conversion to these plates and associated

smooth within 1,6 µm (63 ±0.01”. valves to be used up to

microinch). Mounting bolts, their maximum pressures,

when provided by customer, Conversion for Metric when using Eaton

should be ISO 898 class ISO 4401 gives dimensions recommended bolt kits,

12.9 or better. in mm. Inch conversions are or bolts of an equivalent

16 accurate to 0.01” unless strength. It is recommended

otherwise stated.

Subplates

Description and Mass kg (lb) Functional Symbol Model Code Max. Pressure

Single-station subplate; KDGVM-3-1*-R ▲ 250 bar (3600 psi)

rear ports P, T, A, B; side port L KDGVM-3-676803-1*

Cast iron 1,3 (2.9) P T B A (SAE/UNF ports

* Design number subject ▲ “S” suffix = SAE/UNC

to change. No change of ports and /or UNC

installation dimensions fixing bolt tappings

for design numbers 10 to and/or orifice plugs as

19 or 21 to 29 inclusive. appropriate.

“R” suffix = BSPF and/or

metric fixing bolt tapping

and/or orifice plugs as

appropriate.

12 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

Installation

Dimensions

Four holes tapped according to model type (see

table): For models with BSPF ports, M5 x 12 (0.47) L

deep. For models with SAE ports, #10.24 UNC-2B x

Single-Station Subplates 12,7 (0.5) deep. P T B A

All dimensions in mm (inches)

4 holes Ø 5,6 (0.22

dia) spotfaced to Ø

13,0 (0.51 dia)

Port Threads Ports P, T, A, B

Model Ports P, T, A, B Port L

BSPF ports / M5 mounting bolts:

KDGVM-3-1*-R Rear G 3/8” (3/8” BSPF) x G 1/8” (1/8” BSPF x

12,0 (0.47) deep 12,0 (0.47) deep

SAE ports/#10-24 UNC mounting bolts:

KDGVM-3-676803-1* Rear 3/4”-16 UNF-2B x 14,3 7/16”-20 UNF-2B x

(0.56) deep (SAE) 11,6 (0.46) deep (SAE)

Mounting Surface to ISO

4401 (Size 03)

This interface conforms to:

ISO 4401-03-02-0-05

■ #10-24 UNC-2B optional

46,5

(1.83)

Interface with Additional

Drain Port 4,0 (0.16 dia.)

ANSI/B93.7M (and NFPA) size

25,3

03 CETOP R35H4.2-4-03, plus

location pin hole. (0.99)

Typically used for proportional

L

and other valves requiring an

additional drain port.

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 13

Electrical

Information

Block Diagram

Voltage Input (M1) 7-pin plug connections LVDT Compensation

KBFDG 4V-3 network

+24V A +15V

Power 0V B 0V

–15V

Enable or C

KBFDG4V-3 Wiring not connected +24V

Connections must be made Monitor output F Modulator

via the 7-pin plug mounted

Non-inverting D

on the amplifier. See page Command

15 of this leaflet and Eaton’s signal Inverting E

voltage,

Installation Wiring Practices Gain Of fset

see table

for Vickers® Electronic

Products, leaflet 2468. Protective G

ground +24V

Recommended cable sizes Solenoid

are: Valve envelope

drive

Power cables: Pin C is used for a valve enable signal with electrical connections PH7 and PR7.

For 24V supply 0,75 mm2

(18 AWG) up to 20m (65 ft)

1,00 mm2 (16 AWG) up to

40m (130 ft)

Signal cables:

0,50 mm2 (20 AWG)

Screen (shield):

A suitable cable would have Command Signals and Outputs, M1

seven cores, a separate 7-pin Plug Flow direction

screen for the signal wires Pin D Pin E

and an overall screen. Positive OV

Cable outside diameter 8,0– OV Negative P to A

10,5 mm (0.31–0.41 inches) Ud - Ue = Positive

See connection diagram on Negative OV

next page. OV Positive P to B

Ud - Ue = Negative

KFDG4V-3 Wiring

Wiring details for these

valves are contained in

the appropriate Eurocard

literature and Eaton’s

Installation Wiring Practices

for Vickers® Electronic

Products leaflet 2468.

