Professional Documents

Culture Documents

Noise Pollution in Textile, Printing and Publishing Industries in Saudi Arabia

Noise Pollution in Textile, Printing and Publishing Industries in Saudi Arabia

Uploaded by

iulian_stoicanCopyright:

Available Formats

You might also like

- Assignment 302Document12 pagesAssignment 302armalia78% (41)

- Process Industry PracticeDocument12 pagesProcess Industry PracticeRonald George100% (1)

- Peo2 001Document7 pagesPeo2 001Jimmy Gray0% (1)

- Emergency Management Plan - 20130319 CommentedDocument14 pagesEmergency Management Plan - 20130319 Commentedkirandevi1981No ratings yet

- Inspection ChecklistDocument2 pagesInspection Checklistrobinrubina100% (1)

- Industrial Noise Pollution and Its Health Effects On Workers in Nairobi City IJERTV5IS090374Document10 pagesIndustrial Noise Pollution and Its Health Effects On Workers in Nairobi City IJERTV5IS090374kakamegafinest997No ratings yet

- Evaluation of Occupational Noise Exposure in A Plastic Manufacturing Industry: A Case StudyDocument9 pagesEvaluation of Occupational Noise Exposure in A Plastic Manufacturing Industry: A Case StudyNURUL HIDAYAH BT IBRAHIM / UPMNo ratings yet

- Noise Pollution and Its Control in Textile IndustryDocument6 pagesNoise Pollution and Its Control in Textile IndustryAmir ShahzadNo ratings yet

- Assessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityDocument6 pagesAssessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityMD Najmul HossanNo ratings yet

- Noise Pollution in The Textile IndustryDocument9 pagesNoise Pollution in The Textile IndustryAmmar Maqsood0% (1)

- An Overview of Industrial Employees' Exposure To Noise in Sundry Processing and Manufacturing Industries in Ilorin Metropolis, NigeriaDocument12 pagesAn Overview of Industrial Employees' Exposure To Noise in Sundry Processing and Manufacturing Industries in Ilorin Metropolis, NigeriaPhilmona SamuelNo ratings yet

- 1 PBDocument7 pages1 PBAkif EmekliNo ratings yet

- Noise Control in Textile MachineriesDocument40 pagesNoise Control in Textile MachineriesJagannath SardarNo ratings yet

- Welding NoiseDocument6 pagesWelding NoiseYam SoussanaNo ratings yet

- Noise Risk AssessmentDocument11 pagesNoise Risk AssessmentSunil Babu KhatryNo ratings yet

- Comparative Study of The Noise Generated by Rotating Machines in Industrial Area of Arzew Algeria A Case Study in gp1z PDocument9 pagesComparative Study of The Noise Generated by Rotating Machines in Industrial Area of Arzew Algeria A Case Study in gp1z PIliace ArbaouiNo ratings yet

- D1203012531 With Cover Page v2Document8 pagesD1203012531 With Cover Page v2MarivauxNo ratings yet

- 5 Noise SourcesDocument23 pages5 Noise SourcesMitha TheresiaNo ratings yet

- Applied Sciences: Noise Sources and Control, and Exposure Groups in Chemical Manufacturing PlantsDocument26 pagesApplied Sciences: Noise Sources and Control, and Exposure Groups in Chemical Manufacturing PlantsomarNo ratings yet

- Amani 2014 TaJONAS 5 (1) 741-745Document5 pagesAmani 2014 TaJONAS 5 (1) 741-745MkomaNo ratings yet

- What Is The Allowable Noise LevelDocument2 pagesWhat Is The Allowable Noise LevelbrynobrdnNo ratings yet

- Assessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityDocument7 pagesAssessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityAtiqur RahmanNo ratings yet

- Assessment of Noise Pollution in Different Hatbazars of Butwal City, Rupandehi, NepalDocument4 pagesAssessment of Noise Pollution in Different Hatbazars of Butwal City, Rupandehi, NepalALINA LAMICHHANENo ratings yet

- Noise PollutionDocument7 pagesNoise PollutionkmgroupNo ratings yet

- Noise Dosimeter Lab8 HumanDocument5 pagesNoise Dosimeter Lab8 HumanAsif NawazNo ratings yet

- PreventionofhearinglossDocument12 pagesPreventionofhearinglossibrahimNo ratings yet

- INDUSTRIAL ENGG - LAB (Exp-4) 6053RDocument6 pagesINDUSTRIAL ENGG - LAB (Exp-4) 6053Rpatel1029poojaNo ratings yet

- Noise: Unwanted SoundDocument84 pagesNoise: Unwanted SoundMatthew PerryNo ratings yet

- Noise Pollution-Sources Effects and ControlDocument8 pagesNoise Pollution-Sources Effects and ControlLavish LokhandeNo ratings yet

- Design and Development of Noise Suppression System For Domestic GeneratorsDocument8 pagesDesign and Development of Noise Suppression System For Domestic GeneratorsMackinder Lijarza torresNo ratings yet

- Applying Kurtosis As An Indirect Metric of Noise Temporal Structure in The Assessment of Hearing Loss Associated With Occupational Complex Noise Exposure PDFDocument15 pagesApplying Kurtosis As An Indirect Metric of Noise Temporal Structure in The Assessment of Hearing Loss Associated With Occupational Complex Noise Exposure PDFKaty Marlen GongoraNo ratings yet

- Lab 3 SS21303Document8 pagesLab 3 SS21303Frisha FaqihahNo ratings yet

- Reviewed of Noise Control in Ic EngineDocument3 pagesReviewed of Noise Control in Ic Engineijsret100% (1)

- Evaluation of A Wearable Consumer Noise Measurement Device in A Laboratory SettingDocument6 pagesEvaluation of A Wearable Consumer Noise Measurement Device in A Laboratory SettingbenrobrbfNo ratings yet

