Professional Documents

Culture Documents

ASTM E384 (2022) - Part15

ASTM E384 (2022) - Part15

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E384 (2022) - Part15

ASTM E384 (2022) - Part15

Uploaded by

david4231993Copyright:

Available Formats

cf.

tr E384 -22

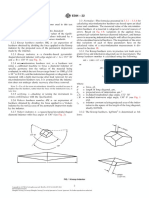

TABLE X1 .3 Relationship Between Diagonal Length and (SR)j, the

Between-Laboratory Estimate of Precision

Correlation

Material Test Regression Equation

Coefficient

Ferrous Vickers ( SR)j = 0.31 + 0.004 d, 0.747

Ferrous Knoop ( SR)j = 0.333 + 0.007 d, 0.899

Nonferrous Vickers ( sR)j = o.357 + 0.01 56 a, 0.8906

Nonferrous Knoop ( sR)j = o.378 + 0.01 77 a, 0.86 1 6

TABLE X 1 . 4 Relationship Between the Diagonal Length and (/R)j,

the Repeatability Interval

Material Test Regression Equation

Ferrous Vickers ( /R)j = 0.877 + 0.01 1 3 CJ,

Ferrous Knoop (/R)j = 0.946 + 0.01 98 CJ,

Nonferrous Vickers ( /R)j = 1 .0 1 03 + 0.0441 CJ,

Nonferrous Knoop (/R)j = 1 .07 + 0.05 CJ1

X2. RESULTS OF AN INTERLABORATORY TEST COMPARING MICROINDENTATION HARDNESS TESTING USING

MANUAL AND AUTOMATED MEASURING SYSTEMS

X2.1 Introduction X2.4 Repeatability

X2. l . l An interlaboratory test program was conducted to X2.4. l Repeatability concerns the variability between indi

develop information comparing Knoop and Vickers microin vidual test results obtained within a single laboratory by a

single operator with a specific set of test apparatus. For both

dentation hardness tests made with measurements using auto

the manual and automated measurements, the repeatability

mated image analysis systems and by the standard manual

interval increased with specimen hardness and decreasing test

procedure. Four ferrous specimens were used in the test

force, Tables X2. l -X2.4, and Figs. X2. l -X2.4. For equivalent

program (see Research Report RR:E04- 1 006). 7

testing conditions, the repeatability interval for automated

measurements was slightly larger than for manual measure

X2.2 Scope ments.

X2.2. l This interlaboratory test program provides informa X2.5 Reproducibility

tion on measurements of the same indentations made by

X2.5. l Reproducibility deals with the variability between

different laboratories using two different measuring methods

single test results obtained by different laboratories applying

according to the procedures of Practice E69 1 .

the same test methods to the same or similar test specimens.

For both the manual and automated measurements, the repro

X2.3 Procedure ducibility interval increased with specimen hardness and de

X2.3. l The test was conducted under controlled conditions creasing test force, Tables X2. l -X2.4, and Figs. X2. l -X2.4.

using loads of 1 00 gf and 300 gf. Ten Knoop and ten Vickers For equivalent testing conditions, the reproducibility interval

for automated measurements was slightly larger than for

indentations were made for each load, a total of 40 indenta

manual measurements.

tions. The participants in the test program measured the same

indentations on the four specimens. Seven laboratories mea X2.6 Comparisons

sured the specimens using both procedures. The results of these X2.6. l Neither Practice E69 1 , nor any other ASTM

seven sets of measurements were used for the analysis. The standard, deals with comparing test results of a single property

Knoop indentations on specimen C l were too long for accurate made by two different test methods. Hence, it is not possible to

measurements to be made by one lab; hence, only six sets of statistically and accurately compare the hardness measure

measurements were made on this specimen. Near the end of the ments made by the manual and automated procedures.

test program, specimen B l was lost in shipping; thus only six However, this information is graphically represented for com

sets of measurements were made on this specimen. parative purposes, Figs. X2.5-X2.8.

15

Copyright by ASTM lnt'I (all rights reserved); Wed Nov 09 07:44:14 GMT 2022

Downloaded/printed by

Shanghai Jiaotong University (Shanghai Jiaotong University) pursuant to License Agreement. No further reproductions authorized.