WARNING

All power must

be switched off

before connecting/discon-

necting any plugs.

14 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

Electrical

Information

Block Diagram

Current Input (M2) 7-pin plug connections Compensation

LVDT network

KFSDG4V-3 +24V A +15V

Power 0V B 0V

-15V

Enable or C

KBSDG4V-3 Wiring not connected +24V

Connections must be made Monitor output F Modulator

F1

via the 7-pin plug mounted Command +4 to 20 mA D

on the amplifier. See page R1

15 of this leaflet and Eaton’s Return E

Installation Wiring Practices Gain Offset

for Vickers® Electronic F2

Products, leaflet 2468. Protective ground G +24V

Recommended cable sizes Solenoid

drive

are: Valve envelope

Power cables: Pin C is used for a valve enable signal with electrical connections PH7 and PR7.

For 24V supply R1 shunt resistor 100R

0,75 mm2 (18 AWG) up to F1, F2 resettable fuse

20m (65 ft) 1,00 mm2 (16

AWG) up to 40m (130 ft)

Signal cables:

0,50 mm2 (20 AWG)

Screen (shield):

Command Signals and Outputs, M2

A suitable cable would have

seven cores, a separate 7-pin plug

screen for the signal wires Pin D Pin E Pin B Flow direction

and an overall screen. More than Current Power

12 mA return ground P to A

Cable outside diameter 8,0–

10,5 mm (0.31–0.41 inches) Less than Current Power

12 mA return ground P to B

See connection diagram on

next page.

KFDG4V-3 Wiring

Wiring details for these

valves are contained in the

appropriate Eurocard literature

and Eaton’s Installation

Wiring Practices for Vickers®

Electronic Products leaflet

2468.

WARNING

All power must

be switched off

before connecting/discon-

necting any plugs.

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 15

Electrical

Information

Wiring Connections User Panel Outer Screen KB..PC7/PE7 valve

Voltage Input (M1)

Power

■ Spool position monitor Supply +24V A

voltage (pin F) will be 0V B

referenced to the KB valve

local ground. C

Inner Screen

Demand

WARNING 0V D or E Valve

Signal

Do not ground ±10V must be

pin C. Drain Wire connected

G

Spool 0V to ground

Position via

Monitor Input subplate

F

Enclosure

Connector

0V must be

shell

connected to ground

Wiring Connections for User Panel KB..PR7/PH7 valve

Outer Screen

M1 Valves with Enable

Feature Power

Supply +24V A

■ Note: In applications 0V B

where the valve must

conform to European

RFI/EMC regulations, the Enable

Signal 0V

outer screen (shield) must +8.5V C

be connected to the outer to 36V

shell of the 7-pin connector, Inner Screen

and the valve body must Demand Valve

Signal 0V D or E

be fastened to the earth E or D must be

ground. Proper earth ±10V Drain Wire connected

grounding practices must G to ground

be observed in this case, as Spool via

0V

any differences in command Position Input F subplate

Monitor

source and valve ground

potentials will result in a

screen (shield) ground loop. Enclosure

0V must be Connector

connected to ground shell

16 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

Electrical

Information

Wiring Connections User Panel Outer Screen KB..PC7/PE7 valve

Current Input (M2)

