Professional Documents

Culture Documents

3475 Metal Set A1

3475 Metal Set A1

Uploaded by

mahmouddiaa554Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3475 Metal Set A1

3475 Metal Set A1

Uploaded by

mahmouddiaa554Copyright:

Available Formats

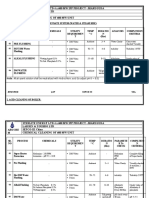

Technical Data Sheet

Research, Development & Engineering Hysol® 3475

Tallaght Business Park, formerly Metal Set A1

Dublin, Ireland August 2003

PRODUCT DESCRIPTION TYPICAL ENVIRONMENTAL RESISTANCE

Loctite Hysol 3475 is an aluminium filled 2-component epoxy Solvent Resistance

adhesive that cures at ambient temperatures. Ideal for the repair Like most epoxy resin based materials, product has excellent

and recovery of worn and damaged machinery. It has a 1:1 resistance to many liquids and solvents. The following

mixing ratio with very low shrinkage properties and does not rust. information may be used as a guide.

Hysol 3475 was developed for easy and convenient use in the

workshop or for on-site maintenance. Type of Liquid/Solvent Product Performance

Water, dilute acids, salt Excellent. Some surface

TYPICAL APPLICATIONS solution discolouration may occur

Repairing worn parts including shafts, housings, keyways and 10% Caustic Soda Excellent

flanges as well as broken or damaged parts such as castings, Gasoline/Petrol, hydrocarbon Excellent

pipes or fabrications. Product can be used for jobs as varied as fuels and lubricants

filling cavities, levelling machinery, repairing cast-steel plates, Chlorinated solvents Good resistance but not

making core moulds, applying a sacrificial coating or sealing recommended for continuous

leaking pipes. long term contact

Methanol, Acetone, MEK Poor resistance

PROPERTIES OF MIXED MATERIAL

NOTE: This information refers to fully cured material.

Typical Value Incomplete cure or inadequate mixing will adversely

Appearance Grey, putty affect solvent resistance.

Mix Ratio by Volume (Resin/Hardener) 1:1

Mix Ratio by Weight (Resin/Hardener) 1:1

GENERAL INFORMATION

Maximum open gap fill (mm) 1mm

Open Time of mixed adhesive, minutes This product is not recommended for use in pure oxygen

@10ºC 180 and/or oxygen rich systems and should not be selected as a

@ 20°C 60 sealant for chlorine or other strong oxidising materials.

@ 30ºC 40

For safe handling information on this product, consult the

Cure: (see table) Material Safety Data Sheet, (MSDS).

Hysol 3475 develops functional strength at 20ºC after 12 hours

At 10ºC 24 hours is required. Directions for Use

1. For best performance surfaces for repair should be clean, dry

TYPICAL PROPERTIES OF CURED MATERIAL and free of grease. Special surface treatments can increase

(Product Cured for 7 days at 23ºC) the bond strength and durability .

Physical Properties Typical Value 2. Stir each component of resin and hardener separately, then

Hardness, Shore D 85 measure out equal amounts of each.

Shrinkage on Cure, % 0.1 3. Stir thoroughly together for up to two minutes until an even

Adhesive strength (ASTM D1002), N/mm² mix is achieved.

Steel 20 4. Apply the product to the working area with the spatula

Aluminium 15 provided.

Compressive strength (ASTM D695), N/m² 70 5. For larger breaks or fractures, the product can be applied to

Tensile strength (ASTM D638), N/mm² 50 glass fibre matting or a similar support and used as a patch

Young’s Modulus (ASTM D695), N/mm² 7,000 or bandage.

Temperature range, °C -20 to +120 6. If used as a moulding compound, use a wax, grease or

silicone release agent to prevent adhesion to any surface.

Functional strength is normally achieved after 10 to 12 hours,

with full cure in up to 72 hours. These times are reduced

with high ambient temperatures. For applications involving

high temperatures or where resistance to solvents is

required, consult the Technical Data Sheet.

NOTE: Due to heat generation during the curing process

larger quantities tend to cure more rapidly.

7. Excess uncured adhesive can be wiped away with organic

solvent (e.g. Acetone).

8. Keep the assembled parts from moving during cure. The

joint should be allowed to develop full strength before

subjecting to any service loads.

9. After use and before adhesive hardens mixing and

dispensing equipment should be cleaned with hot soapy

water.

NOT FOR PRODUCT SPECIFICATIONS.

THE TECHNICAL DATA CONTAINED HEREIN ARE INTENDED AS REFERENCE ONLY.

PLEASE CONTACT LOCTITE CORPORATION QUALITY DEPARTMENT FOR ASSISTANCE AND RECOMMENDATIONS ON SPECIFICATIONS FOR THIS PRODUCT.

