Professional Documents

Culture Documents

Mirafi GX - Tech Data - Anz - 11 - 2019

Mirafi GX - Tech Data - Anz - 11 - 2019

Uploaded by

Panji Okta PrawiraCopyright:

Available Formats

You might also like

- Training PPT (TRB - TAS) PDFDocument135 pagesTraining PPT (TRB - TAS) PDFRizky RamadhanNo ratings yet

- Is 15912 - 2012Document2 pagesIs 15912 - 2012kalpanaadhi100% (1)

- 737Document20 pages737Kaushik SenguptaNo ratings yet

- Tech Data - MG GX Biaxial (100 603 Biaxial-Td-1018) - 1Document1 pageTech Data - MG GX Biaxial (100 603 Biaxial-Td-1018) - 1Sze Mian KuehNo ratings yet

- ACEGrid Brochure HR Final 7Document1 pageACEGrid Brochure HR Final 7Anonymous 0x2pwMCWgjNo ratings yet

- 2tech Data - MF PET (300 601-td-0219)Document4 pages2tech Data - MF PET (300 601-td-0219)Ismacahyadi Mohamed JaisNo ratings yet

- Data Sheet - MiragridR GX (100 603-Td-04-12)Document2 pagesData Sheet - MiragridR GX (100 603-Td-04-12)Anto DestiantoNo ratings yet

- Elcorock 2.5m3 Spec Sheet 05-12Document1 pageElcorock 2.5m3 Spec Sheet 05-12Aleksa CavicNo ratings yet

- Metfloor 60 - Composite Deck Slab Concrete VolumeDocument4 pagesMetfloor 60 - Composite Deck Slab Concrete VolumeHardeo Dennis ChattergoonNo ratings yet

- PDS BXG1216Document2 pagesPDS BXG1216Carlos SorianoNo ratings yet

- A Case Study On Performance of Self-Compacting Concrete in Highly Congested Reinforcement of Cast in Situ StructureDocument11 pagesA Case Study On Performance of Self-Compacting Concrete in Highly Congested Reinforcement of Cast in Situ StructureEASHANNo ratings yet

- TDS Nitowrap FRC Saudi ArabiaDocument3 pagesTDS Nitowrap FRC Saudi ArabiarayNo ratings yet

- TWT M50 Mix DesignDocument6 pagesTWT M50 Mix DesignStupidity TalksNo ratings yet

- ST2013-120-M15-M25-J K Laxmi-SNDDocument4 pagesST2013-120-M15-M25-J K Laxmi-SNDPrakash MakwanaNo ratings yet

- Masonry Structural Behaviour at Different Scales Under Compressive LoadingDocument8 pagesMasonry Structural Behaviour at Different Scales Under Compressive LoadingOyeniyi Samuel KehindeNo ratings yet

- Tensar BX1200Document1 pageTensar BX1200mohammazakNo ratings yet

- Min 340 - Clase 4 - Contour Blasting PDFDocument38 pagesMin 340 - Clase 4 - Contour Blasting PDFHéctor Fernando Sanhueza GonzalezNo ratings yet

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- TemplateDocument17 pagesTemplatemamthaNo ratings yet

- Sikawrap - 230 CDocument4 pagesSikawrap - 230 CNyein ZawNo ratings yet

- UC210AGRDocument2 pagesUC210AGRVolodymуr VorobetsNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Concrete Practice B&FDocument259 pagesConcrete Practice B&Fvijay100% (1)

- TDS Lokfix Saudi ArabiaDocument3 pagesTDS Lokfix Saudi ArabiaDoie QuerubinNo ratings yet

- T. Parhizkar, M. Najimi and A.R. Pourkhorshidi - APPLICATION OF PUMICE AGGREGATE IN STRUCTURAL LIGHTWEIGHT CONCRETEDocument14 pagesT. Parhizkar, M. Najimi and A.R. Pourkhorshidi - APPLICATION OF PUMICE AGGREGATE IN STRUCTURAL LIGHTWEIGHT CONCRETEAniruddha DalviNo ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Annex D - FINANCIAL OFFER FORM Protection Desk BOQDocument5 pagesAnnex D - FINANCIAL OFFER FORM Protection Desk BOQaddismekuria37No ratings yet

- Testing of NEOPRENE Bearings SKGDocument60 pagesTesting of NEOPRENE Bearings SKGshujaNo ratings yet

- Rock Reinforcement Modelling - Cable Bolts in PLAXIS 2DDocument12 pagesRock Reinforcement Modelling - Cable Bolts in PLAXIS 2Dchaymaa MRHARNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

- SMD TR60 DatasheetDocument4 pagesSMD TR60 DatasheetAlfred GandNo ratings yet

- Column Rebar Design - NTPCDocument7 pagesColumn Rebar Design - NTPCVaibhav ShahNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsMohammad Twaha JaumbocusNo ratings yet

- Sikawrap - 300 CDocument4 pagesSikawrap - 300 CAlexis KarampasNo ratings yet

- L01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Document2 pagesL01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Wika SentiongNo ratings yet

- Sikawrap®-300 C: Product Data SheetDocument4 pagesSikawrap®-300 C: Product Data SheetHenri DormoyNo ratings yet

- 2020 ACEGrid GG (Uniaxial)Document1 page2020 ACEGrid GG (Uniaxial)Raka BachtiaraNo ratings yet

- RC Footing Design FinalDocument37 pagesRC Footing Design FinalTarunNo ratings yet

