Professional Documents

Culture Documents

Deutz-MWM 604B Maintenance Schedules

Deutz-MWM 604B Maintenance Schedules

Uploaded by

Hörbi Metz0 ratings0% found this document useful (0 votes)

1 views3 pagesOriginal Title

Deutz-MWM 604B Maintenance schedules

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views3 pagesDeutz-MWM 604B Maintenance Schedules

Deutz-MWM 604B Maintenance Schedules

Uploaded by

Hörbi MetzCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

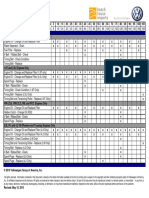

Maintenance schedules 604B.

xls >2000 hrs

E10 E20 E25 E30 E40 E50 E60 E70

Job ref. 50* 500 1000 2000 4000 8000 16000 32000 CG Description Action Jobcard

1 x x x x x x 01 Crankcase breathing Clean 3-1-1

All cylinder units (cylinder liners, pistons, big end Check /

2 x x 01 3-2-3

bearing, valves, valve gears) service

3 x 04 Cylinder liner Renew -

4 x x 05 Main and thrust bearings Renew 2-7-1

5 x 05 Crankshaft rot.shaft lip seal Renew -

6 x 07 Piston Renew -

7 x 08 Screw connection charge air line cylinder head Retighten -

8 x x x x 08 Inlet and outlet valve clearance Check 1-1-1

9 x x 08 Endoscope check of cylinder head and cylinder liner Check 1-1-4

10 x x x 08 Inlet and outlet valves Service 1-7-1

11 x 09 Timing chest Check -

12 x 10 Camshaft Renew -

13 x 10 Camshaft bearing Renew 4-1-1

14 x 14 Lube oil pump Renew -

15 x x x x x x x x 15 Lubrication oil Renew 8-2-2

16 x x x x x x x x 15 Oil filters Service 8-10-1

17 x x x x x x x x 15 Centrifugal filter Service 8-13-1

18 x x x 15 Water and oil sides of oil cooler Clean 8-8-1

19 x x x x 17 Injection timing Check 7-6-1

20 x x x x 17 Drive coupling low pressure fuel feed pump Check 7-11-1

21 x x 17 Injection pump Service 7-4-2

22 x 17 Injection pump Renew -

23 x x x 19 Retighten injector clamps Retighten 7-7-1

24 x x x 19 Injection valves Check 7-8-1

25 x x 19 Injection valves Service 7-9-1

26 x x x x x x x 20 Fuel filter Service 7-10-1

27 x x x x x x x x 22 Air filter Service 6-3-11

28 x x x x x 27 Control motor speed governor Check -

29 x x x x x 27 Control linkage: Check setting Check 5-4-14

30 x x 27 Speed governor Service -

31 x x x x x x x 30 Dirt collector before air starter Clean -

32 x x x 30 Air starting valves Service 1-11-1

33 x x x x x x x 30 Dirt collector in compressed air pipe Clean 10-3-2

34 x x x 30 Rotary starting air distributor Check 10-2-1

35 x x 30 Air starter Service 10-2-2

Visual inspection of compressed air container, at least

36 x 32 Check -

every 2 years

Carry out pressure test on compressed air container,

37 x x x 32 Check -

at least every 4 years

38 x x x x x x 34 Rubber damper Check 12-1-2

Viscosity damper (renew every 4 years in the case of

39 x x x 34 Renew 12-1-1

less than 4000 operating hours/year)

