Professional Documents

Culture Documents

Homework 4: 1) in A Production Turning Operation, The Workpart Is 60 MM in Diameter and 500 MM

Homework 4: 1) in A Production Turning Operation, The Workpart Is 60 MM in Diameter and 500 MM

Uploaded by

Erdem HanoğluOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Homework 4: 1) in A Production Turning Operation, The Workpart Is 60 MM in Diameter and 500 MM

Homework 4: 1) in A Production Turning Operation, The Workpart Is 60 MM in Diameter and 500 MM

Uploaded by

Erdem HanoğluCopyright:

Available Formats

HOMEWORK 4

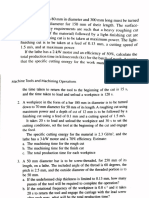

1) In a production turning operation, the workpart is 60 mm in diameter and 500 mm

long. A feed of 0.75 mm/rev is used in the operation. If cutting speed=9 m/s, the tool

must be changed every 4 workparts; But if cutting speed=5 m/s, the tool can be used

to produce 50 pieces between tool changes. Determine the Taylor tool life equation for

this job. (use the equations given below for solution)

vT n C

2) The outside diameter of a cylinder made of steel is to be turned. The starting diameter

is 120 mm and the length is 1400 mm. The feed is 0.3 mm/rev and the depth of cut is

2.5mm. The cut will be made with a cemented carbide cutting tool whose Taylor tool

life parameters are: n= 0.33 and C=500. Units for the Taylor equation are min for tool

life and m/min for cutting speed. Compute the cutting speed that will allow the tool life

to be just equal to the cutting time required to complete this turning operation.

You might also like

- Faculty of Mechanical and Industrial Engineering (2011 E.C.)Document2 pagesFaculty of Mechanical and Industrial Engineering (2011 E.C.)Roha Engineering0% (1)

- Sheets - Sep 2013Document13 pagesSheets - Sep 2013Mohamed OsamaNo ratings yet

- UTA026 Manufacturing Processes Work SheetDocument3 pagesUTA026 Manufacturing Processes Work SheetGUNJAN KHULLARNo ratings yet

- Manufacturing Engineering Assignment Thapar UniversityDocument5 pagesManufacturing Engineering Assignment Thapar UniversitySaurav Kumar0% (1)

- Tutorial Problems in Machining TimeDocument2 pagesTutorial Problems in Machining TimeDHANASEKAR K IV A 9023No ratings yet

- Problems Sheet Machine Tools 2015 16Document9 pagesProblems Sheet Machine Tools 2015 16Shafiq AhmadNo ratings yet

- AssignmentDocument2 pagesAssignmentgirma workuNo ratings yet

- AssignmentDocument2 pagesAssignmentgirma workuNo ratings yet

- Assignment 1 2Document2 pagesAssignment 1 2Jeevan GNo ratings yet

- Man ProDocument2 pagesMan ProlividiveNo ratings yet

- 2023 End Spring Mechanical Engg ME30604 Machine Tools and Machining ES 2023Document5 pages2023 End Spring Mechanical Engg ME30604 Machine Tools and Machining ES 2023riya pandeyNo ratings yet

- Chapter Two PDFDocument70 pagesChapter Two PDFberhaneNo ratings yet

- TUTORIALS 1 (1) - MergedDocument23 pagesTUTORIALS 1 (1) - MergedRUGERO KeslyneNo ratings yet

- Assignment 4 Due: May 15, 2020 MachiningDocument1 pageAssignment 4 Due: May 15, 2020 MachiningngouoNo ratings yet

- Exercise 1Document4 pagesExercise 1Rekawt RashedNo ratings yet

- Problem Set 1Document5 pagesProblem Set 1riyaNo ratings yet

- Cutting Force Thrust ForceDocument1 pageCutting Force Thrust ForcepmagrawalNo ratings yet

- 414 TutorialsDocument2 pages414 TutorialsAMOS SIFUNANo ratings yet

- Assignment 1Document4 pagesAssignment 1antonushany52No ratings yet

- Tutorial-2: Manufacturing Science and Technology-II (ME - 322)Document2 pagesTutorial-2: Manufacturing Science and Technology-II (ME - 322)Deepam ShyamNo ratings yet

- 2 Problems Sheet Machine ToolsDocument9 pages2 Problems Sheet Machine ToolsALOKSRK0% (1)

