Professional Documents

Culture Documents

CFR 2011 Title49 Vol3 Sec192 505

CFR 2011 Title49 Vol3 Sec192 505

Uploaded by

assemalzoubi1983Copyright:

Available Formats

You might also like

- UG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99Document3 pagesUG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99sergiotero100% (1)

- Case 2290 PDFDocument90 pagesCase 2290 PDFDarioNo ratings yet

- Carboxen 1000 Permanent Gases PDFDocument2 pagesCarboxen 1000 Permanent Gases PDFSichem Guerrero100% (2)

- CFR 2011 Title49 Vol3 Sec192 507Document2 pagesCFR 2011 Title49 Vol3 Sec192 507assemalzoubi1983No ratings yet

- CFR 2011 Title49 Vol3 Sec192 513Document1 pageCFR 2011 Title49 Vol3 Sec192 513AssemNo ratings yet

- ASME 2046-2 - 2046-2 Pneumatic Testing of Pressure Vesels, UG-90 (C) (2) Section VIII, Division 1Document1 pageASME 2046-2 - 2046-2 Pneumatic Testing of Pressure Vesels, UG-90 (C) (2) Section VIII, Division 1Mike DukasNo ratings yet

- CFR 2011 Title49 Vol3 Part192 SubparteDocument4 pagesCFR 2011 Title49 Vol3 Part192 SubparteAssemNo ratings yet

- CFR 2011 Title49 Vol3 Part192 AppdDocument2 pagesCFR 2011 Title49 Vol3 Part192 AppdAssemNo ratings yet

- PCC-2 - Code Case For PCC Plugs 52454Document13 pagesPCC-2 - Code Case For PCC Plugs 52454hendropaulNo ratings yet

- CFR 2011 Title49 Vol3 Part178 AppCDocument1 pageCFR 2011 Title49 Vol3 Part178 AppCAssemNo ratings yet

- CFR 2011 Title49 Vol3 Part178 AppdDocument2 pagesCFR 2011 Title49 Vol3 Part178 AppdAssemNo ratings yet

- CFR 2011 Title49 Vol3 Sec192 939Document2 pagesCFR 2011 Title49 Vol3 Sec192 939AssemNo ratings yet

- CFR 2011 Title49 Vol3 Sec195 308Document1 pageCFR 2011 Title49 Vol3 Sec195 308assemalzoubi1983No ratings yet

- CFR 2011 Title49 Vol3 Sec192 751Document1 pageCFR 2011 Title49 Vol3 Sec192 751assemalzoubi1983No ratings yet

- Part TPDocument6 pagesPart TPMARCIONo ratings yet

- CFR 2011 Title49 Vol3 Part178 SubpartpDocument6 pagesCFR 2011 Title49 Vol3 Part178 SubpartpAssemNo ratings yet

- Extracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsDocument1 pageExtracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsRudolph RednoseNo ratings yet

- Pipeline and Hazardous Materials Safety Admin., DOT 178.702Document12 pagesPipeline and Hazardous Materials Safety Admin., DOT 178.702AssemNo ratings yet

- CFR 2011 Title49 Vol3 Part179 SubparteDocument5 pagesCFR 2011 Title49 Vol3 Part179 SubparteAssemNo ratings yet

- April 25, 2018: EXPIRATION DATE: 2022-03-31Document10 pagesApril 25, 2018: EXPIRATION DATE: 2022-03-31Jetwill, C.A. Control de CalidadNo ratings yet

- HH 2Document5 pagesHH 2mirzakamranbaig.mkNo ratings yet

- Para. 345.3.3 (C) Para. 345 Appendix X Para. 345.8: 345.3 Preparation For Leak TestDocument2 pagesPara. 345.3.3 (C) Para. 345 Appendix X Para. 345.8: 345.3 Preparation For Leak TestANIL PLAMOOTTILNo ratings yet

- CFR 2011 Title49 Vol3 Sec193 2509Document1 pageCFR 2011 Title49 Vol3 Sec193 2509assemalzoubi1983No ratings yet

- CFR 2011 Title49 Vol3 Part192 SubpartODocument20 pagesCFR 2011 Title49 Vol3 Part192 SubpartOassemalzoubi1983No ratings yet

