Professional Documents

Culture Documents

Scararobot 2

Scararobot 2

Uploaded by

Thắng LêOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scararobot 2

Scararobot 2

Uploaded by

Thắng LêCopyright:

Available Formats

International Journal of Advanced Computing, ISSN:2051-0845, Vol.46, Issue.

3 1317

actuators-dc servomotors for each joint. Actuator é1 0 0 0 ù

characteristics; dc servo motors were studied in detail. It ê0 1 0 0 úú

T3 = A3 = ê

develops through Virtual Reality Modeling Language 2

(3)

(VRML) a 4-axis SCARA system for handling. The ê0 0 1 - d3 ú

structure to be built depends on the principles of solid-body ê ú

modeling with VR technology. Simulation on ë0 0 0 1 û

MATLAB/Simulink software will reinforce the results

obtained by SD program. The results of both will be

éc4 - s4 0 0 ù

presented and discussed. The paper is organized as follows:

Section 2 introduces robotics and robot kinematics, Section

ês c4 0 0 úú

3 presents the robot‟s inverse kinematics, Section 4, the T4 = A4 = ê 4

3

(4)

dynamics, Sections 5 and 6, the robot‟s actuators and

ê0 0 1 - d4 ú

ê ú

transmission elements, Section 7 a review of ANFIS, ë0 0 0 1 û

Section 8 the VRML design of the model, Section 9 the

ANFIS controller, and Section 10 the simulation, results, After the multiplication and use of addition matrices, one

and conclusions. gets the total transformation matrix:

2. ROBOT KINEMATICS éc124 - s124 0 L2 c1 + L1c1 ù

Table 1 defines the Denavit-Hartenberg (D-H) parameters ês c124 0 L2 s12 + L1s1 úú

specifying the SCARA robot. T4 = ê 124

0

(5)

ê 0 0 1 - d3 - d 4 ú

Table.1 D-H parameters of the robot ê ú

ë 0 0 0 1 û

i i di ai i

3. INVERSE KINEMATICS OF THE ROBOT

1 1 0 L1 0

3.1. Inverse Solution for Position:

2 2 0 L2 0

Desired location of the SCARA robot

3 0 d3 0 0 énx ox ax px ù

ên oy ay p y úú

TH = ê y

4 4 d4 0 0 R

(6)

ê nz oz az pz ú

ê ú

By using (D-H) convention [11], the transformation ë0 0 0 1û

matrices result in:

The final equation representing the robot is [12-16]:

éc1 - s1 0 L1c1 ù

ês c1 0 L úú THR = A1 A2 A3 A4 = T40 (7)

T1 = A1 = ê 1

0

(1)

ê0 0 1 0 ú To solve for the angle 4, both sides of equation (7) are

ê ú successively pre-multiplied with A3-1 A2-1 A1-1 matrices,

ë0 0 0 1 û

such that:

éc2 - s2 0 L2 c2 ù

ês A3-1 A2-1 A1-1THR = A4

0 L2 s2 úú

(8)

c2

T2 = A2 = ê 2

1

(2)

ê0 0 1 0 ú The left side of the equation (8) ( A3-1 A2-1 A1-1THR ) is:

ê ú

ë0 0 0 1 û

(9)

(9)

© RECENT SCIENCE PUBLICATIONS ARCHIVES| June 2013|$25.00 | 27702482 |

*This article is authorized for use only by Recent Science Journal Authors, Subscribers and Partnering Institutions*

International Journal of Advanced Computing, ISSN:2051-0845, Vol.46, Issue.3 1318

é1 0 0 0 ù é c2 s 2 0 - L2 ù é c1 - s1 0 - L1 ù én x o x ax px ù ü Dc1 (L1 + L2 c2 ) px - L2 s2 p y (L1 + L2 c2 ) px - L2 s2 p y

c1 = = = (21)

ê0 1 0 0 úú êê- s 2 c2 0 0 úú êê- s1 c1 0 0 úú êên y o y a y p y úú ï

ï D (L1 + L2 c2 )2 + (L2 s2 )2 px2 + p y2

ê ´ ´ ´ =

ê0 0 1 - d 3 ú ê 0 0 1 0 ú ê 0 0 1 - d1 ú ê n z o z a z pz ú ï

ê

ë0 0

ú ê

0 1 û ë 0 0 0 1 û ë 0 0 0 1 û ë0 0

ú ê ú ê

0 1û ï

ú ï s1 (L1 + L2 c2 ) p y - L2 s2 px

q1 = tan -1 = tan -1 (22)

é nx c12 + n y s12 o x c12 + o y s12 a x c12 + a y s12 p x c12 + p y s12 - L1c2 - L2 ù

ý

ï c1 (L1 + L2 c2 ) px - L2 s2 p y

ê- n s + n c o s + o c - a s + a c - p x s12 + p y c12 - L1 s2 úú ï

ê x 12 y 12 x 12 y 12 x 12 y 12

ï From 4,4 elements of the equation (5) and (6):