- SLM Apad LatestDocument16 pagesSLM Apad Latestnurfadhilah_rosliNo ratings yet

- Noise PollutionDocument8 pagesNoise PollutionGourav Kumar38No ratings yet

- Industrial Noise Monitoring Using Noise Mapping Technique: A Case Study On A Concrete Block Making FactoryDocument12 pagesIndustrial Noise Monitoring Using Noise Mapping Technique: A Case Study On A Concrete Block Making FactorynisaNo ratings yet

- Noise Mapping in FactoryDocument5 pagesNoise Mapping in FactoryNor RazmanNo ratings yet

- Occupational Noise-Induced Hearing Loss in Auto Part Factory Workers in Welding Units in ThailandDocument8 pagesOccupational Noise-Induced Hearing Loss in Auto Part Factory Workers in Welding Units in ThailandPratiwi UmbohNo ratings yet

- Noise Hazards Associated With The Call Centre IndustryDocument9 pagesNoise Hazards Associated With The Call Centre IndustryBagas Zaki MNo ratings yet

- Environmental Noise MeasurementDocument26 pagesEnvironmental Noise MeasurementPalazzo345100% (1)

- Acoustics: Psychoacoustic Analysis of Vacuum Cleaner NoiseDocument14 pagesAcoustics: Psychoacoustic Analysis of Vacuum Cleaner NoiseJoão Paulo CabralNo ratings yet

- Use of Technical Textiles With Special Reference TO Acoustical ApplicationsDocument23 pagesUse of Technical Textiles With Special Reference TO Acoustical ApplicationsSakthivel JegarajanNo ratings yet

- Noise Pollution and Its Control in Textile Industry: A of Searc 26Document6 pagesNoise Pollution and Its Control in Textile Industry: A of Searc 26Nakib Ibna BasharNo ratings yet

- ES 7, Noise PollutionDocument11 pagesES 7, Noise PollutionSajib IglesiasNo ratings yet

- ST Data12 NoisemonitorDocument1 pageST Data12 NoisemonitorUmar SabaNo ratings yet

- An Assessment of Occupational Noise Exposures in Four Construction TradesDocument11 pagesAn Assessment of Occupational Noise Exposures in Four Construction TradespaulNo ratings yet

- CIV4204 Chapter 8 Noise Pollution ControlDocument5 pagesCIV4204 Chapter 8 Noise Pollution Controlmulabbi brianNo ratings yet

- ContentServer PDFDocument14 pagesContentServer PDFLUIS ISAAC LEON PARONo ratings yet

- 8B Noise and Vibration Impact Assessment Criteria and Methodology 8B.1 IntroductionDocument8 pages8B Noise and Vibration Impact Assessment Criteria and Methodology 8B.1 IntroductionManuel BrunalNo ratings yet

- RP Noise 4Document9 pagesRP Noise 4daaNo ratings yet

- Assessment of Perception and Knowledge oDocument12 pagesAssessment of Perception and Knowledge oCannell MeukamNo ratings yet

- Noise Pollution Norms - 1Document25 pagesNoise Pollution Norms - 1ZIPDASHNo ratings yet

- Caso PracticoDocument8 pagesCaso Practicoseguridadysaludeneltrabajo.ogperNo ratings yet

- Noise Investigation in ManufacturingDocument6 pagesNoise Investigation in ManufacturingMarioNo ratings yet

- Textbook Noise in The Plastics Processing Industry Second Edition Peters Ebook All Chapter PDFDocument53 pagesTextbook Noise in The Plastics Processing Industry Second Edition Peters Ebook All Chapter PDFfrancisco.moses588100% (11)

- Cleaner ProductionDocument29 pagesCleaner ProductionhananNo ratings yet

- Industrial Noise Control - The Singapore ExperienceDocument19 pagesIndustrial Noise Control - The Singapore ExperienceMuhammad YazdanNo ratings yet

- Pemetaan Dan Perhitungan Pemaparan Tingkat Kebisingan Pada Industri Pengolahan Kayu Di Kecamatan Siak, Provinsi RiauDocument10 pagesPemetaan Dan Perhitungan Pemaparan Tingkat Kebisingan Pada Industri Pengolahan Kayu Di Kecamatan Siak, Provinsi RiauERIFINNo ratings yet

- Noise: Guide For Risk Assessment in Small and Medium EnterprisesDocument10 pagesNoise: Guide For Risk Assessment in Small and Medium EnterprisesXozanNo ratings yet

- Noise PollutionDocument16 pagesNoise PollutionNaimur Rahim ChowdhuryNo ratings yet

- Industrial Noise and Its Effects On Humans: E. Atmaca I. Peker, A. AltinDocument6 pagesIndustrial Noise and Its Effects On Humans: E. Atmaca I. Peker, A. AltinMuhammad ArslanNo ratings yet

- Noise PollutionDocument6 pagesNoise Pollutionvikash rajNo ratings yet

- 61-Article Text-237-1-10-20230313Document6 pages61-Article Text-237-1-10-20230313VivekNo ratings yet

- Vibration-based Condition Monitoring: Industrial, Aerospace and Automotive ApplicationsFrom EverandVibration-based Condition Monitoring: Industrial, Aerospace and Automotive ApplicationsNo ratings yet

- Factories Act 1948Document12 pagesFactories Act 1948Ashwini BapuNo ratings yet

- Assignment 2Document3 pagesAssignment 2Pradeep Dahiya100% (1)

- HRM 300 (Human Resource Management) Complete CourseDocument18 pagesHRM 300 (Human Resource Management) Complete Coursecoursehomework100% (1)

- ContractorSafetyPolicy 0912Document9 pagesContractorSafetyPolicy 0912Reno Miranda EnticoNo ratings yet

- NarreporDocument3 pagesNarreporfrancessichNo ratings yet

- Taxi Drivers SafetyDocument46 pagesTaxi Drivers SafetyJenna FisherNo ratings yet

- Topic 4 Hazard Identification PDFDocument15 pagesTopic 4 Hazard Identification PDFDiyana OsmanNo ratings yet