- Mix Design of Self Compacting Concrete Using Fly Ash and MicrosilicaDocument4 pagesMix Design of Self Compacting Concrete Using Fly Ash and MicrosilicaAshutosh AnandNo ratings yet

- Sika AnchorFix-S 2012-05 - 1Document7 pagesSika AnchorFix-S 2012-05 - 1Jurutera CTDesignNo ratings yet

- C.C. Geomalla BiaxialDocument1 pageC.C. Geomalla BiaxialCHRISTIAN DENNIS FLORES LLANQUINo ratings yet

- Sikawrap 300 CDocument5 pagesSikawrap 300 CAkram ShakirNo ratings yet

- 25m 3 Girder SuperstructureDocument43 pages25m 3 Girder SuperstructureVivek KumarNo ratings yet

- Analysis and Design Study of Concrete Paver Blocks With Feedback LoopDocument7 pagesAnalysis and Design Study of Concrete Paver Blocks With Feedback LoopMaestro ConstructionNo ratings yet

- Opc 53 SDocument7 pagesOpc 53 SVikram SinghNo ratings yet

- Final Project ReviewDocument13 pagesFinal Project ReviewSiva VarmaNo ratings yet

- Sika® Carbodur® Rods: Carbon Fiber Rods For Structural StrengtheningDocument2 pagesSika® Carbodur® Rods: Carbon Fiber Rods For Structural StrengtheningGonzalo OviedoNo ratings yet

- Testing of NEOPRENE Bearings SKGDocument61 pagesTesting of NEOPRENE Bearings SKGkl Rahul locationNo ratings yet

- A Study On Shear Strength of Sands ReinfDocument8 pagesA Study On Shear Strength of Sands ReinfBenson Mwathi MungaiNo ratings yet

- TenCate Miragrid GX Biaxial TechnicalData EN 502169Document1 pageTenCate Miragrid GX Biaxial TechnicalData EN 502169Juan WeiNo ratings yet

- Nitowrap CFP: High Performance, High Strength, Corrosion Resistant Pultruded Carbon Fi Bre PlatesDocument2 pagesNitowrap CFP: High Performance, High Strength, Corrosion Resistant Pultruded Carbon Fi Bre PlatesbinodNo ratings yet

- Concrete Properties RequirementsDocument1 pageConcrete Properties RequirementsEleazar P. SanchezNo ratings yet

- Experimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshDocument35 pagesExperimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshPraveen RajNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument554 pagesRCC32R Rigorous Ribbed SlabsCioabla Bogdan100% (1)

- Pavement Design ReportDocument11 pagesPavement Design ReportIrfanNo ratings yet

- M864 Product Sheet 07 09 2018Document2 pagesM864 Product Sheet 07 09 2018evedelgamsNo ratings yet

- E-Catalogue (Rock Splitter 2009-01) PDFDocument6 pagesE-Catalogue (Rock Splitter 2009-01) PDFhenry vegaNo ratings yet

- Potaglas GRP Tank BrochureDocument6 pagesPotaglas GRP Tank Brochurebenj bandalNo ratings yet

- IS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthDocument4 pagesIS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthROHIT KUMARNo ratings yet

- DPR - PKG-3 - Ra-28 Date 13.12.2018Document7 pagesDPR - PKG-3 - Ra-28 Date 13.12.2018Prasanta ParidaNo ratings yet

- Lokfix: Polyester Resin Anchoring GroutDocument3 pagesLokfix: Polyester Resin Anchoring GroutMuneer ahmed100% (1)

- TDS Conbextra GP2 BFLDocument4 pagesTDS Conbextra GP2 BFLsabbirNo ratings yet

- Glulam Wood BeamsDocument37 pagesGlulam Wood Beamsu16sr6No ratings yet

- AeroShell Fluid 41 (India)Document3 pagesAeroShell Fluid 41 (India)Aaron ChanNo ratings yet

- Presentable Industrial Training Experience GabrielDocument15 pagesPresentable Industrial Training Experience GabrielOkortnne AyibaNo ratings yet

- Raw Mix Design CementDocument4 pagesRaw Mix Design Cementtariqshah100% (1)

- Sanitary FittingsDocument58 pagesSanitary FittingsMherlieNo ratings yet

- 01 Architecture DrawingsDocument57 pages01 Architecture Drawingstvpham123No ratings yet

- St. Joseph's Convent Hr. Sec. School Quarterly Examination-2021 Subject: - English Time:-3:00hr Class:-12 M.M: - 80Document4 pagesSt. Joseph's Convent Hr. Sec. School Quarterly Examination-2021 Subject: - English Time:-3:00hr Class:-12 M.M: - 80Nitesh PatelNo ratings yet

- Concrete Construction Article PDF - Two-Day Construction Cycle For High-Rise Structures Based On Use of Preshores PDFDocument5 pagesConcrete Construction Article PDF - Two-Day Construction Cycle For High-Rise Structures Based On Use of Preshores PDFPrompt Torre LoyolaNo ratings yet

- Scheme and Syllabus of B.E. (Civil Engineering) : Panjab University, ChandigarhDocument62 pagesScheme and Syllabus of B.E. (Civil Engineering) : Panjab University, Chandigarhgautam9699No ratings yet

- SPDIDocument501 pagesSPDIEugene Odullada MangaringNo ratings yet

- IFM - SM7000 - Debitmetre - Sortie AnalogiqueDocument4 pagesIFM - SM7000 - Debitmetre - Sortie Analogiquenapnap5No ratings yet

