Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

0 viewsPDF TD 393 01 D TDI-En-0-TecDocPdfResource

PDF TD 393 01 D TDI-En-0-TecDocPdfResource

Uploaded by

ngochai15061991Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- 6f35 Rebuild ManualDocument48 pages6f35 Rebuild ManualBossing Vic100% (5)

- HOBART CHAMPION 10,000 t945f - Hob PDFDocument116 pagesHOBART CHAMPION 10,000 t945f - Hob PDFjuan felipe alzate aristizabal100% (3)

- Peugeot Partner 1.6 M59 Flex Spare Parts CatalogDocument244 pagesPeugeot Partner 1.6 M59 Flex Spare Parts CatalogRicardo Vilhena100% (1)

- Parts Catalog For ZS1100 Engine: Cylinder Block AssemblyDocument22 pagesParts Catalog For ZS1100 Engine: Cylinder Block AssemblyWidi Prasetyo100% (5)

- Engine 2.0D-VGT (Chevrolet Captiva '06-'10) Service IntroDocument61 pagesEngine 2.0D-VGT (Chevrolet Captiva '06-'10) Service IntroDangLuyen100% (5)

- Transfer Case Disassembly and AssemblyDocument22 pagesTransfer Case Disassembly and AssemblyBasilio BancurNo ratings yet

- R 70 Technical Data.: Diesel and LP Gas Forklift TrucksDocument6 pagesR 70 Technical Data.: Diesel and LP Gas Forklift TrucksKiều Văn TrungNo ratings yet

- Trio CT3042S Jaw Crusher Parts Manual (SN. 262, 279, 284, 285)Document20 pagesTrio CT3042S Jaw Crusher Parts Manual (SN. 262, 279, 284, 285)GUILLERMO OSIMANI100% (3)

- mtx75 Manual TransmissionDocument243 pagesmtx75 Manual Transmissionalfie apolinario100% (4)

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- MAN EDC7 Common Rail D0836LFDocument8 pagesMAN EDC7 Common Rail D0836LFMircea Gilca100% (3)

- Briggs & Stratton Owners ManualDocument20 pagesBriggs & Stratton Owners ManualgyrfalconNo ratings yet

- A13、A13A ServiceManual PDFDocument1,333 pagesA13、A13A ServiceManual PDFmultiservicios100% (1)

- PDF TD 394 01 D TDI-En-0-TecDocPdfResourceDocument1 pagePDF TD 394 01 D TDI-En-0-TecDocPdfResourcengochai15061991No ratings yet

- Product Datasheet: HelicalbevelgearedDocument7 pagesProduct Datasheet: Helicalbevelgeared손선호No ratings yet

- MAN Diesel & Turbo 600.40 L+V28/32H Data For Tightening TorqueDocument1 pageMAN Diesel & Turbo 600.40 L+V28/32H Data For Tightening TorqueAntonioNo ratings yet

- Technische Fiche Homa TP53M262 D Nieuw 2014Document3 pagesTechnische Fiche Homa TP53M262 D Nieuw 2014Marnix VanbavinckhoveNo ratings yet

- Bevel Gear DatasheetDocument7 pagesBevel Gear Datasheetmohammad khoraminiaNo ratings yet

- Catalogue GSPDocument1,311 pagesCatalogue GSPahmed gtoNo ratings yet

- Heli Parts Manual For ATM H2000 4-5T (Outer Pump)Document16 pagesHeli Parts Manual For ATM H2000 4-5T (Outer Pump)Петр100% (1)

- 307-01 Automatic Transmission 10 Speed - Overhaul - TransmissionDocument183 pages307-01 Automatic Transmission 10 Speed - Overhaul - Transmissionpxg8zdd7grNo ratings yet

- Maximal+Engine+FL (2.0 3.5D-7SA)Document59 pagesMaximal+Engine+FL (2.0 3.5D-7SA)Renato SanchezNo ratings yet

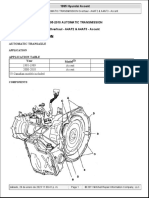

- A4af2 A4af3Document120 pagesA4af2 A4af3Jordan SanchezNo ratings yet

- Tightening TorqueDocument8 pagesTightening TorqueGaurav MaithilNo ratings yet

- Drive Pinion and Hollow Shaft, Disassembling and Assembling: Special Tools, Testers and Auxiliary Items RequiredDocument21 pagesDrive Pinion and Hollow Shaft, Disassembling and Assembling: Special Tools, Testers and Auxiliary Items RequiredTIGANA 15No ratings yet