- Msds HP 20w50Document7 pagesMsds HP 20w50Anonymous PvHmtbNo ratings yet

- Working at Height For Exon MobilDocument66 pagesWorking at Height For Exon Mobillinkenciel100% (2)

- CHPT 1Document20 pagesCHPT 1Mohd Fadhil Mohd NohNo ratings yet

- Data Matrix Company ProfileDocument5 pagesData Matrix Company ProfileMariusNepgenNo ratings yet

- The Following Were The Two DefinitiveDocument28 pagesThe Following Were The Two DefinitiveVAHIDNo ratings yet

- ST Lukes Medical Center Employees Ass Vs NLRCDocument7 pagesST Lukes Medical Center Employees Ass Vs NLRCJacquelyn AlegriaNo ratings yet

- Health & Safety Policy QEB Standards 13Document2 pagesHealth & Safety Policy QEB Standards 13QBE European Operations Risk ManagementNo ratings yet

- Gale Elementary Report and FOIA DocumentsDocument88 pagesGale Elementary Report and FOIA DocumentsChi_Light_BrigadeNo ratings yet

- Martin George Cooke 7th January 2011Document2 pagesMartin George Cooke 7th January 2011Martin Cooke Cert EdNo ratings yet

- Plan de Seguridad e Higiene (Inglés)Document73 pagesPlan de Seguridad e Higiene (Inglés)JuanCarlosVilchisDuránNo ratings yet

- Isu-Isu Semasa Pengurusan Keselamatan Dan KesihatanDocument8 pagesIsu-Isu Semasa Pengurusan Keselamatan Dan KesihatanAzlyn SyafikahNo ratings yet

- Order: Life in Lansing Required To Pay Back WagesDocument31 pagesOrder: Life in Lansing Required To Pay Back WagesLansingStateJournalNo ratings yet

- SVN LOG-P3Document356 pagesSVN LOG-P3Emman Patpert KnuckleheadsNo ratings yet

- Cat Sebu7656-02 SDocument18 pagesCat Sebu7656-02 S2012jNo ratings yet

- TopyDocument64 pagesTopyChristiano Calijorne de BarrosNo ratings yet

- Occupational HealthDocument48 pagesOccupational HealthSapiah Raman50% (4)

- ABC's of Fall Protection: Murray State University Susan MillerDocument24 pagesABC's of Fall Protection: Murray State University Susan MillerSam SalesNo ratings yet

- DOL FOIA Response Re: Bloomberg Leif Olson SmearDocument114 pagesDOL FOIA Response Re: Bloomberg Leif Olson SmearPhil KerpenNo ratings yet

Noise Pollution in Textile, Printing and Publishing Industries in Saudi Arabia

Noise Pollution in Textile, Printing and Publishing Industries in Saudi Arabia

Uploaded by

iulian_stoicanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Noise Pollution in Textile, Printing and Publishing Industries in Saudi Arabia

Noise Pollution in Textile, Printing and Publishing Industries in Saudi Arabia

Uploaded by

iulian_stoicanCopyright:

Available Formats

NOISE POLLUTION IN TEXTILE, PRINTING AND PUBLISHING INDUSTRIES IN SAUDI ARABIA

MADBULI H. NOWEIR and A. T. M. JAMIL

Department of Industrial Engineering, King Abdul Aziz University, Jeddah, Saudi Arabia

(Received 13 March 2001; accepted 26 April 2002)

Abstract. A study of 20 factories belonging to textile, printing, publishing and paper products industries in Jeddah was conducted. Data on Leq, Maximum and Minimum SPL at different octave bands, as well as dBA, were collected. It has been found that textile, publishing and paper products industries are the most noisy industries. The paper is concluded with suitable recommendation for noise control and worker protection. Keywords: noise, printing, publishing, Saudi Arabia, textile

1. Introduction The causal relationship between work place noise and hearing loss has been observed for centuries (Franks, 1988). Lately, there have been many trials for assessing the magnitude of the problem of noise exposure in manufacturing industries. For example, the U.S. Occupational Safety and Health Agency (OSHA), in 1981, estimated that more than 6 mL workers (active and retired) had had noise exposure levels greater than 85 dBA in U.S.A (OSHA, 1981) alone. However, in 1988, Frank (1988), using data of two OSHA-conducted U.S. industry-wide noise surveys (Bolt, Beranek and Newman Inc., 1976; Booz, Allen and Hamilton Inc., 1983), estimated that some 4.7 mL were exposed in 1985 to average daily noise levels of 85 dBA or greater. Meanwhile, a NIOSH National Occupational Hazard Survey (NIOSH-NOHS) (1974, 1977, 1978) revealed that the top seven industries with the greatest percentage of workers exposed to 85 dBA or greater were lumber and wood, textiles, petroleum, utilities, metals, printing, and paper products industries. Similar ndings were reported by the two OSHA-contracted noise surveys (Bolt, Beranek and Newman Inc., 1976; Booz, Allen and Hamilton Inc., 1983). In U.K., noise pollution was reported in 1985 as the biggest hazard in factories, since 700 000 workers were being still exposed to noise levels exceeding the governments recommended limit of 85 dBA (Pearce, 1985). It has been concluded that the problem of industrial noise had been aggravated by the use of high speed, high production machines in textile mills and other industries. In Spain, noise has been identied among the top occupational risk factors in printing and textile inNIOSH: National Institute of Occupational Safety and Health. Environmental Monitoring and Assessment 83: 103111, 2003. 2003 Kluwer Academic Publishers. Printed in the Netherlands.