ROCKY HILL, CT FAX: +1 (860)-571-5473 DUBLIN, IRELAND FAX: +353-(1)-451 - 9959

TDS Hysol 3475, August 2003

Storage

Product shall be ideally stored in a cool, dry location in unopened

containers at a temperature between 8°C to 21°C 46°F to 70°F)

unless otherwise labelled. Optimal storage is at the lower half of

this temperature range. To prevent contamination of unused

product, do not return any material to its original container. For

further specific shelf life information, contact your local Technical

Service Centre.

Data Ranges

The data contained herein may be reported as a typical value

and/or range. Values are based on actual test data and are

verified on a periodic basis.

Note

The data contained herein are furnished for information only and

are believed to be reliable. We cannot assume responsibility for

the results obtained by others over whose methods we have no

control. It is the user's responsibility to determine suitability for

the user's purpose of any production methods mentioned herein

and to adopt such precautions as may be advisable for the

protection of property and of persons against any hazards that

may be involved in the handling and use thereof. In light of the

foregoing, Loctite Corporation specifically disclaims all

warranties expressed or implied, including warranties of

merchantability or fitness for a particular purpose, arising

from sale or use of Loctite Corporation’s products. Loctite

Corporation specifically disclaims any liability for

consequential or incidental damages of any kind, including

lost profits. The discussion herein of various processes or

compositions is not to be interpreted as representation that they

are free from domination of patents owned by others or as a

license under any Loctite Corporation patents that may cover

such processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered by

one or more United States or foreign patents or patent

applications.

Bulk No. Resin: 210259/Hardener: 210260

Loctite and Hysol are Registered Trademarks of Henkel Loctite Corporation U.S.A.

You might also like

- Epoxy Resin Arts and Crafts for BeginnersFrom EverandEpoxy Resin Arts and Crafts for BeginnersRating: 3 out of 5 stars3/5 (5)

- Masterflow 400: High Strength, Free Flowing Epoxy GroutDocument2 pagesMasterflow 400: High Strength, Free Flowing Epoxy GroutFrancois-No ratings yet

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- 3471 Metal Set S1Document2 pages3471 Metal Set S1mahmouddiaa554No ratings yet

- 3474-Metal Set MDocument2 pages3474-Metal Set Mmahmouddiaa554No ratings yet

- 3479-Metal Set HTADocument2 pages3479-Metal Set HTAmahmouddiaa554No ratings yet

- 2 Ton Epoxy: Technical Data SheetDocument2 pages2 Ton Epoxy: Technical Data SheetLeomar TorrealbaNo ratings yet

- 2 Ton Epoxy TDSDocument2 pages2 Ton Epoxy TDSFrichsGabinoCondoriMonzonNo ratings yet

- 739 Plastic AdhesiveDocument4 pages739 Plastic AdhesivevkmsNo ratings yet

- DevCon 5 Minute Epoxy Technical Data SheetDocument2 pagesDevCon 5 Minute Epoxy Technical Data Sheetjohn432questNo ratings yet

- Masterinject 1315 TdsDocument2 pagesMasterinject 1315 TdsMoatz HamedNo ratings yet

- PDS STRATA EPOXY MT 45520 en-GB PDFDocument2 pagesPDS STRATA EPOXY MT 45520 en-GB PDFMohamed NouzerNo ratings yet

- Hempaflor Decorate 600Document2 pagesHempaflor Decorate 600Riian Apriansyah100% (1)

- Masterflow 400 TdsDocument3 pagesMasterflow 400 TdsverNo ratings yet

- Masterbrace Adh 2200 TdsDocument2 pagesMasterbrace Adh 2200 TdsarchahmedassafNo ratings yet

- Ablestik 2114 BiPax-EN-1761143Document3 pagesAblestik 2114 BiPax-EN-1761143نور محمد وحيد القدسيNo ratings yet

- Lite 3060 - TdsDocument2 pagesLite 3060 - TdsJuan Sebastián Fernández RamírezNo ratings yet

- Loctite PC 9020 Nordbak Backing Compound LDSDocument2 pagesLoctite PC 9020 Nordbak Backing Compound LDSWilder Carbajal MayhuaNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Royalthane 450GLDocument2 pagesRoyalthane 450GLSyed FaridNo ratings yet

- Loctite LB 8213 - TDSDocument2 pagesLoctite LB 8213 - TDSmkmtaravindNo ratings yet

- Product Data: HEMPADUR 37620Document2 pagesProduct Data: HEMPADUR 37620Juanda Mardohar Dantec SitompulNo ratings yet

- Hempafloor Self-Level 200Document2 pagesHempafloor Self-Level 200Fadi MagdyNo ratings yet

- PDFDocument2 pagesPDFMuhammad AsifNo ratings yet

- Ra22 ArmourZinc 120 PrimerDocument2 pagesRa22 ArmourZinc 120 PrimerDenis MNo ratings yet

