Professional Documents

Culture Documents

P7 To P9 - 4 - MinorHonors - NDT Techniques - I (VI, LPT, MPT) - 72-86

P7 To P9 - 4 - MinorHonors - NDT Techniques - I (VI, LPT, MPT) - 72-86

Uploaded by

parthgiri90Copyright:

Available Formats

You might also like

- Paut-Specific Exam Paut SP002Document8 pagesPaut-Specific Exam Paut SP002Tuan Pham Minh82% (11)

- ASME SEC V Questions and Answers V2Document18 pagesASME SEC V Questions and Answers V2Ashwani Dogra100% (4)

- NDT Question and AnswerDocument11 pagesNDT Question and Answersatya_chaganti100% (3)

- Asme Questions and Answers Part ViDocument22 pagesAsme Questions and Answers Part ViAshwani DograNo ratings yet

- NDT Exam PDFDocument4 pagesNDT Exam PDFshyamkumar rakotiNo ratings yet

- NDT MCQDocument5 pagesNDT MCQLovejot72% (36)

- VT QuizDocument3 pagesVT QuizGoutam Kumar Deb100% (1)

- 44) API 653 Day 7 Book (1 To 52)Document53 pages44) API 653 Day 7 Book (1 To 52)SHAHIDALI100% (1)

- Machine Fault Diagnostics MCQDocument1 pageMachine Fault Diagnostics MCQKali Kumar VardhineediNo ratings yet

- Asme Sec 5 QuestionsDocument13 pagesAsme Sec 5 Questionsanasseeksscribd100% (1)

- ME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzDocument13 pagesME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzAjithNo ratings yet

- DCQ Assessment Questionnaire Subjective Question Position: NDT InspectorDocument5 pagesDCQ Assessment Questionnaire Subjective Question Position: NDT InspectoramirrulasyrafNo ratings yet

- NDT CT1Document2 pagesNDT CT1பிரதீப் சாமிநாதன்No ratings yet

- 2 4Document9 pages2 4kihal zohirNo ratings yet

- Lion KingsDocument32 pagesLion KingsFahad AhmadNo ratings yet

- Question Answer NDT 27.12.2016Document35 pagesQuestion Answer NDT 27.12.2016Prashant PuriNo ratings yet

- Each One Carries One Mark 20 1 20 Marks: The Penetrant Applied To The Surface of A Test SpecimenDocument4 pagesEach One Carries One Mark 20 1 20 Marks: The Penetrant Applied To The Surface of A Test Specimenshyamkumar rakotiNo ratings yet

- NDE Examination Question PaperDocument6 pagesNDE Examination Question PaperMOhammed PatelNo ratings yet

- Basic NDT QuestionsDocument15 pagesBasic NDT Questionsgbsubbu100% (3)

- Asme Sec V Questions and AnswersDocument32 pagesAsme Sec V Questions and AnswersAshwani Dogra100% (6)

- Soal UjianDocument10 pagesSoal UjianHary SasmayaNo ratings yet

- Quizzes On ASME VDocument11 pagesQuizzes On ASME VHary SasmayaNo ratings yet

- Non-Destructive Testing MCQ Type Question Bank-2: A) Measure Depth of ScratchesDocument6 pagesNon-Destructive Testing MCQ Type Question Bank-2: A) Measure Depth of ScratchesMegha DixitNo ratings yet

- VT General QuestionsDocument6 pagesVT General Questionsgopakumar72100% (1)

- Unit 6 - NDT - Nanotechnology-MCQDocument9 pagesUnit 6 - NDT - Nanotechnology-MCQHarshal NagpureNo ratings yet

- B Tech Mech Ndt-4th Year-Set-1Document6 pagesB Tech Mech Ndt-4th Year-Set-1Anubhav Rathor SahuNo ratings yet

- Sample Questions For The Level 2Document5 pagesSample Questions For The Level 2Reinaldo OrejuelaNo ratings yet

- QB 5 - Basic NDT - LT QBDocument5 pagesQB 5 - Basic NDT - LT QBprabhakaran.SNo ratings yet

- NDT Basics GuideDocument29 pagesNDT Basics Guideravindra_jivaniNo ratings yet

- PTDocument6 pagesPTAbhijith ChandranNo ratings yet

- Dial Calipers - QuizizzDocument13 pagesDial Calipers - QuizizzChristian DimasNo ratings yet

- ECT Level 1Document66 pagesECT Level 1rf85ahmadiNo ratings yet

- Acoustic Emission Testing Method Level I Questions: Southern Inspection ServicesDocument5 pagesAcoustic Emission Testing Method Level I Questions: Southern Inspection Servicesprabhakaran.SNo ratings yet

- Asme Section V Asme 16.5 Asme b31.3 - Questions and AnswersDocument29 pagesAsme Section V Asme 16.5 Asme b31.3 - Questions and AnswersAmr Elsayed100% (4)

- Section 5 QuestionsDocument4 pagesSection 5 QuestionsSameer MohammadNo ratings yet

- Unit 02 ObjDocument2 pagesUnit 02 Obj19114 Govind100% (1)

- ECT Level 2Document66 pagesECT Level 2rf85ahmadiNo ratings yet

- Api 577-5Document17 pagesApi 577-5muhammadazhar100% (1)

- Non Destructive Testing: Instruction To CandidatesDocument2 pagesNon Destructive Testing: Instruction To CandidatesHOD MEDNo ratings yet