40 x x 34 Leaf spring damper Service 12-1-4

41 x x x x 36 Mounted heat exchanger Service 9-10-1

42 x x x x 36 Honeycomb radiator Clean -

43 x 36 Cooling water thermostat Check 9-8-1

44 x x 36 Cooling water thermostat (+ check housing) Renew 9-8-1

45 x x x x x x x 37 Condition of cooling water Check Section 4.4

46 x x x x 37 Raw water pump Lubricate 9-7-4

47 x x 37 Raw water pump Service 9-7-4

48 x x 37 Cooling water pump Service 9-7-1/2/3

49 x 37 Cooling water pump Renew -

50 x 37 Raw water pump Renew -

51 x x x x x x x x 38 Raw water filter Clean -

52 x x x x x 38 Preheating system Check 9-9-1

Integrated fittings and control elements of cooling

53 x x x x 38 Service -

water system

54 x x 38 Raw water thermostat Check -

55 x x 38 Raw water thermostat Renew -

56 x x x 43 Exhaust turbocharger Service 6-6-1

57 x x x x x x x 44 Battery charge Check 13-4-1

58 x x x x x x x 44 Alternator V-belts Check -

59 x x x x x 44 Starter Check 13-3-1

60 x x x x x 44 Alternator Service 13-2-1

61 x x x x x x x 46 Engine alignment and elastic mounting Check 3-7-1

11-1-

1/2/3/21 /

62 x x x x x x x 48 Monitoring and shut down units Check

11-3-1 / 11-

7-1

63 x x x x x x x 48 Cable for chafe marks Check -

64 x x x x x 52 Flexible coupling Check 2-17-1

Water-side of charge air cooler ( in the case of raw

65 x 58 Clean 6-4-1

water cooling)

66 x x x 58 Charge air cooler water side and air side Clean 6-4-1/2

67 x 99 External screw connections, hoses and seals Check -

Maintenance schedule for 604B engines with more than 2000 running hours per year

* Initial maintenance jobs 50 operating hours after commissioning of new or generally overhauled engines

Always check manual for special jobs

Maintenance schedules 604B.xlsile 300-2000 hrs

E10 E20 E30 E40 E50 E60 E70

No 50* 1/2 year 1 year 2 years 4 years 8 years 16 years BG Description Action Jobcard

1 x x x x x 01 Crankcase breathing Clean 3-1-1

2 x x 01 All cylinder units (cylinder liners, pistons, big end Check / 3-2-3

bearing, valves, valve gears) service

3 x 04 Cylinder liner Renew -

4 x x 05 Main and thrust bearings Renew 2-7-1

5 x 05 Crankshaft rot.shaft lip seal Renew -

6 x 07 Piston Renew -

7 x 08 Screw connection charge air line cylinder head Retighten -

8 x x x x 08 Inlet and outlet valve clearance Check 1-1-1

9 x x 08 Endoscope check of cylinder head and cylinder liner Check 1-1-4

10 x 08 Inlet and outlet valves Service 1-7-1

11 x 09 Timing chest Check -

12 x 10 Camshaft Renew -

13 x 10 Camshaft bearing Renew 4-1-1

14 x 14 Lube oil pump Renew -

15 x x x x x x x 15 Lubrication oil Renew 8-2-2

16 x x x x x x x 15 Oil filters (at least every 500 running hrs) Service 8-10-1

17 x x x x x x x 15 Centrifugal filter (at least every 500 running hrs) Service 8-13-1

18 x x x 15 Water and oil sides of oil cooler Clean 8-8-1

19 x x x x 17 Injection timing Check 7-6-1

20 x x x x 17 Drive coupling low pressure fuel feed pump Check 7-11-1

21 x x 17 Injection pump Service 7-4-2

22 x 17 Injection pump Renew -

23 x x 19 Retighten injector clamps Retighten 7-7-1

24 x x x 19 Injection valves Check 7-8-1

25 x x 19 Injection valves Service 7-9-1

26 x x x x x x 20 Fuel filter (at least every 500 running hrs) Service 7-10-1

27 x x x x x x x 22 Air filter Service 6-3-11

28 x x x x 27 Control motor speed governor Check -

29 x x x x x 27 Control linkage: Check setting Check 5-4-14

30 x x 27 Speed governor Service -

31 x x x x x x 30 Dirt collector before air starter Clean -

32 x x x 30 Air starting valves Service 1-11-1

33 x x x x x x 30 Dirt collector in compressed air pipe Clean 10-3-2

34 x x x 30 Rotary starting air distributor Check 10-2-1

35 x x 30 Air starter Service 10-2-2

36 x 32 Visual inspection of compressed air container, at least Check -

every 2 years

37 x x x 32 Carry out pressure test on compressed air container, at Check -

least every 4 years

38 x x x x x x 34 Rubber damper Check 12-1-2

39 x x x 34 Viscosity damper (renew every 4 years in the case of less Renew 12-1-1

than 4000 operating hours/year)