- 09 - TDS - Mastertop 1205Document3 pages09 - TDS - Mastertop 1205aahtagoNo ratings yet

- Setalux® D A 870 BaDocument2 pagesSetalux® D A 870 Baسلطان ابوالعلاNo ratings yet

- Shell Gadus S5 T460: Previously Shell Stamina HdsDocument1 pageShell Gadus S5 T460: Previously Shell Stamina HdsShova MuhammadNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- Loctite PC 7218 TDSDocument2 pagesLoctite PC 7218 TDSDavid MendozaNo ratings yet

- Araldite 3112 US eDocument4 pagesAraldite 3112 US ebinodNo ratings yet

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechNo ratings yet

- Product Data Sheet: Hempafloor Durable 300Document2 pagesProduct Data Sheet: Hempafloor Durable 300Fadi MagdyNo ratings yet

- PDS STRATA EPOXY HT 35590 en-GB PDFDocument3 pagesPDS STRATA EPOXY HT 35590 en-GB PDFMohamed Nouzer0% (1)

- Chemlok 217 Adhesive: Lord Technical Data Lord Technical DataDocument2 pagesChemlok 217 Adhesive: Lord Technical Data Lord Technical DataNeeraj BhallaNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- Cement Properties and CharacteristicsDocument2 pagesCement Properties and CharacteristicsAnonymous XVEucVMsENo ratings yet

- BASF MasterSeal NP 472Document2 pagesBASF MasterSeal NP 472HJNo ratings yet

- Loctite 7232 High Temperature Wear Resistant Putty: Product Description SheetDocument1 pageLoctite 7232 High Temperature Wear Resistant Putty: Product Description SheetjohnNo ratings yet

- RKTQ - Fix All Classic - TdsDocument2 pagesRKTQ - Fix All Classic - TdsYura hamuacNo ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- Technical Data Sheet: For Further Information Regarding This Product Please Refer ToDocument1 pageTechnical Data Sheet: For Further Information Regarding This Product Please Refer ToilterNo ratings yet

- Pu Sealant Mccoy Soudal Soudaflex 611 Pu SealantDocument2 pagesPu Sealant Mccoy Soudal Soudaflex 611 Pu SealantsasidharkanthetiNo ratings yet

- Jotamastic Plus - TDS.engDocument5 pagesJotamastic Plus - TDS.engJayasurya PaluriNo ratings yet

- Flexseal PU425 (K - 27.02.2020)Document2 pagesFlexseal PU425 (K - 27.02.2020)Mohamed RusfanNo ratings yet

- Hyperdesmo PB 2k - v3.1Document3 pagesHyperdesmo PB 2k - v3.1Mahmut AlmalahNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- ADCOTE 548-81R + Coreactant F (TDS)Document4 pagesADCOTE 548-81R + Coreactant F (TDS)Wasif AzimNo ratings yet

- POLYPOXY-NF Technical Data SheetDocument2 pagesPOLYPOXY-NF Technical Data SheetCommando crawlerNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Soudal SpecDocument3 pagesSoudal Specthang TranNo ratings yet

- Vetoflex SS783: High Quality Elastic One Component Moisture Cure Silicone SealantDocument2 pagesVetoflex SS783: High Quality Elastic One Component Moisture Cure Silicone SealantSHAIK ASIMUDDINNo ratings yet

- Product DataDocument2 pagesProduct DataegomoNo ratings yet

- Mastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingFrancois-No ratings yet

- Masterinject 1315 TdsDocument2 pagesMasterinject 1315 Tdsjoem927No ratings yet

- Devcon 2 TonDocument2 pagesDevcon 2 Tonpepefloresx2013No ratings yet

- Masterseal NP 472 (Brisk)Document2 pagesMasterseal NP 472 (Brisk)MumtazNo ratings yet

- 3471 Metal Set S1Document2 pages3471 Metal Set S1mahmouddiaa554No ratings yet

- 3463 Magic SteelDocument2 pages3463 Magic Steelmahmouddiaa554No ratings yet

- Air SystemDocument12 pagesAir Systemmahmouddiaa554No ratings yet

- AlignmentDocument7 pagesAlignmentmahmouddiaa554No ratings yet

- Basic Chilled Water SystemDocument45 pagesBasic Chilled Water Systemmahmouddiaa554No ratings yet

- رابعة ابتدائى تكنولوجيا معلوماتDocument8 pagesرابعة ابتدائى تكنولوجيا معلوماتmahmouddiaa554No ratings yet

- Chemtools Viton Chemical Compatibility ChartDocument18 pagesChemtools Viton Chemical Compatibility Chartmahmouddiaa554No ratings yet