ê nz oz az pz + d3 ú ï

ê ú ï

ë 0 0 0 1 û þ d 3 = - pz - d 4 (23)

(9)

We have

From 1,4 and 2,4 elements of the equations (5) and (6):

px = L1c1 + L2c12 (10)

q3 = 0 (24)

From 1,1 and 2,1 elements of the equation (4) and (9):

p y = L1s1 + L2 s12

(11)

c4 = n x c12 + n y s12 (25)

From equation 10 and equation 11,

s4 = -n x s12 + n y c12 (26)

c2 =

1

(

p x2 + p y2 - L12 - L22 ) (12)

2L1 L2 - n x sin (q1 + q 2 ) + n y cos(q1 + q 2 )

q 4 = tan -1 (27)

nx cos(q1 + q 2 ) + n y sin (q1 + q 2 )

s 2 = ± 1 - c 22 (13)

s2

q 2 = tan -1 (14)

3.2. Inverse Solution for Velocity

c2

From equation (11) and equation (12)

Rearranging equation (10) and equation (11) yields:

px = (L1 + L2 c2 )c1 - L2 s2 s1 (15)

p& x = - L1 s1q&1 - L2 s12 q&1 + q&2( ) (28)

p y = L2 s 2 c1 + (L1 + L2 c2 )s1 (16) p& y = + L1c1q&1 - L2 c12 q&1 + q&2 ( ) (29)

Solving equations (15) and (16) by kramer‟s rule: So,

éL + L c - L2 s2 ù p& x = -(L1 s1 + L2 )q&1 - L2 s12q&2 (30)

D=ê 1 2 2 = (L1 + L2 c2 ) + (L2 c2 )

2 2

ú

L1 + L2 c2 û

(17)

ë L2 s2 p& y = -(L1 s1 + L2 c12 )q&1 + L2 c12q&2 (31)

é L1 + L2 c2 - p x ù

Ds1 = ê = (L1 + L2 c2 ) p y - (L2 s2 ) p x Using Kramer‟s rule to solve equation (31) and equation

- p y úû

(18)

(32)

ë L2 s2

p& x c12 + p& y s12

é p x - L2 s2 ù q&1 =

ú = (L1 + L2 c2 ) p x + (L2 s2 ) p y

(32)

Dc1 = ê (19) L1 s 2

ë p y L1 + L2 c2 û

- p& y (L1 s1 + L2 s12 ) - - p& x (L1c1 + L2 c12 )

Ds (L1 + L2 c2 ) p y - L2 s2 p x (L1 + L2 c2 ) p y - L2 s2 p x q&2 = (33)

s1 = 1 = = (20)

L1 L2 s2

D (L1 + L2 c2 )2 + (L2 s2 )2 p x2 + p 2y

© RECENT SCIENCE PUBLICATIONS ARCHIVES| June 2013|$25.00 | 27702482 |

*This article is authorized for use only by Recent Science Journal Authors, Subscribers and Partnering Institutions*

International Journal of Advanced Computing, ISSN:2051-0845, Vol.46, Issue.3 1319

Translational velocity: ( ) ( )

b12 = r22 + L1r2 c2 m2 + j 2 + g r 2 j m2 + L12 + L1 L2 c2 (m3 + mm3 ) + j3 + jm2

d&3 = - p& z (34)

b13 = g r 3 jm3 ; b14 = 2L1s2 [m2 r2 + (m3 + mm3 )L2 ]

By differentiating the equation (27): b15 = L1s2 [m2 r2 + (m3 + mm3 )L2 ] ;

c4 dq 4 = -[dnx s12 (dq1 + dq 2 )] + d ny c12 - n y s12 (dq1 + dq 2 ) (35) b15 = L1s2 [m2 r2 + (m3 + mm3 )L2 ]

So, b21 = m2 (r22 + L1r2 c2 ) + j2 + g r 2 j m2 + (L12 + L1 L2 c2 )(m3 + mm3 ) + j3 + j m3

b22 = r22 m2 + j 2 + g r22 j m 2 + L22 (m3 + mm3 ) + j3 + jm3

dq1 + dq 2

dq 4 = -

c4

(nx c12 + n y s12 ) - 12 dnx + 12 dny

s

c4

c

c4

(36) b23 = g r 3 jm3 ;

b24 = L1s2 [m2 r2 (m3 + mm3 )L2 ] b31 = b32 = g r 3 jm3 ;

And finally:

b33 = m3 + g r 3 jm3 b34 = m3 g

dq c12 n& - s12 n& x - (nx c12 + n y s12 )q&12

;

q&4 = = (37) 5. ACTUATOR EQUATIONS (ACTUATOR

dt c4

MODELING)