40 x x 34 Leaf spring damper Service 12-1-4

41 x x x x 36 Mounted heat exchanger Service 9-10-1

42 x x x x 36 Honeycomb radiator Clean -

43 x 36 Cooling water thermostat Check 9-8-1

44 x x 36 Cooling water thermostat (+ check housing) Renew 9-8-1

45 x x x x x x 37 Condition of cooling water Check Section 4.4

46 x x x 37 Raw water pump (at least every 500 running hours) Lubricate 9-7-4

47 x x 37 Raw water pump Service 9-7-4

48 x x 37 Cooling water pump Service 9-7-1/2/3

49 x 37 Cooling water pump Renew -

50 x 37 Raw water pump Renew -

51 x x x x x x x 38 Raw water filter Clean -

52 x x x x x 38 Preheating system Check 9-9-1

53 x x x 38 Integrated fittings and control elements of coolingwater Service -

system

54 x x 38 Raw water thermostat Check -

55 x x 38 Raw water thermostat Renew -

56 x x x 43 Exhaust turbocharger Service 6-6-1

57 x x x x x x 44 Battery charge Check 13-4-1

58 x x x x x x 44 Alternator V-belts Check -

59 x x x x x 44 Starter Check 13-3-1

60 x x x x x 44 Alternator Service 13-2-1

61 x x x x x x 46 Engine alignment and elastic mounting Check 3-7-1

62 x x x x x x 48 Monitoring and shut down units Check 11-1-1/2/3/21

/ 11-3-1 / 11-

7-1

63 x x x x x x 48 Cable for chafe marks Check -

64 x x x x x 52 Flexible coupling Check 2-17-1

65 x 58 Water-side of charge air cooler ( in the case of raw water Clean 6-4-1

cooling)

66 x x x 58 Charge air cooler water side and air side Clean 6-4-1/2

67 x 99 External screw connections, hoses and seals Check -

Maintenance schedule for 604B engines which are running between 300 and 2000 hours per year

* Initial maintenance jobs 50 operating hours after commissioning of new or generally overhauled engines

Always check manual for special jobs

Maintenance schedules 604B.xls < 300 hrs

E10 E20 E30 E40 E70

No 50* 1 year 2 years 6 years 16 years BG Description Action Jobcard

1 x x x 01 Crankcase breathing Clean 3-1-1

2 x 01 All cylinder units (cylinder liners, pistons, big end bearing, Check / 3-2-3

valves, valve gears) service

3 x 04 Cylinder liner Renew -

4 x 05 Main and thrust bearings Renew 2-7-1

5 x 05 Crankshaft rot.shaft lip seal Renew -

6 x 07 Piston Renew -

7 x 08 Screw connection charge air line cylinder head Retighten -

8 x x x 08 Inlet and outlet valve clearance Check 1-1-1

9 x x 08 Endoscope check of cylinder head and cylinder liner Check 1-1-4

10 08 Inlet and outlet valves Service 1-7-1

11 x 09 Timing chest Check -

12 x 10 Camshaft Renew -

13 x 10 Camshaft bearing Renew 4-1-1

14 x 14 Lube oil pump Renew -

15 x x x x x 15 Lubrication oil Renew 8-2-2

16 x x x x x 15 Oil filters (at least every 500 running hrs) Service 8-10-1

17 x x x x x 15 Centrifugal filter (at least every 500 running hrs) Service 8-13-1