- 115 01 TD 0906 GBDocument2 pages115 01 TD 0906 GBLada LabusNo ratings yet

- enDocument1,513 pagesen9876460990No ratings yet

- enDocument1,401 pagesenLuis Alberto Rivas GarciaNo ratings yet

- New 010 2012 HyDocument1 pageNew 010 2012 HyРома БлошенкоNo ratings yet

- SST and SSM Land Crusier J80Document11 pagesSST and SSM Land Crusier J80limadacarlosNo ratings yet

- SST and SSM: SST (Special Service Tools) C-2 SSM (Special Service Materials) C-11Document11 pagesSST and SSM: SST (Special Service Tools) C-2 SSM (Special Service Materials) C-11Zeami Abel Pérez CantilloNo ratings yet

- Data For Tightening Torque: LubricantDocument5 pagesData For Tightening Torque: LubricantAtanasio PerezNo ratings yet

- 20 Cooling - Unimog 435 Workshop ManualDocument20 pages20 Cooling - Unimog 435 Workshop ManualJuan JapNo ratings yet

- Echnical Information: Oncept and Main ApplicationsDocument6 pagesEchnical Information: Oncept and Main ApplicationsKakoy Lagusan EcobenNo ratings yet

- Transmission 722.6 in Model 212: AR27.10-P-0500EW Remove/install Transmission With Torque Converter 09.09.2019Document6 pagesTransmission 722.6 in Model 212: AR27.10-P-0500EW Remove/install Transmission With Torque Converter 09.09.2019novanNo ratings yet

- Massey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)Document15 pagesMassey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)zhuangfuqian31No ratings yet

- Toyota Forklift 8FD2Document9 pagesToyota Forklift 8FD2Muh FarhanNo ratings yet

- 8FG25 8FD25: Main Vehicle SpecificationsDocument3 pages8FG25 8FD25: Main Vehicle SpecificationsNuñez JesusNo ratings yet

- Pages7-9 From TDS-10 Picture BookDocument3 pagesPages7-9 From TDS-10 Picture BookHayLenLeeNo ratings yet

- 04 RorDocument107 pages04 RorOleksandr U.No ratings yet

- Part Catalouge - Backhoe Loader EngineDocument271 pagesPart Catalouge - Backhoe Loader EngineLucas LancioniNo ratings yet

- A20/50 & A2550 TRACTOR Service Drawings & Parts List: JUNE 2008Document50 pagesA20/50 & A2550 TRACTOR Service Drawings & Parts List: JUNE 2008richard gordonNo ratings yet

- 9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryDocument2 pages9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryGarcia CruzNo ratings yet

- 9802/9730 F6-10-11 Transmission External Components 2Ws 4Wd 20KPH 449/11140Document2 pages9802/9730 F6-10-11 Transmission External Components 2Ws 4Wd 20KPH 449/11140Javid GuliyevNo ratings yet

- Rear DifferentialDocument15 pagesRear DifferentialCarlos VelázquezNo ratings yet

- Typefile 31740 20191031035647Document4 pagesTypefile 31740 20191031035647Lê KhoaNo ratings yet

- 54 Electrical, Equipment and InstrumentsDocument212 pages54 Electrical, Equipment and InstrumentsAjšaHadžikadunićNo ratings yet

- Preparation 2zr-Fbe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fbe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- 2 Bolts 3 Bolts 4 Rear Engine Mount: AS00.00-Z-0010-01ADocument1 page2 Bolts 3 Bolts 4 Rear Engine Mount: AS00.00-Z-0010-01AgzgwzdxggyNo ratings yet

- Т20 МатакDocument276 pagesТ20 МатакИсмаил100% (1)

- LHYMS30-4F190B-EPY2-80 Spec SheetDocument2 pagesLHYMS30-4F190B-EPY2-80 Spec SheetArielNo ratings yet

- Diferencial FUSODocument27 pagesDiferencial FUSOphinix.eirlNo ratings yet

- Propeller Shaft & Differential CarrierDocument11 pagesPropeller Shaft & Differential CarrierMikiboi LugueNo ratings yet

- mDRIVE - SPECIFICATIONSDocument7 pagesmDRIVE - SPECIFICATIONSvicente456No ratings yet

- Electric System MF5709Document65 pagesElectric System MF5709Fariqin MuhNo ratings yet

- Fuel Injection Pump Service Data: ID Code Issued DateDocument1 pageFuel Injection Pump Service Data: ID Code Issued Datealeksandr.pozdnyakof100% (1)

- Parts Book of ZE230E Hydraulic Crawler Excavator2Document200 pagesParts Book of ZE230E Hydraulic Crawler Excavator2Bruno Rodrigues100% (1)

- 09 Tightening Torques of Bolts & NutsDocument3 pages09 Tightening Torques of Bolts & NutstruryNo ratings yet

- Aumatic TransmissionDocument26 pagesAumatic TransmissionЮра ПетренкоNo ratings yet

