Professional Documents

Culture Documents

General Risk Assessment

General Risk Assessment

Uploaded by

siame festusCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Risk Assessment

General Risk Assessment

Uploaded by

siame festusCopyright:

Available Formats

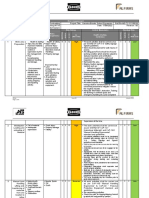

COMPANY NAME (XYZ) General Risk assessment – activity based – Risk Profiling

Company/

Last Review Date:

30th Jan 2024

Department: HSE Department

Prepared by: Reviewed and approved by:

Next Review Date:

30thJuly 2024

Work Initial Risk Residual

No. * Risks Additional Risk Control

Activity/Hazards Level Risk Level

- Obtain PTW when working on any

- system/equipment where there is a hydrogen

- Displace air in a poorly ventilated or

- Before doing anything use a hydrogen detector to

confined space, resulting in asphyxiation.

see if the hydrogen level is inacceptable level

- flammability and the

- Ensure there is MSDA of hydrogen and everyone

possibility of burns resulting from fires and

Activities Involve is understood on the Hydrogen risks and

explosions (At atmospheric pressure, Medium

Hydrogen Gas precautions and properties of hydrogen Low Risk

1 hydrogen is combustible at Risk - Hydrogen gas cylinders must be separated from 3X4= 12

concentrations from 4% to 74.2% by 4X5 = 20 oxidizing gases during storage

volume) - Always ensure that there is adequate ventilation

- When working with liquid hydrogen, there to handle the largest anticipated hydrogen leaks

is an additional health hazard of cryogenic or spills (Ventilation with large quantities of air

burns. will dilute small hydrogen leaks to below the

lower flammable limit of 4% in air)

Exposure to radiation which may cause a - Make sure to establish the communication

Plantt 1- serious health issue to COMPANY NAME protocol between the construction and

High Risk Medium

2 Combined Cycle (XYZ) employees such as Radiation can COMPANY NAME (XYZ) team as before RT

4X4 = 16 Risk

Radiographic tests damage the DNA in our cells, High doses of conduct then shall send an email to COMPANY

4X2 = 8

(RT) radiation can cause Acute Radiation Syndrome NAME (XYZ) teams and mention the time of RT,

(ARS) or Cutaneous Radiation Injuries (CRI). Red zone of radiation, affected area and safe

High doses of radiation could also lead to zone.

cancer later in life. - Provide the Radiation meters to COMPANY

NAME (XYZ) teams to be used while RT in

ongoing in order to make sure the operational

side is safe.

- Safety signs shall be provided and affected area

shall be barricaded

Watchman shall be provided

• Being new to the workplace, young people

will encounter unfamiliar risks from the work - Provide the Plant basic HSE trainings which

they perform and from interacting with the include Plant safety risks, Manual handling

working environment. training, working at heights, electrical safety,

• Common types of occupational accidents Emergency response, etc.

for young people include being struck by a - Provide the comprehensive HSE induction to all

3 Young employees moving vehicle, injuries due to incorrect High Risk - Deliver technical training to them in order to make Low Risk

been hired manual handling procedures, slips, trips 4x4 sure they are technically informed on the 2x3=6

and falls-related injuries, injuries from systems.

electrical equipment, machinery related - Close Monitor on them while they are onsite for a

injuries and injuries due to exposure/use of while till the familiar with the risks and

harmful chemicals/substances. precautions.

- Crane collapse or lifting gears rupture - Any Work in COMPANY NAME (XYZ) shall be

- Fall in the pit / trench under COMPANY NAME (XYZ) PTW system in

Combined Cycle

- Physical injury / permanent disability / fatal order to make sure it is controlled and safe to all

Construction

to human - HSE Inductions and training giving to the EPC

activities such as

4 - Electrical shock, electrocution and ARC High Risk contractor personnel

Lifting, Evacuation, 110

flash 4X4 = 16 - Ensure all the electrical systems are isolated and

Hot works, any

- Damage to underground / aboveground under PTW and LOTO while working on the

other activities that

Services (such pipeline, cables etc) systems

affect

- Fire - Inspection for soil condition before starting

- Blocking Emergency Equipment excavation work

Page | 2 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Isolate services as needed through authorized

permit.

- Keep excavated material at least 1 meter away

from the edge of the trench.

- Ensure the approach to Emergency Equipment is

not blocked due to open trenches.

- Close Monitor shall be done

- EPC Contractor to provide their HSE officers

- Carry out gas test before excavating in

hazardous area.

- Removing all disposable materials

- Proper barricading the excavated area

Carry out equipment pre-operation safety

inspection; Survey the working area for unstable

ground, and using rubber mat for protecting the

concrete and ground

- Pre-use inspection.

- Leaking cylinders

Medium - Ensure cylinders are secured.

3 Oxy-acetylene - Fire Low Risk

Risk - Use flashback arrestor.

cutting. - Dropped cylinders 1X2 = 2

3X4 = 12 - All gas cylinders received at site are checked for

- Air pollution

their hydro-test validity before putting to use

- Make sure the activities is under PTW and this

activity will be communicated with all teams before

- Exposure to high noise

Conduct air blow commence.

4 - Exposure to flying object materials High Risk

out in the project - Affected area will be barricaded and signs been put 2x4=8

- Vibrations 4X5 = 20

side in place.

- Personnel injury due to connect rapture

- Ear muffs and ear plugs to be provided to all teams

- Ensure no personnel near by

Grinding activities - Cracked disc - Inspect grinding disc, must be compatible RPM and

5 - Incompatible RPM of disc and grinder. High Risk no damage. Low Risk

- Flying object 4X4 = 16 - Ensure disc guard are fitted correctly and not loose. 2X3 = 6

- Removed disc guard - Support the grinder with both hands using side

Page | 3 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Abrasion cuts. handle.

- Electric shock - Hold the work piece with bench clamp.

- Risk of injury to other workers - Put on safety gears; full-faced shield, safety glass,

hearing protection, and hand protection.

- Use arc shielding and direct grinding spark away

from people and equipment at risk.

- Perform flammable gas detection, if required.

- Examine all electrical cables, welding cables and

machine accessories are free from defects.

- Isolate ignitable materials.

- Electric shock - Provide shielding of machineries or equipment at

- Fire Hazard Medium

High Risk fire risk, and potential insert of welding stubs.

6 Welding Activities - Welding rods / stubs Risk

- Health issues. exposure to fumes 3X4 = 12 - Spark containment; use fire blanket.

3X3 = 9

- Welders should be equipped with welding butt’s

container.

- Use of appropriate PPE.

- Check workplace for fire risk.

- Make sure the cylinder is equipped with the

correct regulator

- Gas cylinders must be secured at all times to

- Fire / explosion

prevent tipping

Storage and use of - Physical injury / fatal to human Medium

High Risk - Only properly trained personal should handle

6 any kind of - Exposure to gases Risk

5X4 = 20 compressed gas cylinders

cylinders - Suffocation 3X4 = 12

- Do not refill a cylinder; mixing of residual gases

- Air pollution

in a confined area

- All gas cylinders received at site are checked for

their hydro-test validity before putting to use

- Oiling and - Contact with lubricant

greasing of - Irritation Medium - Using properly PPE

7 Low Risk

equipment / - Land / water pollution Risk - Separate and keeping the waste inside

2X3 = 6

pumps / 3X4 = 12 hazardous bin

motors

Page | 4 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Hazardous

Waste

- Accident/ injury to operator, other workers - Inspect the forklift before operation, do not

- Damage to the plant & equipment operate with defects

- Falling materials/Env. aspects - Only qualified and authorized operator familiar

with the forklift safe operating instruction

- Keep all parts and safety devices in working

condition; Completely stop before changing

direction

8 High Risk - Never attempt to lift anyone on the forks; Slow Low Risk

Fork lift Operation

3X5 = 15 down at intersection; No sudden change of 3X2 = 6

direction

- Drive slowly in an area that could possibly

damage loads and goods in its path

- Ensure that no one is standing in the ‘accident

prone zone’, frequently sound the horn

- Park with forks seated flat on the ground; Use all

the safety equipment that are provided.