104

MADBULI H. NOWEIR AND A. T. M. JAMIL

dustries (Escriba-Aguir et al., 1993). Similar studies were reported from Russia (Chkannikov, 1993) and Ukraine (Menshov and Kureva, 1995) in textile industry. In developing countries also, there has been a great concern about the magnitude of industrial noise exposure, particularly in textile industry. In Egypt, (Noweir et al., 1968, 1979, 1985a, b; Noweir, 1984) a population of 500 000 textile workers was estimated in 1985 to be at risk of noise exposure (Noweir et al., 1985a) and many were exposed to noise levels up to 98 dBA. Auditoy (Noweir et al., 1995a), non-auditoy, nervous and cardiovascular effects (Noweir et al., 1985b) were reported among a study sample (n = 2652 vs. controls = 756). Also, bio-chemical changes (Noweir et al., 1979), reduced productivity, increased absenteeism and accidents (Noweir, 1984) etc. are other harmful manifestations of high noise exposure levels. Other similar studies in textile industries came from India (Pal and Rajput, 1991), China (noise levels up to 105 dBA) (Youjia al., 1987), Thailand (noise levels up to 101.3 2.7 dBA) (Chavalitsakulchai et al., 1989), Singapore (Tay, 1996), and Tanzania (Yhdegol, 1991). In Saudi Arabia, a survey in the late eighties of 78 factories producing food, chemicals, plastic, paper and other products (Al-Idrisi et al., 1990) found that 86.6% of the surveyed factories, at least in part, exceeded the permissible level of 85 dBA as recommended (ACGIH, 2000) by ACGIH . The authors recommended more detailed investigations in carefully selected industries. The present study was, therefore, conducted as a part of a plan to study, in details, noise pollution in selected high risk Saudi Industries. The scope of this present study includes textile, carpet, printing, publishing and paper product industries in Jeddah. Future studies are planned to cover lumber and wood, metal, and petroleum industries. The specic objectives of the study may be listed as: To map noise levels in selected industrial premises belonging to the above mentioned industries, and check compliance with the standards for industrial noise exposure. To provide recommendations for noise reduction and health protection of employees.

2. Methodology 2.1. S ELECTION OF FACTORIES A list of all factories in the following 5 categories of industries in Jeddah was obtained. (a) Textile industry, (b) carpets Industry, (c) general printing, (d) publishing industry, and (e) paper products industry.

ACGIH: American Conference of Govermental Industrial Hygienists.

NOISE POLLUTION IN INDUSTRIES IN SAUDI ARABIA

105

A stratied random sample of 20 factories, representing about 40% of the above industries, was selected. These included 3 textile, 2 carpet weaving, 7 printing, 3 publishing and 5 paper products factories. 2.2. N OISE MEASUREMENT AND ANALYSIS In individual factories, noise measurements were taken at strategic locations depending on the type, number and layout of machineries. The noise measurements included Leq dBA, Maximum and Minimum SPLs at the individual octave bands. Other relevant data such as the operation, type and number of machinery, construction materials for roofs, oors, walls and ceilings etc. were also recorded. Noise was measured at each location using the B & K Sound Level Meter (SLM) type 2236. The noise was measured at workers head level. An omni-directional microphone type 4188 was used with the SLM to include noises from all possible sources. The calibration of the instrument was checked before and after each set of measurements as recommended by the SLM manufacturer (B & K, 1978). The measurements were taken over a duration of 10 min at each location. The data were statistically analysed using Excel. For each factory, frequency tables for Leq, Max and Min SPL levels were construced. This was followed by computing the mean dBA of Leq, Max and Min SPLs, and also at different octave bands, for individual factories. The same analysis were done for each type of the industries by pooling the data of related factories.

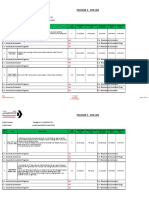

3. Results and Discussion The dBA Means of Leq, Max (SPL) and Min (SPL) of the surveyed factories are given in Table I and graphically shown in Figure 1. The most used and possibly, the most meaningful parameter, the Leq has varying degree of variance, ranging from 1.5 dBA2 (Hygienic Paper Products Co.) to 5.9 dBA2 (Nasr Printing Factory). Factories with smaller variance of Leq could be treated with general noise control and reduction techniques. However, factories with high variation may have hot spots which would need individual noise control at the sources in addition to any general measures. Figure 2 shows the mean Leq (dBA) for the pooled data of the factories belonging to each of the industries under study. These data when compared with noise measurements in similar industries in some developing countries, as presented in Table II, indicate that the presently reported measurements are relatively low. This might be attributed to the better designed machineries and factory installations in Saudi industries. Also, it is interesting to note that noise levels over 85 dBA occur at frequencies mostly below 1 KHz across all industries (Figure 2). This indicates that noise reduction techniques when applied should take special care of frequencies below

106

MADBULI H. NOWEIR AND A. T. M. JAMIL

TABLE I Mean of the Leq and its standard deviation, means of maximum SPL and minimum SPL in the studied factories Industry Factory name Leq mean (SD) (dBA) 83.2 (4.4) 85.0 (3.7) 85.4 (2.8) 86.6 (3.1) 92.0 (1.5) 76.5 (3.3) 77.5 (3.5) 77.8 (5.9) 81.0 (3.6) 82.0 (4.0) 82.4 (3.6) 84.4 (4.1) 84.7 (2.9) 85.0 (4.4) 86.1 (3.6) 88.6 (4.6) 88.6 (1.5) 88.7 (3.3) 89.1 (2.4) 93.3 (2.9) Max. SPL mean (dBA) 92.8 93.1 90.1 93.7 95.5 83.3 87.3 90.6 87.5 92.0 89.0 90.0 88.5 91.4 91.8 95.0 95.2 93.5 95.7 100.1 Min. SPL mean (dBA) 74.0 81.2 81.4 83.1 88.6 72.9 71.0 70.4 75.4 73.3 77.2 80.1 80.8 80.6 82.4 83.4 85.6 84.8 85.1 89.3

Textile and Carpet

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Al-Suriya Carpet Factory Al-Dahlawi Yarn Factory Al-Bahlas National Carpet Company Saudi Spinning and Textile 1 Saudi Spinning and Textile 2 Al-Mubarak Printing Company Sahar Printing Estate Nasr Packing and Printing Company Al-Fateh Printing Company Al-Shark Printing Company Al-Madina Printing 1 Dar Okaz Publishing Estate Sarawat Printing Estate Al-Banawi Packing National Paper Products Company United Carton Products Company Hygienic Paper Products Company Saudi Carton Factory Al-Madina Printing and Publishing-2 Okaz Publishing Estate

Printing, Publishing and Paper Products

1 KHz. Meanwhile, the reduction in noise at these frequency ranges will considerably reduce noise interference with workers speech, since much of the human speech is between 300 and 700 Hz and most vowels are below 1 KHz (Kroemer and Grandjean, 1997).