- New 009 2012 HyDocument1 pageNew 009 2012 HyРома БлошенкоNo ratings yet

- 0.75kW - 1750rpmDocument1 page0.75kW - 1750rpmanush_swaminathanNo ratings yet

- Mill Accessories, Books, and Videos Price List: P/N Description WT Price P/N Description WT PriceDocument2 pagesMill Accessories, Books, and Videos Price List: P/N Description WT Price P/N Description WT PriceAnonymous hos8odNo ratings yet

- Basic Engine: 242-0674 CAMSHAFT GPDocument64 pagesBasic Engine: 242-0674 CAMSHAFT GPFabio MacielNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- kdw1603 2204t ServiceDocument108 pageskdw1603 2204t ServiceFranck MonnierNo ratings yet

- Studen Text - NewDocument264 pagesStuden Text - NewSSE Control MBNo ratings yet

- Exmark Lazer Z Operator ManualDocument68 pagesExmark Lazer Z Operator Manualgroomerz6612No ratings yet

- Cooling System Basics For Spark Ignition EnginesDocument5 pagesCooling System Basics For Spark Ignition EnginesCasey DavisNo ratings yet

- Electric Vehicles - The Need of The FutureDocument2 pagesElectric Vehicles - The Need of The Futurechirag100% (1)

- Powerplant EngineeringDocument29 pagesPowerplant Engineeringswechchha adhikariNo ratings yet

- Powerful Delivery: 250 Series Engine Family of Stationary GensetsDocument2 pagesPowerful Delivery: 250 Series Engine Family of Stationary Gensetsguichen wangNo ratings yet

- Briggs Stratton Small Gas Engine Service MaintenanceDocument7 pagesBriggs Stratton Small Gas Engine Service Maintenanceakommer100% (1)

- Event Codes - Low Coolant Level Shutdown (Error Code - 111) - Blog - TeknisiDocument6 pagesEvent Codes - Low Coolant Level Shutdown (Error Code - 111) - Blog - TeknisimkNo ratings yet

- En dx300lc 5 Brochure PDFDocument24 pagesEn dx300lc 5 Brochure PDFsaroniNo ratings yet

- Material Handling Specifi CationDocument8 pagesMaterial Handling Specifi CationTeknik MakinaNo ratings yet

- AutomobileDocument16 pagesAutomobilesingamNo ratings yet

- Stored Energy - Safety - Bulletin70Document3 pagesStored Energy - Safety - Bulletin70Giulio MencucciniNo ratings yet

- Instructions For Operating Diesel Engine GeneratorDocument3 pagesInstructions For Operating Diesel Engine GeneratorRizzdaron TikingNo ratings yet

- Kia September 2020 Price List: Picanto ProceedDocument2 pagesKia September 2020 Price List: Picanto ProceedCaminito MallorcaNo ratings yet

- Hyundai Porter II 2020 INTDocument13 pagesHyundai Porter II 2020 INTrjenderleonelNo ratings yet

- ATS - Komatsu PC78US-6Document2 pagesATS - Komatsu PC78US-6Gilnad WilsonNo ratings yet

- Universal Engines Fast Moving Parts ListsDocument21 pagesUniversal Engines Fast Moving Parts Liststarek ali ahmedNo ratings yet

- Mitsubishi Fuso FK 2008 Owner's ManualDocument355 pagesMitsubishi Fuso FK 2008 Owner's ManualDenmark Gallenero100% (2)

- CAT 428 3.6l WiringDocument33 pagesCAT 428 3.6l WiringDtl DiagNo ratings yet

- 08 Metro-4000-Spec-Sheet Tower LightDocument2 pages08 Metro-4000-Spec-Sheet Tower LightBilfinger EstimationNo ratings yet

- Manual de Partes D6R CaterpillarDocument894 pagesManual de Partes D6R CaterpillarJose luis VargasNo ratings yet

- Argumentative EssayDocument4 pagesArgumentative Essayvictorbernal7749No ratings yet

PDF TD 393 01 D TDI-En-0-TecDocPdfResource

PDF TD 393 01 D TDI-En-0-TecDocPdfResource

Uploaded by

ngochai150619910 ratings0% found this document useful (0 votes)

0 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views1 pagePDF TD 393 01 D TDI-En-0-TecDocPdfResource