Power

■ Spool position monitor +24V A

Supply

voltage (pin F) will be

0V B

referenced to the KB valve

local ground. C

Inner Screen

Demand

0V E Valve

Signal

4 - 20 mA D must be

WARNING Drain Wire

G connected

Do not ground Spool 0V to ground

pin C. Position via

Monitor Input subplate

F

Enclosure

Wiring Connections for Connector

M2 Valves with Enable 0V must be

connected to ground shell

Feature

▲ Note: In applications

where the valve must

conform to European User Panel KB..PR7/PH7 valve

Outer Screen

RFI/EMC regulations, the

outer screen (shield) must Power

Supply +24V A

be connected to the outer

0V B

shell of the 7-pin connector,

and the valve body must

be fastened to the earth Enable

Signal 0V

ground. Proper earth C

+8.5V

grounding practices must to 36V

be observed in this case, as Inner Screen Valve

any differences in command Demand must be

source and valve ground Signal 0V E

D connected

potentials will result in a 4 - 20 mA

Drain Wire to ground

screen (shield) ground loop. G via

Spool

0V subplate

Position Input F

Monitor

Enclosure

0V must be Connector

connected to ground shell

WARNING

Electromagnetic The metal 7-pin connector transmitters, etc. Difficult demand signal and monitor

Compatibility (EMC) part no. 934939 should environments could mean output from the power

It is necessary to ensure be used for the integral that extra screening may lines.

that the valve is wired up amplifier. In all cases both be necessary to avoid the

valve and cable should be interference. The enable line to pin C

as above. For effective should be outside the

protection the user electrical kept as far away as possible It is important to connect screen which contains the

cabinet, the valve subplate from any sources of elec-

tromagnetic radiation such the 0V lines as shown demand signal cables.

or manifold and the cable above. The multi-core cable

screens should be connected as cables carrying heavy should have at least two

to efficient ground points. current, relays and certain

kinds of portable radio screens to separate the

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 17

Application Data

Fluid Cleanliness Mounting Bolt Kits

Proper fluid condition is essential for long and satisfactory

life of hydraulic components and systems. Hydraulic fluid For K(B)FD/TG4V-3

must have the correct balance of cleanliness, materials BK02-156493M (metric)

and additives for protection against wear of components, BK590716(inch)

elevated viscosity and inclusion of air. If not using Eaton recommended bolt kits, bolts used should be to ISO 898, 12.9 or better.

Recommendations on contamination control methods

and the selection of products to control fluid condition Seal Kits

are included in Eaton’s publication 9132 or 561, “Vickers

KFD/TG4V-3 . . . . . . . . . . . . . . . . . . . . . . . 565108

Guide to Systemic Contamination Control”. The book also

includes information on the Eaton’s concept of “ProActive KBFD/TG4V-3-1* . . . . . . . . . . . . . . . . 02-332693

Maintenance”.

The following recommendations are based on ISO Plugs

cleanliness levels at 2 µm, 5 µm and 15 µm:

KBFDG4V

For products in this catalog the recommended levels are:

7-pin plug (metal) . . . . . . . . . . . . . . . . . . . 934939

0 to 70 bar (1000 psi) . . . . . . . . . . . . . . 18/16/13

7-pin plug (plastic). . . . . . . . . . . . . . . . . . . 694534

70 + bar (1000 + psi) . . . . . . . . . . . . . . . 17/15/12

(metal plug must be used for full EMC protection)

Eaton products, as any components, will operate with

NOTE: An alternative metal connector which gives EMC

apparent satisfaction in fluids with higher cleanliness codes

protection but not IP67 rating is available from ITT-Cannon,

than those described. Other manufacturers will often

part number CA06-COM-E-14S-A7-S.

recommend levels above those specified.

Experience has shown, however, that life of any hydraulic KFDG4V

components is shortened in fluids with higher cleanliness Solenoid (black) . . . . . . . . . . . . . . . . . . . . 710775

codes than those listed above. These codes have been

proven to provide a long trouble-free service life for the Solenoid (gray) . . . . . . . . . . . . . . . . . . . . . 710776

products shown, regardless of the manufacturer. LVDT (gray) . . . . . . . . . . . . . . . . . . . . . . . . 458939

Hydraulic Fluids Extension Cable

Materials and seals used in these valves are compatible Extension Cable: Adapter for extending seven core cable

with antiwear hydraulic oils, and non-alkyl-based phosphate when changing from KA to KB valve and existing wiring is

esters. The extreme operating viscosity range is 500 to not long enough. Consists of a 7-pin plug, a 7-pin socket

13 cSt (2270 to 70 SUS) but the recommended running and a length of cable, fully assembled for ease of use.

range is 54 to 13 cSt (245 to 70 SUS).