18 x x 15 Water and oil sides of oil cooler Clean 8-8-1

19 x x 17 Injection timing Check 7-6-1

20 x 17 Drive coupling low pressure fuel feed pump Check 7-11-1

21 x 17 Injection pump Service 7-4-2

22 x 17 Injection pump Renew -

23 x 19 Retighten injector clamps Retighten 7-7-1

24 x x 19 Injection valves Check 7-8-1

25 x 19 Injection valves Service 7-9-1

26 x x x x 20 Fuel filter (at least every 500 running hrs) Service 7-10-1

27 x x x x x 22 Air filter Service 6-3-11

28 x x x 27 Control motor speed governor Check -

29 x x 27 Control linkage: Check setting Check 5-4-14

30 x 27 Speed governor Service -

31 x x x x 30 Dirt collector before air starter Clean -

32 x 30 Air starting valves Service 1-11-1

33 x x x x 30 Dirt collector in compressed air pipe Clean 10-3-2

34 x x x x 30 Rotary starting air distributor Check 10-2-1

35 x 30 Air starter Service 10-2-2

36 x x 32 Visual inspection of compressed air container, at least Check -

every 2 years

37 x x x 32 Carry out pressure test on compressed air container, at Check -

least every 4 years

38 x x x x 34 Rubber damper Check 12-1-2

39 x x x 34 Viscosity damper (renew every 4 years in the case of less Renew 12-1-1

than 4000 operating hours/year)

40 x 34 Leaf spring damper Service 12-1-4

41 x x 36 Mounted heat exchanger Service 9-10-1

42 x x 36 Honeycomb radiator Clean -

43 x x x 36 Cooling water thermostat Check 9-8-1

44 x 36 Cooling water thermostat (+ check housing) Renew 9-8-1

45 x x x x 37 Condition of cooling water Check Section 4.4

46 x x 37 Raw water pump (at least every 500 running hours) Lubricate 9-7-4

47 x 37 Raw water pump Service 9-7-4

48 x 37 Cooling water pump Service 9-7-1/2/3

49 x 37 Cooling water pump Renew -

50 x 37 Raw water pump Renew -

51 x x x x x 38 Raw water filter Clean -

52 x x x x 38 Preheating system Check 9-9-1

53 x x 38 Integrated fittings and control elements of coolingwater Service -

system

54 x x x 38 Raw water thermostat Check -

55 x 38 Raw water thermostat Renew -

56 x x 43 Exhaust turbocharger Service 6-6-1

57 x x x x 44 Battery charge Check 13-4-1

58 x x x x 44 Alternator V-belts Check -

59 x x x x 44 Starter Check 13-3-1

60 x x x x 44 Alternator Service 13-2-1

61 x x x x 46 Engine alignment and elastic mounting (also from Check 3-7-1

generator)

62 x x x x 48 Monitoring and shut down units Check 11-1-1/2/3/21

/ 11-3-1 / 11-7-

1

63 x x x x 48 Cable for chafe marks Check -

64 x x x 52 Flexible coupling Check 2-17-1

65 x 58 Water-side of charge air cooler ( in the case of raw water Clean 6-4-1

cooling)

66 x x 58 Charge air cooler water side and air side Clean 6-4-1/2

67 x 99 External screw connections, hoses and seals Check -

68 x x x x 99 Test run of engine palnt Check -

69 x x x x 00 Linkage of intake and discharge air louvres Check -

Maintenance schedule for 604B engines which are < 300 hours per year

* Initial maintenance jobs 50 operating hours after commissioning of new or generally overhauled engines

Always check manual for special jobs

You might also like

- Scania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLDocument3 pagesScania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLramsey2220% (1)

- Akk 416Document278 pagesAkk 416CBRASOV100% (1)

- BoschDistPump PDFDocument134 pagesBoschDistPump PDFivcretni100% (4)

- Maintenance KitsDocument6 pagesMaintenance Kitssebastian BugueñoNo ratings yet

- Maintenance Alat BeratDocument3 pagesMaintenance Alat BeratPeralatan Divisi3No ratings yet

- NH L218 - Maintenance ChartDocument2 pagesNH L218 - Maintenance ChartKristomiDerMarine-Ingenieur100% (1)

- Eurocarbody PDFDocument2 pagesEurocarbody PDFMaria0% (2)