PDF TD 393 01 D TDI-En-0-TecDocPdfResource

Uploaded by

ngochai15061991Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

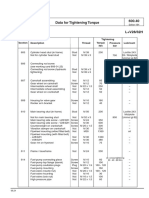

TECHNICAL DATA TYPE 393 5 TORQUES Thread Nm

5.1 Drive - Engine:

H 25D / H 30D / H 35D

Engine mounting to engine M8 23

1 SPEED SETTINGS min-1 min-1

Left, right, centre silentblocs to counterweight M 12 80

1.1 Engine (idle - driving) lower/upper 1000 2700 LH & RH engine mounting to spring element M 12 110

(idle - lifting) lower/upper 1000 2800

Engine mounting to intermediate flange M 16 195

1.2 Wheels forwards/reverse 180-20 180-20 Flywheel on engine M 10x1 95

2 PRESSURE SETTINGS bar bar Rod to centre spring element (forged rod) A 20 110

2.1 Tyre pressure front /rear Rod to centre spring element (welded rod) A 20 70

H 25/30/35 27x10-12/20 PR / 23x9-10/14 PR 10.0 7.0 Intermediate flange to engine M 12 80

250/75 R 12 / 225/75 R 10 10.0 7.0 Injection line union nuts 25

H 25/30/35 Twin 7.00-12/16 PR / 23x9-10/14 PR 7.5 7.0 Injector nozzle clamping bracket M8 20

7.00 R12 / 225/75 R10 7.5 7.0 Oil drain plug (with new oil seal) 30

2.2 Pressure relief valve Mast type 188 Standard Duplex/ 5.2 Drive - Gearbox:

on control unit Triplex Power unit HPV 75-02 to intermediate flange M 12 80

H 25 200+5 200+5 Adjuster to power unit (8.8) M 8 23

H 30 225+5 225+5 Adjuster to power unit (10.9) M 8 32

H 35 245+5 245+5 Gear pump to power unit M 10 65

2.3 Max. working pressure / Boost pressure 435+20 19+0,5 Slotted nut to wheel shaft (with Loctite Type 270) M 65x2 1300 ±50

Fixed displacement motor to axle housing M 12 110

2.4 Nozzle injection pressure/wear limit 220-10 200

Screw plug in fixed displacement motor cover M 14x1.5 25

3 SETTINGS mm

393 807 4001.1006

5.3 Drive - Gearbox:

3.1 Flyer chain, max. projection of lower guide roller Bearing halves to frame M 16 275

Fork carriage from inner channel 2 5 .0 Overhead guard to counterweight M 24 660

Counterweight to frame M 24 660

3.2 Double hose on mast (per referred metre) 5+5

5.4 Steering system and Wheels:

3.3 Lateral stop of drive axle 1.0 Steering axle to counterweight M 16 195

3.4 Slider in the sideshift (minimum) 2.5 Steering column to rotary valve M 10 46

4 FILLING QUANTITIES Litre Lubricant* Steering wheel 40 ±5

4.1 Hydraulic tank Lifting height to 5000 mm 24.0 Hydraulic oil King pin NM 18x1.5 290

Lifting height from 5000 mm to 6900 mm 25.5 Mounting of steer cylinder M 16x1.5 210

Lifting height from 6900 mm to 8000 mm 28.0 Wheel hub to steering knuckle VM 16x1.5 225

4.2 Hydraulic oil level difference between min. and max. Front wheel mounting M 14x1.5 170

all lifting heights 2.0 Hydraulic oil Rear wheel mounting A 18 460

4.3 Engine oil (diesel engine) 4.5 Engine oil 5.5 Hydraulic System:

4.4 Engine oil level difference between min. and max. 1.0 Engine oil Bypass valve HPV - locknut M 12 80

4.5 Fuel tank 40.0 Diesel Set screw M 12 20 + 5

4.6 Cooling system - 25° C with heater and air conditioning 11.0 Coolant Oil drain plug in hydraulic tank M 14x1.5 25

w/o heater u. air conditioning 9.0 G 12 5.6 Mast und tilt cylinders:

4.7 Air conditioning 1600 Refrigerant Mast to drive axle

Gram R 134 a First tightening / retightening torque (version I) top M 12 110/ --

4.8 Grease steer axle As Grease bottom M 16 275/ --

required First tightening / retightening torque (version. II) top M 12 110/ --

4.9 Flyer chain protection As Linde bottom M 20 385/ --

required chain spray Mounting of tilt cylinder front / rear M 16 275/275

* See recommended fuels and lubricants Clamping screw of eyebolt at tilt cylinder M 12 80

6 RECOMMENDED FUELS AND LUBRICANTS: 9 INSPECTION AND MAINTENANCE SCHEDULE

Engine oil - Oil change every 1000 service hours or 12 months Maintenance as required

- Clean the lift truck, clean and spray the lift chains

Longlife engine oils acc. to VW standard 506 00 and 506 01. - Clean the vent hose to the tank

These oils are only available in viscosity SAE 0W-30. - Replace the air filter safety element

The factory filling is a 1000-service-hour oil. - Check the dust discharge valve, clean the prefilter