- 49 CFR 180.209 (Up To Date As of 11-28-2023)Document7 pages49 CFR 180.209 (Up To Date As of 11-28-2023)ahamedkyanaNo ratings yet

- Asme CCase N-432Document4 pagesAsme CCase N-432julianmorantesNo ratings yet

- ASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Document5 pagesASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Rafael Esteban BarriaNo ratings yet

- Testing Concrete: BS 1881: Part 115: 1986Document11 pagesTesting Concrete: BS 1881: Part 115: 1986Mohamed AnasNo ratings yet

- Cast Aluminum Alloy Railing Posts: Standard Specification ForDocument2 pagesCast Aluminum Alloy Railing Posts: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- BS 1881-Part 115-86Document11 pagesBS 1881-Part 115-86jaafar abdullahNo ratings yet

- Code Case 2742 - Sec XDocument2 pagesCode Case 2742 - Sec XlincinkrishnanNo ratings yet

- Specmca Ons " "'H" Sections of The Technical IDocument7 pagesSpecmca Ons " "'H" Sections of The Technical ISIVANo ratings yet

- 07 QAP-DynamicDocument7 pages07 QAP-DynamicEticala RohithNo ratings yet

- CFR 2014 Title46 Vol2 Part59Document7 pagesCFR 2014 Title46 Vol2 Part59amm110amm90No ratings yet

- Astm C 1107Document5 pagesAstm C 1107Adán Vera Go100% (1)

- Sec. II A - SA - 202Document4 pagesSec. II A - SA - 202RamuAlagappanNo ratings yet

- Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution SystemsDocument5 pagesManually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution SystemsRichard PNo ratings yet

- CFR 2011 Title49 Vol3 Sec195 116Document2 pagesCFR 2011 Title49 Vol3 Sec195 116assemalzoubi1983No ratings yet

- 345 Leak TestingDocument4 pages345 Leak TestingStephen RajNo ratings yet

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-27Document2 pagesAsme BPVC 2021 Section Viii Div. 1-2 - Ug-27canizales70No ratings yet

- Part TG General Requirements Article TG-1 Scope and JurisdictionDocument8 pagesPart TG General Requirements Article TG-1 Scope and JurisdictionMARCIONo ratings yet

- 1 Lot 1a Vol 2 of 10 235Document1 page1 Lot 1a Vol 2 of 10 235dana setiawanNo ratings yet

- Compression Testing Machine Used For Testing of Concrete and Mortar - RequirementsDocument9 pagesCompression Testing Machine Used For Testing of Concrete and Mortar - RequirementsUppala Krishna ChaitanyaNo ratings yet

- 9.section - 9 QAPDocument77 pages9.section - 9 QAPheroNo ratings yet

- Testing Application Standard TAS 201-94Document6 pagesTesting Application Standard TAS 201-94Shawn DeolNo ratings yet

- Ac 33 64-1Document4 pagesAc 33 64-1mohamadhosein mohamadiNo ratings yet

- Asme Sec Viii Div 1 Uw-51Document1 pageAsme Sec Viii Div 1 Uw-51ALEXIS MORALESNo ratings yet

- Asme Section 8 Div 1 - RTDocument12 pagesAsme Section 8 Div 1 - RTGulfnde Industrial ServiceNo ratings yet

- RMC CHK Guideking On SiteDocument2 pagesRMC CHK Guideking On SiteSachin ShindeNo ratings yet

- Indian Standard: Prestressed Concrete Pipes (Including Specials) - SpecificationDocument36 pagesIndian Standard: Prestressed Concrete Pipes (Including Specials) - Specificationsixramesh123No ratings yet

- N-2409 - Flexible Pipes PDFDocument88 pagesN-2409 - Flexible Pipes PDFIgor BastosNo ratings yet

- C 1277 - 97 Qzeynzctotc - PDFDocument4 pagesC 1277 - 97 Qzeynzctotc - PDFwahyudiNo ratings yet

- Pages From ASME B31.3 - 2016Document5 pagesPages From ASME B31.3 - 2016Gulzar AliNo ratings yet

- SP8718 1Document11 pagesSP8718 1sergiy.matushchenkoNo ratings yet

- Vitrified Clay Pipe, Extra Strength, Standard Strength and PerforatedDocument3 pagesVitrified Clay Pipe, Extra Strength, Standard Strength and PerforatedEvert RiveraNo ratings yet