- Project Report - CNG CylindersDocument23 pagesProject Report - CNG CylindersNaresh DhakerNo ratings yet

- Al Plate Heat Ex ChangersDocument686 pagesAl Plate Heat Ex ChangersMario Mendoza33% (3)

- Det Ails of Expansion Joint in Concrete Carriagewa Y: Highways DepartmentDocument1 pageDet Ails of Expansion Joint in Concrete Carriagewa Y: Highways Departmentcho673524No ratings yet

- Flow Through Circular PipesDocument105 pagesFlow Through Circular PipesArchangel VenantNo ratings yet

- Advanced Structural Design - Lecture Note 02Document7 pagesAdvanced Structural Design - Lecture Note 02Chamil MahagamageNo ratings yet

- GEAKueba Katalog MarketSP enDocument12 pagesGEAKueba Katalog MarketSP enRodrigo GonçalvesNo ratings yet

- Rockwell Hardness TestDocument5 pagesRockwell Hardness TestAdil Javed Chaudhary89% (9)

- Pile Cap Design Examples To Eurocode 2Document12 pagesPile Cap Design Examples To Eurocode 2Krishna SodhaNo ratings yet

- Unit-I - Limit State Method Concept and Design of Beams: 1. MaterialsDocument7 pagesUnit-I - Limit State Method Concept and Design of Beams: 1. MaterialsYAZHININo ratings yet

- Daniel Adofo AmeyawDocument102 pagesDaniel Adofo AmeyawJoel Morales PerezNo ratings yet

- ASHRAE 2014 Evaporation Paper PDFDocument15 pagesASHRAE 2014 Evaporation Paper PDFBenjamin ChavezNo ratings yet

- ISO Quality Manual 9001-2015 - Final - 20.07.2017 - Part51Document2 pagesISO Quality Manual 9001-2015 - Final - 20.07.2017 - Part51ganrashNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDF PIPING Engineering Interview QuestionsDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDF PIPING Engineering Interview Questionssteepa22100% (1)

- Charging by RubbingDocument18 pagesCharging by RubbingLora GarciaNo ratings yet

- Magnetic Force MicrosDocument15 pagesMagnetic Force MicrosArvindGovaNo ratings yet

- Astm D6677-2007Document2 pagesAstm D6677-2007Chris SchnurchNo ratings yet

Mirafi GX - Tech Data - Anz - 11 - 2019

Mirafi GX - Tech Data - Anz - 11 - 2019

Uploaded by

Panji Okta PrawiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mirafi GX - Tech Data - Anz - 11 - 2019

Mirafi GX - Tech Data - Anz - 11 - 2019

Uploaded by

Panji Okta PrawiraCopyright:

Available Formats

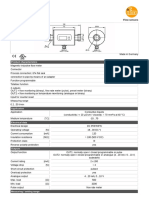

Miragrid GX Geogrids

Properties of TenCate Miragrid® GX Geogrids

GX GX GX GX

Property Unit

40/40 60/30 80/30 100/30

Initial Mechanical Properties

Characteristic initial strength, Tu (ISO 10319) MD kN/m 40 60 80 100

Characteristic initial strength (ISO 10319) CD kN/m 40 30 30 30

Characteristic initial strength at 5% strain (ISO 10319) MD kN/m 22 33 44 55

Strain at initial strength MD % 8 8 8 8

Material reduction factor creep-rupture, f

cr

at 50 years design life 1.40 1.40 1.40 1.40

at 100 years design life 1.43 1.43 1.43 1.43

Creep limited strength based on creep-rupture, TCR

at 50 years design life kN/m 28.6 42.9 57.1 71.4

at 100 years design life kN/m 28.0 42.0 55.9 69.9

Material reduction factor - installation damage, fid

in clay, silt or sand 1.10 1.10 1.06 1.06

in aggregate base course (32mm maximum size) 1.15 1.15 1.15 1.10

in well graded gravel (63mm maximum size) 1.30 1.15 1.15 1.15

Material reduction factor - environmental effects (4 < pH < 9), fen

at 50 years design life 1.03 1.03 1.03 1.03

at 100 years design life 1.05 1.05 1.05 1.05

Long term design strengths, TD

at 50 years design life

in clay, silt or sand kN/m 25.2 37.8 52.3 65.4

in aggregate base course (32mm maximum size) kN/m 24.1 36.2 48.2 63.0

in well graded gravel (63mm maximum size) kN/m 21.3 36.2 48.2 60.3

at 100 years design life

in clay, silt or sand kN/m 24.2 36.3 50.3 62.8

in aggregate base course (32mm maximum size) kN/m 23.2 34.7 46.3 60.5

in well graded gravel (63mm maximum size) kN/m 20.5 34.7 46.3 57.9

Nominal roll width m 5.2 5.2 5.2 5.2

Nominal roll length m 100 100 100 100

Estimated roll weight kg 155 155 170 189

* Estimated roll weight is a guidance for logistic purpose only. Other forms of supply as well as grades,

adjusted to the requirements of specific projects, are available on request.

TenCate Miragrid® is a registered trademark of TenCate Geosynthetics.

Further details of this application and products can be obtained by contacting your nearest TenCate Technical Support Office. Unauthorized reproduction and distribution is prohibited. This document is provided as supporting

service only. The information contained in this document is to the best of our knowledge true and correct. No warranty whatsoever is expressed or implied or given. Engineers wishing to apply this information shall satisfy

themselves on the validity of the input data relative to the applicable soil and engineering conditions and in doing so assume design liability.