Medium

- Injuries, - Carry out equipment pre-operation safety Medium

9 Cranes/Mobile Risk

- fatalities and inspection; Survey the working area for unstable Risk

Lifting Equipment 4X4 = 16

- costly damage to buildings and materials ground 4X2 = 8

Maintenance of - physical injury/ Medium

10 - performing Isolation Low Risk

transformer, cut and wound Risk

- maintenance work performing by trained person 2X2 = 4

Compressor - fall and slip 4X3 = 12

- Equipment and tools safety checks

- Use cable drum jack fit for the purpose and of

- Physical injury Medium suitable capacity and base; Teamwork must be

11 Low Risk

Cable pulling - Solid waste generation Risk followed

2X2 = 4

4X3 = 12 - No pulling cable in fast mode; Crews should have

cable pulling and laying technique training

- Stay away from the line of fire, do not stand or sit

Page | 5 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

on cable.

- Switching ON

/ OFF of

various

switches,

- RCD protection installed to prevent electric

Spark due to - Faulty electrical equipment/Faulty

shock; Earthing of electrical equipment

lose fittings connections

- Test equipment to detect current; Lock Out / Tag

- Transformer - Electric shock Medium

12 High Risk Out equipment prior to starting work; Use PPE

Operation - Electrical arc flash Risk

5X4 = 20 - Use of non-conductive hand gloves.

- Maintenance / - Fatal to human 3X3 = 9

- Electrification is checked periodically and

Operation - Physical injury

damaged electrical parts are replaced

electrical - Damage to property

immediately

Panels

- Activity inside

SWY, Load

centre, 6.6 kv

- sprains and strains

- Manual Medium

13 - back injuries - Do not hand carry over your handling capacity; Low Risk

handling/Incor Risk

- chronic pain Use correct lifting technique; Use of lifting device 3X3 = 6

rect lifting 3X4 = 12

- Waste generation

- Adequate PPE is used by employees

- Loading / - Taking beak during work time

unloading of Medium - Earthing provision

14 - Contact with human Irritation / burns Low Risk

liquid Risk - Availability of fire watchman

- Exposure to human Suffocation dizziness 3X3 = 6

materials from 3X4 = 12 - The vehicles don’t start when unloading activity is

the tanks going on

- PTW issuing

Page | 6 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Any person working above 1.5 m height shall be

considered as working at height.

- Ensure all personnel assigned to work at height

are not afraid of height and medically fit for height

works.

- Work shall not be allowed to be carried out

standing over wooden boxes; empty barrels and

- Fall from height. other make shift arrangements.

- Unsafe working platforms and working - In case of any practical difficulties to provide Medium

15 Working at High Risk

conditions. proper working platform, safety harness shall be Risk

heights. 4X4 = 16

- Unsafe access / egress. installed and used. 3X9 = 9

- Hit by the structure. - For small openings floor covers shall be provided

with adequate strength.

- Stop work at height in high wind velocity.

- Homemade ladders not to be used; Ladders with

broken rug not to be used; Placement of ladder to

be in proper securing position. Secured against

falling; use correct type of ladder for the kind of

working condition

Scaffold - Only competent scaffolders to erect scaffold.

- Inspection of scaffold and tagging by competent

- Defective ladders / incomplete scaffold

scaffold inspector.

- Overloading, unstable scaffold.

- Risk of fall from scaffold. - Always hook-up 100%.

Painting: use Medium

16 - Use of appropriate respiratory and hand protection. Low Risk

of supported Risk

Paint vapor - Wash and clean thoroughly hands before handling 2X1 = 2

scaffold. 3X4 = 12

foods.

- Toxicity, flammability and health hazards - Use hand soaps, do not use paint thinner or

- Risk of fire

kerosene.

- Respiratory sickness

- Hazardous waste generation - Separate waste and labelling

Page | 7 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Confined - Know the hazards inside confined space; Apply

- Oxygen deficiency / Toxic gas exposure

space entry permit to work

- Fatal to human / suffocation / dizziness /

- Entry for - Provide ventilation to dilute or remove flammable Medium

17 Injury High Risk

maintenance gas or vapour; Apply safe work practices Risk

- Electrical shocks 4X4 = 16

work in - Giving orientation to persons about using SCBA 3X3 = 9

- Excessive heat

vessels / tanks and gas detectors.

/ reactor - Provide a proper fan when required.

- Possibility of toxic / flammable gas - Inspection for soil condition before starting

- Fall in the pit / trench excavation work

- Physical injury / permanent disability / fatal - Isolate services as needed through authorized

to human permit.

- Damage to underground / aboveground - Keep excavated material at least 1 meter away

18 High Risk Low Risk

Excavation Services (such pipeline, cables etc) from the edge of the trench.

4X4 = 16 2X2 = 4

- Blocking Emergency Equipment - Ensure the approach to Emergency Equipment is

- Land/water pollution not blocked due to open trenches.

- Carry out gas test before excavating in

hazardous area.

- Removing all disposable materials

Ground

Works: - Obstructed Access

Medium - Obtain PTW; STARRT

Material - Manual handling

19 Risk - - Competent / trained steel erectors. Low Risk

handling, - Pinch point

3X4 = 12 - - Use mechanical means. 2X1 = 2

storage, and - Displaced / fall of stack materials

- - Seek help, if overweight.

setting - Crushed extremities

equipment.

- Store paints at ventilated space, and

- Safekeeping of tools and equipment. - Keep paints away from source of ignition.

Housekeeping Medium

- Hazardous Waste - Keep work areas clean and orderly and in a Low Risk

20 / Work Risk

- Contaminated paint containers, brush, paint sanitary condition. 1X2 = 2

completion 2X4 = 8

liners. - Collect waste at each working day, dispose at

appropriate bin.

Page | 8 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Review each system LOTO map.

Survey /

- Overlooked isolation point. Medium - Ensure correct isolation point.

21 mapping of Low Risk

- Stored energy, can cause harm. Risk - Ensure padlock number and Tag is not swap

GT system for 1X2 = 2

- Tags removed; padlock disengaged. 3X3 = 9 over.

LOTO

- Use suitable cable tie.

- Conveyors

- Power transmission

lock out and - Inform affected parties before commencing Medium

22 - Electric shock High Risk

tag out. isolations. Risk

- Incorrect isolation or placement of LOTO. 4X4= 16

- De-isolate the - ISO 14121 hazard measures 3X3 = 9

-

equipment

- Mechanical: Shaft,

- Sprocket wheel, pulley, chain, driving belt, - Skilled workers

Clean end gear. - Replace idlers with skids or slider bed

Medium Low Risk

23 chutes, belts, - Entrainment - Use fixed enclosing guard or impending device to

Risk 1X2 = 2

pulleys, chain, - Crushing limit immediate access to hazard zone

3X4 =12

gears. - Entrapment - Safeguarding zone by zone

- Pinching, abrasion between belt and - Distant workers from hazards

pulley.

- Be aware of pinch points.

- Inadvertent moving components or sub-

- Ensure equipment correctly isolated as before

Using cold assemblies Medium

commencing. Low Risk

24 tools, remove - Flying object Risk

- Use tool made of tempered steel. 1X2 = 2

end guarding. - Sharp edges, pointed ends 3X3 = 9

- Use correct tools for task.

- Crushing, abrasion, pinching.

- Use impending device

Checking /

breaking the - Always leave one nut.

lines; - Trapped air. Medium - Use correct size spanners.

25 Low Risk

Dismantling - Wrong size spanners, can cause damage. Risk - Due care in opening closing No over forced pry

1X2 = 2

burners, TP, - Hammering 3X4 = 12 open.

liners, spark - Use rubber hammer.

plugs, etc…

Page | 9 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

Installing / and

- Head bump, Pinch point

reinstalling;

- Hot works. Medium - Be aware of head bumps, and pinch points.