- Surface PhenomenaDocument16 pagesSurface PhenomenaDuy Anh ĐàoNo ratings yet

- Standard Raw Material Information Citruskin: 1. Supplier Name / Manufacturing LocationDocument5 pagesStandard Raw Material Information Citruskin: 1. Supplier Name / Manufacturing Locationchristophe teissierNo ratings yet

- Plant Biochemistry 2 RevDocument59 pagesPlant Biochemistry 2 Revenrico andrionNo ratings yet

- GCSE Comb Higher Chemistry 2023Document57 pagesGCSE Comb Higher Chemistry 2023Ramy MohamedNo ratings yet

- 6.chemical Changes PDFDocument15 pages6.chemical Changes PDFHakim Abbas Ali PhalasiyaNo ratings yet

- Topic Practice 3: Very Short Answer Type Questions - 1 MarkDocument7 pagesTopic Practice 3: Very Short Answer Type Questions - 1 MarkDebasis GhosalNo ratings yet

- Ce212 Lecture 5 - Geology For Civil Engineering (Geology and Civil Engineering Relationship)Document8 pagesCe212 Lecture 5 - Geology For Civil Engineering (Geology and Civil Engineering Relationship)KIM JINHWANNo ratings yet

- Christmas Essay in EnglishDocument6 pagesChristmas Essay in Englishd3h7qfpr100% (2)

- MSDS GlucoseDocument17 pagesMSDS GlucosedesyekaaNo ratings yet

- Journal of Environmental Chemical Engineering: SciencedirectDocument13 pagesJournal of Environmental Chemical Engineering: SciencedirectGerson MartinezNo ratings yet

- Alcohols, Phenols & Ether - QuestionsDocument8 pagesAlcohols, Phenols & Ether - QuestionsK. RupaNo ratings yet

- Mil IndexDocument57 pagesMil IndexFranco SwanepoelNo ratings yet

- Advanced Chemical Escape Hood: Oil & Gas - Petrochemical and Chemical Processing - Mining - DefenceDocument4 pagesAdvanced Chemical Escape Hood: Oil & Gas - Petrochemical and Chemical Processing - Mining - DefenceJan VenterNo ratings yet

- Propagation MediaDocument38 pagesPropagation MediaHumayne SutherlandNo ratings yet

- Physical Chemistry - Redox ReactionDocument4 pagesPhysical Chemistry - Redox ReactionDivyanshuMittalNo ratings yet

- LeChatelier Virtual LabDocument2 pagesLeChatelier Virtual LabJuan PabloNo ratings yet

- CPE666 - Chapter 4 PDFDocument71 pagesCPE666 - Chapter 4 PDFbruce bartonNo ratings yet

- NCERT Solutions For Class 10 Science Chapter 1 Chemical Reactions & EquationsDocument1 pageNCERT Solutions For Class 10 Science Chapter 1 Chemical Reactions & Equationscaptain6233No ratings yet

- Grillet 2019 - Iron Acquisition Strategies in Land Plants - Not So Different After AllDocument8 pagesGrillet 2019 - Iron Acquisition Strategies in Land Plants - Not So Different After AlllolysstoNo ratings yet

- Industrial Visit ReportDocument49 pagesIndustrial Visit ReportRajat Rastogi 143No ratings yet

- Accepted Manuscript: International Journal of Biological MacromoleculesDocument66 pagesAccepted Manuscript: International Journal of Biological MacromoleculesMinuNo ratings yet

- Earth Science Module 2 Physical and Chemical Properties of MineralsDocument19 pagesEarth Science Module 2 Physical and Chemical Properties of MineralsJongseong ParkNo ratings yet

- 12chapter FERROCEMENT STRUCTURES - BNBC 2020 CommentaryDocument25 pages12chapter FERROCEMENT STRUCTURES - BNBC 2020 CommentaryTarif Aziz MarufNo ratings yet

- Chemical Bonding Lewis Structure Formal Charges Molecular GeometryDocument29 pagesChemical Bonding Lewis Structure Formal Charges Molecular GeometryChristine FerrerNo ratings yet

- Articulo 2Document31 pagesArticulo 2Lissy TabordaNo ratings yet

- Chapter 4Document29 pagesChapter 4MD. Aminul IslamNo ratings yet

- Principles of Human Physiology 4th Edition Stanfield Test BankDocument35 pagesPrinciples of Human Physiology 4th Edition Stanfield Test Bankjulieterrellqojnsrfdix100% (9)

- Strength and Durability Studies of Concrete Containing Waste Foundry SandDocument173 pagesStrength and Durability Studies of Concrete Containing Waste Foundry Sanddilip bNo ratings yet

- Chemical Cleaning ChartDocument4 pagesChemical Cleaning ChartSudhanshu DashNo ratings yet

- Emailing SEM - V (C-I)Document5 pagesEmailing SEM - V (C-I)Sbjakkcbhj fbhdNo ratings yet