TenCate Geosynthetics Asia Sdn. Bhd. (264232-U)

14, Jalan Sementa 27/91, Seksyen 27,

40400 Shah Alam, Selangor Darul Ehsan, Malaysia.

Tel: +60 3 5192 8568 Fax: +60 3 5192 8575 CERTIFIED

MANAGEMENT

SYSTEM

Email: info.asia@tencategeo.com www.tencategeo.asia ISO9001 : 2015

© 2019 TenCate Geosynthetics Asia Sdn. Bhd. All Rights Reserved.

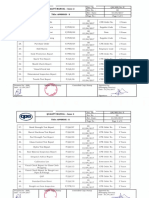

Miragrid GX Geogrids

®

Properties of TenCate Miragrid® GX Geogrids

GX GX GX GX

Property Unit

130/30 160/50 200/50 400/50

Initial Mechanical Properties

Characteristic initial strength, Tu (ISO 10319) MD kN/m 130 160 200 400

Characteristic initial strength (ISO 10319) CD kN/m 30 50 50 50

Characteristic initial strength at 5% strain (ISO 10319) MD kN/m 72 88 110 220

Strain at initial strength MD % 8 8 8 8

Material reduction factor creep-rupture, f

cr

at 50 years design life 1.40 1.40 1.40 1.40

at 100 years design life 1.43 1.43 1.43 1.43

Creep limited strength based on creep-rupture, TCR

at 50 years design life kN/m 92.2 114.3 142.9 285.7

at 100 years design life kN/m 90.9 111.9 139.9 279.7

Material reduction factor - installation damage, fid

in clay, silt or sand 1.06 1.06 1.06 1.06

in aggregate base course (32mm maximum size) 1.10 1.10 1.10 1.10

100 603-tdANZ-11|19

in well graded gravel (63mm maximum size) 1.15 1.15 1.10 1.10

Material reduction factor - environmental effects (4 < pH < 9), fen

at 50 years design life 1.03 1.03 1.03 1.03

at 100 years design life 1.05 1.05 1.05 1.05

Long term design strengths, TD

at 50 years design life

in clay, silt or sand kN/m 85.0 104.7 130.8 261.7

in aggregate base course (32mm maximum size) kN/m 82.0 100.9 126.1 252.2

in well graded gravel (63mm maximum size) kN/m 78.4 96.5 126.1 252.2

at 100 years design life

in clay, silt or sand kN/m 81.7 100.5 125.7 251.3

in aggregate base course (32mm maximum size) kN/m 78.7 96.9 121.1 242.2

in well graded gravel (63mm maximum size) kN/m 75.3 92.7 121.1 242.2

Nominal roll width m 5.2 5.2 5.2 5.2

Nominal roll length m 100 100 100 100

Estimated roll weight kg 244 310 374 660

* Estimated roll weight is a guidance for logistic purpose only. Other forms of supply as well as grades,

adjusted to the requirements of specific projects, are available on request.

TenCate Miragrid® is a registered trademark of TenCate Geosynthetics.

Further details of this application and products can be obtained by contacting your nearest TenCate Technical Support Office. Unauthorized reproduction and distribution is prohibited. This document is provided as supporting

service only. The information contained in this document is to the best of our knowledge true and correct. No warranty whatsoever is expressed or implied or given. Engineers wishing to apply this information shall satisfy

themselves on the validity of the input data relative to the applicable soil and engineering conditions and in doing so assume design liability.

TenCate Geosynthetics Asia Sdn. Bhd. (264232-U)

14, Jalan Sementa 27/91, Seksyen 27,

40400 Shah Alam, Selangor Darul Ehsan, Malaysia.

Tel: +60 3 5192 8568 Fax: +60 3 5192 8575 CERTIFIED

MANAGEMENT

SYSTEM

Email: info.asia@tencategeo.com www.tencategeo.asia ISO9001 : 2015

© 2019 TenCate Geosynthetics Asia Sdn. Bhd. All Rights Reserved.

Design Strengths and Strains for TenCate Miragrid® GX Geogrids

1. Miragrid® GX geogrids design strengths and strains The initial tensile loads and strains of Miragrid® GX geogrids can

be represented by a single master curve covering all grades. This

Miragrid® GX geogrids are engineered materials suitable for

master curve is shown in Figure 1. Here the ordinate value is

short and long term soil reinforcement applications. They are

expressed as a percentage of the initial characteristic tensile

composed of high modulus polyester yarns, assembled to form a

strength. Because of the use of special high modulus PET yarns

directionally structured and stable geogrid that enables

Miragrid® GX geogrids exhibit tensile loads of 55% of the initial

maximum load carrying efficiency.

tensile strength at only 5% strain which makes these materials

Miragrid® GX geogrids are manufactured in a wide range of very efficient in carrying tensile loads at relatively low strains.

tensile strengths to suit different soil reinforcement conditions.

Standard assessment procedures exist to determine the long 100

term design strengths of Miragrid® GX geogrids. These rely on

the application of material reduction factors to the initial tensile

strength of the geosynthetic reinforcement in order to determine

the appropriate long term design strength. For example, such

80

procedures are standard practice in US Federal Highway

Administration documentation and well-recognized Codes of

Practice such as British Standard BS8006-1:2010.

Initial tensile load (% of Tu)

The generic relationship for assessing the long term design 60

strengths of geosynthetic reinforcements is shown below.