4. Recommendations Based on the analysis, the following recommendations may be considered to improve the overall situation.

NOISE POLLUTION IN INDUSTRIES IN SAUDI ARABIA

107

Figure 1. Mean noise levels at different factories.

Hot spots (ie., sources that produce high noise levels) should be identied in individual factories, specically, in publishing, paper products and textile industries. As a rst line of defense, noise control/reduction measures such as replacing or modifying noisy machines, better installation and maintenance of machines and where necessary, quarantining very noisy sources etc., should be adopted. Many examples of noise control methods are described in the literature (B & K, 1982; Bies and Hansen, 1985), and many reports of noise control in textile industry (Dzwonnik, 1977; Mills, 1969; Graffagnini, 1970; El-Dakhakhni et al., 1975; Wilhelm et al., 1991) are also available. For the publishing and paper products industries, the situation seems critical. Noise reduction techniques such as redesigning walls and ceilings, using noise absorbing materials etc. should be adopted in addition to noise control measures suggested above. In textile and printing industries, which are among the noisiest, it is not possible to isolate the machineries since the workers have to work close to the machines. Hence, in these industries, workers should have personal protection measures and should be rotated to reduce their exposure level. A general hearing conservation program to protect workers should be introduced in all these industries and more specically in publishing, textile and

108

MADBULI H. NOWEIR AND A. T. M. JAMIL

Figure 2. Mean of Leq, max. SPL and min. SPL at different octave bands.

NOISE POLLUTION IN INDUSTRIES IN SAUDI ARABIA

109

TABLE II Comparison of noise levels (Leq in dBA) of the studied textile industries with recently reported similar studies in some other countries Country (References) Textile Carpet comprehensive weaving 83.285.4 90105 96.9 92.7 80.493.8 Textile weaving Spinning Yarn processing

Saudi Arabia (present study) China (Youjia et al., 1987) Egypt (Noweir et al., 1985; Noweir, 1984) Poland (Dzwonnik, 1977) Tanzania >90 (Yhdegol, 1991) Thailand (Chavalitsakulchai et al., 1989) Ukrain (Menshov and Kurev, 1995)

86.692.0 85.0

90110

101.3 86.097.7

89.8

paper products industries. Workers should have periodic audiometric tests to check the effectiveness of the noise controls and hearing conservation program. A general policy to supply ear protectors to all workers should be adopted (or even made compulsory) by all factories, since it is also very inexpensive. The results of this study point to the need of further studies at the remaining factories belonging to these industries and the other industries as well.

References

ACGIH: 2000, Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices, American Conference of Governmental Industrial Hygienists, Cincinnati, Ohio, U.S.A. Al-Idrisi, M., Jamil, A. T. M., Al-Jifry, M. S., Jifri, M. A. and Erturk, F.: 1990, Evaluation of noise stresses in Jeddah industrial estate, J. Environ. Sci. Health A 25(8) 873896. B & K: 1978, Application Manual for Acoustic Noise Equipment, Bruel and Kjaer, Naermark, Denmark. B & K: 1982, Noise Control: Principles and Practice, Bruel and Kjaer, Naerum, Denmark. Bies, D. A. and Hansen, C. H.: 1985, Engineering Noise Control, Chapman and Hall, London.