3.3 Inverse Solution for Acceleration Actuator is the device moving a robot. The device types

( & & ) & (&& && ) & &

include pistons (pneumatic, hydraulic) and motors (DC,

&q& = - p x s12 + p y c12 q12 + p x c12 + p y s12 - L1c2q1q 2 (38)

stepper). Most robots use DC motors, so a detailed model

for this actuator type will be derived for use throughout this

1

L1 s1 research. To control the voltage supply, the motor drive will

use PWM control, which use microcontrollers for these

q&&2 =

[

( &p&x s1 - &p&x c1 )L1 + ( &p&x s12 - &p&xc12 )L2 + (p& y c1 - p& x s1 )L1q&1 + (p& y c12 + p& x s12 )L2q&12 + L1L2q&22 ] advantages [18-20]:

L1L2 s2

(39) 1) their size and lightness

2) the fewer inputs and outputs, and

d&&3 = - &p& x (40) 3) remote operation using

n&&y c12 - n&&x s12 -(2n& y s12 + 2n& x c12 )q&&12 - (n y c12 - nx s12 )q&122 - (nx c12 + n y s12 )q&&12 + s4q&42

4) changeable with minimum loss of the armature voltage

q&&4 =

c4 Equations governing permanent-magnet operation with

(41) separate-wound or shunt-wound DC motors (see Figure 4)

when the flux is constant are [12]:

4. Dynamics of the Robot dia

Va = Ria + ea + L (45)

For SCARA robot figure 3, torques exerted on the robot dt

joints are [17]:

ea = kefwm = kwwm (46)

T1 = b11q&&1 - b12q&&1 - b13 d 3 - b14q&1q&2 + b15q&22 (42)

T = kefia = kT iw (47)

T2 = b21q&&1 + b22q&&2 + b23d&&3 + b24q&22 (43)

dwm

T = TL + jm + bw m (48)

T3 = -b31q&&1 + b32q&&2 + b33d&&3 - b34 (44) dt

6. TRANSMISSION EQUATIONS

Where:

(

b11 = r12 m1 + j1 + g r21 jm1 + L12 + r22 + 2L1r2 c2 m2 + L12 mm2 + j2 + j m2 + ) The many types of transmission elements in a robot convey

mechanical power from the actuator to the load. Gear is the

(L 2

1 + L22 + 2L1 L2 c2 )(m 3 + mm 3 ) + j 3 + j m 3 most common transmission element. A common robotic

© RECENT SCIENCE PUBLICATIONS ARCHIVES| June 2013|$25.00 | 27702482 |

*This article is authorized for use only by Recent Science Journal Authors, Subscribers and Partnering Institutions*

International Journal of Advanced Computing, ISSN:2051-0845, Vol.46, Issue.3 1320

revolute-joint transmission element is harmonic drive [13] - networks‟ [23]. ANFIS design starts with a pre-structured

compact in-line parallel shafts with very high transmission system; DOF for learning is thus limited, i.e., the MF of the

ratio. The torque transmitted to the motor shaft (T) can be input variables and the output variables contain more

calculated from Figure 5 as: information that NN has to drive from sampled data sets.

Knowledge on the systems being designed can be used

wm q straightaway. Part of the system can be excluded from

T = TL / g rh Þ T h = T m h = TL (49) training. ANFIS is thus more effective. The rules are

wL qL linguistic, easing analysis and interpretation of intermediate

results. Rules can be modified during training and

Also, the transmitted inertia is optimization can be manual. ANFIS also supports TS-based

systems. To start ANFIS learning, a training data set

J = j m + J L / g r2 (50) containing the desired input/output data pairs of the target

systems to be modelled it. The design parameters to any

For the third joint, the translational variable (linear velocity) ANFIS controller are viz., number of data pairs, training

can be derived as: data set, checking data sets, fuzzy inference systems for

training, number of epochs to be chosen to start the training,

D & learning results to be verified after mentioning the step size

wm = = d3 (51) [24-28].

2

In this work, the following is the general ANFIS control

7. ADAPTIVE NEURO FUZZY INFERENCE structure for the control of any plant. The structure contains

SCHEME (ANFIS) the same components as does FIS, except for the NN block.

The network structure is a set of units (and connections)

This section reviews the ANFIS concepts used in arranged into five connected network layers, viz., l1 to l5.

controlling a plant‟s system parameters. Neural network

Layer 1: This layer consists of input variables (MFs), viz.,

(NN) concepts began as an attempt at transliterating human

inputs 1 and 2. Triangular or bell-shaped MF can be used

thought. NNs have had successful application in speech

here. This layer just supplies the input values i x to the next

recognition, image analysis, and adaptive control,

layer, where I = 1 to n.

constructing software agents or autonomous robots and

controlling machines. ANNs are a family of intelligent Layer 2: This layer (the membership layer) checks the

algorithms that can be used for time-series prediction, weight of each MF. It receives the input values i x from the

classification, and control and identification. NNs have the 1st layer and acts as MF to represent the fuzzy sets of the

ability to train with induction motor‟s various parameters. input variables. It also computes the membership values

As a non-linear function, they can identify extremely specifying the degree to which the input value i x belongs to

nonlinear system parameters with high accuracy. Use of the fuzzy set, inputting the next layer.