Extension Cable . . . . . . . . . . . . . . . . . . . . 944450

Installation

Service Information

The proportional valves in this catalog can be mounted in

any attitude, but it may be necessary in certain demanding The products from this range are preset at the factory for

applications, to ensure that the solenoids are kept full optimum performance; disassembling critical items would

of hydraulic fluid. Good installation practice dictates that destroy these settings. It is therefore recommended that

the tank port and any drain port are piped so as to keep should any mechanical or electronic repair be necessary

the valves full of fluid once the system start-up has been they should be returned to the nearest Eaton repair center.

completed. The products will be refurbished as necessary and retested

to specification before return.

Field repair is restricted to the replacement of the seals.

NOTE: The feedback/solenoid assembly installed in this

valve should not be disassembled.

18 EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009

EATON Vickers® Proportional Valves KBFD/TG4V-3 V-VLPO-MC007-E1 April 2009 19

Eaton Eaton Eaton

Hydraulics Group USA Hydraulics Group Europe Hydraulics Group Asia Pacific

14615 Lone Oak Road Route de la Longeraie 7 11th Floor Hong Kong New World Tower

Eden Prairie, MN 55344 1110 Morges 300 Huaihai Zhong Road

USA Switzerland Shanghai 200021

Tel: 952-937-9800 Tel: +41 (0) 21 811 4600 China

Fax: 952-294-7722 Fax: +41 (0) 21 811 4601 Tel: 86-21-6387-9988

www.eaton.com/hydraulics Fax: 86-21-6335-3912

© 2009 Eaton Corporation

All Rights Reserved

Printed in USA

Document No. V-VLPO-MC007-E1

April 2009

You might also like

- Sewa Bill PDFDocument1 pageSewa Bill PDFabdulmanan67% (3)

- 230/460 and 460/575 Volt ModelsDocument104 pages230/460 and 460/575 Volt ModelsIan McNair100% (3)

- Miller XMT 304 Manual de Servicio PDFDocument104 pagesMiller XMT 304 Manual de Servicio PDFNINO100% (1)

- Power OneDocument170 pagesPower OneRicardo Paul100% (4)

- ModulanteDocument23 pagesModulanteVBPNo ratings yet

- Force Ez Electrosurgical Generator C 8c Service Manual PDFDocument256 pagesForce Ez Electrosurgical Generator C 8c Service Manual PDFGabriel ArrienNo ratings yet

- EY Introduction To Financial ModellingDocument8 pagesEY Introduction To Financial ModellingPrashantKNo ratings yet

- Vickers Valve Kftg4v3kfdg4v3Document20 pagesVickers Valve Kftg4v3kfdg4v3Siju Mon SNo ratings yet

- PLL - 2105 Valv Prop UH 77-78Document18 pagesPLL - 2105 Valv Prop UH 77-78Leopoldo WilleNo ratings yet

- Isl 98604Document28 pagesIsl 98604divubi2004No ratings yet

- Tle 8209Document41 pagesTle 8209Olga PlohotnichenkoNo ratings yet

- C7 CableAccessDocument73 pagesC7 CableAccess00014114No ratings yet

- Powerflex: Operating ManualDocument16 pagesPowerflex: Operating Manualjap0258No ratings yet

- Atlas 210 XDocument67 pagesAtlas 210 Xdgerson1No ratings yet

- KBWM DC Drive Series ManualDocument9 pagesKBWM DC Drive Series ManualKBElectronicsincNo ratings yet

- AN-211 New Op Amp IdeasDocument29 pagesAN-211 New Op Amp IdeasMallickarjuna A.SNo ratings yet