- Abstract of ASTM F959M 1997Document12 pagesAbstract of ASTM F959M 1997Jesse ChenNo ratings yet

- CFR 2011 Title49 Vol3 Part193 SubparthDocument3 pagesCFR 2011 Title49 Vol3 Part193 Subparthassemalzoubi1983No ratings yet

- 243 RegulatorDocument24 pages243 RegulatorDavid Somogyi DovalNo ratings yet

- Mini Project Process ControlDocument3 pagesMini Project Process ControlAnonymous pUBVkkKNo ratings yet

- TE-5-MD 60HZ Efficiency CurvesDocument7 pagesTE-5-MD 60HZ Efficiency CurvesRachit SharmaNo ratings yet

- What Is Characteristic CurveDocument7 pagesWhat Is Characteristic Curvehafiz hassan100% (1)

- Turbulent Flow Through PipesDocument17 pagesTurbulent Flow Through Pipesdurga345No ratings yet

- Cold Water Plumbing DesignDocument17 pagesCold Water Plumbing DesignKHA120096 StudentNo ratings yet

- EvaporationDocument11 pagesEvaporationMary Rose Martinez100% (1)

- Convection SummaryDocument10 pagesConvection SummarycacafaruqNo ratings yet

- Devilbiss 8005 To 8015 Air Dryer ManualDocument11 pagesDevilbiss 8005 To 8015 Air Dryer Manualamijoski6051No ratings yet

- Nueva Lista de Piezas Excavadora 325 BLDocument3 pagesNueva Lista de Piezas Excavadora 325 BLWilmert TRNo ratings yet

- Wall Boiling ModelsDocument10 pagesWall Boiling ModelsMohsen SalehiNo ratings yet

- Silotop Zero en 0217 EditDocument4 pagesSilotop Zero en 0217 EditJulio Vega AngelesNo ratings yet

- Aft-Catalog s3 SecDocument10 pagesAft-Catalog s3 SecwemersonsrNo ratings yet

- API Mpms 5.6 CoriolisDocument4 pagesAPI Mpms 5.6 CoriolisadatahdNo ratings yet

- Validation of OLGA HD BHR-2015-G4Document17 pagesValidation of OLGA HD BHR-2015-G4kwonilNo ratings yet

- Pitot TubeDocument2 pagesPitot TubeJinco JoseNo ratings yet

- NS EquationDocument81 pagesNS EquationRitik ChaturvediNo ratings yet

- Manual de La Caldera PDFDocument149 pagesManual de La Caldera PDFHenry RojasNo ratings yet

- Scrubbers PDFDocument8 pagesScrubbers PDFTAREK ALMAHDYNo ratings yet

- Eclipse Tutorial1Document6 pagesEclipse Tutorial1jefpri simanjuntak100% (1)

- Presentation On Centrifugal CompressorsDocument17 pagesPresentation On Centrifugal CompressorsakshayupadhyayNo ratings yet

- CompressorDocument22 pagesCompressorMuhammad Nursalam100% (2)

- Lecture07 Pipeflow HandoutDocument3 pagesLecture07 Pipeflow Handoutgtarun22gupta50% (2)

- Tutorial 2. With SolutionsDocument4 pagesTutorial 2. With SolutionsJoyful GreenNo ratings yet

- Chapter 4 - Fluid Mechanics - Fis - 2020Document69 pagesChapter 4 - Fluid Mechanics - Fis - 2020Noratiqah Binti Mohd AminNo ratings yet

- A New Procedure To Estimate BLEVE OverpressureDocument16 pagesA New Procedure To Estimate BLEVE OverpressureJuan R. Uribe PichiriloNo ratings yet

- Guidelines For Piping Design For Metallurgical IndustriesDocument128 pagesGuidelines For Piping Design For Metallurgical Industriesbalavengu100% (2)

- Gas Shielding For GMAWDocument1 pageGas Shielding For GMAWkapsarcNo ratings yet

- Compressed Air Qualification Gaps Standard Requirement: 1) Dew Point SensorDocument2 pagesCompressed Air Qualification Gaps Standard Requirement: 1) Dew Point SensorAli KureishiNo ratings yet

CFR 2011 Title49 Vol3 Sec192 505

CFR 2011 Title49 Vol3 Sec192 505

Uploaded by

assemalzoubi1983Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CFR 2011 Title49 Vol3 Sec192 505

CFR 2011 Title49 Vol3 Sec192 505

Uploaded by

assemalzoubi1983Copyright:

Available Formats

§ 192.505 49 CFR Ch.