110

MADBULI H. NOWEIR AND A. T. M. JAMIL

Bolt, Beranek and Newman, Inc.: 1976, Economic Impact Analysis of Proposed Noise Control Regulation, BBN Report 3246, U.S. Department of Labor, Washington, DC. Booz, Allen and Hamilton, Inc.: 1983, Technical and Economic Analysis of Alternative Noise Standards, Prepared for the Ofce of Regulatory Analysis, Occupational Safety and Health Administration, U.S. Department of Labor, Washington, DC. Chavalitsakulchai, P., Kawakami, T., Kongmuag, U., Vivatjestsadawat, P. and Leongsrisook, W.: 1989, Noise exposure and permanent hearing loss of textile workers in Thailand, Ind. Health 27, 165173. Chkannikov, A. N.: 1993, Correlation between Acoustic and Systematic Vascular Disorders in Workers Exposed to Industrial Noise, Gigiena Truedai prefessionalnye Zabolevaniya, 2 February, pp. 1216 (English Abstract: Medline Express, 19911993). Dzwonnik, Z.: 1977, Effect of machine modernization on the level of noise and its characteristics in the textile industry, Med. Pr. 28, 135141, (English Abstract). El-Dakhakhni, A., Noweir, M. H. and Kamel, N. R.: 1975, Study of some parameters affecting noise level in textile spinning and weaving mills, Am. Ind. Hyg. Assoc. J. 36, 6972. Escriba-Aguir, V., Sanchez-Miguel, A. and Moncoda-Lluis, S.: 1993, Occupational risk factors in the sectors of economic activity of Barcelona. Gac-Sanit 7(37), 15853, (English Abstract: Medline Express, 19911993). Franks, J. R.: 1988, Number of Workers Exposed to Occupational Noise, Seminars in Hearing, Vol. 9, No. 4, November, Thieme Medical Publishers, Inc., New York, N.Y., U.S.A. Graffagnini, S.: 1970, Practical experience in measures to reduce noise in a chemico-textile industry, Med. Lav. 61, 652657 (English Abstract). Kroemer, K. H. E. and Grandjean, E.: 1997, Fitting the Task to the Human, 5th ed., Taylor and Francis, Bristol, Pa, U.S.A., p. 320. Menshov, A. A. and Kureva, P. M.: 1995, Effects of Occupational and Community Noise on Workers, Proceedings of INTERNOISE 95, Vol. 2, 1012 July, New Port Beach, CA, U.S.A., pp. 843845. Mills, R. O.: 1969, Noise reduction in a textile weaving mill, Am. Ind. Hyg. Assoc. J. 30, 7176. National Occupational Hazard Survey: 1974, Department of Health and Human Services, National Institute for Safety and Health, Rockville, MD, Publication Number (NIOSH), 74127. National Occupational Hazard Survey: 1977, Department of Health and Human Services, National Institute for Safety and Health, Rockville, MD, Publication Number (NIOSH), 77213. National Occupational Hazard Survey: 1978, Department of Health and Human Services, National Institute for Safety and Health, Rockville, MD, Publication Number (NIOSH), 78114. Noweir, M. H., El-Dakhakhny, A. A. and Valic, F.: 1968, Exposure to noise in the textile industry of U.A.R., Am. Ind. Ayg. Assoc. J. 29, 541546. Noweir, M. H., Abdel-Kader, H. M., El-Gazzar, R. H., Moslehi, M. and Ghorab, S.: 1979, Study of some biochemical changes in workers exposed to noise in textile industry, Arh. hig rada toksikol 30, 719726 (Suppl.). Noweir, M. H.: 1984, Noise exposure as related to productivity, disciplinary actions, absenteeism and accidents among textile workers, J. Safety Res. 15, 163174. Noweir, M. H., El-Sadik, Y. M. and Nofal, L. M.: 1985a, Noise exposure and its impact on hearing threshold of textile workers in Egypt, Part I: Noise exposure and induced hearing loss, Bull. H. Inst. Publ. Health 15, 126 (Suppl.). Noweir, M. H., Moslehi, M., Hussein, M. and Nofal, L.: 1985b, Noise exposure as related to nonauditory health conditions among Egyptian textile workers, Bull, H. Inst. Publ. Health 15, 5376 (Suppl.). OSHA (1981): 1986, Final Regulatory Analysis for the Hearing Conservation Amendment. Reported in Noise Induced Loss of Hearing, Morbidity and Mortality Weekly Report, 28 March, Vol. 35, No. 12, PHS, U.S. Department of Health and Human Services.

NOISE POLLUTION IN INDUSTRIES IN SAUDI ARABIA

111

Pal, P. B. and Rajput, M. R.: 1991, Status of occupational environment of industries in Kanpur City, Indian J. Environ. Prot. 11(3), 209315. Pearce, F.: 1985, Noise: Industry turns a deaf ear, New Sci. 108 (1485), 38(5). Tay, P.: 1996, Severe noise-induced deafness: A ten-year review of cases, Singapore Med. J. 37, 362364. Yhdegol, M.: 1991, Assessment of noise pollution in friendship textile mill limited, Ubong-Dar es Salam, Environ. Int. 17(5), 479485. Youjia, Ji, Yushan, T. and Song, Zurang: 1987, Reducing the Noise in a Weaving Room of Looms 1511: Research and Practice in the Pilot Test, Noise Control Engineering 16th Int. Conference, Vol. 1, 1517 September 1987, Beijing, China, p. 303. Wilhelm, H., Woerndle, E. L. and Airtex, S.: 1991, Working Towards a Cleaner Future, Textile Month (July), pp. 2934.

You might also like

- Assignment 302Document12 pagesAssignment 302armalia78% (41)

- Process Industry PracticeDocument12 pagesProcess Industry PracticeRonald George100% (1)

- Peo2 001Document7 pagesPeo2 001Jimmy Gray0% (1)

- Emergency Management Plan - 20130319 CommentedDocument14 pagesEmergency Management Plan - 20130319 Commentedkirandevi1981No ratings yet

- Inspection ChecklistDocument2 pagesInspection Checklistrobinrubina100% (1)

- Industrial Noise Pollution and Its Health Effects On Workers in Nairobi City IJERTV5IS090374Document10 pagesIndustrial Noise Pollution and Its Health Effects On Workers in Nairobi City IJERTV5IS090374kakamegafinest997No ratings yet

- Evaluation of Occupational Noise Exposure in A Plastic Manufacturing Industry: A Case StudyDocument9 pagesEvaluation of Occupational Noise Exposure in A Plastic Manufacturing Industry: A Case StudyNURUL HIDAYAH BT IBRAHIM / UPMNo ratings yet

- Noise Pollution and Its Control in Textile IndustryDocument6 pagesNoise Pollution and Its Control in Textile IndustryAmir ShahzadNo ratings yet

- Assessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityDocument6 pagesAssessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityMD Najmul HossanNo ratings yet

- Noise Pollution in The Textile IndustryDocument9 pagesNoise Pollution in The Textile IndustryAmmar Maqsood0% (1)

- An Overview of Industrial Employees' Exposure To Noise in Sundry Processing and Manufacturing Industries in Ilorin Metropolis, NigeriaDocument12 pagesAn Overview of Industrial Employees' Exposure To Noise in Sundry Processing and Manufacturing Industries in Ilorin Metropolis, NigeriaPhilmona SamuelNo ratings yet

- 1 PBDocument7 pages1 PBAkif EmekliNo ratings yet

- Noise Control in Textile MachineriesDocument40 pagesNoise Control in Textile MachineriesJagannath SardarNo ratings yet

- Welding NoiseDocument6 pagesWelding NoiseYam SoussanaNo ratings yet

- Noise Risk AssessmentDocument11 pagesNoise Risk AssessmentSunil Babu KhatryNo ratings yet

- Comparative Study of The Noise Generated by Rotating Machines in Industrial Area of Arzew Algeria A Case Study in gp1z PDocument9 pagesComparative Study of The Noise Generated by Rotating Machines in Industrial Area of Arzew Algeria A Case Study in gp1z PIliace ArbaouiNo ratings yet