- Catalogo Grua ManitexDocument14 pagesCatalogo Grua ManitexEdgar Mendieta EchazarretaNo ratings yet

- HTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Document4 pagesHTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Riddhi DasNo ratings yet

- Maintenance Schedule Bauer CompressorsDocument1 pageMaintenance Schedule Bauer CompressorsCristel_DC100% (3)

- 2010 HD Buell Service IntervalsDocument20 pages2010 HD Buell Service IntervalsEugenio CandrevaNo ratings yet

- D528 Maintenance Schedule - Xls Maintenance ScheduleDocument1 pageD528 Maintenance Schedule - Xls Maintenance ScheduleDPNo ratings yet

- 2 Stroke Maintenance SchedulesDocument3 pages2 Stroke Maintenance SchedulesGeo PalNo ratings yet

- Atlas Copco Xrvs 476 Manual (050 054)Document5 pagesAtlas Copco Xrvs 476 Manual (050 054)joseNo ratings yet

- Series 2000 Stocking ListDocument14 pagesSeries 2000 Stocking ListGerman O.No ratings yet

- D540 D640 Maintenance ScheduleDocument2 pagesD540 D640 Maintenance ScheduleDPNo ratings yet

- 1.3 Maintenance Schedule: GeneralDocument2 pages1.3 Maintenance Schedule: GeneralÉder Oliveira NicolletiNo ratings yet

- Equipment GA132 75 Bar (W) PackDocument1 pageEquipment GA132 75 Bar (W) Packsurendra SinghNo ratings yet

- Kilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersDocument2 pagesKilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersaleksandarlaskovNo ratings yet

- 2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTDocument1 page2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTLeonardo PachecoNo ratings yet

- 2005 HD Buell Service IntervalsDocument12 pages2005 HD Buell Service IntervalsHéctor Alejandro Ayala SolisNo ratings yet

- 2006 HD Buell Service IntervalsDocument12 pages2006 HD Buell Service IntervalsAdrián CasarrubiasNo ratings yet

- Harley-Davidson: and Buell Service IntervalsDocument16 pagesHarley-Davidson: and Buell Service IntervalsPeluzitaNo ratings yet

- 2007 HD Buell Service IntervalsDocument14 pages2007 HD Buell Service IntervalsCleverson SantosNo ratings yet

- VW Maintenance Cards 2000 - 5!10!10Document2 pagesVW Maintenance Cards 2000 - 5!10!10Samuel BohnNo ratings yet

- Preventive Maintenance PlanDocument1 pagePreventive Maintenance PlanScribdTranslationsNo ratings yet

- Service Program A Service Program A Service Program A Service Program ADocument3 pagesService Program A Service Program A Service Program A Service Program ApeterNo ratings yet

- Harley-Davidson and Buell Service IntervalsDocument15 pagesHarley-Davidson and Buell Service IntervalsCleverson SantosNo ratings yet

- Service Program A Service Program A Service Program A Service Program ADocument6 pagesService Program A Service Program A Service Program A Service Program ApeterNo ratings yet

- UNIT DRILLING TOP DRIVE SERVICE MANUALDocument102 pagesUNIT DRILLING TOP DRIVE SERVICE MANUALjulioramcaNo ratings yet

- Repair Options FOR 950G/H/M Wheel LoadersDocument2 pagesRepair Options FOR 950G/H/M Wheel LoadersАдыль БабировNo ratings yet

- Standard Service Oil Injected Compressor Atlas CopcoDocument1 pageStandard Service Oil Injected Compressor Atlas CopcoAhmad FauzieNo ratings yet

- VW-2004 Schedule ManualDocument3 pagesVW-2004 Schedule Manualanyone331No ratings yet

- GSIC - Global Service Information CenterDocument1 pageGSIC - Global Service Information Centergracekanyanta14No ratings yet

- RLR 100 MaintenanceDocument1 pageRLR 100 MaintenanceTahmidtuhinNo ratings yet

- 2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Document1 page2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Raihan GrimuflihinNo ratings yet