- Me 014Document2 pagesMe 014Jimmy JindalNo ratings yet

- Tutorial 2Document10 pagesTutorial 2omar salahNo ratings yet

- Documento Estrada 9D - Parte15Document3 pagesDocumento Estrada 9D - Parte15Luis Hakim Vega GutierrezNo ratings yet

- Ch-4 LatheDocument99 pagesCh-4 LatheMahendra TantuwayNo ratings yet

- Ch-4 LatheDocument82 pagesCh-4 LathejaiNo ratings yet

- Assign 1 2012Document2 pagesAssign 1 2012chiru1431No ratings yet

- Turning EccentricDocument3 pagesTurning EccentricFaisal Raza100% (1)

- Lecture No. 7 Turning ParametersDocument29 pagesLecture No. 7 Turning ParametersMuhammad Irfan100% (1)

- Mm216 Eigenvalue EigenvalueDocument4 pagesMm216 Eigenvalue EigenvalueFurkan ŞahinNo ratings yet

- MachiningDocument2 pagesMachiningprashantNo ratings yet

- Lecture 5 Lathe Speed and FeedDocument14 pagesLecture 5 Lathe Speed and FeedYAWARNo ratings yet

- 2 Numericals Bank MP II PDFDocument7 pages2 Numericals Bank MP II PDFThenarasumohanveluNo ratings yet

- 02 Taylors Tool Life Problems UpdatedDocument2 pages02 Taylors Tool Life Problems Updated19G133 VASANTH B100% (1)

- D Ch-4 LatheDocument81 pagesD Ch-4 LatheNimish JoshiNo ratings yet

- Tutorial - Topic 4Document2 pagesTutorial - Topic 4Kavish CserNo ratings yet

- MP Unit-2Document113 pagesMP Unit-2Parth MaldhureNo ratings yet

- Cos Tan Here Is The Chip T 1 Si Hickness Ratio. N: R R R WDocument1 pageCos Tan Here Is The Chip T 1 Si Hickness Ratio. N: R R R WpmagrawalNo ratings yet

- Ch-4 LatheDocument103 pagesCh-4 LatheSachin SinghNo ratings yet

- Solution To Taylors Tool Life ProblemsDocument1 pageSolution To Taylors Tool Life Problems19G133 VASANTH B100% (1)

- Drilling and Thread CuttingDocument11 pagesDrilling and Thread CuttingSami SamiNo ratings yet

- DOPT AssignmentDocument6 pagesDOPT AssignmentRabindra Kumar LakraNo ratings yet

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingDocument7 pagesAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilNo ratings yet

- Types of Operation: Facing OperationDocument9 pagesTypes of Operation: Facing OperationSai KiranNo ratings yet

- Lathe OperationsDocument40 pagesLathe OperationsRavi Sharma100% (4)

- Theory of Metal Cutting - NumericalsDocument2 pagesTheory of Metal Cutting - Numericalspmagrawal100% (1)

- Sheet 8Document5 pagesSheet 8mo635107No ratings yet

- Mother of Machine Tools ": Cylindrical and Flat SurfacesDocument28 pagesMother of Machine Tools ": Cylindrical and Flat SurfacesRamu KakaNo ratings yet

- 09 Problem Sheet 02Document2 pages09 Problem Sheet 02Shweta raiNo ratings yet

- Ch-4 LatheDocument98 pagesCh-4 LathePARESHNo ratings yet

- انتاج ٢Document9 pagesانتاج ٢khaledfarrag281No ratings yet

- Model - I Turning Operations Performed On A Given Mild Steel Work PieceDocument4 pagesModel - I Turning Operations Performed On A Given Mild Steel Work PiecejssrikantamurthyNo ratings yet

- Theory of Metal Cutting Numericals PDFDocument2 pagesTheory of Metal Cutting Numericals PDFsanjayNo ratings yet

- Piping Course MaterialDocument29 pagesPiping Course MaterialLOKESHNo ratings yet

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- ME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)Document23 pagesME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)WILYNo ratings yet

- Cutting ParametersDocument5 pagesCutting Parametersabdulwaseh0292No ratings yet

- 03 Cutting Conditions - MILLING - EXDocument9 pages03 Cutting Conditions - MILLING - EXNicolle Gil RamosNo ratings yet

- Solution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minDocument11 pagesSolution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minwoihoNo ratings yet