Tu

TD = (1) 40

fcr fid fen

where,

TD is the long term design strength of the reinforcement;

Tu is the initial tensile strength of the reinforcement;

20

fcr is the material reduction factor relating to creep effects

over the required life of the reinforcement;

fid is the material reduction factor relating to installation

damage of the reinforcement;

fen is the material reduction factor relating to environmental 0

0 2 4 6 8

effects over the required life of the reinforcement. Initial strain (%)

Figure 1. Initial tensile load – strain master curve for Miragrid® GX geogrids.

The magnitudes of the material reduction factors fcr and fen are

not only affected by time (the design life of the reinforcement) but In prescribing suitable reinforcement strain limits to soil

also by temperature (the average in-ground temperature). In this reinforcement applications reference is normally made to

datasheet a standard in-ground temperature of 20°C is used as well-recognized Codes of Practice, e.g. BS8006-1:2010. Normally,

the basis for measurement. This also agrees with in-ground for most soil reinforcement applications, reinforcement strains

conditions in many parts of the world and can also be considered are limited to 5% or less over the design life of the reinforcement.

to be conservative for colder climates. Thus, the lower part of the tensile load – strain curve shown in

Figure 1 (less than 5% strain) is the most important part of the

2. Initial strengths and strains curve when assessing allowable reinforcement strain levels.

All geosynthetic reinforcement materials should be described in

terms of their characteristic initial strengths and not their mean

initial strengths. This ensures the representation of initial tensile

strength is statistically safe. The initial tensile strengths of

Miragrid® GX geogrids shown at the front of this datasheet are

expressed in terms of characteristic (95th percentile) values,

which are statistically safe values.

Design Strengths and Strains for TenCate Miragrid® GX Geogrids

3. Material reduction factor for creep effects, fcr 3b. Material reduction factors for creep-strain

effects, fcr2

Creep effects can influence the behaviour of geosynthetic

reinforcements in two ways – by decreasing the rupture load The material reduction factor for creep-strain fcr2 is derived from

over time and by increasing the strain over time. Creep-rupture the isochronous creep curves of the geosynthetic reinforcement.

effects are associated with ultimate limit states (i.e. collapse These curves show the change in strain of the reinforcement

modes) and are considered a critical case where reinforced soil over time at different load levels. The isochronous creep-strain

walls, reinforced soil slopes and basal reinforced embankments curves for Miragrid® GX geogrids are shown in Figure 3. The

constructed on soft foundations are concerned. Creep-strain isochronous curves show that Miragrid® GX geogrids exhibit low

effects are associated with serviceability limit states (i.e. creep strains over long design lives.

deformation modes) and may be critical where maximum 100

reinforcement strains need to be limited and controlled. t= 0

t = 1 mth

3a. Material reduction factors for creep-rupture t = 1 yr

effects, fcr1 80

The material reduction factor for creep-rupture fcr1 is derived

100 yr rupture load

from the creep-rupture curve of the geosynthetic reinforcement.

The creep-rupture curve for Miragrid® GX geogrids is shown in

Initial tensile load (% of Tu)

t = 50 yrs

Figure 2. This curve has been generated from a combination of 60

long term (in accordance with ISO 13431) and accelerated creep t = 100 yrs

testing (in accordance with ASTM D6992). For example, from

Figure 2, the material reduction factor for creep-rupture at 100

yrs is fcr1 = 100%/70% = 1.43. Table 1 below lists the creep-rupture 40

material reduction factors for Miragrid® GX geogrids at 10 yrs, 50

yrs and 100 yrs design lives. Interpretation of the creep-rupture

curve in Figure 2 can provide appropriate creep-rupture

reduction factors for other reinforcement design lives.

20

100

80

0

0 2 4 6 8

Strain (%)

Rupture load (% of Tu)

Figure 3. Isochronous creep-strain curves at 20°C for Miragrid GX geogrids.®

60

For example, if a design requires the total reinforcement strain to

be limited to a maximum of 5% strain over a 100 year design life,

40

then from Figure 3 a load level of 45% over 100 years will meet

this requirement for Miragrid® GX geogrids. Thus, fcr2 = 100%/45%

20 50yrs = 2.22.

10yrs 100yrs

In some cases, it may be required to limit the post-construction

strain in the reinforcement to, say, 1% in order to prevent long

0

1 2 3 4 5 6 7 term deformations in a reinforced soil structure. In this case the

Log time (hrs) t = 1 mth curve shown in Figure 3 can be used as a good

Figure 2. Creep-rupture curve at 20°C for Miragrid® GX geogrids. approximation of the time it takes to construct the structure, and

Table 1. Material reduction factors fcr1 based on creep-rupture at 20°C for

if the design life is 100 years and the maximum creep-strain has

Miragrid® GX geogrids at three different reinforcement design lives. to be limited to 1%, then a maximum load level of around 65% can

be sustained. Thus, here fcr2 = 100%/65% = 1.54.

at 10 yrs at 50 yrs at 100 yrs

fcr

1.37 1.40 1.43

Design Strengths and Strains for TenCate Miragrid® GX Geogrids

3c. When to use fcr1 or fcr2 for the value fcr in Long term environmental testing in pH conditions ranging from

Equation 1 4 < pH < 9 at 20°C yield the material reduction factors listed in

Whether to use fcr1 or fcr2 for the value fcr in Equation 1 depends on Table 2 for Miragrid® GX geogrids.

the design method being used as well as the type of analysis

Table 2. Material reduction factors based on environmental effects at 20°C for

being undertaken. Miragrid® GX geogrids at three different reinforcement design lives.