- 580N Tier 4B Loader Backhoe Maintenance ChartDocument4 pages580N Tier 4B Loader Backhoe Maintenance ChartCARLOSNo ratings yet

- G990 S.I.PDocument1 pageG990 S.I.Pأبو خالد الأثرىNo ratings yet

- Acf UcfDocument4 pagesAcf UcfAli KianersiNo ratings yet

- CAT REMAN Long Block CM20200519-5fc05-607d7Document2 pagesCAT REMAN Long Block CM20200519-5fc05-607d7maggioraNo ratings yet

- Maintenance Reimbursement Letter - D37-24 - vs1 - 104150Document2 pagesMaintenance Reimbursement Letter - D37-24 - vs1 - 104150ANo ratings yet

- Lubrication & Maintenance Chart TLB Case (Andy)Document3 pagesLubrication & Maintenance Chart TLB Case (Andy)Zakhele MpofuNo ratings yet

- Service Specifications: Author: DateDocument1 pageService Specifications: Author: DateClodoaldo BiassioNo ratings yet

- Isl 845-885 Tier IiDocument5 pagesIsl 845-885 Tier IiGarcia CruzNo ratings yet

- CX210C - Maintenance ChartDocument3 pagesCX210C - Maintenance ChartKristomiDerMarine-IngenieurNo ratings yet

- Datos Tecnicos Hilux 2trfeDocument1 pageDatos Tecnicos Hilux 2trfeIrving Alexander RujanoNo ratings yet

- Digmax Parts CatalogeDocument630 pagesDigmax Parts CatalogeChirag BansalNo ratings yet

- Service ScheduleDocument5 pagesService Scheduleronare6613No ratings yet

- HL Owners Manual 2021Document2 pagesHL Owners Manual 2021Dutchie169No ratings yet

- Uploads Media Document BAC Rigging-VXI RVXIv15ENDocument28 pagesUploads Media Document BAC Rigging-VXI RVXIv15ENsidsaleemNo ratings yet

- Rig:50 Diesel / Hydraulic Crane Weekly and Monthly ChecksDocument1 pageRig:50 Diesel / Hydraulic Crane Weekly and Monthly Checksvikrant911No ratings yet

- D628 Maintenance ScheduleDocument3 pagesD628 Maintenance ScheduleDPNo ratings yet

- Maintenance Reimbursement Letter - D51-24 - vs1 - 106717Document2 pagesMaintenance Reimbursement Letter - D51-24 - vs1 - 106717ANo ratings yet

- Torque Specification: Service Specifications Engine MechanicalDocument2 pagesTorque Specification: Service Specifications Engine MechanicalIslam AttiaNo ratings yet

- 8D100 10 PDFDocument5 pages8D100 10 PDFChristian BedoyaNo ratings yet

- Maintenance Reimbursement Letter - D61-23 - vs3 - 102939Document2 pagesMaintenance Reimbursement Letter - D61-23 - vs3 - 102939ANo ratings yet

- Momen Spesifikasi 2NR-VEDocument3 pagesMomen Spesifikasi 2NR-VEMuhamad Abdul AzizNo ratings yet

- Imo Pump Ace PDFDocument4 pagesImo Pump Ace PDFpetrakou aglaia100% (1)

- Recondition Engine DCEC 4BTA ThriveniDocument9 pagesRecondition Engine DCEC 4BTA ThriveniRegi HermawanNo ratings yet

- Torque - Specs 2JZDocument2 pagesTorque - Specs 2JZaffonso.pradoNo ratings yet

- Tool Kit Termination Termination Joint Joint Complete 3-Core 1-Core 3-Core 1-CoreDocument1 pageTool Kit Termination Termination Joint Joint Complete 3-Core 1-Core 3-Core 1-CoreAnthonyNo ratings yet

- Torque 40Document1 pageTorque 40Luis Oswaldo Roa PerezNo ratings yet

- Rig:50 Diesel / Hydraulic Crane Weekly and Monthly ChecksDocument1 pageRig:50 Diesel / Hydraulic Crane Weekly and Monthly Checksvikrant911No ratings yet