NNs to identify and control nonlinear dynamic systems has

been proposed because they can approximate a wide range Layer 3: Called the rule layer, each node (neuron) in it pre-

of non-linear functions to any desired accuracy. They also condition matches the fuzzy rules, i.e., computing the

have extremely fast parallel computation and high fault activation level of each rule, the number of layers equalling

tolerance characteristics. NNs in power electronics and AC the number of fuzzy rules. Each node calculates the

drives have been investigated, including in speed estimation. normalized weights.

NN technique estimates speed fairly well and is robust to Layer 4: Called the defuzzification layer, it provides the

parameter variation. For better performance, an NN speed output values y resulting from rule inference. Connections

estimator should be trained sufficiently with various between layers l3 and l4 are weighted by the fuzzy

patterns. Fuzzy logic (FL) can control various parameters of singletons that represent another set of parameters for the

real-time systems. Its combination with NNs gives neuro fuzzy network.

significant results. NNs can learn from data but

understanding that knowledge is difficult, especially in Layer 5: Called the output layer, it sums up all the inputs

giving meaning to each neuron and each weight [21-23]. from layer 4 and transforms fuzzy-classified results into

crisps (binary).

Fuzzy-rule models are easier to understand because they use

linguistic terms and the IF-THEN rule structure, but FL The ANFIS structure is tuned automatically by least-square

cannot learn on its own. Its learning and identification adopt estimation and back propagation algorithm. The algorithm

techniques from fields such as statistics and system shown above is used in the next section to develop the

identification. NNs can learn; merging it with FL is only ANFIS controller to control the various parameters of the

natural. Merging NN‟s learning with FL‟s knowledge induction motor. ANFIS‟s flexibility enables its use in many

representation is a hybrid technique called „neuro fuzzy control applications.

© RECENT SCIENCE PUBLICATIONS ARCHIVES| June 2013|$25.00 | 27702482 |

*This article is authorized for use only by Recent Science Journal Authors, Subscribers and Partnering Institutions*

International Journal of Advanced Computing, ISSN:2051-0845, Vol.46, Issue.3 1321

8. THE MODEL in VIRTUAL REALITY small), may be represented by fuzzy sets. Fuzzy set is an

extension of a „crisp‟ set where an element belongs to either

The requirements for design in VRML are explained in a set (full membership) or to none (no membership). Fuzzy

finite processing allocations, autonomy, consistent self- sets allow partial membership, i.e., membership to more

registration and calculability. Design in VRML depends on than one set.

the designer‟s information and his imagination of the object.

VR design choices are standard configurations (sphere,

cone, cylinder, etc.) and free-form (the indexed face set

button is selected, to get many configurations with points

that can be rearranged). Every real-form design is

considered free-form designing, which starts with building

parts one by one and checking the shape against a related,

real manipulator part. That robot part cannot be simulated in

VR when the standard shape from the VR library is used, Fig. 2: The ANFIS control scheme for speed control of

where they are not uniform shape. The design uses the the IM

indexed face set in VR. The next design step is connecting

all the parts to produce the object and to limit the object‟s A fuzzy set A of a universe of discourse X is represented by

point of origin. This job was made by setting the first shape a collection of ordered pairs of generic element and its

(e.g. the base) and then connecting the next shape (joint membership function : X [ 0 1], which associates a

two) in the “children” button; the same procedure is number A(x) : X [ 0 1] to each element x of X. An FLC

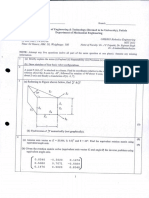

repeated with other parts. Fig. 1 is the design, in full VR, of uses a set of control rules called fuzzy rules,

a SCARA robot with vacuum handling wrist [29-31].

Table 2

The rule base for speed control

E\E NB NM NS ZE PS PM PB

NB NB NB NB NB NM NS ZE

NM NB NB NM NM NS ZE PS

NS NB NM NS NS ZE PS PM

ZE NB NM NS ZE PS PM PB

PS NM NS ZE PS PS PM PB

Fig. 1. A SCARA robot left arm, in VR view through

PM NS ZE PS PM PM PB PB

Matlab

9. ANFIS CONTROLLER DESIGN PB ZE PS PM PB PB PB PB

A controller is a device controlling each and every system

operation through the decisions it makes. A control system

brings stability during disturbances, safeguarding from

equipment damages. It may be hardware-based, software- expressed among the linguistic variables as conditional

based, or both. This section develops an ANFIS control statements. The basic structure of this work‟s ANFIS

scheme (see Fig. 2) for SCARA robot parameters such as controller comprises 4 blocks: fuzzification, knowledge

speed, accuracy, envelop and high performance. Fuzzy base, neural network, and de-fuzzification; each will be

logic is one of the successful applications of fuzzy set in explained briefly in the next paragraphs. The inputs to the

which the variables are linguistic rather than the numeric ANFIS controller, i.e., the error and the change in error, are

variables. Linguistic variables, defined as variables whose modelled through Eqn. (51) as

values are sentences in a natural language (such as large or

© RECENT SCIENCE PUBLICATIONS ARCHIVES| June 2013|$25.00 | 27702482 |

*This article is authorized for use only by Recent Science Journal Authors, Subscribers and Partnering Institutions*