- Aircraft Construction and Repair Chap.2Document8 pagesAircraft Construction and Repair Chap.2Yenoh SisoNo ratings yet

- NDT PT Level 1Document59 pagesNDT PT Level 1Long BinNo ratings yet

- VT No: 1Document12 pagesVT No: 1JithuJohnNo ratings yet

- NDT Objective Paper 2023-24Document2 pagesNDT Objective Paper 2023-24venkyNo ratings yet

- ASME V QuestionsDocument25 pagesASME V QuestionsAshish PatelNo ratings yet

- Multiple Choice 5 NDEDocument4 pagesMultiple Choice 5 NDEBoon India TrichyNo ratings yet

- Met 312 NDTDocument8 pagesMet 312 NDTJanit JijiNo ratings yet

- Name: - DateDocument7 pagesName: - Datekarioke mohaNo ratings yet

- Unit Test 1 (23nov21)Document5 pagesUnit Test 1 (23nov21)Abhishek GosaviNo ratings yet

- API 570 Exam ClosedDocument12 pagesAPI 570 Exam ClosedMisbah ur Rehman100% (1)

- ECT Level 3Document66 pagesECT Level 3rf85ahmadiNo ratings yet

- Magnetic Particles Testing Eng РаздаткаDocument10 pagesMagnetic Particles Testing Eng Раздаткаoluwatobi ajayiNo ratings yet

- 11-12-13-14-15 NDTDocument9 pages11-12-13-14-15 NDTDevaryan MishraNo ratings yet

- PT CW 3Document6 pagesPT CW 3jasminneeNo ratings yet

- Unit 01 ObjDocument3 pagesUnit 01 Obj19114 GovindNo ratings yet

- MT Level - I QB 4Document8 pagesMT Level - I QB 4kingstonNo ratings yet

- Practice 2 - Questions - CSWIPDocument10 pagesPractice 2 - Questions - CSWIPravichandran0506No ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Photonics, Volume 2: Nanophotonic Structures and MaterialsFrom EverandPhotonics, Volume 2: Nanophotonic Structures and MaterialsNo ratings yet

- Full-Field Measurements and Identification in Solid MechanicsFrom EverandFull-Field Measurements and Identification in Solid MechanicsMichel GrediacNo ratings yet

- Datasheet PDFDocument21 pagesDatasheet PDFheriNo ratings yet

- Einstein PHD DissertationDocument6 pagesEinstein PHD DissertationBuyCollegePaperOnlineBillings100% (1)

- 1 3343hs652c24 PDFDocument1 page1 3343hs652c24 PDFmarko9292No ratings yet

- The Limit Deposit Velocity Model, A New Approach: Sape A. Miedema, Robert C. RamsdellDocument14 pagesThe Limit Deposit Velocity Model, A New Approach: Sape A. Miedema, Robert C. RamsdellZhadyra BerdauletovaNo ratings yet

- Thermal Characterization of Phase Change Materials by Differential Scanning Calorimetry-A ReviewDocument33 pagesThermal Characterization of Phase Change Materials by Differential Scanning Calorimetry-A Reviewramy Mohamed abdel-monemNo ratings yet

- Res Lab QPDocument5 pagesRes Lab QPeee2014.rvsNo ratings yet

- Maquina Portatil de Cerradura de BolsaDocument22 pagesMaquina Portatil de Cerradura de Bolsakaterin1329No ratings yet

- Brake Control System: SectionDocument54 pagesBrake Control System: SectionYB MOTOR Nissan - Datsun SpecialistNo ratings yet

- Bending Strength of Gear Teeth by Cantilever-Plate TheoryDocument8 pagesBending Strength of Gear Teeth by Cantilever-Plate TheoryIsmail Ali Abdul AzizNo ratings yet

- X5200 Pulse UVIR Flame Detector InstructionsDocument34 pagesX5200 Pulse UVIR Flame Detector Instructionsbouzeghoul walidNo ratings yet

- BF Elcos enDocument24 pagesBF Elcos enMuntasir MunirNo ratings yet

- Design EngineeringDocument11 pagesDesign EngineeringzainabNo ratings yet

- Slit-Lamp Biomicroscopy Module 1.4 - FINALDocument136 pagesSlit-Lamp Biomicroscopy Module 1.4 - FINALloris1978s100% (2)

- Microwave Engineering Chapter 2 Example 3Document21 pagesMicrowave Engineering Chapter 2 Example 3John Bofarull GuixNo ratings yet

- Concrete Midi BlocksDocument1 pageConcrete Midi BlocksAjdinNo ratings yet

- BE Civil Degree Programme 18Document471 pagesBE Civil Degree Programme 18biopharmacyNo ratings yet

- Installation, Operation and Maintenance Manual For Air CurtainsDocument40 pagesInstallation, Operation and Maintenance Manual For Air CurtainsMithen MostafizurNo ratings yet

- DC Molded-Case Circuit Breakers Industry ComparisonDocument8 pagesDC Molded-Case Circuit Breakers Industry ComparisonJEFFERSON ALEJANDRO MURILLO CAPERANo ratings yet

- Gcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HDocument18 pagesGcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HOmar AbdallaNo ratings yet

- Datasheet Vertex DE19R EU en 2023 BDocument2 pagesDatasheet Vertex DE19R EU en 2023 Bbehzad esNo ratings yet