Engine oil - Oil change every 500 service hours - Top up the washer system water tank

Engine oil acc. to VW standard 505 00 and. 505 01. - Drain the fuel filter, regenerate the soot filter

Engine oil for oil change every 300 service hours - Clean and check the radiator and hydraulic oil cooler for leaks

- Change the oil in the oil bath air cleaner

Also approved are engine oils of the quality class API CD or ACEA B2 / B3 and of - Tighten the wheel fasteners wheel fasteners (after each servicing or repair,

higher API-C or ACEA-B quality classes. every 100 hours minimum)

ATTENTION - Check the tyres for damage and foreign objects

When refilling oil, different types of oil can be mixed; in this case the lowest quality - Lubricate the steering axle bearings

oil determines the oil change interval. - Check the lap seat belt for condition and proper operation

Do not add additives of any kind to the lubricating oils. Only use oils with a low ash - Service the air conditioner

Maintenance every 500 to 1000 service hours* or every year

content for trucks equipped with soot filter system. - Change engine oil (at least once a year), replace engine oil filter (at least once a year)

Diesel fuel: Use only Diesel fuel to EN 590 with a cetane number not lower than - Check coolant concentration, hydraulic system: Check oil level

51. The sulphur content should not exceed 350mg/kg. If diesel fuel with a sulphur - Check correct operation of breather valve on the hydraulic oil tank

content higher than allowed by EN 590, the engine oil change intervals must be - Replace fuel filter

reduced as follows: - Check function of control unit

- Check the state of the ribbed V-belts

Change the engine oil every 300 service hours if the sulphur content is over 350 - Check the state of the toothed belt, check tension

mg/kg and under 2000 mg/kg. Change the engine oil every 150 service hours if the - Clean water and hydraulic oil cooler

sulphur content is over 2000 mg/kg. - Check the condition and secure positioning of electric cables, cable connectors

If the sulphur content of diesel fuel is higher than 350 mg/kg, an engine oil acc. to and connections

VW standard 505 00 / 505 01 / 506 01 must be used despite of reduced engine oil - Battery: Check condition, level and density of acid (even if battery is maintenance-free)

change intervals. - Replace the air filter cartridge, check the vacuum switch

- Check the condition of the engine mount and engine suspension; check that they

Hydraulic oil: Hydraulic oil recommendation for regular duty: Hydraulic oil are attached securely

ISO - L - HM 68 to ISO 6743 - 4 to. HLP ISO VG 68 to DIN 51524, T.2 (factory - Check suction and exhaust leads for leaks

filling) average oil temperature 60-80° C. Hydraulic oil recommendation for heavy - Check hydraulic system for leaks

duty: Hydraulic oil ISO - L - HM 100 to ISO 6743 - 4 and HLP ISO VG 100 to DIN - Check how securely the frame, tilt cylinder und steering axle are attached

- Check the security of the axle clamps and drive motors

51524, T.2 for heavy and multi-shift duty, operation in warm climate zones or at high - Check the side stops on the drive axle

ambient temperatures, average continuous oil temperature over 80° C. Hydraulic oil - Check pedals and oil them if necessary, check the soot filter system

recommendation for regular and heavy duty: Hydraulic oil ISO - L - HV 68 to - Check other bearings and joints and oil

ISO 6743 - 4 and HVLP ISO VG 68 to DIN 51524, T.3 (multigrade oil). - Clean the steering axle, grease it

Grease: Linde heavy duty grease with a lithium base and EP additives and MOS2. - Sideshift: Clean and grease, check fastening

Designation to DIN 51825-KPF2N-20. Do not mix with other than lithium base - Clean and grease the fork arm adjustment device, checkfastening

- Check fork arms and arm safety devices

greases. - Lift mast chain, lift cylinders and end stops: check condition, secure fastening

Coolant: Use only coolant G12 A8D to VW specification TL-VW 774D (factory and function

filling) or G 12 A8F to VW specification TL-VW- 774F. - Adjust lift mast chain, apply chain spray to it

Refrigerant for air conditioning: R 134 a - Check the operation of the parking brake

Chain spray: Linde chain spray - Check the fastening on the steering cylinder and axle stub bolt

7 INITIAL OPERATION - Check the pre-tension of the double tubes

- Clean the oil bath air filter

- Check the engine oil level, check the hydraulic oil level, refuelling Maintenance every 3000 service hours or every 2 years

- Check the coolant level in the expansion reservoir, - Change feed / pressure / suction filter and breather of hydraulic system

- Check condition, electrolyte level and acid density of the battery - Change ribbed V-belt

- Tighten the wheel nuts, check the tyre inflation pressure - Change safety cartridge of air filter

- Check the braking and steering system, check the lifting device and attachments - Check tilt cylinder bearing for wear