I (10–1–11 Edition)

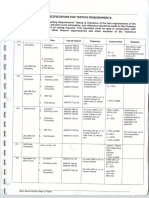

(3) Except for natural gas, nonflam- (c) Except as provided in paragraph

mable. (e) of this section, the strength test

(c) Except as provided in § 192.505(a), must be conducted by maintaining the

if air, natural gas, or inert gas is used pressure at or above the test pressure

as the test medium, the following max- for at least 8 hours.

imum hoop stress limitations apply: (d) If a component other than pipe is

the only item being replaced or added

Maximum hoop stress allowed as per- to a pipeline, a strength test after in-

centage of SMYS

Class location stallation is not required, if the manu-

Natural gas Air or inert gas facturer of the component certifies

1 ......................... 80 80 that—

2 ......................... 30 75 (1) The component was tested to at

3 ......................... 30 50 least the pressure required for the pipe-

4 ......................... 30 40 line to which it is being added;

(2) The component was manufactured

(d) Each joint used to tie in a test under a quality control system that en-

segment of pipeline is excepted from sures that each item manufactured is

the specific test requirements of this at least equal in strength to a proto-

subpart, but each non-welded joint type and that the prototype was tested

must be leak tested at not less than its to at least the pressure required for the

operating pressure. pipeline to which it is being added; or

[35 FR 13257, Aug. 19, 1970, as amended by (3) The component carries a pressure

Amdt. 192–58, 53 FR 1635, Jan. 21, 1988; Amdt. rating established through applicable

192–60, 53 FR 36029, Sept. 16, 1988; Amdt. 192– ASME/ANSI, MSS specifications, or by

60A, 54 FR 5485, Feb. 3, 1989] unit strength calculations as described

in § 192.143.

§ 192.505 Strength test requirements (e) For fabricated units and short

for steel pipeline to operate at a sections of pipe, for which a post in-

hoop stress of 30 percent or more of stallation test is impractical, a pre-

SMYS.

installation strength test must be con-

(a) Except for service lines, each seg- ducted by maintaining the pressure at

ment of a steel pipeline that is to oper- or above the test pressure for at least

ate at a hoop stress of 30 percent or 4 hours.

more of SMYS must be strength tested

[35 FR 13257, Aug. 19, 1970, as amended by

in accordance with this section to sub-

Amdt. 192–85, 63 FR 37504, July 13, 1998;

stantiate the proposed maximum al- Amdt. 192–94, 69 FR 32895, June 14, 2004;

lowable operating pressure. In addi- Amdt. 195–94, 69 FR 54592, Sept. 9, 2004]

tion, in a Class 1 or Class 2 location, if

there is a building intended for human § 192.507 Test requirements for pipe-

occupancy within 300 feet (91 meters) of lines to operate at a hoop stress less

a pipeline, a hydrostatic test must be than 30 percent of SMYS and at or

conducted to a test pressure of at least above 100 p.s.i. (689 kPa) gage.

125 percent of maximum operating Except for service lines and plastic

pressure on that segment of the pipe- pipelines, each segment of a pipeline

line within 300 feet (91 meters) of such that is to be operated at a hoop stress

a building, but in no event may the less than 30 percent of SMYS and at or

test section be less than 600 feet (183 above 100 p.s.i. (689 kPa) gage must be

meters) unless the length of the newly tested in accordance with the fol-

installed or relocated pipe is less than lowing:

600 feet (183 meters). However, if the (a) The pipeline operator must use a

buildings are evacuated while the hoop test procedure that will ensure dis-

stress exceeds 50 percent of SMYS, air covery of all potentially hazardous

or inert gas may be used as the test leaks in the segment being tested.

medium. (b) If, during the test, the segment is

(b) In a Class 1 or Class 2 location, to be stressed to 20 percent or more of

wreier-aviles on DSK3TPTVN1PROD with CFR

each compressor station regulator sta- SMYS and natural gas, inert gas, or air

tion, and measuring station, must be is the test medium—

tested to at least Class 3 location test (1) A leak test must be made at a

requirements. pressure between 100 p.s.i. (689 kPa)