- Grade 5 Science Lesson 8-Force, Energy and Machines Module 1Document21 pagesGrade 5 Science Lesson 8-Force, Energy and Machines Module 1praviseNo ratings yet

- Herstein: Topics in Algebra - Subgroups and A Counting PrincipleDocument2 pagesHerstein: Topics in Algebra - Subgroups and A Counting Principleul trNo ratings yet

- Investigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusDocument14 pagesInvestigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusEmre EmlekNo ratings yet

- NBC 105 2020 FINAL (DUDBC Site)Document106 pagesNBC 105 2020 FINAL (DUDBC Site)N TNo ratings yet

- RME Data Sheet - Millmast HandlerDocument1 pageRME Data Sheet - Millmast HandlerСергейNo ratings yet

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasNo ratings yet

- CNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqDocument51 pagesCNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqEngr.shamiNo ratings yet

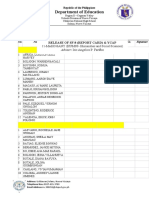

- Attendance Release of Report Card 11-HumssDocument3 pagesAttendance Release of Report Card 11-HumssIsis Angelica FarinasNo ratings yet

- Atlanta Permaline 2021Document2 pagesAtlanta Permaline 2021Christopher VelascoNo ratings yet

P7 To P9 - 4 - MinorHonors - NDT Techniques - I (VI, LPT, MPT) - 72-86

P7 To P9 - 4 - MinorHonors - NDT Techniques - I (VI, LPT, MPT) - 72-86

Uploaded by

parthgiri90Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P7 To P9 - 4 - MinorHonors - NDT Techniques - I (VI, LPT, MPT) - 72-86

P7 To P9 - 4 - MinorHonors - NDT Techniques - I (VI, LPT, MPT) - 72-86

Uploaded by

parthgiri90Copyright:

Available Formats

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

PRACTICAL: 7

Numerical/MCQ based on VI and LT.

Date:

AIM: Numerical/MCQ based on VI and LT.

Relevant CO:

1. To learn the principles, working and applications of Visual inspection, liquid

penetrant testing and magnetic particle testing.

2. Inspect different metals and alloys by visual inspection method.

1. What is the tube diameter of rigid borescope?

a) 0.1 to 10 mm b) 0.5 to 90 mm c) 0.2 to 100 mm d) 0.9 to 70 mm

Answer: d

What is the field of view range of borescope?

a) 30 to 180 degree b) 10 to 90 degree c) 60 to 360 degree d) 10 to 180 degree

2. Answer: b

What type of fibre is present in the optical tube of mini borescope?

a) Quartz fibre b) Asbestos fibre c) Plastic fibre d) Resin fibre

Answer: a

3. Which of the following option is true about hybrid borescopes?

a) Use rod lenses combined with concave lenses

b) Use rod lenses combined with concave mirror

c) Use rod lenses combined with convex lenses

d) Use rod lenses combined with convex mirror

Answer: c

4. Upto which length the flexible fiberscopes are available?

a) 12 m b) 14 m c) 16 m d) 18 m

Answer: a

5. Which of the following can not be detected with visual inspection.

a) Blow hole b) Crack within the casting c) Tears d) Rattails

Answer: b

6. Visual inspection is essentially carried out using magnifying glass.

a) True b) False

Answer: b

7. A common inspection instrument that is used to visually inspect internal bore surfaces

is

a. magnifying glass b. borescope c. phototube d. microscope

Answer: b

8. During a visual examination, a welding discontinuity that could not be detected would

be:

a. undercut b. cracks c. porosity d. side wall lack of fusion

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

71

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

Answer: d

9. An inherent discontinuity in forgings that cannot be detected using visual testing is:

a. bursts b. cracks c. seams d. laps

Answer: a

10. To examine areas around bends inside a pipe section, the visual examiner uses a:

a. telescope b. fiber-optic borescope c. bore scope d. microscope

Answer: b

11. The visible portion of the electromagnetic spectrum extends form:

a. 100-400 nm b. 210-370 nm c. 380-770 nm d. 570-891 nm

Answer: c

12. The portion of the eye that regulates the quantity of light admitted is called:

a. iris b. pupil c. retina d. cones

Answer: b

13. In general, the total magnification of borescopes is in the range of:

a. 3x – 4x b. 2x – 8x c. 4x – 10x d. 5x – 15x

Answer: c

14. A method used for copying the topography of a surface that cannot be moved or one

that would be damaged in transferal is called:

a. NDT b. in-situ NDT c. replication d. surface metallography

Answer: c

15. When should the visual inspection be performed for most effectiveness?

a) After Welding b) Before Welding c) During Welding d) All the Above

Answer: d

16. Which of the following NDT can detect only surface defects?

a) Radiographic b) Ultrasonic c) Visual Inspection d) None of the above

Answer: c

17. Which of the following are visual examination methods?

a) Shear and Longitudinal b) Visible and Fluorescent c) Direct and Indirect d) Manual

and Automatic

Answer: c

18. In normal healthy eye, incoming light is focused on

a) Retina b) Iris c) Optic Disc d) Cornea

Answer: a

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

72

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

Leak Testing

Which of the following is the basic type of true defect that would be indicated during a

bubble leak test by a continuous flow of bubbles?