- Maintenance Chart - 60Document1 pageMaintenance Chart - 60Khincho ayeNo ratings yet

- Catalogo de Partes Mtu Nuevo 5272010539 - enDocument202 pagesCatalogo de Partes Mtu Nuevo 5272010539 - enDiego RodriguezNo ratings yet

- PSM BulletinDocument11 pagesPSM BulletinSideth ChivNo ratings yet

- Yzf-R1 2004 5vy1-Me1Document494 pagesYzf-R1 2004 5vy1-Me1Chris CoulsonNo ratings yet

- Steering System: Introduction: This System Provides The Directional ChangeDocument14 pagesSteering System: Introduction: This System Provides The Directional ChangeAkash Sood100% (1)

- Silibus Diesel CommanrailDocument2 pagesSilibus Diesel CommanrailPokcik ZaidNo ratings yet

- 12 ZF 6HP26 TeardownDocument32 pages12 ZF 6HP26 TeardownSanda Neuman100% (1)

- KoblingsskjemaDocument2 pagesKoblingsskjemaAnonymous vBZS1Jm1aNo ratings yet

- Aplicación Inter. Exter. Altura: Catalogo de RetenesDocument27 pagesAplicación Inter. Exter. Altura: Catalogo de Reteneskevin metzelerNo ratings yet

- Hemi Web CatalogDocument62 pagesHemi Web CatalogAdson LimaNo ratings yet

- Finding Your Detroit Diesel Engine Serial NumberDocument6 pagesFinding Your Detroit Diesel Engine Serial Numberfajee_farid100% (1)

- Ajuste Valve Perins 1104Document5 pagesAjuste Valve Perins 1104josel204No ratings yet

- KDPF Regeneration Operator Tips: Passive Active Manual StationaryDocument2 pagesKDPF Regeneration Operator Tips: Passive Active Manual StationaryMatshitaNo ratings yet

- Basic Engine Comp AnalysisDocument123 pagesBasic Engine Comp AnalysisMarco AvNo ratings yet

- Service Training 1015 DBJDocument36 pagesService Training 1015 DBJThein Htoon lwin100% (1)

- E 200 K (Wdb2110425a597343), Engine 271.941 - Engine Electrical Equipment, Switches, Sender Units, SensorsDocument6 pagesE 200 K (Wdb2110425a597343), Engine 271.941 - Engine Electrical Equipment, Switches, Sender Units, SensorsPham van QuyetNo ratings yet

- Caterpillar Cat 320 GC Excavator (Prefix ZBT) Service Repair Manual (ZBT00001 and Up)Document21 pagesCaterpillar Cat 320 GC Excavator (Prefix ZBT) Service Repair Manual (ZBT00001 and Up)kfmuseddk100% (1)

- SSP 38 Octavia 2001Document34 pagesSSP 38 Octavia 2001Kaloyan MarinovNo ratings yet

- Audi A4Document4 pagesAudi A4nelaimelNo ratings yet

- Amt 1201 - Prelim - Lab Module 2 - DelgadoDocument5 pagesAmt 1201 - Prelim - Lab Module 2 - DelgadoBrendan Lewis DelgadoNo ratings yet

- ssp380 - Audi TT Coupé '07Document52 pagesssp380 - Audi TT Coupé '07psychoreality100% (2)

- Transmission GP - 4-Speed PowersyncroDocument9 pagesTransmission GP - 4-Speed PowersyncroDaniel NavasNo ratings yet

- 191MSL Ember RVDocument1 page191MSL Ember RVMercado-Rivera FamilyNo ratings yet

- Leon Katalog My19Document45 pagesLeon Katalog My19Zarko MikicNo ratings yet

- Deutz TCG2032 Limit ValuesDocument19 pagesDeutz TCG2032 Limit ValuesKhokon Kumer SahaNo ratings yet

- ABS (Diagnostics)Document59 pagesABS (Diagnostics)Cristiano Gustafson LopesNo ratings yet