450

VerDate Mar<15>2010 14:56 Jan 03, 2012 Jkt 223216 PO 00000 Frm 00462 Fmt 8010 Sfmt 8010 Y:\SGML\223216.XXX 223216

You might also like

- UG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99Document3 pagesUG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99sergiotero100% (1)

- Case 2290 PDFDocument90 pagesCase 2290 PDFDarioNo ratings yet

- Carboxen 1000 Permanent Gases PDFDocument2 pagesCarboxen 1000 Permanent Gases PDFSichem Guerrero100% (2)

- CFR 2011 Title49 Vol3 Sec192 507Document2 pagesCFR 2011 Title49 Vol3 Sec192 507assemalzoubi1983No ratings yet

- CFR 2011 Title49 Vol3 Sec192 513Document1 pageCFR 2011 Title49 Vol3 Sec192 513AssemNo ratings yet

- ASME 2046-2 - 2046-2 Pneumatic Testing of Pressure Vesels, UG-90 (C) (2) Section VIII, Division 1Document1 pageASME 2046-2 - 2046-2 Pneumatic Testing of Pressure Vesels, UG-90 (C) (2) Section VIII, Division 1Mike DukasNo ratings yet

- CFR 2011 Title49 Vol3 Part192 SubparteDocument4 pagesCFR 2011 Title49 Vol3 Part192 SubparteAssemNo ratings yet

- CFR 2011 Title49 Vol3 Part192 AppdDocument2 pagesCFR 2011 Title49 Vol3 Part192 AppdAssemNo ratings yet

- PCC-2 - Code Case For PCC Plugs 52454Document13 pagesPCC-2 - Code Case For PCC Plugs 52454hendropaulNo ratings yet

- CFR 2011 Title49 Vol3 Part178 AppCDocument1 pageCFR 2011 Title49 Vol3 Part178 AppCAssemNo ratings yet

- CFR 2011 Title49 Vol3 Part178 AppdDocument2 pagesCFR 2011 Title49 Vol3 Part178 AppdAssemNo ratings yet

- CFR 2011 Title49 Vol3 Sec192 939Document2 pagesCFR 2011 Title49 Vol3 Sec192 939AssemNo ratings yet

- CFR 2011 Title49 Vol3 Sec195 308Document1 pageCFR 2011 Title49 Vol3 Sec195 308assemalzoubi1983No ratings yet

- CFR 2011 Title49 Vol3 Sec192 751Document1 pageCFR 2011 Title49 Vol3 Sec192 751assemalzoubi1983No ratings yet

- Part TPDocument6 pagesPart TPMARCIONo ratings yet

- CFR 2011 Title49 Vol3 Part178 SubpartpDocument6 pagesCFR 2011 Title49 Vol3 Part178 SubpartpAssemNo ratings yet

- Extracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsDocument1 pageExtracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsRudolph RednoseNo ratings yet

- Pipeline and Hazardous Materials Safety Admin., DOT 178.702Document12 pagesPipeline and Hazardous Materials Safety Admin., DOT 178.702AssemNo ratings yet

- CFR 2011 Title49 Vol3 Part179 SubparteDocument5 pagesCFR 2011 Title49 Vol3 Part179 SubparteAssemNo ratings yet

- April 25, 2018: EXPIRATION DATE: 2022-03-31Document10 pagesApril 25, 2018: EXPIRATION DATE: 2022-03-31Jetwill, C.A. Control de CalidadNo ratings yet

- HH 2Document5 pagesHH 2mirzakamranbaig.mkNo ratings yet

- Para. 345.3.3 (C) Para. 345 Appendix X Para. 345.8: 345.3 Preparation For Leak TestDocument2 pagesPara. 345.3.3 (C) Para. 345 Appendix X Para. 345.8: 345.3 Preparation For Leak TestANIL PLAMOOTTILNo ratings yet

- CFR 2011 Title49 Vol3 Sec193 2509Document1 pageCFR 2011 Title49 Vol3 Sec193 2509assemalzoubi1983No ratings yet

- CFR 2011 Title49 Vol3 Part192 SubpartODocument20 pagesCFR 2011 Title49 Vol3 Part192 SubpartOassemalzoubi1983No ratings yet