A. A hole or crack through the test boundary

B. Slag inclusion in center of weld

C. Extended area of surface defects or cracks

D. Lack of fusion at room of weld

What parameter can directly affect the sensitivity of any vacuum box bubble leak test?

A. Ambient air dew point temperature is more than -4 oC (25 oF).

B. Slight residual magnetism in test specimen

C. Amount of pressure differential created with the box

D. Test specimen size

Which of the following factors can most affect the sensitivity attainable by a pressure

bubble leak test?

A. Operator alertness and technique

B. Size and shape of test specimen

C. Time of day testing is done

D. Number of test technicians

Which type of leaking discontinuity is most likely to go undetected during a pressure

bubble leak test?

A. A discontinuity (such as a crack) that shows up well on a radiograph

B. A very small leak or a very large leak

C. A defect in a mechanically rolled joint

D. A defect in a welded joint

When performing a bubble leak test, the reason for periodically checking a leak detector

solution against a known path leak would be to:

A. Determine the viscosity of the solution

B. Measure the size of the leak

C. Verify that the leak still existed

D. Verify that the solution functioned as required

Which of the following systems or components are not good candidates for leak testing?

A. Piping and pressure vessels

B. Refrigerator piping

C. Vacuum chambers

D. Sintered material components

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

73

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

A helium mass spectrometer is used in which of the following NDT techniques or methods?

A. X-Ray spectrocopy

B. Optical holography

C. Acoustic holography

D. Leak testing

Which of the following is a technique of leak testing?

A. Static

B. Gaseous diffusion

C. Dynamic

D. Direct probe

Potentially, the most sensitive leak testing technique is the?

A. Bubble test

B. Pressure change test

C. Mass spectrometer test

D. Liquid penetrant test

Establishing differential pressure between the test object and environment is an essential

element in which of the following NDT methods?

A. X-Ray diffraction

B. Neutron radiography

C. Leak testing

D. Eddy current testing

Which of the following best describes the type of leak test used when the interior of the test

object is evaluated and the tracer gas is applied to the exterior, while the leak detector is

connected to the evacuating system?

A. Static leak test

B. Helium leak test

C. Dynamic leak test

D. Halogen leak test

Assuming no significant leakage, if the temperature increased during a pressure drop leak test,

the pressure in the system under test would?

A. Increase

B. Remain the same

C. Decrease

D. First increase, then decrease to its former level

If the sensitivity of the halogen leak detector is constant throughout a test, which of the

following is true upon completion of the test?

A. No leaks smaller than a certain size have gone undetected

B. The total leak rate of the test object is less than a certain amount

C. The instrument and the test procedure were capable of detecting leakage of a certain size

during the test

D. The instrument and the test procedure were only capable of detecting leakage of a certain

size upstream from the tracer gas during the test.

All leak detection methods are dependent upon:

A. Barometric pressure

B. Gas or fluid flow

C. Mass spectrometer analysis

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

74

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

D. Mean free paths of helium flow

In an evaluated system, sensitivity of a pressure change leak test is dependent not only on the

pressure change observed, but also on the degree of outgassing. Outgassing is best defined as:

A. The viscosity of the pressurizing gas

B. Being directly proportional to the temperature of the gas

C. The release of gas from materials in a vacuum

D. The drop in test pressure due to leakage from the vacuum manifold

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

75

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

76

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

PRACTICAL: 8

Numerical/MCQ based on LPT.

Date:

AIM: Numerical/MCQ based on LPT.

.

Relevant CO:

1. To learn the principles, working and applications of Visual inspection,

liquid penetrant testing and magnetic particle testing.

2. Apply liquid penetrant testing and magnetic particle testing NDT

methods for a given problem and identify defects.

1. Liquid penetrant testing is based on the principle of:

A. Polarized sound waves in a liquid

B. Magnetic domains

C. Absorption of X rays

D. Capillary action

Answer: D

2. When a small diameter tube is placed in a glass of water, water rises in the tube

to a level above the adjacent surface. This is called:

A. Viscosity

B. Capillary action

C. Surface tension

D. Barometric testing

Answer: B

3. How is the size of a liquid penetrant indication usually related to the

discontinuity it represents:

A. Larger than

B. Smaller than

C. Equal to

D. Not related to

Answer: A

4. A penetrant that is self-emulsifying is called:

A. Solvent removable

B. Water washable

C. Post-emulsified

D. Dual sensitivity method

Answer: B

5. A penetrant process which employs an emulsifier as a separate step in the

penetrant removal process is called:

A. Solvent removable

B. Water washable

C. Post-emulsified

D. Dual sensitivity method

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

77

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

Answer: C

6. A penetrant process in which excess penetrant is removed with an organic

solvent is called:

A. Solvent removable

B. Water washable

C. Post-emulsified

D. Dual method

Answer: A

7. Which of the following statements accurately describes the capabilities of liquid

penetrant testing?

A. Liquid penetrant testing is useful for locating subsurface discontinuities in a test piece

B. Liquid penetrant testing is useful for locating discontinuities in porous materials

C. Liquid penetrant testing is useful for locating discontinuities which are open to the surface

in non-porous materials

D. none of the above

Answer: C

8. Which of the following discontinuity types could typically be found with a liquid

penetrant test?

A. Internal slag in a weld

B. Internal slag in a casting

C. Sensitization in austenitic stainless steel

D. Fatigue cracks

Answer: D

9. Which of the following chemical elements are normally held to a minimum in

liquid penetrant materials, when testing stainless steel and titanium?