Where a design method based on a global factor of safety

at 10 yrs at 50 yrs at 100 yrs

approach is being used then values of fcr1 based on fen

reinforcement creep-rupture should be used as the value of fcr in 1.00 1.03 1.05

Equation 1.

Where a design method based on a limit state approach is being 6. Bond resistance - direct sliding and pull-out

used then both fcr1 and fcr2 should be used as the value of fcr in For geosynthetic reinforced soil structures the reinforcement

Equation 1 depending on whether an ultimate limit state analysis must behave in a composite manner with the adjacent soil. To

or a serviceability limit state analysis is being performed. In an accomplish this there must be a good bond resistance developed

ultimate limit state analysis fcr1 should be used as the value for fcr, between the reinforcement and the adjacent soil. Two different

whereas in a serviceability limit state analysis fcr2 should be used forms of bond resistance can arise – bond resistance due to

as the value for fcr in Equation 1. direct sliding and bond resistance due to pull-out. Direct sliding

occurs when a potential failure plane coincides with the surface

4. Material reduction factor for installation damage of the reinforcement layer. Pull-out occurs when a potential

effects, fid failure plane intersects reinforcement layers at an inclined angle.

When the reinforcement is installed and fill is compacted against

The effectiveness of the reinforcement bond resistance is

it, some loss in initial strength can be experienced by the

100 603-tdANZ-11|19

governed by the magnitude of the interaction coefficient

reinforcement. This loss in strength due to installation damage is

between the reinforcement and the adjacent soil and its bond

accounted for by use of a material reduction factor, fid. The

length. Miragrid® GX geogrids exhibit high bond resistance with

magnitude of the material reduction factor for installation

a variety of soil types. This is demonstrated by the high

damage effects depends on the reinforcement structure and the

interaction coefficients shown in Table 3 for a range of soil types.

type of fill being compacted against the reinforcement. Normally,

installation damage tests are carried out on sites, in accordance Table 3. Interaction coefficients for direct sliding and pull-out resistance for

with established methods such as ASTM D5818 or BS8006-1:2010 different adjacent fill types.

Annex D, using different fill types. Interaction

Coefficient Silt or Clay Sand Gravel (< 50mm)

Miragrid® GX geogrids exhibit material reduction factors for For direct sliding, αds 0.7 0.9 0.95

installation damage, the magnitude of which depends on the For pull-out, αpo 0.7 0.9 0.9

grade of product and the type of fill used. For example, when

clay, silt or sand fill is compacted against Miragrid® GX geogrids References

a value of fid = 1.10 is a conservative upper limit to be used for ASTM D5818 : Standard practice for exposure and retrieval of samples

design. For coarser fills the material reduction factor will be to evaluate installation damage of geosynthetics.

greater. ASTM D6992 : Standard test method for accelerated tensile creep and

creep rupture of geosynthetic materials based on time-temperature

5. Material reduction factor for environmental effects, superposition using the stepped isothermal method.

fen

BS8006-1:2010 Code of practice for strengthened/reinforced soils and

The chemical inertness of the high modulus PET yarns used in other fills, British Standards Institution.

Miragrid® GX geogrids makes them highly durable when installed ISO 13431 : Geotextiles and geotextile-related products-Determination

in a wide range of soil environments. For PET reinforcement to be of tensile creep and creep rupture behaviour.

used for long term design lives (100 years) the US Federal

Highway Administration recommends that the PET molecular

weight ≥ 25,000 g/mol and Carboxyl End Group count ≤ 30

mmol/kg. Miragrid® GX geogrids surpass these requirements.

You might also like

- Training PPT (TRB - TAS) PDFDocument135 pagesTraining PPT (TRB - TAS) PDFRizky RamadhanNo ratings yet

- Is 15912 - 2012Document2 pagesIs 15912 - 2012kalpanaadhi100% (1)

- 737Document20 pages737Kaushik SenguptaNo ratings yet

- Tech Data - MG GX Biaxial (100 603 Biaxial-Td-1018) - 1Document1 pageTech Data - MG GX Biaxial (100 603 Biaxial-Td-1018) - 1Sze Mian KuehNo ratings yet

- ACEGrid Brochure HR Final 7Document1 pageACEGrid Brochure HR Final 7Anonymous 0x2pwMCWgjNo ratings yet

- 2tech Data - MF PET (300 601-td-0219)Document4 pages2tech Data - MF PET (300 601-td-0219)Ismacahyadi Mohamed JaisNo ratings yet

- Data Sheet - MiragridR GX (100 603-Td-04-12)Document2 pagesData Sheet - MiragridR GX (100 603-Td-04-12)Anto DestiantoNo ratings yet

- Elcorock 2.5m3 Spec Sheet 05-12Document1 pageElcorock 2.5m3 Spec Sheet 05-12Aleksa CavicNo ratings yet

- Metfloor 60 - Composite Deck Slab Concrete VolumeDocument4 pagesMetfloor 60 - Composite Deck Slab Concrete VolumeHardeo Dennis ChattergoonNo ratings yet

- PDS BXG1216Document2 pagesPDS BXG1216Carlos SorianoNo ratings yet

- A Case Study On Performance of Self-Compacting Concrete in Highly Congested Reinforcement of Cast in Situ StructureDocument11 pagesA Case Study On Performance of Self-Compacting Concrete in Highly Congested Reinforcement of Cast in Situ StructureEASHANNo ratings yet

- TDS Nitowrap FRC Saudi ArabiaDocument3 pagesTDS Nitowrap FRC Saudi ArabiarayNo ratings yet