You might also like

- Astm E-18 PDFDocument22 pagesAstm E-18 PDFEnriqueVe100% (2)

- AMS 2759 8A Ion NitridingDocument12 pagesAMS 2759 8A Ion NitridingSinan YıldızNo ratings yet

- E 399Document31 pagesE 399H_DEBIANENo ratings yet

- NanoXP IndenterDocument25 pagesNanoXP IndenterhamimNo ratings yet

- Dewinter Software CatalogueDocument6 pagesDewinter Software CatalogueShivraman ThapliyalNo ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E384 (2022) - Part12Document1 pageASTM E384 (2022) - Part12david4231993No ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- Plane-Strain Fracture Toughness of Metallic Materials1: Standard Test Method ForDocument36 pagesPlane-Strain Fracture Toughness of Metallic Materials1: Standard Test Method ForIgnacio Hiram M RoqueNo ratings yet

- Bailly Et Al. - 1992 - Mechanical Properties of Catheters Designing of TDocument2 pagesBailly Et Al. - 1992 - Mechanical Properties of Catheters Designing of TMerlin FangirlNo ratings yet

- Anova GumDocument6 pagesAnova GumGLORIA JIMENEZNo ratings yet

- E384 Test Method For Microindentation Hardness of MaterialsDocument33 pagesE384 Test Method For Microindentation Hardness of MaterialssumherilNo ratings yet

- Astm E384. Sustituye A Astm E92Document43 pagesAstm E384. Sustituye A Astm E92carlos hurtadoNo ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- Characterization and Validation of The Slim-Form Open-Ended Coaxial Probe For The Dielectric Characterization of Biological Tissues at Millimeter-Wave FrequenciesDocument3 pagesCharacterization and Validation of The Slim-Form Open-Ended Coaxial Probe For The Dielectric Characterization of Biological Tissues at Millimeter-Wave FrequenciesDenis JaissonNo ratings yet

- 2018 - Nonlinear Numerical Analysis of The V-Notched Rail Shear Test SpecimenDocument10 pages2018 - Nonlinear Numerical Analysis of The V-Notched Rail Shear Test SpecimenLuís CarvalhoNo ratings yet

- Numerical and Experimental Simulation of Liquefaction For Scenario EarthquakeDocument7 pagesNumerical and Experimental Simulation of Liquefaction For Scenario EarthquakekamatchiNo ratings yet

- E319-85 (2014) Standard Practice For The Evaluation of Single-Pan Mechanical BalancesDocument9 pagesE319-85 (2014) Standard Practice For The Evaluation of Single-Pan Mechanical BalancesAhmed AlzubaidiNo ratings yet

- High Strain Accelerated Fatigue Failure Testing of Niti Implantable DevicesDocument6 pagesHigh Strain Accelerated Fatigue Failure Testing of Niti Implantable DevicesabhiarvindNo ratings yet

- Real-Time Inline Predictions of Jet Fuel Properties by NIRSDocument3 pagesReal-Time Inline Predictions of Jet Fuel Properties by NIRShhNo ratings yet

- VL2 ReportDocument25 pagesVL2 ReportMatthew NelsonNo ratings yet

- Sample Paper 2Document10 pagesSample Paper 2waqarNo ratings yet

- 1DiseñoyCalibreGalgaDocument11 pages1DiseñoyCalibreGalgatabaresmtzNo ratings yet

- Lab2 Group5 Mechanical VibrationsDocument5 pagesLab2 Group5 Mechanical VibrationsMaria jose ValdezNo ratings yet

- Fatigue Strength of A Fibre-Reinforced Material 1977Document6 pagesFatigue Strength of A Fibre-Reinforced Material 1977AliReza ZiaratiNo ratings yet

- CH158Document4 pagesCH158trashto2002No ratings yet

- Measurement of Shives in Retted Flax: Standard Test Method ForDocument3 pagesMeasurement of Shives in Retted Flax: Standard Test Method ForDineshKumar VermaNo ratings yet

- The Difficulty of Measuring Low Friction: Uncertainty Analysis For Friction Coefficient MeasurementsDocument6 pagesThe Difficulty of Measuring Low Friction: Uncertainty Analysis For Friction Coefficient MeasurementsCE 17 AsheeshNo ratings yet

- Knoop and Vickers Hardness of Materials: Standard Test Method ForDocument43 pagesKnoop and Vickers Hardness of Materials: Standard Test Method ForRaúl Venegas MunitaNo ratings yet

- 2003 Data Driven SRDocument4 pages2003 Data Driven SRSusanta SarangiNo ratings yet

- ASTM E646 Tensile Strain-Hardening PDFDocument8 pagesASTM E646 Tensile Strain-Hardening PDFhdierkeNo ratings yet

- Determining The X-Ray Elastic Constants For Use in The Measurement of Residual Stress Using X-Ray Diffraction TechniquesDocument6 pagesDetermining The X-Ray Elastic Constants For Use in The Measurement of Residual Stress Using X-Ray Diffraction Techniquesbenjaminverduzco4No ratings yet