A. Hydrogen

B. Chlorine

C. Carbon

D. Oil

Answer: B

10. Which of the following chemical elements are normally held to a minimum in

liquid penetrant materials when testing nickel based alloys?

A. Sulphur

B. Oxygen

C. Carbon

D. Nitrogen

Answer: A

11. Which of the following is the most desirable method of pre-cleaning a test piece

prior to penetrant testing?

A. Sand blasting

B. Vapour degreasing

C. Emery cloth

D. Wire brushing

Answer: B

12. Which of the following pre-cleaning processes is not recommended?

A. Detergent cleaning

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

78

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

B. Vapour degreasing

C. Shot blasting

D. Ultrasonic cleaning

Answer: C

13. A wire brush should be used for pre-cleaning:

A. When grease and oil must be removed

B. Only as a last resort

C. When rust is to be removed

D. When grinding burrs must be removed

Answer: C

14. A hydrometer is used to measure:

A. Penetrant viscosity

B. Specific gravity of water based wet developers

C. Penetrant specific gravity

D. Cleaner specific gravity

Answer: B

15. Visible, solvent removable penetrants are most advantageous for:

A. Inspecting parts with rough surfaces

B. Inspecting batches of small parts

C. Inspecting parts at remote locations

D. Inspecting parts with porous surfaces

Answer: C

16. For adequate test results, the black light used in fluorescent penetrant

examination should provide what minimum black light intensity at the test

surface?

A. 100 foot candles per square centimetre

B. 1000 microwatts per square centimetre

C. 800 foot candles

D. 35 microwatts per square centimetre

Answer: B

17. What minimum warm-up time is required for acceptable performance of a

mercury Vapour arc black light?

A. None

B. 2 minutes

C. 5 minutes

D. 10 minutes

Answer: C

18. Which of the following penetrants contains an emulsifying agent?

A. Solvent removable

B. Water washable

C. Post emulsifiable

D. Fluorescent

Answer: B

19. Which of the following penetrants must be treated with an emulsifier prior to

water removal?

A. Solvent removable

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

79

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

B. Water washable

C. Post emulsifiable

D. Fluorescent

Answer: C

20. What is the function of an emulsifier?

A. To remove the excess penetrant

B. To develop indications with a post emulsifiable penetrant system

C. To assist penetration with a post emulsifiable penetrant system

D. To make a post emulsifiable penetrant water washable

Answer: D

21. An oil based emulsifier is called:

A. Hydrophilic

B. Hydrophobic

C. Lipophilic

D. Fluoroscopic

Answer: C

22. A water based emulsifier is called:

A. Hydrophilic

B. Hydrophobic

C. Lipophilic

D. Fluoroscopic

Answer: A

23. Methylene chloride, isopropyl, alcohol, naptha and mineral spirits are examples

of:

A. Emulsifiers

B. Developers

C. Solvent removers

D. None of the above

Answer: C

24. What type of solvent removers may be used with a solvent removable

penetrant?

A. Any organic solvent

B. Only the cleaner recommended by the manufacturer of the penetrant

C. Any alcohol based solvents

D. Only chlorinated hydrocarbons

Answer: B

25. Which of the following is a prerequisite for a penetrant test?

A. Developer must be applied in a thin, even coat

B. Any surface coatings or soils must be completely removed

C. All traces of penetrant materials should be removed after testing is complete

D. The test object must be non-magnetic

Answer: B

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

80

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

PRACTICAL: 9

Numerical/MCQ based on MPT.

Date:

AIM: Numerical/MCQ based on MPT.

.

Relevant CO:

1. To learn the principles, working and applications of Visual inspection,

liquid penetrant testing and magnetic particle testing.

2. Apply liquid penetrant testing and magnetic particle testing NDT

methods for a given problem and identify defects.

1. Selection of magnetic particle colour is based on:

A. Optimum performance of magnetic particle/developer

B. Colour of inspection light available

C. Obtaining maximum contrast with the test piece background

D. Optimum colour response of the human eye

Answer: C

2. The residual method is applicable to:

A. Surface discontinuities only

B. Subsurface discontinuities only

C. Either surface or subsurface discontinuities

D. All but tight surface cracks

Answer: A

3. Highest sensitivity to fine surface cracks would be obtained by which of the

following techniques?

A. Residual field, wet method

B. Residual field, dry method

C. Continuous field, wet method

D. Continuous field, dry method

Answer: C

4. A residual field is always less than a continuous field because?

A. The magnetic field, as shown by a hysteresis curve, is zero when there is no

magnetising force

B. The magnetic field, as shown by a hysteresis curve, is less when there is no

magnetising force

C. The magnetic field, as shown by a hysteresis curve, is greater when there is no

magnetising

force

D. None of the above

Answer: B

5. Where possible, circular magnetisation is preferable to longitudinal

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

81

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

magnetization because:

A. Less current is required

B. Stronger fields are obtained

C. Fewer confusing secondary poles are produced

D. None of the above is true

Answer: D

6. Which of the following is a disadvantage of the dry method?

A. Ease of application with portable equipment

B. Superior sensitivity for fine surface cracks

C. Good particle mobility with AC and HWDC

D. Good sensitivity for subsurface discontinuities

Answer: B

7. Which of the following is an advantage of the dry method

A. Good sensitivity for subsurface discontinuities

B. Faster than wet method for quantities of small test pieces

C. Easily applied in an automated system

D. Easy coverage of surfaces of irregularly shaped test pieces

Answer: A

8. Loss of fine particle sizes due to re-use of dry particles would probably lead

to:

A. Loss of sensitivity to larger discontinuities

B. Loss of sensitivity to finer discontinuities

C. Unpredictable results

D. Slower inspection speeds

Answer: B

9. Which of the following is a disadvantage of the wet method?

A. It is the most sensitive method for detection of very fine surface cracks

B. Rapid testing of large quantities of small test pieces

C. Readily adaptable to mechanised equipment

D. Excellent detection of completely subsurface discontinuities

Answer: D

10. Which of the following is an advantage of the wet method?

A. Excellent detection of completely subsurface discontinuities

B. Ease of bath recovery and re-use

C. Low flash point ensures freedom from fire hazards

D. Relatively clean and easy to work with

Answer: B

11. The primary reason for using water rather than oil as a suspension

medium for

wet method baths is that:

A. Water is more chemically inert than oil

B. Bath flammability hazards are eliminated

C. Water has the capability to dissolve the needed rust inhibitors

D. Water baths may be used at lower temperatures than oil baths

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

82

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

Answer: B

12. A disadvantage of fluorescent magnetic particles is:

A. Darkened area and black light are required

B. Abnormally high sensitivity

C. Only dry particles are available

D. Only wet concentrate is available

Answer: A

13. A common physiological effect of black light inspection on the inspector

is:

A. Burned retinas of the eyes

B. Rejected cornea syndrome

C. Eye fatigue

D. Retarded iris control

Answer: C

14. A common physiological effect of black light inspection on the inspector

is:

A. Burned retinas of the eyes

B. Rejected cornea syndrome

C. Eyeball fluorescence

D. Retarded iris control

Answer: C

15. Which of the following represents ultraviolet light of wavelengths which

are

potentially injurious (1 Å = 10-10m)

A. 2000 to 3200Å

B. 3200 to 4000 Å

C. 4000 to 4600Å

D. 4600 to 5200 Å

Answer: A

16. Dyes which receive light at one wavelength and re-emit light of another

wavelength are called:

A. L.E.Ds

B. Phosphorescent

C. Luminescent

D. Fluorescent

Answer: D

17. Most fluorescent dyes used for magnetic particle testing fluoresce what

colour?

A. Blue green

B. Yellow green

C. Blue black

D. Red orange

Answer: B

18. The best available source of black light for inspection is:

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

83

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

A. The mercury vapour lamp

B. The fluorescent tube

C. The incandescent bulb

D. Sunlight

Answer: A

19. Which of the following would be likely to cause variations in the output of

an inspection black light?

A. Voltage fluctuations

B. Aged bulb

C. Dirty filter

D. All of the above

Answer: D

20. The temperature above which steels become nonmagnetic is called the:

A. Zero retentivity

B. Curie point

C. Demagnetisation temperature

D. Random polar point

Answer: B

21. The temperature above which most soft steels become nonmagnetic is

about:

A. 440ºC(770oF)

B. 523ºC (975ºF)

C. 626ºC (1160ºF)

D. 754ºC (1390ºF)

Answer: D

22. The most common method of demagnetising small test pieces is:

A. Heat treatment

B. Shot peening

C. Passing through an AC coil

D. Direct contact with AC current

Answer: C

23. Demagnetisation with reversing DC is more effective than AC because:

A. DC is more penetrating

B. Demagnetisation is assisted by the skin effect

C. DC is more direct

D. Not true - AC is more effective

Answer: A

24. The type of discontinuity which magnetic particle testing most effectively

locates is:

A. Slag inclusions

B. Magnetic writing

C. Porosity

D. Surface cracks

Answer: D

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

84

METALLURGY ENGINEERING DEPARTMENT

GOVERNMENT ENGINEERING COLLEGE, SECTOR-28, GANDHINAGAR

25. An indication which is formed when two pieces of magnetised steel come

in contact with each other is called:

A. A metallurgical discontinuity

B. Magnetic writing

C. Magnetic transfer

D. A ferromagnetic notch

Answer: B

NDT 1 (VI, LPT, MPT) (NDT114AR01) B.E. Sem IV

85

You might also like

- Paut-Specific Exam Paut SP002Document8 pagesPaut-Specific Exam Paut SP002Tuan Pham Minh82% (11)

- ASME SEC V Questions and Answers V2Document18 pagesASME SEC V Questions and Answers V2Ashwani Dogra100% (4)

- NDT Question and AnswerDocument11 pagesNDT Question and Answersatya_chaganti100% (3)

- Asme Questions and Answers Part ViDocument22 pagesAsme Questions and Answers Part ViAshwani DograNo ratings yet

- NDT Exam PDFDocument4 pagesNDT Exam PDFshyamkumar rakotiNo ratings yet

- NDT MCQDocument5 pagesNDT MCQLovejot72% (36)

- VT QuizDocument3 pagesVT QuizGoutam Kumar Deb100% (1)

- 44) API 653 Day 7 Book (1 To 52)Document53 pages44) API 653 Day 7 Book (1 To 52)SHAHIDALI100% (1)

- Machine Fault Diagnostics MCQDocument1 pageMachine Fault Diagnostics MCQKali Kumar VardhineediNo ratings yet