- D1203012531 With Cover Page v2Document8 pagesD1203012531 With Cover Page v2MarivauxNo ratings yet

- 5 Noise SourcesDocument23 pages5 Noise SourcesMitha TheresiaNo ratings yet

- Applied Sciences: Noise Sources and Control, and Exposure Groups in Chemical Manufacturing PlantsDocument26 pagesApplied Sciences: Noise Sources and Control, and Exposure Groups in Chemical Manufacturing PlantsomarNo ratings yet

- Amani 2014 TaJONAS 5 (1) 741-745Document5 pagesAmani 2014 TaJONAS 5 (1) 741-745MkomaNo ratings yet

- What Is The Allowable Noise LevelDocument2 pagesWhat Is The Allowable Noise LevelbrynobrdnNo ratings yet

- Assessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityDocument7 pagesAssessment of Noise Level and Its Impacts On Health in Different Industries Located in Khulna CityAtiqur RahmanNo ratings yet

- Assessment of Noise Pollution in Different Hatbazars of Butwal City, Rupandehi, NepalDocument4 pagesAssessment of Noise Pollution in Different Hatbazars of Butwal City, Rupandehi, NepalALINA LAMICHHANENo ratings yet

- Noise PollutionDocument7 pagesNoise PollutionkmgroupNo ratings yet

- Noise Dosimeter Lab8 HumanDocument5 pagesNoise Dosimeter Lab8 HumanAsif NawazNo ratings yet

- PreventionofhearinglossDocument12 pagesPreventionofhearinglossibrahimNo ratings yet

- INDUSTRIAL ENGG - LAB (Exp-4) 6053RDocument6 pagesINDUSTRIAL ENGG - LAB (Exp-4) 6053Rpatel1029poojaNo ratings yet

- Noise: Unwanted SoundDocument84 pagesNoise: Unwanted SoundMatthew PerryNo ratings yet

- Noise Pollution-Sources Effects and ControlDocument8 pagesNoise Pollution-Sources Effects and ControlLavish LokhandeNo ratings yet

- Design and Development of Noise Suppression System For Domestic GeneratorsDocument8 pagesDesign and Development of Noise Suppression System For Domestic GeneratorsMackinder Lijarza torresNo ratings yet

- Applying Kurtosis As An Indirect Metric of Noise Temporal Structure in The Assessment of Hearing Loss Associated With Occupational Complex Noise Exposure PDFDocument15 pagesApplying Kurtosis As An Indirect Metric of Noise Temporal Structure in The Assessment of Hearing Loss Associated With Occupational Complex Noise Exposure PDFKaty Marlen GongoraNo ratings yet

- Lab 3 SS21303Document8 pagesLab 3 SS21303Frisha FaqihahNo ratings yet

- Reviewed of Noise Control in Ic EngineDocument3 pagesReviewed of Noise Control in Ic Engineijsret100% (1)

- Evaluation of A Wearable Consumer Noise Measurement Device in A Laboratory SettingDocument6 pagesEvaluation of A Wearable Consumer Noise Measurement Device in A Laboratory SettingbenrobrbfNo ratings yet

- SLM Apad LatestDocument16 pagesSLM Apad Latestnurfadhilah_rosliNo ratings yet

- Noise PollutionDocument8 pagesNoise PollutionGourav Kumar38No ratings yet

- Industrial Noise Monitoring Using Noise Mapping Technique: A Case Study On A Concrete Block Making FactoryDocument12 pagesIndustrial Noise Monitoring Using Noise Mapping Technique: A Case Study On A Concrete Block Making FactorynisaNo ratings yet

- Noise Mapping in FactoryDocument5 pagesNoise Mapping in FactoryNor RazmanNo ratings yet

- Occupational Noise-Induced Hearing Loss in Auto Part Factory Workers in Welding Units in ThailandDocument8 pagesOccupational Noise-Induced Hearing Loss in Auto Part Factory Workers in Welding Units in ThailandPratiwi UmbohNo ratings yet

- Noise Hazards Associated With The Call Centre IndustryDocument9 pagesNoise Hazards Associated With The Call Centre IndustryBagas Zaki MNo ratings yet

- Environmental Noise MeasurementDocument26 pagesEnvironmental Noise MeasurementPalazzo345100% (1)

- Acoustics: Psychoacoustic Analysis of Vacuum Cleaner NoiseDocument14 pagesAcoustics: Psychoacoustic Analysis of Vacuum Cleaner NoiseJoão Paulo CabralNo ratings yet

- Use of Technical Textiles With Special Reference TO Acoustical ApplicationsDocument23 pagesUse of Technical Textiles With Special Reference TO Acoustical ApplicationsSakthivel JegarajanNo ratings yet

- Noise Pollution and Its Control in Textile Industry: A of Searc 26Document6 pagesNoise Pollution and Its Control in Textile Industry: A of Searc 26Nakib Ibna BasharNo ratings yet

- ES 7, Noise PollutionDocument11 pagesES 7, Noise PollutionSajib IglesiasNo ratings yet

- ST Data12 NoisemonitorDocument1 pageST Data12 NoisemonitorUmar SabaNo ratings yet

- An Assessment of Occupational Noise Exposures in Four Construction TradesDocument11 pagesAn Assessment of Occupational Noise Exposures in Four Construction TradespaulNo ratings yet

- CIV4204 Chapter 8 Noise Pollution ControlDocument5 pagesCIV4204 Chapter 8 Noise Pollution Controlmulabbi brianNo ratings yet

- ContentServer PDFDocument14 pagesContentServer PDFLUIS ISAAC LEON PARONo ratings yet

- 8B Noise and Vibration Impact Assessment Criteria and Methodology 8B.1 IntroductionDocument8 pages8B Noise and Vibration Impact Assessment Criteria and Methodology 8B.1 IntroductionManuel BrunalNo ratings yet