- Regenerate the soot filter, check the third auxiliary hydraulic function and safety - Check drive axle bearing for wear

- Hydraulic pump on engine: check fastening

system - Change toothed belt and tension pulley (at latest after 5 years)

8 SERVICING AFTER THE FIRST 50 SERVICE HOURS - Check slide guides on sideshift for wear

- Check the parking brake for proper operation, tighten the wheel fasteners - Check fork arm adjustment device for wear and tear

- Check the hydraulic system, drive motors, hydraulic pumps and lines for leaks Maintenance every 6000 service hours or every 3 years

(visual inspection),drain water from the fuel filter - Renew the hydraulic oil

- Check the mast, lift chain, lift cylinders and stops for condition, security and Maintenance every 9000 service hours or every 4 years

- Renew the water pump, renew the G 12 coolant

proper operation

- Clean, adjust and lubricate the lift chain with chain spray * Depending on driving style and duty conditions, also see the fuel and lubricant

- Check electric cables and connections for condition and security recommendations.

You might also like

- 6f35 Rebuild ManualDocument48 pages6f35 Rebuild ManualBossing Vic100% (5)

- HOBART CHAMPION 10,000 t945f - Hob PDFDocument116 pagesHOBART CHAMPION 10,000 t945f - Hob PDFjuan felipe alzate aristizabal100% (3)

- Peugeot Partner 1.6 M59 Flex Spare Parts CatalogDocument244 pagesPeugeot Partner 1.6 M59 Flex Spare Parts CatalogRicardo Vilhena100% (1)

- Parts Catalog For ZS1100 Engine: Cylinder Block AssemblyDocument22 pagesParts Catalog For ZS1100 Engine: Cylinder Block AssemblyWidi Prasetyo100% (5)

- Engine 2.0D-VGT (Chevrolet Captiva '06-'10) Service IntroDocument61 pagesEngine 2.0D-VGT (Chevrolet Captiva '06-'10) Service IntroDangLuyen100% (5)

- Transfer Case Disassembly and AssemblyDocument22 pagesTransfer Case Disassembly and AssemblyBasilio BancurNo ratings yet

- R 70 Technical Data.: Diesel and LP Gas Forklift TrucksDocument6 pagesR 70 Technical Data.: Diesel and LP Gas Forklift TrucksKiều Văn TrungNo ratings yet

- Trio CT3042S Jaw Crusher Parts Manual (SN. 262, 279, 284, 285)Document20 pagesTrio CT3042S Jaw Crusher Parts Manual (SN. 262, 279, 284, 285)GUILLERMO OSIMANI100% (3)

- mtx75 Manual TransmissionDocument243 pagesmtx75 Manual Transmissionalfie apolinario100% (4)

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- MAN EDC7 Common Rail D0836LFDocument8 pagesMAN EDC7 Common Rail D0836LFMircea Gilca100% (3)

- Briggs & Stratton Owners ManualDocument20 pagesBriggs & Stratton Owners ManualgyrfalconNo ratings yet

- A13、A13A ServiceManual PDFDocument1,333 pagesA13、A13A ServiceManual PDFmultiservicios100% (1)

- PDF TD 394 01 D TDI-En-0-TecDocPdfResourceDocument1 pagePDF TD 394 01 D TDI-En-0-TecDocPdfResourcengochai15061991No ratings yet

- Product Datasheet: HelicalbevelgearedDocument7 pagesProduct Datasheet: Helicalbevelgeared손선호No ratings yet

- MAN Diesel & Turbo 600.40 L+V28/32H Data For Tightening TorqueDocument1 pageMAN Diesel & Turbo 600.40 L+V28/32H Data For Tightening TorqueAntonioNo ratings yet

- Technische Fiche Homa TP53M262 D Nieuw 2014Document3 pagesTechnische Fiche Homa TP53M262 D Nieuw 2014Marnix VanbavinckhoveNo ratings yet

- Bevel Gear DatasheetDocument7 pagesBevel Gear Datasheetmohammad khoraminiaNo ratings yet

- Catalogue GSPDocument1,311 pagesCatalogue GSPahmed gtoNo ratings yet

- Heli Parts Manual For ATM H2000 4-5T (Outer Pump)Document16 pagesHeli Parts Manual For ATM H2000 4-5T (Outer Pump)Петр100% (1)

- 307-01 Automatic Transmission 10 Speed - Overhaul - TransmissionDocument183 pages307-01 Automatic Transmission 10 Speed - Overhaul - Transmissionpxg8zdd7grNo ratings yet

- Maximal+Engine+FL (2.0 3.5D-7SA)Document59 pagesMaximal+Engine+FL (2.0 3.5D-7SA)Renato SanchezNo ratings yet