- Test Design and Result Interpretation Methods For Evaluating Rolling Contact Fatigue Life To Maintain Both Efficiency and ReliabilityDocument8 pagesTest Design and Result Interpretation Methods For Evaluating Rolling Contact Fatigue Life To Maintain Both Efficiency and ReliabilityJojee MarieNo ratings yet

- Lab 2Document9 pagesLab 2abhinav.43.86No ratings yet

- Astm E646-00Document8 pagesAstm E646-00Felipe De la cruzNo ratings yet

- An Eis 006Document4 pagesAn Eis 006Gemblung01No ratings yet

- Testing Elastomers For Hyperelastic Material ModelsDocument7 pagesTesting Elastomers For Hyperelastic Material ModelsAxelAxel94100% (1)

- Astm E-23 PDFDocument27 pagesAstm E-23 PDFbladdeeNo ratings yet

- Verification of Specimen Alignment Under Tensile Loading: Standard Practice ForDocument8 pagesVerification of Specimen Alignment Under Tensile Loading: Standard Practice ForTuan Nguyen BaNo ratings yet

- Fatigue LimitDocument4 pagesFatigue LimitShirohime HajikujiNo ratings yet

- Resistivity Laboratory Measurement of Geomaterial: Haryati AwangDocument7 pagesResistivity Laboratory Measurement of Geomaterial: Haryati AwangbabiaaaNo ratings yet

- Calibration and Compensation of Near-Field Scan MeasurementsDocument10 pagesCalibration and Compensation of Near-Field Scan MeasurementsJake W. LiuNo ratings yet

- Vibration (Flexible Structures)Document14 pagesVibration (Flexible Structures)Faiz AhmedNo ratings yet

- Astm E606Document16 pagesAstm E606SuteeNo ratings yet

- A Regression Technique With Dynamic Parameter Selection For Phase-Behavior MatchingDocument6 pagesA Regression Technique With Dynamic Parameter Selection For Phase-Behavior MatchingMohamed ElkumatiNo ratings yet

- Zhang 2021Document11 pagesZhang 2021Gerson MNo ratings yet

- Comparaison Méthodes ShearDocument8 pagesComparaison Méthodes Shearfitoussi JosephNo ratings yet

- Computer Statistics With R: 8. Nonparametric TestsDocument10 pagesComputer Statistics With R: 8. Nonparametric TestsFimaIei10No ratings yet

- Evaluating Scientific Data S4 To s6Document19 pagesEvaluating Scientific Data S4 To s6VLNo ratings yet

- Gogolinskii 2019 J. Phys. Conf. Ser. 1384 012012Document8 pagesGogolinskii 2019 J. Phys. Conf. Ser. 1384 012012InspectorNo ratings yet

- $RUSQ59SDocument12 pages$RUSQ59SKerim SevinçNo ratings yet

- 4th ExpDocument3 pages4th ExpYashraj ChowdhuryNo ratings yet

- Shannon-Theoretic Limits On Noisy Compressive SamplingDocument13 pagesShannon-Theoretic Limits On Noisy Compressive SamplingdefiNo ratings yet

- ASTM E319 Standard Practice For The Evaluation of Single-Pan Mechanical Balances1Document9 pagesASTM E319 Standard Practice For The Evaluation of Single-Pan Mechanical Balances1David Vega100% (1)

- Van Den Abeele PaperDocument8 pagesVan Den Abeele PaperNguyen HieuNo ratings yet

- ASTM E 303 - 93 (Reapproved 1998) : Standard Test Method For Measuring Surface Frictional Properties Using The British Pendulum TesterDocument5 pagesASTM E 303 - 93 (Reapproved 1998) : Standard Test Method For Measuring Surface Frictional Properties Using The British Pendulum TesterShaheer Ahmad67% (3)

- Numerical and Experimental Simulation of Liquefaction For Scenario EarthquakeDocument8 pagesNumerical and Experimental Simulation of Liquefaction For Scenario EarthquakeMas Hamzah FansuriNo ratings yet

- Experimental Determination of Elastic Constant of Composite Materials Using Vibration PropertiesDocument11 pagesExperimental Determination of Elastic Constant of Composite Materials Using Vibration PropertiesMarianella Lizbeth Guerrero CastilloNo ratings yet

- Referencia 7 - Quantifying Interparticle Forces and Heterogeneity in 3D Granular MaterialsDocument5 pagesReferencia 7 - Quantifying Interparticle Forces and Heterogeneity in 3D Granular MaterialsvicenteNo ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- Resistivity Correction Factor For The Four-Probe Method: Home Search Collections Journals About Contact Us My IopscienceDocument4 pagesResistivity Correction Factor For The Four-Probe Method: Home Search Collections Journals About Contact Us My IopscienceMohit RawatNo ratings yet