International Journal of Advanced Computing, ISSN:2051-0845, Vol.46, Issue.3 1322

e(k ) = w ref - w r ü final output and is the weighted average of the proper rule-

based outputs selected by the back-propagation algorithm.

ý

De(k ) = e(k ) - e(k - 1)þ (51)

Where wref is the reference speed, wr the actual rotor speed,

e(k) the error, and e(k) the change in error. The

fuzzification unit converts the crisp data into linguistic

variables, given as inputs to the rule-based block. The set of

49 rules are based on past knowledge/experiences in the

rule-based block, which connects to the NN block. Back

propagation algorithm trains the NN to select the proper set

of rule base. In developing the control signal, the training is

very important for selection of the proper rule base. - -b-

Selection, and then firing of the proper rules, generates the

control signal needed for optimal outputs. The output of the

NN unit is given as input to the de-fuzzification unit and the

linguistic variables are re-converted into numeric data, as

crisps. In fuzzification, the crisp variables, the speed error,

and the change in error are converted into fuzzy variables or

linguistics variables. The fuzzification maps the 2 input

variables to linguistic labels of the fuzzy sets. The fuzzy

coordinated controller uses the linguistic labels. Each fuzzy -d-

--

label has an associated MF. Triangular MF was used here

(see Fig. 3-a,b). The inputs are fuzzified through the fuzzy

sets and given as input to the ANFIS controller. Table II

lists the rule base for selection of the proper rules through

back propagation algorithm.

æ R i i ö R

çç å m a1 x1 ÷÷ + L + å m i aqi xq

y = è i =1 ø i =1

(52)

R

åm

i =1

i

-e- -

The control decisions are based on the fuzzified variables in Fig. 3. Learning and analysis of the ANFIS controller

Table 2. The inference uses a set of rules in determining the

output decisions. As there are 2 input variables and 7 10.SIMULATION RESULTS & DISCUSSION

fuzzified variables, the controller has a set of 49 rules for Fig. 4 is the Matlab Simulink R2012a VR model for the

the ANFIS controller. From the 49 rules [Fig. 4-c,d], the neuro-fuzzy controller tracking the SCARA trajectory.

proper rules are selected by NN training helped by back- Starting off the simulations is the invoking of the 49-fuzzy-

propagation algorithm, before the selected rules are fired. rule set from the Matlab command window; the fuzzy file

Further, it has to be converted into numerical output, i.e., where the rules are written with T-S control strategy

they have to be de-fuzzified. This process is defuzzification, incorporated is opened, then the fuzzy editor (FIS) dialogue

which produces a quantifiable result in FL. box opens (see Fig. 3). The .fis file (yousif_FZ_Des) is

Defuzzification transforms fuzzy set information into imported through the command window from the source,

numeric data information. Methods of defuzzification and then opened (through file-open command) in the fuzzy

include centre of gravity, centre of singleton, maximum, editor dialog box. Figs. 4 a-f shows opening of the file

marginal properties of centroid, etc. This work used the activating the TS fuzzy-rule file. The data is exported to the

centre-of-gravity method. The output of the defuzzification workspace, and the simulations are run for e.g., 60s.

unit generates the control commands that are given as input

The fuzzy MF editor is next obtained from the menu bar,

(crisp input), through the inverter, to the plant. Any

through view membership command (see Figs. 3 a-b). The

deviation in the controlled output is feedback and compared

rule-view command enables viewing of the TS-fuzzy rules

with the set value and the error signal generated, and given

written. It is the pictorial rule viewer for the 2 inputs and 1

as input to the ANFIS controller, which restores the output

output. Post preliminary operations, the VR model is called

to the normal value, maintaining system stability. Eqn. (52)

up through the interface block between it and Matlab. Fig.

gives the controlled output signal y, which is the controller‟s

4e shows the ANFIS editor opening in the command

© RECENT SCIENCE PUBLICATIONS ARCHIVES| June 2013|$25.00 | 27702482 |

*This article is authorized for use only by Recent Science Journal Authors, Subscribers and Partnering Institutions*

You might also like

- Compiled QB Mech 8thDocument36 pagesCompiled QB Mech 8thGyanesh RaoNo ratings yet