- A4af2 A4af3Document120 pagesA4af2 A4af3Jordan SanchezNo ratings yet

- Tightening TorqueDocument8 pagesTightening TorqueGaurav MaithilNo ratings yet

- Drive Pinion and Hollow Shaft, Disassembling and Assembling: Special Tools, Testers and Auxiliary Items RequiredDocument21 pagesDrive Pinion and Hollow Shaft, Disassembling and Assembling: Special Tools, Testers and Auxiliary Items RequiredTIGANA 15No ratings yet

- 115 01 TD 0906 GBDocument2 pages115 01 TD 0906 GBLada LabusNo ratings yet

- enDocument1,513 pagesen9876460990No ratings yet

- enDocument1,401 pagesenLuis Alberto Rivas GarciaNo ratings yet

- New 010 2012 HyDocument1 pageNew 010 2012 HyРома БлошенкоNo ratings yet

- SST and SSM Land Crusier J80Document11 pagesSST and SSM Land Crusier J80limadacarlosNo ratings yet

- SST and SSM: SST (Special Service Tools) C-2 SSM (Special Service Materials) C-11Document11 pagesSST and SSM: SST (Special Service Tools) C-2 SSM (Special Service Materials) C-11Zeami Abel Pérez CantilloNo ratings yet

- Data For Tightening Torque: LubricantDocument5 pagesData For Tightening Torque: LubricantAtanasio PerezNo ratings yet

- 20 Cooling - Unimog 435 Workshop ManualDocument20 pages20 Cooling - Unimog 435 Workshop ManualJuan JapNo ratings yet

- Echnical Information: Oncept and Main ApplicationsDocument6 pagesEchnical Information: Oncept and Main ApplicationsKakoy Lagusan EcobenNo ratings yet

- Transmission 722.6 in Model 212: AR27.10-P-0500EW Remove/install Transmission With Torque Converter 09.09.2019Document6 pagesTransmission 722.6 in Model 212: AR27.10-P-0500EW Remove/install Transmission With Torque Converter 09.09.2019novanNo ratings yet

- Massey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)Document15 pagesMassey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)zhuangfuqian31No ratings yet

- Toyota Forklift 8FD2Document9 pagesToyota Forklift 8FD2Muh FarhanNo ratings yet

- 8FG25 8FD25: Main Vehicle SpecificationsDocument3 pages8FG25 8FD25: Main Vehicle SpecificationsNuñez JesusNo ratings yet

- Pages7-9 From TDS-10 Picture BookDocument3 pagesPages7-9 From TDS-10 Picture BookHayLenLeeNo ratings yet

- 04 RorDocument107 pages04 RorOleksandr U.No ratings yet

- Part Catalouge - Backhoe Loader EngineDocument271 pagesPart Catalouge - Backhoe Loader EngineLucas LancioniNo ratings yet

- A20/50 & A2550 TRACTOR Service Drawings & Parts List: JUNE 2008Document50 pagesA20/50 & A2550 TRACTOR Service Drawings & Parts List: JUNE 2008richard gordonNo ratings yet

- 9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryDocument2 pages9802/6220 D1-3-1 Control, Foot Excavator AuxiliaryGarcia CruzNo ratings yet

- 9802/9730 F6-10-11 Transmission External Components 2Ws 4Wd 20KPH 449/11140Document2 pages9802/9730 F6-10-11 Transmission External Components 2Ws 4Wd 20KPH 449/11140Javid GuliyevNo ratings yet

- Rear DifferentialDocument15 pagesRear DifferentialCarlos VelázquezNo ratings yet

- Typefile 31740 20191031035647Document4 pagesTypefile 31740 20191031035647Lê KhoaNo ratings yet

- 54 Electrical, Equipment and InstrumentsDocument212 pages54 Electrical, Equipment and InstrumentsAjšaHadžikadunićNo ratings yet

- Preparation 2zr-Fbe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fbe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- 2 Bolts 3 Bolts 4 Rear Engine Mount: AS00.00-Z-0010-01ADocument1 page2 Bolts 3 Bolts 4 Rear Engine Mount: AS00.00-Z-0010-01AgzgwzdxggyNo ratings yet

- Т20 МатакDocument276 pagesТ20 МатакИсмаил100% (1)

- LHYMS30-4F190B-EPY2-80 Spec SheetDocument2 pagesLHYMS30-4F190B-EPY2-80 Spec SheetArielNo ratings yet

- Diferencial FUSODocument27 pagesDiferencial FUSOphinix.eirlNo ratings yet

- Propeller Shaft & Differential CarrierDocument11 pagesPropeller Shaft & Differential CarrierMikiboi LugueNo ratings yet

- mDRIVE - SPECIFICATIONSDocument7 pagesmDRIVE - SPECIFICATIONSvicente456No ratings yet