- 49 CFR 180.209 (Up To Date As of 11-28-2023)Document7 pages49 CFR 180.209 (Up To Date As of 11-28-2023)ahamedkyanaNo ratings yet

- Asme CCase N-432Document4 pagesAsme CCase N-432julianmorantesNo ratings yet

- ASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Document5 pagesASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Rafael Esteban BarriaNo ratings yet

- Testing Concrete: BS 1881: Part 115: 1986Document11 pagesTesting Concrete: BS 1881: Part 115: 1986Mohamed AnasNo ratings yet

- Cast Aluminum Alloy Railing Posts: Standard Specification ForDocument2 pagesCast Aluminum Alloy Railing Posts: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- BS 1881-Part 115-86Document11 pagesBS 1881-Part 115-86jaafar abdullahNo ratings yet

- Code Case 2742 - Sec XDocument2 pagesCode Case 2742 - Sec XlincinkrishnanNo ratings yet

- Specmca Ons " "'H" Sections of The Technical IDocument7 pagesSpecmca Ons " "'H" Sections of The Technical ISIVANo ratings yet

- 07 QAP-DynamicDocument7 pages07 QAP-DynamicEticala RohithNo ratings yet

- CFR 2014 Title46 Vol2 Part59Document7 pagesCFR 2014 Title46 Vol2 Part59amm110amm90No ratings yet

- Astm C 1107Document5 pagesAstm C 1107Adán Vera Go100% (1)

- Sec. II A - SA - 202Document4 pagesSec. II A - SA - 202RamuAlagappanNo ratings yet

- Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution SystemsDocument5 pagesManually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution SystemsRichard PNo ratings yet

- CFR 2011 Title49 Vol3 Sec195 116Document2 pagesCFR 2011 Title49 Vol3 Sec195 116assemalzoubi1983No ratings yet

- 345 Leak TestingDocument4 pages345 Leak TestingStephen RajNo ratings yet

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-27Document2 pagesAsme BPVC 2021 Section Viii Div. 1-2 - Ug-27canizales70No ratings yet

- Part TG General Requirements Article TG-1 Scope and JurisdictionDocument8 pagesPart TG General Requirements Article TG-1 Scope and JurisdictionMARCIONo ratings yet

- 1 Lot 1a Vol 2 of 10 235Document1 page1 Lot 1a Vol 2 of 10 235dana setiawanNo ratings yet

- Compression Testing Machine Used For Testing of Concrete and Mortar - RequirementsDocument9 pagesCompression Testing Machine Used For Testing of Concrete and Mortar - RequirementsUppala Krishna ChaitanyaNo ratings yet

- 9.section - 9 QAPDocument77 pages9.section - 9 QAPheroNo ratings yet

- Testing Application Standard TAS 201-94Document6 pagesTesting Application Standard TAS 201-94Shawn DeolNo ratings yet

- Ac 33 64-1Document4 pagesAc 33 64-1mohamadhosein mohamadiNo ratings yet

- Asme Sec Viii Div 1 Uw-51Document1 pageAsme Sec Viii Div 1 Uw-51ALEXIS MORALESNo ratings yet

- Asme Section 8 Div 1 - RTDocument12 pagesAsme Section 8 Div 1 - RTGulfnde Industrial ServiceNo ratings yet

- RMC CHK Guideking On SiteDocument2 pagesRMC CHK Guideking On SiteSachin ShindeNo ratings yet

- Indian Standard: Prestressed Concrete Pipes (Including Specials) - SpecificationDocument36 pagesIndian Standard: Prestressed Concrete Pipes (Including Specials) - Specificationsixramesh123No ratings yet

- N-2409 - Flexible Pipes PDFDocument88 pagesN-2409 - Flexible Pipes PDFIgor BastosNo ratings yet

- C 1277 - 97 Qzeynzctotc - PDFDocument4 pagesC 1277 - 97 Qzeynzctotc - PDFwahyudiNo ratings yet

- Pages From ASME B31.3 - 2016Document5 pagesPages From ASME B31.3 - 2016Gulzar AliNo ratings yet

- SP8718 1Document11 pagesSP8718 1sergiy.matushchenkoNo ratings yet

- Vitrified Clay Pipe, Extra Strength, Standard Strength and PerforatedDocument3 pagesVitrified Clay Pipe, Extra Strength, Standard Strength and PerforatedEvert RiveraNo ratings yet