26 burners, Low Risk

- Rust powder Risk - Perform by two people for handling larger load.

liners, spark 1X2 = 2

- Eye injury and respiratory illness. 3X4 = 12 - Wear adequate eye and respiratory protection

plugs, TP,

- Solid waste generation

etc…

- Provide suitable length of rope to reach workers with

- Work adjacent to pedestrian corridor.

floating device.

Removing *Struck by

- Install traffic control device to keep distance from

water from - Other mobile equipment.

27 High Risk other vehicles and pedestrians. Low Risk

settlement * Collision.

4X4 = 16 - Pre-operation inspection. 1X2 = 2

pond; using - Vacuum truck failure

- Operator standby watching siphoning operation.

vacuum truck. - Release or failure of hose connections

- Confirm all hoses connections are intact, use tag

- Env. pollution

line between joints.

- Obtain PTW, STARRT

Handling of

- Manual handling of heavy load. - Experienced / skilled workers

equipment,

- Crushing due to impact. Medium - Use mechanical means.

and Pumping Low Risk

28 - Acute trauma such as cuts or fractures. Risk - Avoid lifting or pushing loads that require excessive

out water from 2X1 = 2

- MSI such as muscle strain and sprain. 3X4 = 12 force.

evaporation

- Sludge spillage - Ensure water Ph is allowable for discharge.

pond.

- Correct body positioning to avoid struck by.

- Take due care walking on the slopes and muddy

- Working and walking surface

surface.

Removing sludge; - Slip and fall on muddy floor surface.

- Use long-handle shovel to nudge sludge from the

Cleaning slopes - Slip while climbing or descending slope.

slope. Medium

29 and concrete floor - Health hazards High Risk

- Wear proper footwear for better traction on slippery Risk

- Diseases caused by water related vector- 4X4 = 16

surfaces. 2X4 = 8

Final wash borne contaminants like asthma, bronchitis.

- Avoid skin contact to pond mud and water.

over - Sludge spillage

- Use hand protection and rubber boots.

- Land/water pollution

Wash hands and body thoroughly after work.

Page | 10 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Get PTW from Bezhan refinery to dispose mixed

sludge and water.

Medium

30 Transport and - Be careful in approaching disposal pit. Low Risk

Environmental Harm Risk

disposal of waste - Clean up truck in designated wash station. 1X2 = 2

2X4 = 8

- Ensure all wheels are free of dirt and mud.

- Traffic instruction and directions to operator.

Housekeeping - Maintaining foot walks on walking surface

Medium - Wear proper footwear for better traction on slippery

31 - Slip and fall on grating stair and floor. Low Risk

Risk surfaces.

Handover physical - Hand injuries while gathering and removing 1X2 = 2

2X4= 8 - Avoid crossover walking on laid hose.

inspection debris to keep the pond orderly.

- Electrical shock

- Check voltage/ read manual for electrical pump

Filling and washing - Exposure to Chemical Agents

Medium - Wearing PPE / consulting MSDS / Using mask

32 tanks - ergonomic risk/ back pain Low Risk

Risk suitable to chemicals

- Intoxication / Eye irritation 2X2 = 4

3X3= 9 - Taking care about the hazardous waste

- Sludge/solid/ chemical waste generation

separate/labelling

- Land/Water pollution

Page | 11 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

WTP operation;

- Working with

Chemicals

- Working at

height

- Working - burns skin and eyes affect / breathing

Electrical vapers

pump - Falling at height - Wearing suitable of PPE (Harness, Mask/respirator,

- Slippery place - Electrical shock Cover all, Glove, Glass) / consulting MSDS

- Working in - Slip/trip - Authorized person allows to work with electrical Medium

33 - damage to ear High Risk

noisy place pumps. Risk

- Fatigue / stress 4X4 = 16

- leaking at - Cover arms and neck and limit exposure time. Wear 3X4 = 12

chemical lines - Risk to explosion protective eyewear and gloves.

- UV lamps - Exposure, Radiation - Hazardous waste separation and labelling

- Inspections - Land/water pollution

and following

maintenance

activities

- Solid/chemical

hazardous

waste

generation

Page | 12 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- should be handled only by chemists with the

knowledge and skills to work with them safely.

Analysis of - Wearing suitable PPE / consulting MSDS / Use

- irritate or even burn the eyes, irritate the

laboratory; skin, and cause respiratory distress- mask, glasses and clothes suitable to chemicals

- Corrosives - The temperature of the lab. Should low and stable

34 High Risk Low Risk

- Handling - Flammable/Combustible/ Fire risk - Never use any type of open flame or any source of

4X4 = 16 2X2 = 4

Chemicals - Electrical Hazards ignition around flammable chemicals.

- Working with - Hazardous waste generation - ensure that all electrical devices are functioning

analyser - Chemical spillage properly and that the electrical cords are in good

equipment condition

- Handling - separating and labelling the hazardous wastes.

glassware /

accessories

Disposal of - Contact with human - All such materials are stored in the closed container

chemical - Irritation / hot or cold burns or area

contaminated bags - Environmental Impacts - Separated and labelled

- May lead to fire

/ barrels / drums / - Keeping under sun light or rain

35 High Risk Low Risk

bottles - Recycling in refinery, not disposing in

4X4 = 16 2X2 = 4

Disposal of spilled environmental

chemicals

Page | 13 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Ensure proper storage area is designated to

specific chemicals.

- Ensure the chemicals will have proper MSDSs

and bases on MSDSs are separately stored and

arranged.

Medium - Proper spill kits are available.

36 Low Risk

Chemical storage Risk of Chemical spillages on ground and Risk - Proper cleaning methods will be applied when

2x3=6

areas health issues 3x4=12 spilled on ground

- Proper PPE will be used for dealing with

chemicals in compliance with MSDS.

- Ensure proper ventilation obtained and

maintained.

- Ensure all involved personnel are trained

properly.

- Never carrying out work involved chemicals

without a proper MSDS.

- Ensure MSDS is readable and understood by all

Lack of MSDS workers and all have access to read it.

Exposure with unknown chemicals and health High Risk Low Risk

37 while dealing with - MSDS should be attached to the PTW and prior

effects 4x4=12 2x3=6

chemicals to work ensure all understand the MSDS.

- The contents of MSDS need to be discussed and

communicated within involved personnel.

- All chemical should have own MSDS.

- Uneven floor surface, - Floor surfaces are in level, dry and free of frayed

- electrical cables or computer wires may seams; carpets are well secured to the floor.

cause problems. Surfaces are set free of tripping, slipping, or

Walking and - Uneven stairs, floors, High Risk bumping hazards. Low Risk

38 wandering in the - stairs without handrails may lead to fall

3X5 = 15 Not to allow electrical or telephone cords in 2X2 = 4

office. down from the height

- Physical injury / fractures / bone injury walkways.

- Excessive workload, lack of control or All stairs are equipped with the handrails.

communication, workplace physical - The office is situated in a well-ventilated area.

Page | 14 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

environment, etc. leading to stress Smoking is prohibited in the office/plant

- Improper chairs, chairs with broken

handles or sharp angles cause to minor

cuts and wounds

- Improper ventilation,

- insufficient air, bad odor in air or poor air

quality cause to eye, nose and throat

irritation. In case of carbon monoxide

poisoning – even lead to death.

- Manual handling may cause to back pain,

etc.

- Solid waste(paper) waste generation

- Overloaded outlets with too many plugs are

avoided.

Electrical supply - Shot circuit or major fire - Circuit breakers or fuse panels are labelled and

- Minor to major electrical shocks

and overload of accessible.

the wires for the - Electrical plugs, cords, panels, and receptacles

Medium

computer and High Risk are in good condition and free of frayed or loose

39 Risk

electricity. 4X4 = 16 wires, bare conductors, or broken insulation.

3X3 = 9

- Computer equipment is connected to a surge

protector.

- Phone lines, electrical cords and extension wires

are secured under a desk or alongside a

baseboard.