- 2.5A Output Current Gate Driver Optocoupler: Features DescriptionDocument11 pages2.5A Output Current Gate Driver Optocoupler: Features DescriptiononafetsNo ratings yet

- DPV 50 HZ Vertical Pumps Technical DataDocument92 pagesDPV 50 HZ Vertical Pumps Technical DataEugenia BondarenkoNo ratings yet

- Eaton Vickers KFDG4V-5, KFTG4V-5, KBFDG4V-5, KBFTG 230907 192537Document19 pagesEaton Vickers KFDG4V-5, KFTG4V-5, KBFDG4V-5, KBFTG 230907 192537ottosusenoNo ratings yet

- Scea 030 ADocument17 pagesScea 030 ACarlos EstevesNo ratings yet

- TLE8208Document41 pagesTLE8208Luis VilchezNo ratings yet

- 5.1 Monitoring Relays: Motor Protection Circuit BreakerDocument118 pages5.1 Monitoring Relays: Motor Protection Circuit BreakerPraise Sam AbrahamNo ratings yet

- CB Spec SvenskaDocument44 pagesCB Spec SvenskaTravis WoodNo ratings yet

- Auto Continuum PDFDocument164 pagesAuto Continuum PDFJosé Carlos de Alencar Dias100% (1)

- Infineon TLE8209 4SA DS v01 - 02 EN 785725Document39 pagesInfineon TLE8209 4SA DS v01 - 02 EN 785725balajiboss005No ratings yet

- Liebert VFD Condenser - Model TCDV - Product Information Manual PDFDocument12 pagesLiebert VFD Condenser - Model TCDV - Product Information Manual PDFingfcontrerasNo ratings yet

- Tle8102Sg: Smart Dual Channel Powertrain Switch CoreflexDocument34 pagesTle8102Sg: Smart Dual Channel Powertrain Switch CoreflexMiguel Angel de la Cruz de la CruzNo ratings yet

- Infineon ApplicationNote ReferenceBoard REF XDPL8105 CDM10V ApplicationNotes v02 00 enDocument53 pagesInfineon ApplicationNote ReferenceBoard REF XDPL8105 CDM10V ApplicationNotes v02 00 enDuy HiếuNo ratings yet

- Aks4100 (Ficha Tecnica-Nivel de Liquido Danfoss)Document20 pagesAks4100 (Ficha Tecnica-Nivel de Liquido Danfoss)Crypto LegendNo ratings yet

- Guide To Low Voltage System Design and SelectivityDocument31 pagesGuide To Low Voltage System Design and Selectivityty14344100% (1)

- Infineon TLE9104SH DataSheet v01 - 31 ENDocument35 pagesInfineon TLE9104SH DataSheet v01 - 31 ENMohamed AbdulmaksoudNo ratings yet

- KBMM SMT Manual PDFDocument32 pagesKBMM SMT Manual PDFRicardo Garcia FuentesNo ratings yet

- Tle 92464 EdDocument117 pagesTle 92464 EdcqlNo ratings yet

- Siemens WL II 3200Document40 pagesSiemens WL II 3200felipe0% (2)

- Bigblue400cxce (Lj140121e)Document88 pagesBigblue400cxce (Lj140121e)masswelding ingenieriaNo ratings yet

- LENZE E84AVxCx - 8400 StateLine-HighLine-TopLine 0.25-45kW - v9-0 - ENDocument291 pagesLENZE E84AVxCx - 8400 StateLine-HighLine-TopLine 0.25-45kW - v9-0 - ENClaudioNo ratings yet

- HBM MGCplusAB22ADocument480 pagesHBM MGCplusAB22ADalila VaroghNo ratings yet

- KBMM DC Drive Series ManualDocument32 pagesKBMM DC Drive Series ManualKBElectronicsincNo ratings yet

- Big Blue 400 CXDocument122 pagesBig Blue 400 CXmasswelding ingenieria0% (1)