- Kinematic Modeling and Verification For A SCARA Robot: Chenhuan Feng, Guanbin Gao, Yongli CaoDocument4 pagesKinematic Modeling and Verification For A SCARA Robot: Chenhuan Feng, Guanbin Gao, Yongli Caoसन्तोस दाहालNo ratings yet

- E186Document2 pagesE186asit kumarNo ratings yet

- Ume805 4Document2 pagesUme805 4Raunaq SinghNo ratings yet

- Final Report ENPM662 SiddheshRaneDocument21 pagesFinal Report ENPM662 SiddheshRaneChristian Ismaël Tcheutchoua Takam100% (1)

- Camera Ready - AM-16Document6 pagesCamera Ready - AM-16jaya sahaNo ratings yet

- Reference Trajectory Tracking For A multi-DOF Robot Arm: 10.1515/acsc-2015-0033Document15 pagesReference Trajectory Tracking For A multi-DOF Robot Arm: 10.1515/acsc-2015-0033Zafer GökNo ratings yet

- Comparative Study of Different Control Techniques Applied On 6 Dof Robot ArmDocument12 pagesComparative Study of Different Control Techniques Applied On 6 Dof Robot Armد. ثائر جبار نتيشNo ratings yet

- Kinematics Analysis of 5250 Lab-Volt 5-Dof Robot Arm: Dr. Wathik Isaa Mahdi Al-TameemiDocument9 pagesKinematics Analysis of 5250 Lab-Volt 5-Dof Robot Arm: Dr. Wathik Isaa Mahdi Al-TameemiEfren Alamillo MataNo ratings yet

- Department of Electronics and Telecommunication Engineering: R T R T TDocument3 pagesDepartment of Electronics and Telecommunication Engineering: R T R T TSurangaGNo ratings yet

- RoboticsDocument6 pagesRoboticsetitahNo ratings yet

- High Speed Trajectory Control of 2-Degree-Of-Freedom Robotic ArmDocument24 pagesHigh Speed Trajectory Control of 2-Degree-Of-Freedom Robotic ArmRameez HayatNo ratings yet

- Introduction To Robotics (CS223A) Homework #3 (Winter 2007/2008)Document2 pagesIntroduction To Robotics (CS223A) Homework #3 (Winter 2007/2008)Shukrullo NazirjonovNo ratings yet

- Dynamic Behavior of A SCARA RobotDocument16 pagesDynamic Behavior of A SCARA RobotMeryem MimiNo ratings yet

- EasyChair Preprint 1619Document14 pagesEasyChair Preprint 1619paulo baptistaNo ratings yet

- DHKJHDJKHDDDocument4 pagesDHKJHDJKHDDRavindra PawarkarNo ratings yet

- Workspace Analysis and Dynamics Simulation of Manipulator Based On MatlabDocument9 pagesWorkspace Analysis and Dynamics Simulation of Manipulator Based On Matlab肯尼No ratings yet

- Dynamic Analysis of Robot in MachiningDocument14 pagesDynamic Analysis of Robot in MachiningHưng Trần ĐứcNo ratings yet

- Intelligent Inverse Kinematic Control of PDFDocument12 pagesIntelligent Inverse Kinematic Control of PDFDavid ZambranoNo ratings yet

- Modelling and Simulation of 5 DOFDocument6 pagesModelling and Simulation of 5 DOFaditdharkarNo ratings yet

- Modeling and Control of 2-DOF Robot ArmDocument8 pagesModeling and Control of 2-DOF Robot ArmOtter OttersNo ratings yet

- Inverse Kinematics For A Humanoid Robot: A Mix Between Closed Form and Geometric SolutionsDocument32 pagesInverse Kinematics For A Humanoid Robot: A Mix Between Closed Form and Geometric SolutionsUrielNo ratings yet

- Fetching Trajectory Planning of Explosive Ordnance Disposal RobotDocument14 pagesFetching Trajectory Planning of Explosive Ordnance Disposal RobotLamiss HamdNo ratings yet

- ELEC3201 2021 For StudentsDocument16 pagesELEC3201 2021 For Studentsjiales225No ratings yet

- BMS College of Engineering, Bangalore-560019: June 2017 Semester End Make Up ExaminationsDocument3 pagesBMS College of Engineering, Bangalore-560019: June 2017 Semester End Make Up Examinationskoushik bhatNo ratings yet

- Experiment - 05: FIG1: 2 Prismatic Joint Manipulator FIG 2: 2 Prismatic Joint ManipulatorDocument8 pagesExperiment - 05: FIG1: 2 Prismatic Joint Manipulator FIG 2: 2 Prismatic Joint ManipulatorManthan SinghNo ratings yet