Usage of items - Handling sharp edges for cutting or joining - Such equipment is stored at safe location and

having sharp the papers cause to cuts and wound away in a drawer to prevent the injury

edges like Medium Low Risk

40 staplers, scissors Risk 1X3 = 3

and steel scales, 3X4 = 12

letter openers.

Page | 15 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Ergonomic Hazards after chronic exposure - Workstations are arranged in a manner that they

to computers are comfortable and do not cause unnecessary

Working on the - May lead to poor vision, back pain, and strain on the back, arms or neck.

many other muscles and joints related pain

computer for long - A standard five–legged computer chair with good

- Clotting of blood at certain location, wrist

duration. pain back and arm supports are provided to

Medium

employees. Low Risk

41 Risk

- Take some breaks where you can stretch, get up, 2X3 = 6

2X5 = 10

and move around

- The computers are placed on a standard height

desk or workstation specifically designed for use.

- Position of the keyboard is set directly in front of

the user at approximate elbow height

- The illumination level is monitored regularly and

Medium sufficient lights are provided for both the day and

42 Working in evening - Eye stress / loss of eye vision night light working. Low Risk

Risk

or after day lights. 2X3 = 6

2X5 = 10

Working anywhere - All the fixtures are set by trained personnel and

under hanging are checked periodically

fixtures like ceiling - Physical injury / burns Medium

43 Low Risk

fans, fluorescent Risk

2X3 = 6

tubes, electric 3X4 = 12

bulbs etc.

Usage of - Emission of the carbon particles from the - All the printers and Xerox machines are set away

photocopy printing and Xerox machines from the seating areas.

machine and - Skin irritation; particles may get inhaled Medium - Expert person allow to change cartridge

44 - Hazardous waste generation (cartridge) Low Risk

printer in the office Risk - Separate and labelling hazardous wastes. 2X2 = 4

area. 2X4 = 8

Page | 16 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

Arranging the - Improper AC functioning. - The ACs are always set at normal tolerable

seminars in the - Discomfort / pain / unconsciousness Medium temperature

45 Low Risk

training rooms and Risk

2X2 = 4

conference room. 2X4 = 8

Planning of on-the- - Improper working in the trainee position, - All the employees are allowed to work after

job training in the dismantling at work proper induction only.

plant or at site as - Minor to major risk to the product as well Medium

46 as co-operators Low Risk

well as operating Risk

- Solid waste generation 2X2 = 4

the machine / 2X4 = 8

product related on

the job training

Operation of fire - Improper handling Physical injury - Fire extinguishers are operated by trained

Medium

extinguishers - Ignition of fire for mock performance personnel only. Low Risk

47 Risk

- Hot burns / severe burns - Only small catch of fire is ignited. 2X3 = 6

- Waste generation (solid, powder) /Spillage 3X4 = 12

- Housekeeping the area

Transportation of - Accidents - Only licensed person allows to drive Medium

48 High Risk

employees - Fatal to human / Physical injury - Refreshment defensive driving must do for the Risk

- Air pollution 4X4 = 16

drivers. 4X3 = 12

Grass cutting in - Disposal of grass - Well supervising

garden - Dumping of grass and creation of natural Medium - Wearing suitable PPE

49 fertilizer Low Risk

Risk - Dumping all grassed waste and remove.

- Injury, cut, wound 1X4 = 4

3X4 = 12

- Suffocation

- Land pollution

- Disposal of - Slippery floors due to spillage - All such materials are stored in the closed

used - Slips and fall / physical injury container

lubricating oil - Fire - Prepared team for housekeeping

- Damages to property High Risk Low Risk

50 and grease - Using properly PPE

- Exposure to human 3X5 = 15 2X3 = 6

- Disposal of - Fatal to human / severe burns

foam / DCP / - Contact with human Irritation / hot or cold

fired materials burns

Page | 17 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

after use of - Waste generation / spillage

fire

extinguishers

after incident /

mock drill

- Blast / Fire - Providing gas detector

- Burn / injury - Well ventilated

51 - Cooking inside - Slip/ trip / fall High Risk Low Risk

- Training staff about extinguishing fire

Restaurant - Ergonomic hazard 5X4 = 20 2X3 = 6

- Orientating staff about the hazards

- Food waste generation

- Oil waste - Not let to stay the foods waste and disposing

- Various blind not removed leading to - All pressure reactors are checked for safe

pressurizing working pressure regularly and pre-checks are

Blast / fire done before start-up

Air pollution / resource depletion - Perform housekeeping

Medium

- Oil and grease left over at various places High Risk

52 Plant Start- Up Risk

Spillage 4X4 = 16

3X3 = 9

Land / water pollution

- Improper housekeeping

Solid waste generation

Air / land pollution

- Temperature may shoot up due to no - Before start-up, all controls are checked properly

control to ensure their working condition

Blast / fire / - Housekeeping

Physical injury resource depletion

Medium

Emergency Plant - Ph may shoot up towards acidic in nature High Risk

53 Risk

Shut Down Spillage on floor 4X4 = 16

3X4 = 12

Gaseous emission / spillage

- Gas / overflowing of materials may start

- Spillage on floor

- Air / land / water pollution

Page | 18 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Ensure PTW and relevant documents are

obtained and properly completed.

- Ensure the system is isolated properly.

- Log out and tag out must be implemented

- Ensure proper Tool Box talk conducted and all

personnel aware on the scope of work and

hazards related to jobs and proper control

measures area in place.

- Competent personnel will involve the activities

Risk of Electrocution - Proper PPE must be used in compliance with

high electrical voltage

- Proper barricading of the area will be used Medium

Working on high

54 - Never work alone with high voltage area and Risk

Electrical voltage High risk

system. 3x4=12

areas 4x5=20

- Use of radio to better communications.

- Use of proper grounding.

- Ensue all is trained before the start the work

- Emergency plans and rescue need to be

discussed.

- Use a safety equipments which are designed to

deal with high volts and ensure they area

approved.

- Ensure the area is clean and dry.

- Never work in wet or rainy environment.

- Ensue personnel area aware of location of AED

and how to use it if someone electrocuted

- Never work on electrical live system, if possible.

- Ensure PTW and relevant documents are

Working on high

55 obtained and properly completed. Medium

Electrical voltage Risk of Electrical shocks High Risk

- Ensure proper Tool Box talk conducted and all Risk

areas Risk of Arc Flash 4x5=20

personnel aware on the scope of work and 3x4=12

hazards related to jobs and proper control

Page | 19 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

measures area in place.

- Ensure the system is isolated properly.

- Log out and tag out must be implemented

- Competent personnel will involve the activities

- Proper PPE must be used in compliance with

high electrical voltage

- Proper barricading of the area will be used

- Never work alone with high voltage area and

system.

- Use of radio to better communications.

- Use of proper grounding.

- Ensue all is trained before the start the work

- Emergency plans and rescue need to be

discussed.

- Use safety equipment which are designed to deal

with high volts and ensure they area approved to

protect workers against arc flash

- Ensure the area is clean and dry.

- Never work in wet or rainy environment.

- Ensue personnel area aware of location of AED

and how to use it if someone electrocuted

- Ensure PTW and relevant documents are

obtained and properly completed.

- Ensure the system is isolated properly.

- Log out and tag out must be implemented

- Competent personnel will involve the activities Medium

Working on high

56 - Proper PPE must be used in compliance with Risk

Electrical voltage High risk

high electrical voltage 3x4=12

areas 4x5=20

- Proper barricading of the area will be used

- Never work alone with high voltage area and

system.

- Ensure proper Tool Box talk conducted and all

Risk of Electrical burns

Page | 20 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

personnel aware on the scope of work and

hazards related to jobs and proper control

measures area in place.

- Use of radio to better communications.

- Use of proper grounding.

- Ensue all is trained before the start the work

- Emergency plans and rescue need to be

discussed.

- Use a safety equipments which are designed to

deal with high volts and ensure they area

approved.

- Ensure the area is clean and dry.