- Asme Sec 5 QuestionsDocument13 pagesAsme Sec 5 Questionsanasseeksscribd100% (1)

- ME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzDocument13 pagesME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzAjithNo ratings yet

- DCQ Assessment Questionnaire Subjective Question Position: NDT InspectorDocument5 pagesDCQ Assessment Questionnaire Subjective Question Position: NDT InspectoramirrulasyrafNo ratings yet

- NDT CT1Document2 pagesNDT CT1பிரதீப் சாமிநாதன்No ratings yet

- 2 4Document9 pages2 4kihal zohirNo ratings yet

- Lion KingsDocument32 pagesLion KingsFahad AhmadNo ratings yet

- Question Answer NDT 27.12.2016Document35 pagesQuestion Answer NDT 27.12.2016Prashant PuriNo ratings yet

- Each One Carries One Mark 20 1 20 Marks: The Penetrant Applied To The Surface of A Test SpecimenDocument4 pagesEach One Carries One Mark 20 1 20 Marks: The Penetrant Applied To The Surface of A Test Specimenshyamkumar rakotiNo ratings yet

- NDE Examination Question PaperDocument6 pagesNDE Examination Question PaperMOhammed PatelNo ratings yet

- Basic NDT QuestionsDocument15 pagesBasic NDT Questionsgbsubbu100% (3)

- Asme Sec V Questions and AnswersDocument32 pagesAsme Sec V Questions and AnswersAshwani Dogra100% (6)

- Soal UjianDocument10 pagesSoal UjianHary SasmayaNo ratings yet

- Quizzes On ASME VDocument11 pagesQuizzes On ASME VHary SasmayaNo ratings yet

- Non-Destructive Testing MCQ Type Question Bank-2: A) Measure Depth of ScratchesDocument6 pagesNon-Destructive Testing MCQ Type Question Bank-2: A) Measure Depth of ScratchesMegha DixitNo ratings yet

- VT General QuestionsDocument6 pagesVT General Questionsgopakumar72100% (1)

- Unit 6 - NDT - Nanotechnology-MCQDocument9 pagesUnit 6 - NDT - Nanotechnology-MCQHarshal NagpureNo ratings yet

- B Tech Mech Ndt-4th Year-Set-1Document6 pagesB Tech Mech Ndt-4th Year-Set-1Anubhav Rathor SahuNo ratings yet

- Sample Questions For The Level 2Document5 pagesSample Questions For The Level 2Reinaldo OrejuelaNo ratings yet

- QB 5 - Basic NDT - LT QBDocument5 pagesQB 5 - Basic NDT - LT QBprabhakaran.SNo ratings yet

- NDT Basics GuideDocument29 pagesNDT Basics Guideravindra_jivaniNo ratings yet

- PTDocument6 pagesPTAbhijith ChandranNo ratings yet

- Dial Calipers - QuizizzDocument13 pagesDial Calipers - QuizizzChristian DimasNo ratings yet

- ECT Level 1Document66 pagesECT Level 1rf85ahmadiNo ratings yet

- Acoustic Emission Testing Method Level I Questions: Southern Inspection ServicesDocument5 pagesAcoustic Emission Testing Method Level I Questions: Southern Inspection Servicesprabhakaran.SNo ratings yet

- Asme Section V Asme 16.5 Asme b31.3 - Questions and AnswersDocument29 pagesAsme Section V Asme 16.5 Asme b31.3 - Questions and AnswersAmr Elsayed100% (4)

- Section 5 QuestionsDocument4 pagesSection 5 QuestionsSameer MohammadNo ratings yet

- Unit 02 ObjDocument2 pagesUnit 02 Obj19114 Govind100% (1)

- ECT Level 2Document66 pagesECT Level 2rf85ahmadiNo ratings yet

- Api 577-5Document17 pagesApi 577-5muhammadazhar100% (1)

- Non Destructive Testing: Instruction To CandidatesDocument2 pagesNon Destructive Testing: Instruction To CandidatesHOD MEDNo ratings yet

- Aircraft Construction and Repair Chap.2Document8 pagesAircraft Construction and Repair Chap.2Yenoh SisoNo ratings yet

- NDT PT Level 1Document59 pagesNDT PT Level 1Long BinNo ratings yet

- VT No: 1Document12 pagesVT No: 1JithuJohnNo ratings yet

- NDT Objective Paper 2023-24Document2 pagesNDT Objective Paper 2023-24venkyNo ratings yet

- ASME V QuestionsDocument25 pagesASME V QuestionsAshish PatelNo ratings yet

- Multiple Choice 5 NDEDocument4 pagesMultiple Choice 5 NDEBoon India TrichyNo ratings yet

- Met 312 NDTDocument8 pagesMet 312 NDTJanit JijiNo ratings yet

- Name: - DateDocument7 pagesName: - Datekarioke mohaNo ratings yet

- Unit Test 1 (23nov21)Document5 pagesUnit Test 1 (23nov21)Abhishek GosaviNo ratings yet

- API 570 Exam ClosedDocument12 pagesAPI 570 Exam ClosedMisbah ur Rehman100% (1)

- ECT Level 3Document66 pagesECT Level 3rf85ahmadiNo ratings yet

- Magnetic Particles Testing Eng РаздаткаDocument10 pagesMagnetic Particles Testing Eng Раздаткаoluwatobi ajayiNo ratings yet