- Emerson Cooling SystemDocument140 pagesEmerson Cooling SystempoetoetNo ratings yet

- LAW 420 LAW 520: Service ManualDocument46 pagesLAW 420 LAW 520: Service ManualquangppNo ratings yet

- 1605 8136 RVW Manual TehnicDocument24 pages1605 8136 RVW Manual Tehnicd403242No ratings yet

- TB01200003EDocument132 pagesTB01200003EJohn LorenzoNo ratings yet

- Infineon TLE7251V DS v01 - 10 ENDocument35 pagesInfineon TLE7251V DS v01 - 10 ENMarco RumorosoNo ratings yet

- DBSC105 ManualDocument37 pagesDBSC105 ManualSpider74No ratings yet

- Se-330 Manual Neutral-Grounding-Resistor Monitor: All Rights ReservedDocument44 pagesSe-330 Manual Neutral-Grounding-Resistor Monitor: All Rights ReservedAlmir GarciaNo ratings yet

- 60W1 ApplicationNotes v01 - 00 ENDocument36 pages60W1 ApplicationNotes v01 - 00 ENorkun burkayNo ratings yet

- MCCB EatonDocument132 pagesMCCB EatonibnuharyNo ratings yet

- Series HSV-180D AC Servo Drive User's ManualDocument114 pagesSeries HSV-180D AC Servo Drive User's ManualKen JunNo ratings yet

- Infineon TLE9251V DataSheet v01 11 EN-3167665Document31 pagesInfineon TLE9251V DataSheet v01 11 EN-3167665Julio Cesar Tapia ReyesNo ratings yet

- Instructions Manual EVR IMEV900002Document20 pagesInstructions Manual EVR IMEV900002Ivan Dario QuirogaNo ratings yet

- CPC5620 21Document18 pagesCPC5620 21teguhscribdNo ratings yet

- SHB 9300 Servo Position Controller v2-0 EN PDFDocument462 pagesSHB 9300 Servo Position Controller v2-0 EN PDFGuillermo Osvaldo Rivera MelladoNo ratings yet

- DatasheetDocument80 pagesDatasheetselocaNo ratings yet

- 3-Phase AC/BLDC High Voltage Power Stage Board: Users GuideDocument68 pages3-Phase AC/BLDC High Voltage Power Stage Board: Users GuideCq LiNo ratings yet

- 6ED2230S12TXUMA1Document29 pages6ED2230S12TXUMA1kittijaNo ratings yet

- Denison Ec01 A10Document17 pagesDenison Ec01 A10Margaret DaughertyNo ratings yet

- Proservo NMS5Document38 pagesProservo NMS5abcNo ratings yet

- FBW2440 4820RevC EnglishDocument6 pagesFBW2440 4820RevC EnglishfernandoNo ratings yet

- Design and Layout Guidelines For The CDCVF2505 Clock Driver: Kal Mustafa Bus SolutionsDocument15 pagesDesign and Layout Guidelines For The CDCVF2505 Clock Driver: Kal Mustafa Bus Solutionsapi-26061087No ratings yet

- Digital Compensation for Analog Front-Ends: A New Approach to Wireless Transceiver DesignFrom EverandDigital Compensation for Analog Front-Ends: A New Approach to Wireless Transceiver DesignNo ratings yet

- Conference SEERC2023 SystemDocument6 pagesConference SEERC2023 SystemKamil Gökberk ErginNo ratings yet

- Flyback TR 5W 100kHzDocument1 pageFlyback TR 5W 100kHzKamil Gökberk ErginNo ratings yet

- Highvoltage OpampDocument28 pagesHighvoltage OpampKamil Gökberk ErginNo ratings yet

- Features Description: LT8316 560V Micropower No-Opto Isolated Flyback ControllerDocument26 pagesFeatures Description: LT8316 560V Micropower No-Opto Isolated Flyback ControllerKamil Gökberk ErginNo ratings yet