- Never work in wet or rainy environment.

- Ensue personnel area aware of location of AED

and how to use it if someone electrocuted

- Ensure PTW is obtained

- Ensure gas testing carried out by competent

person

- Ensure proper Tool Box talk conducted and all

Risk of

-Fire personnel aware on the scope of work and

-Explosions and exposed to hazardous gases hazards related to jobs and proper control

measures area in place.

Hot works in Medium - Never place flammable materials near by the Medium

57 flammable Risk location of hot works. Risk

environment 4x4=16 - Ensure proper housekeeping conducted 3x3=9

- If needed, ensure proper fire blankets are in

place

- Ensure fire extinguishers are inplace

- Fire watch must be ready and be present always

in the jobsite.

- Ensure all personnel have a proper PPE

- Emergency and fire escape route will be

Page | 21 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

discussed known by all.

- Isolate vehicles from workers and plant is

possible.

- Ensure operators and driver are fully trained and

have a proper licence for related

- Ensure reversing warning device are active and

active hazards light.

Risk of workers being trapped between a - Use of traffic controller to manage traffic

vehicle and structure, or hit by vehicle, Vehicle Medium

58 Moving vehicles - Provide adequate lighting on site so that drivers Low Risk

colliding with each other or structure, items that Risk

inside plant and workers have a good visibility 2x3=6

fall off vehicle and falling from vehicles 3x4=12

- Banks man must be used to giving a signals

when required

- Manage the work hours and duration for divers to

minimize fatigue.

- Provide warning signs at all entrance and exist.

- Ensure workers wear visibility clothes.

- Provide and speed limit signs inside the plant

- Ensure the PTW is obtained and all hazards and

control measures are identified.

- If possible use a sound –reducing enclosure that

fully encloses the machines

Risk of - Reduce a sound by using a proper ear plugs and

- Tinnitus ear muff.

- Noise-Induced hearing loss Medium

59 Woking in high - Use sound absorbent materials on floors, ceiling Low Risk

- Physiological effect Risk

noise area and walls to reduce a sound level. 2x3=6

- Stress 2x4=8

- Permanent deaf - Schedule the working hours and shifts to

- Temporary reduction minimise the exposure to noise

- Reducing the sound by involving more workers in

tasks so that the time of exposure will be

reduced.

- Take a frequent rest when needed

Page | 22 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Ensure employees are trained on risks and

control measures of noise

- When required a proper medical screen to an

employee.

- Ensure the PTW is obtained, if the hot works will

be conducted then Hot PTW must be obtained.

- Gas testing must be carried out before start the

work.

- Continuous gas monitoring will be considered

when hot work is carrying out.

- Ensure Personnel are aware of the scope of

works, hazards and control measures of the jobs.

- Ensure emergency plan, escape route, master

Working with Medium

60 Flammable gases Risk of High Risk point are discussed and all aware about them.

Natural gases in Risky

- Fire and explosions 4x5=20 - Ensure Fire extinguishers, fire blanket and fire

GPRS facility 2x5=10

watch are in place all the time when hot work

conducted.

- If working the system, then the system must be

isolated properly by competent personnel.

- Log out and tag out will be used and

implemented by competent personnel.

- Standby personnel must be ready always and

briefed on what he/she/they actions need to be

taken in emergency cases.

- Obtain the correct type of PTW.

- Conduct a proper gas testing to ensure free gas

Working with environment. Medium

61 Present of hazardous gases, Risk of High Risk

Natural gases in - Continuous gas monitoring will be considered Risk

- Poisoning and health effects 3x5=15

GPRS facility when hot work is carrying out. 3x3=9

- If needed the SCBA must be used to avoid

contact with hazardous gases.

Page | 23 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Ensure Personnel are aware of the scope of

works, hazards and control measures of the jobs.

- Ensure emergency plan, escape route, master

point are discussed and all aware about them.

- Ensure Fire extinguishers, fire blanket and fire

watch are in place all the time when hot work

conducted.

- If working the system, then the system must be

isolated properly by competent personnel.

- Log out and tag out will be used and

implemented by competent personnel.

- Ensure the system is purged, vented and

depressurized.

- Standby personnel must be ready always and

briefed on what he/she/they actions need to be

taken in emergency cases.

- Wind sock will be in place to detect the wind

direction.

- Ensure proper radio communication is

maintained.

- Ensure PTW is obtained for specific task.

- Ensure the door is fully opened for the duration of

the work.

- Ensure the access/egress are not obstructed.

- Gas testing to be performed prior to entry and

results recorded. Medium

Entry into the CO2 Asphyxiation due to oxygen displacement and High Risk

62 - If there will be risk of Co2 release then the Risk

Cabinet (confined exposed to CO2 gases

3x5=15 system need to isolated or all personnel must be

Space) 3x4=12

under SCBA and no ignition sources will be

nearby.

- Continuous gas monitoring throughout the entry

by personal gas detectors.

- Safety Attendant to maintain visual and verbal

communications with entrants throughout entry.

Page | 24 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- All personnel involved in the CS operations must

have the CS awareness training.

- Tool box talk to be held prior each entry.

- If gas alarm activates, entrants to evacuate

cabinet or container immediately.

- All personnel to know how to raise the alarm in

case of emergency

- Minimal personnel to enter the pit to minimize

exposure.

- Only activities specified in the permit to be carried

out.

- Safety attendant to monitor all above control

measures throughout the task(s).

Medium - All isolation to be in place and recorded on Isolation Medium

63 Working inside Unintentional or uncontrolled movement of Risk Certificate. Risk

Restricted areas machinery - Log out and Tag out must be confirmed before entry.

4x4=16 - Confirm the entire system is free of gas. 2X4=8

- PPE as per Company Policy must be worn.

- Identify and eliminate possible ignition sources.

- Permit to Work to be in place all times

- Toolbox talk to be held prior each entry

- Gas test to be carried out Prior entry, gas test results

to be confirmed and approve.

- All personnel involved in the CS entry must have the

Fire/Explosion due to of release or presence of Qaiwan CSE training

Medium - Continuous gas monitoring throughout the entry by Medium

flammable gas

64 Working inside Risk use of personal gas detectors. Risk

Restricted area - If gas alarm activates, entrants to evacuate area

2x4=8 immediately. 2x4=8

Asphyxiation due to oxygen displacement by - Only persons named on the permit to enter the pit to

flammable gas minimize exposure.

- Only activities specified in the permit to be carried out.

- Follow job specific procedure

- All personnel to know how to raise the alarm in case of

emergency.

- Safety attendant to monitor all above control measures

throughout the task(s)

Page | 25 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Construct safe work platform by using a

competent personnel and proper scaffolding

material.

- Provide a trainings

- Provide a safe access and egress.

- Provide a fall body protection while election.

- Check the work platform is sited on suitable

ground.

- Construct a proper work platform safely like have

Erection of Medium a guard rails, middle rails and tow boards.

Falling from Work platform while erection and Low Risk

65 scaffold as a Risk - Cordon off the affected area.

falling materials from work platform

platform to work 2x3=6

3x4=12 - Use a proper PPE

on it

- Ensure to be used only in a suitable weather and

stop the work when the weather is bad.

- Safety net or mesh to be used to avoid dropping

objects.

- Ensure tools are properly stored in a tool bx.

- Never throw the tools.

- Ensure at least 10 Feet away from Power lines

- Ensure proper tagging will be used for safe

scaffolding.

- Ensure proper barricading of the area is

maintained.

Erection of - Adequate signs are in place.

Medium

66 scaffold as a - Competent personnel to conduct a scaffold Low Risk

Risk

platform to work Hit or Struck by Moving objects erection. 2x3=6

2x4=8

on it - Banks man should be used when a moving

vehicle working nearby.

- Standby person always be there and ready.

Failure of scaffolding - Scaffold teams to ensure that all scaffold Medium

Dismantle High Risk

67 structures are dismantled as per relevant codes Risk

scaffold

Personnel injury 4x4=16 of practice and that safe systems of work are

Platforms 3x3=9

implemented at all times.