- Electric System MF5709Document65 pagesElectric System MF5709Fariqin MuhNo ratings yet

- Fuel Injection Pump Service Data: ID Code Issued DateDocument1 pageFuel Injection Pump Service Data: ID Code Issued Datealeksandr.pozdnyakof100% (1)

- Parts Book of ZE230E Hydraulic Crawler Excavator2Document200 pagesParts Book of ZE230E Hydraulic Crawler Excavator2Bruno Rodrigues100% (1)

- 09 Tightening Torques of Bolts & NutsDocument3 pages09 Tightening Torques of Bolts & NutstruryNo ratings yet

- Aumatic TransmissionDocument26 pagesAumatic TransmissionЮра ПетренкоNo ratings yet

- New 009 2012 HyDocument1 pageNew 009 2012 HyРома БлошенкоNo ratings yet

- 0.75kW - 1750rpmDocument1 page0.75kW - 1750rpmanush_swaminathanNo ratings yet

- Mill Accessories, Books, and Videos Price List: P/N Description WT Price P/N Description WT PriceDocument2 pagesMill Accessories, Books, and Videos Price List: P/N Description WT Price P/N Description WT PriceAnonymous hos8odNo ratings yet

- Basic Engine: 242-0674 CAMSHAFT GPDocument64 pagesBasic Engine: 242-0674 CAMSHAFT GPFabio MacielNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- kdw1603 2204t ServiceDocument108 pageskdw1603 2204t ServiceFranck MonnierNo ratings yet

- Studen Text - NewDocument264 pagesStuden Text - NewSSE Control MBNo ratings yet

- Exmark Lazer Z Operator ManualDocument68 pagesExmark Lazer Z Operator Manualgroomerz6612No ratings yet

- Cooling System Basics For Spark Ignition EnginesDocument5 pagesCooling System Basics For Spark Ignition EnginesCasey DavisNo ratings yet

- Electric Vehicles - The Need of The FutureDocument2 pagesElectric Vehicles - The Need of The Futurechirag100% (1)

- Powerplant EngineeringDocument29 pagesPowerplant Engineeringswechchha adhikariNo ratings yet

- Powerful Delivery: 250 Series Engine Family of Stationary GensetsDocument2 pagesPowerful Delivery: 250 Series Engine Family of Stationary Gensetsguichen wangNo ratings yet

- Briggs Stratton Small Gas Engine Service MaintenanceDocument7 pagesBriggs Stratton Small Gas Engine Service Maintenanceakommer100% (1)

- Event Codes - Low Coolant Level Shutdown (Error Code - 111) - Blog - TeknisiDocument6 pagesEvent Codes - Low Coolant Level Shutdown (Error Code - 111) - Blog - TeknisimkNo ratings yet

- En dx300lc 5 Brochure PDFDocument24 pagesEn dx300lc 5 Brochure PDFsaroniNo ratings yet

- Material Handling Specifi CationDocument8 pagesMaterial Handling Specifi CationTeknik MakinaNo ratings yet

- AutomobileDocument16 pagesAutomobilesingamNo ratings yet

- Stored Energy - Safety - Bulletin70Document3 pagesStored Energy - Safety - Bulletin70Giulio MencucciniNo ratings yet

- Instructions For Operating Diesel Engine GeneratorDocument3 pagesInstructions For Operating Diesel Engine GeneratorRizzdaron TikingNo ratings yet

- Kia September 2020 Price List: Picanto ProceedDocument2 pagesKia September 2020 Price List: Picanto ProceedCaminito MallorcaNo ratings yet

- Hyundai Porter II 2020 INTDocument13 pagesHyundai Porter II 2020 INTrjenderleonelNo ratings yet

- ATS - Komatsu PC78US-6Document2 pagesATS - Komatsu PC78US-6Gilnad WilsonNo ratings yet

- Universal Engines Fast Moving Parts ListsDocument21 pagesUniversal Engines Fast Moving Parts Liststarek ali ahmedNo ratings yet

- Mitsubishi Fuso FK 2008 Owner's ManualDocument355 pagesMitsubishi Fuso FK 2008 Owner's ManualDenmark Gallenero100% (2)

- CAT 428 3.6l WiringDocument33 pagesCAT 428 3.6l WiringDtl DiagNo ratings yet

- 08 Metro-4000-Spec-Sheet Tower LightDocument2 pages08 Metro-4000-Spec-Sheet Tower LightBilfinger EstimationNo ratings yet

- Manual de Partes D6R CaterpillarDocument894 pagesManual de Partes D6R CaterpillarJose luis VargasNo ratings yet

- Argumentative EssayDocument4 pagesArgumentative Essayvictorbernal7749No ratings yet