- TWT M50 Mix DesignDocument6 pagesTWT M50 Mix DesignStupidity TalksNo ratings yet

- ST2013-120-M15-M25-J K Laxmi-SNDDocument4 pagesST2013-120-M15-M25-J K Laxmi-SNDPrakash MakwanaNo ratings yet

- Masonry Structural Behaviour at Different Scales Under Compressive LoadingDocument8 pagesMasonry Structural Behaviour at Different Scales Under Compressive LoadingOyeniyi Samuel KehindeNo ratings yet

- Tensar BX1200Document1 pageTensar BX1200mohammazakNo ratings yet

- Min 340 - Clase 4 - Contour Blasting PDFDocument38 pagesMin 340 - Clase 4 - Contour Blasting PDFHéctor Fernando Sanhueza GonzalezNo ratings yet

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- TemplateDocument17 pagesTemplatemamthaNo ratings yet

- Sikawrap - 230 CDocument4 pagesSikawrap - 230 CNyein ZawNo ratings yet

- UC210AGRDocument2 pagesUC210AGRVolodymуr VorobetsNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Concrete Practice B&FDocument259 pagesConcrete Practice B&Fvijay100% (1)

- TDS Lokfix Saudi ArabiaDocument3 pagesTDS Lokfix Saudi ArabiaDoie QuerubinNo ratings yet

- T. Parhizkar, M. Najimi and A.R. Pourkhorshidi - APPLICATION OF PUMICE AGGREGATE IN STRUCTURAL LIGHTWEIGHT CONCRETEDocument14 pagesT. Parhizkar, M. Najimi and A.R. Pourkhorshidi - APPLICATION OF PUMICE AGGREGATE IN STRUCTURAL LIGHTWEIGHT CONCRETEAniruddha DalviNo ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Annex D - FINANCIAL OFFER FORM Protection Desk BOQDocument5 pagesAnnex D - FINANCIAL OFFER FORM Protection Desk BOQaddismekuria37No ratings yet

- Testing of NEOPRENE Bearings SKGDocument60 pagesTesting of NEOPRENE Bearings SKGshujaNo ratings yet

- Rock Reinforcement Modelling - Cable Bolts in PLAXIS 2DDocument12 pagesRock Reinforcement Modelling - Cable Bolts in PLAXIS 2Dchaymaa MRHARNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

- SMD TR60 DatasheetDocument4 pagesSMD TR60 DatasheetAlfred GandNo ratings yet

- Column Rebar Design - NTPCDocument7 pagesColumn Rebar Design - NTPCVaibhav ShahNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsMohammad Twaha JaumbocusNo ratings yet

- Sikawrap - 300 CDocument4 pagesSikawrap - 300 CAlexis KarampasNo ratings yet

- L01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Document2 pagesL01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Wika SentiongNo ratings yet

- Sikawrap®-300 C: Product Data SheetDocument4 pagesSikawrap®-300 C: Product Data SheetHenri DormoyNo ratings yet

- 2020 ACEGrid GG (Uniaxial)Document1 page2020 ACEGrid GG (Uniaxial)Raka BachtiaraNo ratings yet

- RC Footing Design FinalDocument37 pagesRC Footing Design FinalTarunNo ratings yet

- Mix Design of Self Compacting Concrete Using Fly Ash and MicrosilicaDocument4 pagesMix Design of Self Compacting Concrete Using Fly Ash and MicrosilicaAshutosh AnandNo ratings yet

- Sika AnchorFix-S 2012-05 - 1Document7 pagesSika AnchorFix-S 2012-05 - 1Jurutera CTDesignNo ratings yet

- C.C. Geomalla BiaxialDocument1 pageC.C. Geomalla BiaxialCHRISTIAN DENNIS FLORES LLANQUINo ratings yet

- Sikawrap 300 CDocument5 pagesSikawrap 300 CAkram ShakirNo ratings yet

- 25m 3 Girder SuperstructureDocument43 pages25m 3 Girder SuperstructureVivek KumarNo ratings yet

- Analysis and Design Study of Concrete Paver Blocks With Feedback LoopDocument7 pagesAnalysis and Design Study of Concrete Paver Blocks With Feedback LoopMaestro ConstructionNo ratings yet

- Opc 53 SDocument7 pagesOpc 53 SVikram SinghNo ratings yet

- Final Project ReviewDocument13 pagesFinal Project ReviewSiva VarmaNo ratings yet

- Sika® Carbodur® Rods: Carbon Fiber Rods For Structural StrengtheningDocument2 pagesSika® Carbodur® Rods: Carbon Fiber Rods For Structural StrengtheningGonzalo OviedoNo ratings yet

- Testing of NEOPRENE Bearings SKGDocument61 pagesTesting of NEOPRENE Bearings SKGkl Rahul locationNo ratings yet

- A Study On Shear Strength of Sands ReinfDocument8 pagesA Study On Shear Strength of Sands ReinfBenson Mwathi MungaiNo ratings yet

- TenCate Miragrid GX Biaxial TechnicalData EN 502169Document1 pageTenCate Miragrid GX Biaxial TechnicalData EN 502169Juan WeiNo ratings yet

- Nitowrap CFP: High Performance, High Strength, Corrosion Resistant Pultruded Carbon Fi Bre PlatesDocument2 pagesNitowrap CFP: High Performance, High Strength, Corrosion Resistant Pultruded Carbon Fi Bre PlatesbinodNo ratings yet

- Concrete Properties RequirementsDocument1 pageConcrete Properties RequirementsEleazar P. SanchezNo ratings yet

- Experimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshDocument35 pagesExperimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshPraveen RajNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument554 pagesRCC32R Rigorous Ribbed SlabsCioabla Bogdan100% (1)

- Pavement Design ReportDocument11 pagesPavement Design ReportIrfanNo ratings yet

- M864 Product Sheet 07 09 2018Document2 pagesM864 Product Sheet 07 09 2018evedelgamsNo ratings yet

- E-Catalogue (Rock Splitter 2009-01) PDFDocument6 pagesE-Catalogue (Rock Splitter 2009-01) PDFhenry vegaNo ratings yet

- Potaglas GRP Tank BrochureDocument6 pagesPotaglas GRP Tank Brochurebenj bandalNo ratings yet

- IS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthDocument4 pagesIS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthROHIT KUMARNo ratings yet

- DPR - PKG-3 - Ra-28 Date 13.12.2018Document7 pagesDPR - PKG-3 - Ra-28 Date 13.12.2018Prasanta ParidaNo ratings yet

- Lokfix: Polyester Resin Anchoring GroutDocument3 pagesLokfix: Polyester Resin Anchoring GroutMuneer ahmed100% (1)

- TDS Conbextra GP2 BFLDocument4 pagesTDS Conbextra GP2 BFLsabbirNo ratings yet

- Glulam Wood BeamsDocument37 pagesGlulam Wood Beamsu16sr6No ratings yet

- AeroShell Fluid 41 (India)Document3 pagesAeroShell Fluid 41 (India)Aaron ChanNo ratings yet

- Presentable Industrial Training Experience GabrielDocument15 pagesPresentable Industrial Training Experience GabrielOkortnne AyibaNo ratings yet

- Raw Mix Design CementDocument4 pagesRaw Mix Design Cementtariqshah100% (1)

- Sanitary FittingsDocument58 pagesSanitary FittingsMherlieNo ratings yet

- 01 Architecture DrawingsDocument57 pages01 Architecture Drawingstvpham123No ratings yet

- St. Joseph's Convent Hr. Sec. School Quarterly Examination-2021 Subject: - English Time:-3:00hr Class:-12 M.M: - 80Document4 pagesSt. Joseph's Convent Hr. Sec. School Quarterly Examination-2021 Subject: - English Time:-3:00hr Class:-12 M.M: - 80Nitesh PatelNo ratings yet

- Concrete Construction Article PDF - Two-Day Construction Cycle For High-Rise Structures Based On Use of Preshores PDFDocument5 pagesConcrete Construction Article PDF - Two-Day Construction Cycle For High-Rise Structures Based On Use of Preshores PDFPrompt Torre LoyolaNo ratings yet

- Scheme and Syllabus of B.E. (Civil Engineering) : Panjab University, ChandigarhDocument62 pagesScheme and Syllabus of B.E. (Civil Engineering) : Panjab University, Chandigarhgautam9699No ratings yet

- SPDIDocument501 pagesSPDIEugene Odullada MangaringNo ratings yet

- IFM - SM7000 - Debitmetre - Sortie AnalogiqueDocument4 pagesIFM - SM7000 - Debitmetre - Sortie Analogiquenapnap5No ratings yet

- Project Report - CNG CylindersDocument23 pagesProject Report - CNG CylindersNaresh DhakerNo ratings yet

- Al Plate Heat Ex ChangersDocument686 pagesAl Plate Heat Ex ChangersMario Mendoza33% (3)

- Det Ails of Expansion Joint in Concrete Carriagewa Y: Highways DepartmentDocument1 pageDet Ails of Expansion Joint in Concrete Carriagewa Y: Highways Departmentcho673524No ratings yet

- Flow Through Circular PipesDocument105 pagesFlow Through Circular PipesArchangel VenantNo ratings yet

- Advanced Structural Design - Lecture Note 02Document7 pagesAdvanced Structural Design - Lecture Note 02Chamil MahagamageNo ratings yet

- GEAKueba Katalog MarketSP enDocument12 pagesGEAKueba Katalog MarketSP enRodrigo GonçalvesNo ratings yet

- Rockwell Hardness TestDocument5 pagesRockwell Hardness TestAdil Javed Chaudhary89% (9)

- Pile Cap Design Examples To Eurocode 2Document12 pagesPile Cap Design Examples To Eurocode 2Krishna SodhaNo ratings yet

- Unit-I - Limit State Method Concept and Design of Beams: 1. MaterialsDocument7 pagesUnit-I - Limit State Method Concept and Design of Beams: 1. MaterialsYAZHININo ratings yet

- Daniel Adofo AmeyawDocument102 pagesDaniel Adofo AmeyawJoel Morales PerezNo ratings yet

- ASHRAE 2014 Evaporation Paper PDFDocument15 pagesASHRAE 2014 Evaporation Paper PDFBenjamin ChavezNo ratings yet

- ISO Quality Manual 9001-2015 - Final - 20.07.2017 - Part51Document2 pagesISO Quality Manual 9001-2015 - Final - 20.07.2017 - Part51ganrashNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDF PIPING Engineering Interview QuestionsDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDF PIPING Engineering Interview Questionssteepa22100% (1)

- Charging by RubbingDocument18 pagesCharging by RubbingLora GarciaNo ratings yet

- Magnetic Force MicrosDocument15 pagesMagnetic Force MicrosArvindGovaNo ratings yet

- Astm D6677-2007Document2 pagesAstm D6677-2007Chris SchnurchNo ratings yet