Page | 26 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

erected Falls from height - Good communication to be established among

the scaffolding team to avoid personnel injury.

- All personnel working over 2m without suitable

barriers to utilise a harness at all times. Attach

the harness to the robust handrails which is

welded to the overhead I-beam.

- Appropriate PPE for task to be utilised at all times

Dismantle - All tools to be adequately secured throughout

Medium operation.

scaffold Low Risk

68 Falling of materials Risk - Good lifting practices to be observed at all times

Platforms 1x3=3

2x4=8 - No throwing/dropping of equipment to personnel

erected working on different levels

- Ensure PTW is obtained.

- All parties involved to ensure the isolation is

implemented.

- Gas testing will be conducted prior to work and

continuous gas monitoring is must.

- Job performers to wear SCBA sets controlled by

HSE.

- Loosen the union in a controlled manner to

Breaking control the depressurization and check the Medium

69 containment Risk of presence of Hazardous gases, fires and High Risk integrity of the valve upstream. Risk

hydrocarbon explosions and risk of health effect 4x5=20 - Use only hand tools.

3x3=9

lines - Job performers to be briefed in the TBT on the

risk of using hand tools to cause sparks.

- Emergency plan, escape routes and master

points are to be discussed prior to Work.

- Restricted access must be maintained.

- Ensure the Line is properly purged, vented,

depressurized and drained.

- Ensure all personnel are trained proper.

- Standby personnel are required at all the time.

Gas pipe line - Ensure the pipeline is undergrounded if possible.

Medium

70 rapture due to High Risk - Ensure the pipelines are properly signed, marked

Risk

mechanical failure Risk of fire, explosion and health effect 3x5=15 and labelled.

3x4=12

and hit by vehicle - Ensure proper barricading of the area is

Page | 27 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

movement maintained and physical barrier is obtained as

well.

- If vehicle need to work nearby pipe line then

banks man is mandatory to give a signal to

operators.

- Ensure personnel are trained on how to use a

hand tools properly.

- Use of proper PPE at all the time.

- Use and read a manual of hand tools

- Proper storage and inspection od tools on regular

Risk of personal injuries such as Permanent basis and when needed.

Medium

disabilities, eyes injury, back injury, cuts and - Sharp Edge hand tools must be covered by Low Risk

71 Use of hand tools Risk

abrasions proper cover. 2x3=6

3x3=9

- Hand tools must be secured in special box while

carrying nd using as well.

- Ensure the tools with head are always checked

before to use.

- Never throw tools.

- Never use a defective tools

- Ensure to follow a heat stress program.

- Wear Breathable clothes at always.

- Use a fans and shade when needed onsite.

- Take rest as much as possible.

- Schedule you work to be done in early morning

Medium and later afternoon.

72 Working in hot Low Risk

Risk - Use sunscreen when needed.

environment Heat stress can cause risk of Heat cramps, 1x3=3

3x3=9 - High liquid intake especially water.

heat rash, heat exhaustion and heat stroke

- Ensure to drink adequate amout of water

- Eat Foods that contains high amount of water.

- If you feel that you are affected by heat stress

stop the work and seek a medic.

- Use ice pads when needed

Page | 28 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Take frequent showr and body cool down

- Train worker on how to prevent and recognize the

cold stress illnesses and injuries and how to do a

first aid.

- Use a proper PPE and use of proper winter

clothes to keep the body warm at all the time.

- Allow for appropriate rest periods.

Medium - Provide warm areas to rest periods.

73 Working in Cold Low Risk

Risk of Shivering, fatigue, muscle turn rigid, Risk - Provide warn beverages to workers.

environment 1x3=3

breathing and heart rates slow, loss of 3x3=9 - Provide radiant heaters to warm workers or

consciousness , frostbite and Hypothermia shielding work areas from wind to reduce a wind

chill.

- Monitor Workers who are at risk of cold stress.

- Wear layers of loose clothes.

- Wear PPEs which are water proof s and cold

resistance.

- Train the workers not to use defective tools.

- Proper inspection and storing the tools will be

maintained.

- Proper PPE must be used.

- Inform the workers if defective tools are noted

High Risk Low Risk

74 Use of Defective and observed then remove them from site and

2x4=8 2x3=6

tools Risk of Personal injuries and property damage never use it.

- Insure to follow the tools inventory and

maintenance properly.

Work place violence such as Physical violence, - Introduce a grievance system.

Medium

Work Place bulling, harassment and disruptive behaviour - Ensure all aware to reporting of any workplace Low Risk

75 Risk

violence violence. 1x3=3

2x4=8

- Ensure violence follow up.

Page | 29 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Zero tolerance for any violence by all.

- All workplace violence will be taken into account.

- Security alerts will be used.

- Management to ensure that the workplace is zero

violence and if any then take appropriate actions.

- All ladders must be maintained in good condition,

joints between steps and side rails tight and

hardware and fittings securely attached.

- Non Slip safety feet provided on each ladder.

- A ladder rungs and steps are free from oil and

grease.

- A ladder should be used a means of access not

designed to use to work on it unless it is required

which will be a step ladder and three point of

Medium contact must be maintained always.

76 Low Risk

Use of ladder Risk - Non Metal ladders must be used nearby

2x3=6

Risk of fall from height, dropping object and trip 3x4=12 electricity.

- The rungs of ladders uniformly spaced center to

centre (12 inches are preferable).

- Employees will be trainied on how to use a ladder

safely.

- Never use a ladder with defective parts.

- Ensure the feet properly firm on ground.

- Never store or keep the tools on the top of ladder

- Someone need to hold the ladder when is not

secured.

- Ensure proper types of PPEs are used.

- Ensure personnel are trained on how to use of

Use of portable powered tools.

77 Risk of electrocution, personal injuries, cuts,

powered tools - Ensure grinders, saws and similar equipments

abrasions and broken bones and secondary

effects (Falls from height and dropping objects) provided with appropriate safety guards.

and fire. - Barricade the area properly and never store

Page | 30 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

flammable materials nearby.

- Pneumatic and hydraulic hoses on powered

Medium operated tools checked regularly fro deterioration Low Risk

Risk or damage. 2x3=6

3x4=12 - Never use any defective tools and remove if any

in use.

- Proper shields need to be used based on job

requirements.

- All combustible scraps, debris and waste

materials stored in covered metal receptacles

and removed from worksite promptly.

- Proper storage need to be practiced to avoid risk

of fire including spontaneous combustion.

- Designated containers and kips will be sued to

storage and handling of flammable material and

Use of Flammable Medium combustible materials.

Low Risk

78 and combustible Risk of fire, explosions and health effect Risk - All flammable liquids must be kept in closed

2x3=6

Materials 3x4=12 container when not in use and need to be in fire

resistance containers.

- Proper ventilation will be maintained.

- All materials need to be labelled properly and

have a proper MSDS with.

- The area needs to be barricaded and no hot

works will be carrying out nearby.

- Fire Extinguishers will be in place.

- Ensure there will be a proper emergency action

plan in place.

Lack of Emergency action plan will cause - All employees trained on Emergency action plan Medium

79 Emergency action Employees to get injury and confused when High Risk

and all must be understood on the emergency Risk

plan onsite (EAP) there will not be any or the existing one is not 3x5=15

action plan. 3x3=9

properly communicated

- Ensure emergency action plan comply with

Bazyan Power Plant requirements.

Page | 31 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Emergency escape procedures and routes are

developed and communicated within all.

- Ensure the alarm system which provides a

warning for emergency action recognized and

perceptible above ambient conditions.

- EAP need to be revised and reviewed when

needed.

- Ensure employees know their duties and know

they have a right for reporting

- Ensure a proper emergency rescue team are set

up and fully aware of what are their duties when

there will be an emergency

- Redesigning the work environment

- Providing regular and proper breaks for

employees.

- Increasing employee participation in decision

making and work planning.