- RP Noise 4Document9 pagesRP Noise 4daaNo ratings yet

- Assessment of Perception and Knowledge oDocument12 pagesAssessment of Perception and Knowledge oCannell MeukamNo ratings yet

- Noise Pollution Norms - 1Document25 pagesNoise Pollution Norms - 1ZIPDASHNo ratings yet

- Caso PracticoDocument8 pagesCaso Practicoseguridadysaludeneltrabajo.ogperNo ratings yet

- Noise Investigation in ManufacturingDocument6 pagesNoise Investigation in ManufacturingMarioNo ratings yet

- Textbook Noise in The Plastics Processing Industry Second Edition Peters Ebook All Chapter PDFDocument53 pagesTextbook Noise in The Plastics Processing Industry Second Edition Peters Ebook All Chapter PDFfrancisco.moses588100% (11)

- Cleaner ProductionDocument29 pagesCleaner ProductionhananNo ratings yet

- Industrial Noise Control - The Singapore ExperienceDocument19 pagesIndustrial Noise Control - The Singapore ExperienceMuhammad YazdanNo ratings yet

- Pemetaan Dan Perhitungan Pemaparan Tingkat Kebisingan Pada Industri Pengolahan Kayu Di Kecamatan Siak, Provinsi RiauDocument10 pagesPemetaan Dan Perhitungan Pemaparan Tingkat Kebisingan Pada Industri Pengolahan Kayu Di Kecamatan Siak, Provinsi RiauERIFINNo ratings yet

- Noise: Guide For Risk Assessment in Small and Medium EnterprisesDocument10 pagesNoise: Guide For Risk Assessment in Small and Medium EnterprisesXozanNo ratings yet

- Noise PollutionDocument16 pagesNoise PollutionNaimur Rahim ChowdhuryNo ratings yet

- Industrial Noise and Its Effects On Humans: E. Atmaca I. Peker, A. AltinDocument6 pagesIndustrial Noise and Its Effects On Humans: E. Atmaca I. Peker, A. AltinMuhammad ArslanNo ratings yet

- Noise PollutionDocument6 pagesNoise Pollutionvikash rajNo ratings yet

- 61-Article Text-237-1-10-20230313Document6 pages61-Article Text-237-1-10-20230313VivekNo ratings yet

- Vibration-based Condition Monitoring: Industrial, Aerospace and Automotive ApplicationsFrom EverandVibration-based Condition Monitoring: Industrial, Aerospace and Automotive ApplicationsNo ratings yet

- Factories Act 1948Document12 pagesFactories Act 1948Ashwini BapuNo ratings yet

- Assignment 2Document3 pagesAssignment 2Pradeep Dahiya100% (1)

- HRM 300 (Human Resource Management) Complete CourseDocument18 pagesHRM 300 (Human Resource Management) Complete Coursecoursehomework100% (1)

- ContractorSafetyPolicy 0912Document9 pagesContractorSafetyPolicy 0912Reno Miranda EnticoNo ratings yet

- NarreporDocument3 pagesNarreporfrancessichNo ratings yet

- Taxi Drivers SafetyDocument46 pagesTaxi Drivers SafetyJenna FisherNo ratings yet

- Topic 4 Hazard Identification PDFDocument15 pagesTopic 4 Hazard Identification PDFDiyana OsmanNo ratings yet

- Msds HP 20w50Document7 pagesMsds HP 20w50Anonymous PvHmtbNo ratings yet

- Working at Height For Exon MobilDocument66 pagesWorking at Height For Exon Mobillinkenciel100% (2)

- CHPT 1Document20 pagesCHPT 1Mohd Fadhil Mohd NohNo ratings yet

- Data Matrix Company ProfileDocument5 pagesData Matrix Company ProfileMariusNepgenNo ratings yet

- The Following Were The Two DefinitiveDocument28 pagesThe Following Were The Two DefinitiveVAHIDNo ratings yet

- ST Lukes Medical Center Employees Ass Vs NLRCDocument7 pagesST Lukes Medical Center Employees Ass Vs NLRCJacquelyn AlegriaNo ratings yet

- Health & Safety Policy QEB Standards 13Document2 pagesHealth & Safety Policy QEB Standards 13QBE European Operations Risk ManagementNo ratings yet

- Gale Elementary Report and FOIA DocumentsDocument88 pagesGale Elementary Report and FOIA DocumentsChi_Light_BrigadeNo ratings yet

- Martin George Cooke 7th January 2011Document2 pagesMartin George Cooke 7th January 2011Martin Cooke Cert EdNo ratings yet

- Plan de Seguridad e Higiene (Inglés)Document73 pagesPlan de Seguridad e Higiene (Inglés)JuanCarlosVilchisDuránNo ratings yet

- Isu-Isu Semasa Pengurusan Keselamatan Dan KesihatanDocument8 pagesIsu-Isu Semasa Pengurusan Keselamatan Dan KesihatanAzlyn SyafikahNo ratings yet

- Order: Life in Lansing Required To Pay Back WagesDocument31 pagesOrder: Life in Lansing Required To Pay Back WagesLansingStateJournalNo ratings yet

- SVN LOG-P3Document356 pagesSVN LOG-P3Emman Patpert KnuckleheadsNo ratings yet

- Cat Sebu7656-02 SDocument18 pagesCat Sebu7656-02 S2012jNo ratings yet

- TopyDocument64 pagesTopyChristiano Calijorne de BarrosNo ratings yet

- Occupational HealthDocument48 pagesOccupational HealthSapiah Raman50% (4)

- ABC's of Fall Protection: Murray State University Susan MillerDocument24 pagesABC's of Fall Protection: Murray State University Susan MillerSam SalesNo ratings yet

- DOL FOIA Response Re: Bloomberg Leif Olson SmearDocument114 pagesDOL FOIA Response Re: Bloomberg Leif Olson SmearPhil KerpenNo ratings yet