- Robotics LabDocument10 pagesRobotics LabAbdul Moiz QarniNo ratings yet

- 438 826 1 SMDocument6 pages438 826 1 SMimtiyazNo ratings yet

- Workspace Analysis of 7-DOF Humanoid Robotic Arm: Jinliang Luo, Qun Wen, Jialai He and Bin YeDocument4 pagesWorkspace Analysis of 7-DOF Humanoid Robotic Arm: Jinliang Luo, Qun Wen, Jialai He and Bin YeOnlyBy MyselfNo ratings yet

- EE101 - Quiz6 2Document4 pagesEE101 - Quiz6 2Just EntertainmentNo ratings yet

- The Kinematics Analysis of Robotic Arm ManipulatorDocument9 pagesThe Kinematics Analysis of Robotic Arm ManipulatorJorge Adrian Lucas SanchezNo ratings yet

- Ma5156 PDFDocument3 pagesMa5156 PDFJsvijay KumarNo ratings yet

- Modeling and Control of 2-DOF Robot Arm: November 2018Document9 pagesModeling and Control of 2-DOF Robot Arm: November 2018Lavinia CuldaNo ratings yet

- DH Program1Document6 pagesDH Program1strrrweNo ratings yet

- Introduction To Robotics (CS223A) Homework #3 Solution (Winter 2007/2008)Document5 pagesIntroduction To Robotics (CS223A) Homework #3 Solution (Winter 2007/2008)علي كامل الاسديNo ratings yet

- Robotics1 MidTerm 2020-21 20.11.20Document12 pagesRobotics1 MidTerm 2020-21 20.11.20SHUBHAM MALLNo ratings yet

- Assignment 3Document5 pagesAssignment 3Kalpit AgarwalNo ratings yet

- Development of Autonomous Bucket Wheel Reclaimer With LaserDocument5 pagesDevelopment of Autonomous Bucket Wheel Reclaimer With Laserleandro martinsNo ratings yet

- Robotics QP Dec.2023 BE ECSDocument2 pagesRobotics QP Dec.2023 BE ECSKaran PatelNo ratings yet

- Human Arm Imitation by A 7 DOF Serial MaDocument5 pagesHuman Arm Imitation by A 7 DOF Serial MaPrateek Kumar PandeyNo ratings yet

- Lecture 10 D.K.Analysis 2Document34 pagesLecture 10 D.K.Analysis 2Krishna KulkarniNo ratings yet

- Data Sheet 1Document10 pagesData Sheet 1Ano nymNo ratings yet

- Ume805 2Document2 pagesUme805 2Raunaq SinghNo ratings yet

- Me6 Iar May08Document3 pagesMe6 Iar May08kunalsapoliaNo ratings yet

- Robotics Lab123Document19 pagesRobotics Lab123belsty dersehNo ratings yet

- Faculty of Media Engineering and TechnologyDocument4 pagesFaculty of Media Engineering and TechnologyBharath Ane NenuNo ratings yet

- Elements of Computing Systems CH 6 AssemblerDocument9 pagesElements of Computing Systems CH 6 AssemblerSaad Imran δδNo ratings yet

- Robotics Report On ABB IRBDocument19 pagesRobotics Report On ABB IRBkingdom23420% (1)

- Robot Kinematics and Dynamics ModelingDocument23 pagesRobot Kinematics and Dynamics ModelingshitalchiddarwarNo ratings yet

- Dynamic Behavior of A SCARA Robot by Using N-E Met PDFDocument13 pagesDynamic Behavior of A SCARA Robot by Using N-E Met PDFMeryem MimiNo ratings yet

- Paper IEEE-Forward and Inverse Kinematics of IRB1200Document7 pagesPaper IEEE-Forward and Inverse Kinematics of IRB1200Phan Phúc TàiNo ratings yet

- Manipulator KinematicsDocument24 pagesManipulator KinematicsQueron Williams100% (2)

- Identification of Crack Location in A Rotor-Bearing System Using Wavelet TransformsDocument7 pagesIdentification of Crack Location in A Rotor-Bearing System Using Wavelet TransformsJoel Morales PerezNo ratings yet

- Dynamic Modeling of 3 Dof Robot Manipulator: Ahmet SHALA, Ramë LikajDocument4 pagesDynamic Modeling of 3 Dof Robot Manipulator: Ahmet SHALA, Ramë LikajmikeNo ratings yet

- Linearization of Radial Force Characteristic of Active Magnetic Bearings Using Finite Element Method and Differential EvolutionDocument15 pagesLinearization of Radial Force Characteristic of Active Magnetic Bearings Using Finite Element Method and Differential Evolutionharis shehzadNo ratings yet

- Unit 1Document68 pagesUnit 1N EDUNo ratings yet

- Direct Kinematic Modeling of 6R Robot Using Robotics ToolboxDocument4 pagesDirect Kinematic Modeling of 6R Robot Using Robotics ToolboxNedim BabicNo ratings yet

- Article - 2015 - FFT Bifurcation Analysis of Routes To Chaos ViaDocument10 pagesArticle - 2015 - FFT Bifurcation Analysis of Routes To Chaos ViamoslemNo ratings yet