- Increasing the time, employees and resources to

completing the specific tasks

80 Work Place stress - Matching job description with skills and

Risk of Physical health and psychological

qualifications.

health, mental health and behaviour

- Creating clear promotion and reward pathways.

Medium - Eliminate or reducing physical hazards.

Low Risk

Risk - Establishing control measures to reduce worker's

2x3=6

3x4=12 exposure to occupational hazards.

- Promoting the use of PPE.

- Routine health surveillance.

- Ensure the personnel involved in the job have a

Involve non Non competent workers can cause harm to proper training, experience, skills and knowledge. Medium

81 High Risk

competent workers employees, damage to environment and - Never involve any person in critical jobs who is Risk

4x4=16

in jobs damage to property or plant not competent. 3x3=9

- Ensure competent personnel will have ability to

Page | 32 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

conduct a works safely.

- PPE must be considered as last line of

protection.

- Eliminating the hazards onsite so that employees

will not face hazards.

- Change the hazardous material by less

hazardous ones.

- Use engineering controls to avoid using a PPE.

- Ensure to Read MSDS to detect a right PPE

Can cause serious injury to personnel such as while dealing with chemicals.

Lack of proper Medium

Permanent disability, eyes injuries, back injury, - Ensure Proper PPEs must be used to conduct a Low Risk

82 PPE to conduct a Risk

suffocations, burns, cuts and abrasions and jobs based on Hazard Assessment process. 2x3=6

job 3x4=12

even damage to property - Inspect the PPEs before use.

- Good quality of PPEs must be ordered and

maintained.

- Use a right PPE for a right job.

- Ensure all personnel know that they have a right

to change the PPEs when damaged and not

protect properly.

- Ensure Special PPEs must be inspected regularly

and recorded.

- Ensure all personnel trained on use of right type

of PPE for the right job.

- Good Quality of PPEs will be ordered for

employees

Medium - All employees must use a right PPE for the right

Employees not use Low Risk

83 Risk job onsite.

a right type of PPE Risk of Personal injury and property damage 2x3=6

3x4=12 - Provide a Special PPEs for special jobs such a

working with chemicals, working at height,

working in confined spaces and working with high

electricity volts.

- Ensure proper supervision on employees to use

Page | 33 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

aright PPE for right job.

- Conduct training on PPE for all employees.

- Fails to not wear PPE intentional will be

considered as Disciplinary actions.

- Any damaged or expire PPE must be changed

immediately.

- Ensure proper PTW procedure and formats are in

place and all aware about them.

- Ensure the PTW will be filled up by competent

personnel.

- Only authorized personnel must be signing PTW.

- Ensure the PTW is valid.

- Ensure proper training given to all employees.

Lack of Proper Could cause serious accidents such a injury to - Ensure all involed personnel in jobs are fully Medium

84 Permit to Work employees, damage to plant and property and High Risk aware of contents and requirement of PTW Risk

(PTW) environment damage as well 4x4=16 - Ensure all hazards are identified and all control 3x3=9

measures are in place and all team members are

aware of it.

- Proper Tool Box talk will be conducted before

start the work and all involved personnel must in

Tool box talk.

- If the situation changed then the PTW will be

reassessed.

- Conduct a proper risk assessment in terms to

pregnant women

- Modifying the working conditions.

Present of Pregnant women can exposure to biological Medium

85 - Avoid to manual handling, vibrations activities Low Risk

Pregnant women agents, chemical agents, manual handling and Risk

vibration and biological agents while in workplace. 2x3=6

in workplace 3x4=12

- Changing the shifts or working hours to less and

with suspension on full pay till maternity

commences as a final solution.

Page | 34 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Carrying out a full site induction for young

workers.

- Ensure proper supervision, training and

Young Workers might be at greater risks due to instruction will be given to them.

Medium

86 Young workers lack of proper experience, knowledge and - Ensure young workers are adequately supervised Low Risk

Risk

onsite skills. Attempt to perform tasks beyond their when performing risky activities. 2x2=4

3x3=9

skill set and ability - No lone work will be allowed to them.

- The work procedures and HSE policies and

procedures properly discussed and

communicated with them.

- Weld in ventilated isolation booths.

- Substitute welding processes where practicable

(eg use submerged arc welding instead of flux-

core wire welding or use low fume/less

hazardous welding rods).

- Locate welding operations away from other

workers (eg use screens, curtains, or distance

Medium Medium

87 UV radiation, visible light, and IR radiation from other work stations, aisles, or walkways).

Welding Risk Risk

which can cause - Encourage job rotation and/or job sharing.

4x4=16 3x3=9

- Train workers in the correct fit, use and

maintenance of PPE.

- Use a proper PPE which is designed to UV Light

protection such as proper gloves, body

protection, eyes protection, safety shoes and

apron.

- Always welding shield must be used properly.

- Weld in ventilated isolation booths.

- Substitute welding processes where practicable

Medium

88 (eg use submerged arc welding instead of flux- Low Risk

Risk

Welding Fumes core wire welding or use low fume/less 2x3=6

3x4=12

hazardous welding rods).

- Use engineering controls to capture and remove

Page | 35 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

fumes, gases and vapours.

- Locate welding operations away from other

workers (eg use screens, curtains, or distance

from other work stations and walkways).

- Clean base metals to reduce fume generation

(oils, greases, mill scale, and solvents).

- Encourage job rotation and/or job sharing.

- Use the right PPE (eg respiratory protection and

a welding helmet with the correct side shields and

filter, for other workers nearby; safety glasses

with UV protective side shields).

- Train workers in the correct fit, use and

maintenance of PPE.

- Do regular air monitoring.

- Ensure the cleaners are fully trained on working

with detergents and chemicals and they are fully

aware of hazards, risks and control measures.

- All chemicals and detergents should have MSDS

and it will be discussed and communicated with

cleaners prior to start works.

- Ensure proper labelling for containers, Jerricans

Use of detergents Medium

High Risk and bottles.

89 and Chemicals for Has a potential to cause acute and chronic Risk

4x4=16 - Ensure proper ventilation will be maintained.

cleaning up by risks to employees especially cleaners 2x4=8

- Use of proper PPE including masks and gloves.

cleaners

- While using ensure the area already barricaded

and signs are available to let other know.

- Never use a chemicals and detergents without

proper identifications on the chemical containers.

- Clean and dry the area right away and no one will

be allowed to coe in till the area is safe.

90 Medium - Encourage workers to report poor lighting. Low Risk

Floor cleaning Slips a Trips hazards

Risk - Keep floors dry and clean. 2x2=4

Page | 36 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

3x3=9 - Hang power cords over aisles or work areas

to prevent tripping accidents.

- Use anti-slip flooring or non-slip working

shoes.

- Place signs to warn of slippery surfaces.

- Barricade the area.

- Encourage workers to report poor lighting.

- Keep floors and stairs dry and clean.

- Ensure carpets and rugs are free of holes and

loose edges.

- Hang power cords over aisles or work areas to

prevent tripping accidents.

- Use anti-slip flooring or non-slip working shoes.

Working and Medium - Place signs to warn of slippery surfaces.

91 Low Risk

walking on slippery Slip, trip and falls Risk - Hold onto handrails when climbing stairs or

3x2=6

surface 3x4=12 slopes.

- Keep work area neat - do not leave materials and

boxes lying haphazardly around.

- Install guardrails on elevated platforms to prevent

falls. Where physical guards are not feasible,

provide alternatives like safety harnesses

anchored to a lifeline or

- Anchorage point will be used when needed.

- Ensue proper PPE is used including Non-slip

rubber boots and impervious gloves.

Can become - A suitable face shield or safety glasses to protect

Pressurised Dangerous should the operator lose control of Medium

92 the Low Risk

washing using the jet, Risk

- eyes; and Ear plugs if it is noisy. 2x3=6

spray jet This may result in injury to the operator or 3x4=12

others within the cleaning area and electrical - Cordon area during washing to prevent slips and

risks falls.

- Ensure electrical cables, unless designed to be

Page | 37 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

used in wet conditions, are not lying on a wet

floor.