- 11-12-13-14-15 NDTDocument9 pages11-12-13-14-15 NDTDevaryan MishraNo ratings yet

- PT CW 3Document6 pagesPT CW 3jasminneeNo ratings yet

- Unit 01 ObjDocument3 pagesUnit 01 Obj19114 GovindNo ratings yet

- MT Level - I QB 4Document8 pagesMT Level - I QB 4kingstonNo ratings yet

- Practice 2 - Questions - CSWIPDocument10 pagesPractice 2 - Questions - CSWIPravichandran0506No ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Photonics, Volume 2: Nanophotonic Structures and MaterialsFrom EverandPhotonics, Volume 2: Nanophotonic Structures and MaterialsNo ratings yet

- Full-Field Measurements and Identification in Solid MechanicsFrom EverandFull-Field Measurements and Identification in Solid MechanicsMichel GrediacNo ratings yet

- Datasheet PDFDocument21 pagesDatasheet PDFheriNo ratings yet

- Einstein PHD DissertationDocument6 pagesEinstein PHD DissertationBuyCollegePaperOnlineBillings100% (1)

- 1 3343hs652c24 PDFDocument1 page1 3343hs652c24 PDFmarko9292No ratings yet

- The Limit Deposit Velocity Model, A New Approach: Sape A. Miedema, Robert C. RamsdellDocument14 pagesThe Limit Deposit Velocity Model, A New Approach: Sape A. Miedema, Robert C. RamsdellZhadyra BerdauletovaNo ratings yet

- Thermal Characterization of Phase Change Materials by Differential Scanning Calorimetry-A ReviewDocument33 pagesThermal Characterization of Phase Change Materials by Differential Scanning Calorimetry-A Reviewramy Mohamed abdel-monemNo ratings yet

- Res Lab QPDocument5 pagesRes Lab QPeee2014.rvsNo ratings yet

- Maquina Portatil de Cerradura de BolsaDocument22 pagesMaquina Portatil de Cerradura de Bolsakaterin1329No ratings yet

- Brake Control System: SectionDocument54 pagesBrake Control System: SectionYB MOTOR Nissan - Datsun SpecialistNo ratings yet

- Bending Strength of Gear Teeth by Cantilever-Plate TheoryDocument8 pagesBending Strength of Gear Teeth by Cantilever-Plate TheoryIsmail Ali Abdul AzizNo ratings yet

- X5200 Pulse UVIR Flame Detector InstructionsDocument34 pagesX5200 Pulse UVIR Flame Detector Instructionsbouzeghoul walidNo ratings yet

- BF Elcos enDocument24 pagesBF Elcos enMuntasir MunirNo ratings yet

- Design EngineeringDocument11 pagesDesign EngineeringzainabNo ratings yet

- Slit-Lamp Biomicroscopy Module 1.4 - FINALDocument136 pagesSlit-Lamp Biomicroscopy Module 1.4 - FINALloris1978s100% (2)

- Microwave Engineering Chapter 2 Example 3Document21 pagesMicrowave Engineering Chapter 2 Example 3John Bofarull GuixNo ratings yet

- Concrete Midi BlocksDocument1 pageConcrete Midi BlocksAjdinNo ratings yet

- BE Civil Degree Programme 18Document471 pagesBE Civil Degree Programme 18biopharmacyNo ratings yet

- Installation, Operation and Maintenance Manual For Air CurtainsDocument40 pagesInstallation, Operation and Maintenance Manual For Air CurtainsMithen MostafizurNo ratings yet

- DC Molded-Case Circuit Breakers Industry ComparisonDocument8 pagesDC Molded-Case Circuit Breakers Industry ComparisonJEFFERSON ALEJANDRO MURILLO CAPERANo ratings yet

- Gcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HDocument18 pagesGcse Combined Science: Trilogy: Higher Tier Paper 6: Physics 2HOmar AbdallaNo ratings yet

- Datasheet Vertex DE19R EU en 2023 BDocument2 pagesDatasheet Vertex DE19R EU en 2023 Bbehzad esNo ratings yet

- Grade 5 Science Lesson 8-Force, Energy and Machines Module 1Document21 pagesGrade 5 Science Lesson 8-Force, Energy and Machines Module 1praviseNo ratings yet

- Herstein: Topics in Algebra - Subgroups and A Counting PrincipleDocument2 pagesHerstein: Topics in Algebra - Subgroups and A Counting Principleul trNo ratings yet

- Investigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusDocument14 pagesInvestigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusEmre EmlekNo ratings yet

- NBC 105 2020 FINAL (DUDBC Site)Document106 pagesNBC 105 2020 FINAL (DUDBC Site)N TNo ratings yet

- RME Data Sheet - Millmast HandlerDocument1 pageRME Data Sheet - Millmast HandlerСергейNo ratings yet

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasNo ratings yet

- CNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqDocument51 pagesCNC Machining Operations: Submitted By: Waqar Ahmad (22) Sibghat Ullah (20) Submitted To: Engr. Umer FarooqEngr.shamiNo ratings yet

- Attendance Release of Report Card 11-HumssDocument3 pagesAttendance Release of Report Card 11-HumssIsis Angelica FarinasNo ratings yet

- Atlanta Permaline 2021Document2 pagesAtlanta Permaline 2021Christopher VelascoNo ratings yet