- Cayuela Sanchez 2023 Specific Normalization Method For Nirs CalibrationsDocument4 pagesCayuela Sanchez 2023 Specific Normalization Method For Nirs CalibrationshiilNo ratings yet

- Materials and Design: P. Williams, M. Liakat, M.M. Khonsari, O.M. KabirDocument8 pagesMaterials and Design: P. Williams, M. Liakat, M.M. Khonsari, O.M. KabirAwan AJaNo ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Indian Institute of Technology, Guwahati: Laboratory SheetDocument6 pagesIndian Institute of Technology, Guwahati: Laboratory SheetKamini GoyalNo ratings yet

- Properties and Applications of MaterialsDocument59 pagesProperties and Applications of Materialssuryanarayandash100% (2)

- Astm E6Document12 pagesAstm E6Nacer KisyNo ratings yet

- BHT & VHTDocument8 pagesBHT & VHTMoHammadNashatSabbahNo ratings yet

- Standard Hardness Conversion Tables For Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, and Scleroscope HardnessDocument21 pagesStandard Hardness Conversion Tables For Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, and Scleroscope Hardnesso_l_0No ratings yet

- Mechanical Characterisation of Very Thin Films: Physics of Advanced Materials Winter School 2008 1Document11 pagesMechanical Characterisation of Very Thin Films: Physics of Advanced Materials Winter School 2008 1Alekcandyr AlekcNo ratings yet

- Mechanics of Materials: Olivier Bartier, Xavier Hernot, Gérard MauvoisinDocument17 pagesMechanics of Materials: Olivier Bartier, Xavier Hernot, Gérard Mauvoisinvicky prasadNo ratings yet

- أسئلة شاملة 1Document25 pagesأسئلة شاملة 1ibraheemalabsi99No ratings yet

- Are Intermetallics Really BrittleDocument5 pagesAre Intermetallics Really BrittleChia Chang CSquared LohNo ratings yet

- GENG 231 Materials Science2Document10 pagesGENG 231 Materials Science2JojoAl-mansouriNo ratings yet

- International Standard: Metallic Materials - Vickers Hardness Test - Calibration of Reference BlocksDocument8 pagesInternational Standard: Metallic Materials - Vickers Hardness Test - Calibration of Reference Blocksnikunjsingh04No ratings yet

- Mitutoyo Testing EquipmentsDocument19 pagesMitutoyo Testing EquipmentsBiljana UšćumlićNo ratings yet

- Influence of Laser Hardening On Mechanical Properties of A Low Alloy SteelDocument9 pagesInfluence of Laser Hardening On Mechanical Properties of A Low Alloy SteelkarimNo ratings yet

- Material Tech Questions Solved BitsDocument22 pagesMaterial Tech Questions Solved BitsBalakumarNo ratings yet

- Material Testing SinglePDF PDFDocument33 pagesMaterial Testing SinglePDF PDFManjunath GowdaNo ratings yet

- Structural and Mechanical Behaviour of Severe Plastically Deformed High Purity Aluminium Sheets Processed by Constrained Groove Pressing TechniqueDocument7 pagesStructural and Mechanical Behaviour of Severe Plastically Deformed High Purity Aluminium Sheets Processed by Constrained Groove Pressing TechniqueMoin ANo ratings yet

- 2009FDocument26 pages2009FdaimaheshNo ratings yet

- Desene SuduraDocument256 pagesDesene SuduraTicuLaurentiuNo ratings yet

- Procedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterDocument12 pagesProcedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterVitor100% (1)

- JPPYDocument12 pagesJPPYMohtisham JuttNo ratings yet

- Effects of Metakaolin On Nanomechanical Properties of Cement PasteDocument8 pagesEffects of Metakaolin On Nanomechanical Properties of Cement PasteRaja RajanNo ratings yet

- Astm E10Document32 pagesAstm E10FelipeNo ratings yet

- ME 207 - Chapter 5 - P2Document9 pagesME 207 - Chapter 5 - P2rathanNo ratings yet

- E18 Standard Test Methods For Rockwell Hardness of Metallic MaterialsDocument39 pagesE18 Standard Test Methods For Rockwell Hardness of Metallic MaterialsAlejandro Valdés RojasNo ratings yet

- Hardness Test: NO: 3 Supervised By: Dr. OsmanDocument9 pagesHardness Test: NO: 3 Supervised By: Dr. Osmanwrya hussainNo ratings yet

- Vickers and Kno Op 402 MVDDocument2 pagesVickers and Kno Op 402 MVDMohammad MohsinNo ratings yet