- Abstract of ASTM F959M 1997Document12 pagesAbstract of ASTM F959M 1997Jesse ChenNo ratings yet

- CFR 2011 Title49 Vol3 Part193 SubparthDocument3 pagesCFR 2011 Title49 Vol3 Part193 Subparthassemalzoubi1983No ratings yet

- 243 RegulatorDocument24 pages243 RegulatorDavid Somogyi DovalNo ratings yet

- Mini Project Process ControlDocument3 pagesMini Project Process ControlAnonymous pUBVkkKNo ratings yet

- TE-5-MD 60HZ Efficiency CurvesDocument7 pagesTE-5-MD 60HZ Efficiency CurvesRachit SharmaNo ratings yet

- What Is Characteristic CurveDocument7 pagesWhat Is Characteristic Curvehafiz hassan100% (1)

- Turbulent Flow Through PipesDocument17 pagesTurbulent Flow Through Pipesdurga345No ratings yet

- Cold Water Plumbing DesignDocument17 pagesCold Water Plumbing DesignKHA120096 StudentNo ratings yet

- EvaporationDocument11 pagesEvaporationMary Rose Martinez100% (1)

- Convection SummaryDocument10 pagesConvection SummarycacafaruqNo ratings yet

- Devilbiss 8005 To 8015 Air Dryer ManualDocument11 pagesDevilbiss 8005 To 8015 Air Dryer Manualamijoski6051No ratings yet

- Nueva Lista de Piezas Excavadora 325 BLDocument3 pagesNueva Lista de Piezas Excavadora 325 BLWilmert TRNo ratings yet

- Wall Boiling ModelsDocument10 pagesWall Boiling ModelsMohsen SalehiNo ratings yet

- Silotop Zero en 0217 EditDocument4 pagesSilotop Zero en 0217 EditJulio Vega AngelesNo ratings yet

- Aft-Catalog s3 SecDocument10 pagesAft-Catalog s3 SecwemersonsrNo ratings yet

- API Mpms 5.6 CoriolisDocument4 pagesAPI Mpms 5.6 CoriolisadatahdNo ratings yet

- Validation of OLGA HD BHR-2015-G4Document17 pagesValidation of OLGA HD BHR-2015-G4kwonilNo ratings yet

- Pitot TubeDocument2 pagesPitot TubeJinco JoseNo ratings yet

- NS EquationDocument81 pagesNS EquationRitik ChaturvediNo ratings yet

- Manual de La Caldera PDFDocument149 pagesManual de La Caldera PDFHenry RojasNo ratings yet

- Scrubbers PDFDocument8 pagesScrubbers PDFTAREK ALMAHDYNo ratings yet

- Eclipse Tutorial1Document6 pagesEclipse Tutorial1jefpri simanjuntak100% (1)

- Presentation On Centrifugal CompressorsDocument17 pagesPresentation On Centrifugal CompressorsakshayupadhyayNo ratings yet

- CompressorDocument22 pagesCompressorMuhammad Nursalam100% (2)

- Lecture07 Pipeflow HandoutDocument3 pagesLecture07 Pipeflow Handoutgtarun22gupta50% (2)

- Tutorial 2. With SolutionsDocument4 pagesTutorial 2. With SolutionsJoyful GreenNo ratings yet

- Chapter 4 - Fluid Mechanics - Fis - 2020Document69 pagesChapter 4 - Fluid Mechanics - Fis - 2020Noratiqah Binti Mohd AminNo ratings yet

- A New Procedure To Estimate BLEVE OverpressureDocument16 pagesA New Procedure To Estimate BLEVE OverpressureJuan R. Uribe PichiriloNo ratings yet

- Guidelines For Piping Design For Metallurgical IndustriesDocument128 pagesGuidelines For Piping Design For Metallurgical Industriesbalavengu100% (2)

- Gas Shielding For GMAWDocument1 pageGas Shielding For GMAWkapsarcNo ratings yet

- Compressed Air Qualification Gaps Standard Requirement: 1) Dew Point SensorDocument2 pagesCompressed Air Qualification Gaps Standard Requirement: 1) Dew Point SensorAli KureishiNo ratings yet