- Robot Manipulators: Modeling, Performance Analysis and ControlFrom EverandRobot Manipulators: Modeling, Performance Analysis and ControlNo ratings yet

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99From EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99No ratings yet

- RGPV S.G.S.I.T.S Indore 2018 6.43 CGPA Govt. Shubash Higher Secondary Excellence School, Bhopal 2013 90.20 %Document2 pagesRGPV S.G.S.I.T.S Indore 2018 6.43 CGPA Govt. Shubash Higher Secondary Excellence School, Bhopal 2013 90.20 %Arun TadNo ratings yet

- Task 2 CodeDocument3 pagesTask 2 CodeCc CcNo ratings yet

- DBMS Aggignment ManualDocument12 pagesDBMS Aggignment ManualprogramNo ratings yet

- Vo IPDocument37 pagesVo IPD10 newsNo ratings yet

- ATG854 Item Document For Honeywell Endarf Series 854 Level GaugeDocument88 pagesATG854 Item Document For Honeywell Endarf Series 854 Level GaugeThái NgọcNo ratings yet

- Se Commercial Three Phase Inverters For Medium Voltage GridDocument2 pagesSe Commercial Three Phase Inverters For Medium Voltage GridDaniel CastroNo ratings yet

- Installing NFS Server To Work On A SSH TunnelDocument3 pagesInstalling NFS Server To Work On A SSH TunnelSmh AbidiNo ratings yet

- Bde ImpDocument20 pagesBde Impyash rayateNo ratings yet

- LS 1Document10 pagesLS 1Ms. Divya KonikkaraNo ratings yet

- CWS3050 Hardware Installation Guide TCHPB3.1.4-0014-01Document44 pagesCWS3050 Hardware Installation Guide TCHPB3.1.4-0014-01Corp Inetel SacNo ratings yet

- Research Papers On Satellite Communication PDFDocument7 pagesResearch Papers On Satellite Communication PDFfvey0xan100% (1)

- ReactJS - Store Management ProjectDocument4 pagesReactJS - Store Management ProjectGs Pavan KumarNo ratings yet

- Katalog Saklar Schneider LEONADocument16 pagesKatalog Saklar Schneider LEONAYusup Supri YadieNo ratings yet

- Answer: MN 2Document8 pagesAnswer: MN 2Alok TripathiNo ratings yet

- CV Outline (Khalid Nasser Ahmad Bin Ghaith Almarri (h00210985) )Document2 pagesCV Outline (Khalid Nasser Ahmad Bin Ghaith Almarri (h00210985) )api-284854751No ratings yet

- PAM FeaturesDocument9 pagesPAM Featuresquyetpv144No ratings yet

- Nitin - Pant Magento - Lead Resume Sep 2022Document2 pagesNitin - Pant Magento - Lead Resume Sep 2022Manisha AswarNo ratings yet

- InstructionsDocument1 pageInstructionsAdelia Safitri0% (1)

- Cognex Deep Learning Release NotesDocument64 pagesCognex Deep Learning Release NotesBasil SoulouknaNo ratings yet

- Government Supporting Documents GuideDocument7 pagesGovernment Supporting Documents Guidemaricar buisanNo ratings yet

- Statistics II 2078 QuestionpaperDocument2 pagesStatistics II 2078 Questionpaperlimit lessNo ratings yet

- Donna Jno. Baptiste-Athanaze Assignment 3Document19 pagesDonna Jno. Baptiste-Athanaze Assignment 3Donna AthanazeNo ratings yet

- A Systematic Review For Enabling of Develop A Blockchain Technology in Healthcare Application TaxonomyDocument35 pagesA Systematic Review For Enabling of Develop A Blockchain Technology in Healthcare Application TaxonomyAshraf AbdouNo ratings yet

- Informix Ids DBXT BookmapDocument305 pagesInformix Ids DBXT Bookmapkalyan pavan kumar kamineniNo ratings yet

- 5) Public Relations Budget TemplateDocument11 pages5) Public Relations Budget TemplateBhaktivedanta HospitalNo ratings yet

- Update Firmware of BMW ICOM A2 Diagnostic ToolDocument4 pagesUpdate Firmware of BMW ICOM A2 Diagnostic ToolPhan LamNo ratings yet

- Log 1 1 201960010Document2 pagesLog 1 1 201960010yisselNo ratings yet

- Array QuestionsDocument1 pageArray QuestionsGiestNo ratings yet

- ARINC Data Encoding Assignment With SolutionDocument4 pagesARINC Data Encoding Assignment With SolutionBlessing ZanaNo ratings yet

- Drone Movement Detection Network Using Raspberry PiDocument7 pagesDrone Movement Detection Network Using Raspberry PiInternational Journal of Innovative Science and Research TechnologyNo ratings yet