- High-Performance, Single-Ended, Current-Mode PWM ControllersDocument22 pagesHigh-Performance, Single-Ended, Current-Mode PWM ControllersKamil Gökberk ErginNo ratings yet

- Cheetah Sdi c1920 W FDocument2 pagesCheetah Sdi c1920 W FAwais MianNo ratings yet

- Emergent Reading Lesson Plan-2Document11 pagesEmergent Reading Lesson Plan-2api-310193303No ratings yet

- Cnidaria and CtenophoraDocument53 pagesCnidaria and CtenophorakingbanakonNo ratings yet

- Maham Ke Bari GaandDocument13 pagesMaham Ke Bari GaandFaisal GNo ratings yet

- Critical Self-Assessment LetterDocument2 pagesCritical Self-Assessment Letterapi-570528793No ratings yet

- US ARMY - Inventory of Field Manuals As of January 23, 2002Document13 pagesUS ARMY - Inventory of Field Manuals As of January 23, 2002AKsentinelNo ratings yet

- Intraplast N 200 100816Document2 pagesIntraplast N 200 100816Brijendra Mani PandeyNo ratings yet

- SAMPLE: Emergency Response Plan: Minor EmergenciesDocument3 pagesSAMPLE: Emergency Response Plan: Minor EmergenciesCyn SyjucoNo ratings yet

- Coke - Ethical Issues: The RecallDocument7 pagesCoke - Ethical Issues: The RecallPriya JainNo ratings yet

- CRMDocument9 pagesCRMJITESH KHURANANo ratings yet

- Interpreting PLCDocument30 pagesInterpreting PLCpraveenNo ratings yet

- Glorious Innings of Prof.a R RaoDocument24 pagesGlorious Innings of Prof.a R RaoMeghmeghparva100% (1)

- Rezene Business PlanDocument37 pagesRezene Business PlanMehari GebreyohannesNo ratings yet

- Individual Assignment Rubric - Infographic (15%) : Name Course Name Matrix Number Course Code Group Lecturer's NameDocument1 pageIndividual Assignment Rubric - Infographic (15%) : Name Course Name Matrix Number Course Code Group Lecturer's NameInaa12No ratings yet

- Chapter 7 Linear Momentum and Collisions - CompressDocument30 pagesChapter 7 Linear Momentum and Collisions - Compressdeez IINo ratings yet

- Brkipm-2011 - Multicast MplsDocument106 pagesBrkipm-2011 - Multicast MplsmatarakiNo ratings yet

- Portal Frame - SuperpositionDocument6 pagesPortal Frame - SuperpositionWan Izzuddin RadziNo ratings yet

- Animal Nutrition 21-22Document12 pagesAnimal Nutrition 21-22lowkeydeadNo ratings yet

- Exodus (Comics)Document8 pagesExodus (Comics)alexNo ratings yet

- 10 CarbohydratesDocument6 pages10 CarbohydratesBryanNo ratings yet

- Course Overview A1.1 5L EdDocument2 pagesCourse Overview A1.1 5L EdTere Huestis VargasNo ratings yet

- Lesson Plan Convection With AnswersDocument3 pagesLesson Plan Convection With AnswersQueencess Ara TorresNo ratings yet

- HFM App Settings 11124Document12 pagesHFM App Settings 11124Sudhakar kNo ratings yet

- Goldberg v. Jenkins and Law.Document6 pagesGoldberg v. Jenkins and Law.GoldFishNo ratings yet

- Lab Manual FEB 9Document67 pagesLab Manual FEB 9kingraajaNo ratings yet

- Hydra Text BookDocument3 pagesHydra Text BookRinku kumar PatelNo ratings yet

- High Court at NairobiDocument6 pagesHigh Court at NairobiAronyu ArthurNo ratings yet

- Questions and Answers - PMP Exam PrepDocument14 pagesQuestions and Answers - PMP Exam PrepPramod Gupta100% (2)