- Handle the pressure jet carefully.

- Beware of back pressure when the motor is

turned on.

- Point the pressure jet gun away from the feet

during washing.

- Plan the route of travel of the water jet.

- Never spray the water on electrical appliances to

avoid risk of electrical.

- Turn off the spray gun when not in use.

- Do not entangle the water hose

- Look out for members of public while cleaning.

- Switch off the machine and turn off the water

supply immediately after washing.

- Involve workers, who often have the best

understanding of the conditions that create

hazards and insights into how they can be

controlled.

- Identify and evaluate options for controlling

hazards, using a "hierarchy of controls."

- Use a hazard control plan to guide the selection

Lack of Hazard Medium and implementation of controls, and implement Medium

93 Prevention and Increase workplace hazards, injuries, illnesses, Risk controls according to the plan. Risk

and incidents;

Control 4x4=16 - Develop plans with measures to protect workers 2x4=8

during emergencies and no routine activities.

- Evaluate the effectiveness of existing controls to

determine whether they continue to provide

protection, or whether different controls may be

more effective. Review new technologies for their

potential to be more protective, more reliable, or

less costly.

Page | 38 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Do not wear Jewelleries at work to eliminate

- Contact with electricity catch on machineries, protruding objects,

94 Wearing of High Risk Low Risk

- Entanglement piercings

Jewelleries 4X4 = 16 2X3 = 6

- Skin injury - Prevent habitation of bacteria/virus between

jewelleries and skin;

- communication is very important: mobile phone,

telephone or radio

- controlled periodic checks

- Automatic warning devices, e.g. panic alarms, no

movement alarms, automatic distress message

systems, i.e. pre-recorded message sent if not

actively cancelled by operative, etc.

accidents or emergencies arising out of the

work, including inadequate provision of first aid - Instruction and training in proper procedures, e.g.

Lone

sudden illnesses Medium code words for potentially violent situations when Medium

95 workers/working

inadequate provision of rest, hygiene and Risk combined with mobile phone communication. Risk

alone in risky

welfare facilities 3x4=12 - Use of Personal Protective Equipment (PPE) 3x3=9

areas physical violence from members of the public - Health surveillance

and/or intruders - First-aid kits and training

- Implementing Standard Operating Procedures

(SOP’s)

- locking and securing place of work

- Implementing correct incident reporting

procedures

- Provision of counselling

- Regular maintenance and inspection of remote

and manual controls

- Maintenance of controls/access device; Heighten Medium

Un known personal/ Threating High Risk

96 Security Gaps manual security measures; Risk

4X4 = 16

- Post security policies, standards, guidelines, and 3X4 = 12

controls addressing prevention;

- Trained security personnel will be available

Page | 39 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Areas kept dry.

Medium - Spills, floods, water penetration cleaned and

97 Low Risk

Biological Hazards Mold /fungus Risk dried immediately, within first 48 hours.

2x2=4

3X3=6

- Areas are kept clean and free of food

- Food secured in containers or fridge

Medium - Doors to outside kept close

98 Low Risk

Biological Hazard Risk - If pests are identified, staff must

Pests/rodents 2x3=6

3x4=12 - report to immediate supervisor

- Housekeeping notified to arrange for

pest control

- Have a proper Alcohol and drugs policy.

- The policy should be discussed and

Medium communicated with all personnel.

99 Use of Drugs and Craving, loss of control, physical dependence Low Risk

Risk - Conduct a Drug and alcohol Screening and

alcohols and tolerance 1x3=3

3x3=9 testing.

- Ensure all personnel will follow that if not then

disciplinary actions might be taken.

- Explosion Medium - Implement regular maintenance schedule;

100 Corrosion or Low Risk

- Fire Risk Prevention from exposure to substances.

erosion 2X3 = 6

- Personal injury 4X3 = 12

High Risk - Free from wets and slip potential objects; Low Risk

101 Use of Stairs Falling

4X4 = 16 Handrails secured; Do not store any materials 3X2 = 6

- Fire - Include in safety orientation, where to smoke

102 High Risk Low Risk

Smoking cigarette - Env. Pollution safely and how to dispose of cigarette butts

4X4 = 16 3X2 = 6

- Health problem - Provide smoking shelter and signages

- Fire High Risk - Preventive maintenance schedule; Inspect, test, Low Risk

103 Valve leak

- Slipping 4X4 = 16 and detect: Investigate faults, record in Maximo 2X2 = 2

Medium - Hand washing when leaving work rooms. Low Risk

104 Personal Hygiene Contact with Bacteria and viruses Risk - Careful removal and disposal of potentially 1x3=3

3x3=9 contaminated PPE to prevent cross

Page | 40 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

contamination to normal clothes.

- Prohibition of eating, drinking and smoking in

work areas

- Before eating and drinking the hands must be

washed properly.

- Provide an adequate training for employees to

use machinery for work.

- Safe procedures and adequate level of

Contact with moving parts can result in serious High Risk supervision need to be done for employees. Medium

105 Plant and

injury and even fatal injury as a result of 4x4=16 - Guards and safety devices must be fitted to Risk

machinery

Entanglement, drawing in and ejection of parts machinery. 3x4=12

- Proper guards need to be used such as Interlock

guards, fixed guards, self-adjusting guards and

adjustable guards.

- tore batteries in a cool, well-ventilated area away

from ignition sources, and do not handle batteries

near heat, sparks or open flames

- avoid contact with internal components

- Explosion - strictly follow all instructions and diagrams when

- delivering an electric charge at a very high installing or maintaining battery systems

rate Medium

106 High Risk - short-circuit may occur and cause battery failure

Lead acid batteries - serious injury Risk

5X4 = 20 and fire.

- significant damage to property and the 3x3=9

environment - tools or cables should not be placed on batteries

or in an area where they can fall onto the

terminals

- only insulated tools should be used

- when working on batteries, workers must not

wear items of jewellery, and using correct PPE.

- Forklift turnover - Ensure the competent forklift driver will drive

- Blind spot High Risk - Before use ensure to proper inspection for forklift Low Risk

107 Use of Forklift - Load instability

4x4=16 by using of pre use checklist 2x3=3

- Over speed limit - May sure the load is stable and safely arranged

- Struck/heat by objective

Page | 41 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

- Lack of maintenance and lack of precheck on forks and secured

list use - Avoid tilting the forks unless its required

- Floor conditions - Separate the forklift traffic and other workers

- Lack of trained operator where is possible otherwise the proper sign and

- Ramps and seat belt

- Improper attachment banks man is used

- Hazards to pedestrians - Revers horn will be used

- Property damage - Never speed over limitation

- Personal injury

- Equipment failure

- Prepare the covid-19 /Pandemic procedure

including infection protocols and emergency

response plan

- Follow the WHO, OSHA and local governorate

guidelines and rules related to covid-19

precautions.

- Prepare and conduct HSE talks on Covid 19

precautions such as transmission ways, effects,

symptoms and ensure everyone attend the talks

- Being infected by covid-19 or any other on regular basis

COVID-19 or Pandemic health issues - Provide the employees with masks, gloves, hand

108 Pandemic - Minor and medium personal effect 2 x 4=8 sanitizer, body temperature, and warnings as 2x3=6

Exposure - Death may occur due to infected by well.

COVID-19 - Provide the HSE posters to all buildings, offices,

workplaces to ensure everyone will clearly

understand the precautions and pass the advices

through.

- Changing working schedules including reducing

working hours and manpower as well.

- Reduced the face-to-face meeting, scheduling

eating times, providing foods to everyone’s office

and workplaces.

- Close monitoring the situations and continues

Page | 42 General Risk Assessment - ABC-COMPANY NAME (XYZ)-HSE-P-022/01

giving advices on this to all employees

- Minimizing contractor on site and prepared the

covid-19 plans and precautions to contractor

personnel.

- Prepared COvid-19 induction for employees and

new commers a swell.

- Disinfect the offices, workplaces, vehicles and