Professional Documents

Culture Documents

A Perspective Look at Fracture Porosity

A Perspective Look at Fracture Porosity

Uploaded by

oa984760Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Perspective Look at Fracture Porosity

A Perspective Look at Fracture Porosity

Uploaded by

oa984760Copyright:

Available Formats

A Perspective Look at Fracture Porosity

W.M. Hen.e. Jr., * SPE, Sun E&P co.

Summary. Because overly optimistic estimates of hydrocarbons associated with reservoir fractures may lead to economic disasters,

it is important that fracture porosity values, assigned by whatever means, be examined critically. Some basic fracture models together

with documented examples of fracture width and frequency tend to suggest an upper limit for fracture porosity.

Introduction Fracture Porosity Calculation Methods

Fractures can be an important feature of hydrocarbon reservoirs Aguilera6 documents a means of estimating fracture porosity from

because their presence (either naturally occurring or induced) in- well logs in a dual-porosity system where a partitioning coefficient,

creases the productive capacity. Many low-matrix-permeability V, is calculated. This V factor is applied to the matrix porosity and

reservoirs would not be commercially attractive without a natural results in an estimation of the fracture porosity. Aguilera provides

or induced fracture system. While fractures are unquestionably im- a chart for estimating V, with the basic assumption that the matrix

portant with respect to formation permeability, the importance of and fractures are connected in parallel.

the contribution that fractures make to the reservoir storage capac- Weber and Bakker7 state that the classic method for estimating

ityor, more specifically, the porosity is unclear. The assigmnents fracture porosity is to examine cores, count the number of natural

of porosity in a dual-porosity system (e.g., matrix and fractures) fractures, and measure their width. The qualifications placed on

may be critical in estimating both in-place reserves and ultimate this method include having a knowledge of fracture systems, bed

production of hydrocarbons. An assigmnent of too much porosity thickness, and lithology.

to the fracture system could lead to grossly optimistic production Bergosh and Lord 8 report on two new techniques: computerized

and economic predictions.' tomographic (CT) scanning and fluorescent epoxy impregnation.

Porosity is expressed in terms of void (pore) space per unit bulk Both techniques are enhanced by use of full-diameter cores, and

volume. The terms grain volume, PV, and bulk volume also are the tests are conducted at overburden stress conditions. Bergosh

involved. To calculate porosity, two of the three must be meas- and Lord state that these techniques have advantages over other

ured or known. In a fracture system, the pore space is a function core-analysis methods, such as Boyle's-law helium porosimetry,

of the block size, which relates to the frequency of the fractures, thin-section microscopy, and brine displacement.

and the fracture width. A simplified example of a fracture porosity Well testing and material balance are additional tools that are used

calculation is shown in Fig. 1. The arbitrary assignment of a frac- to estimate fracture porosity. Material balance appears to suffer in

ture width of 254 I-'m results in a porosit} of 1 %. (The permeabil- accuracy if matrix porosity exists, and buildup curves likewise have

ity of this fracture is about 54 darcies. ) limitations, such as insufficient time to obtain truly representative

Jones 3 states that fracture volume and, therefore, fracture porosi- curves. 7

ty are directly proportiOlial to fracture clearance, and that the ef-

fective porosity is proportional to the cube root of permeability. Fracture.Wldth/Block.Helght Considerations

Fracture porosity is a function of block size and fracture widths.

Fracture Models Fractures with large widths occurring at infrequent intervals (i.e.,

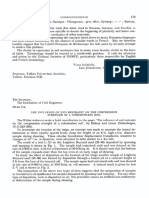

Reiss 4 proposes four types of fracture networks for calculating large block sizes) will yield very low porosities. Extensively frac-

fracture porosity (Fig. 2). The rectangular elements (blocks) have tured rock (i.e., small block sizes) with very small fracture widths

sides a, , az, and a3, and the fracture widths are denoted by b (Fig. likewise will yield low porosity values. In other words, to have

3). For the four schemes the fracture porosity is calculated as significant fracture porosity (e.g., 4 to 6%), the formation must

follows. be fractured with a high degree of frequency and the fracture widths

must be of a significant size.

(Type A) Sheets: Table 1 shows the results of a literature survey of docu-

<bJ=b/a. . ........................................ (1) mented',7,9,10 fracture widths and block heights. With one or two

exceptions, the fracture widths fall into the 100- to 200-l-'m range.

(Type B) Matchsticks: Very little is documented regarding fracture frequency or block size.

The one confidential study that reports on extensive fracture den-

<bJ=2b/a. . ....................................... (2)

sity (336 fractures for one foot of core examined) couples this with

(Type C) Cubes with two effective fracture planes: assigned fracture widths of only to I-'m. This is a classic example

of the small-block-size, small-fracture-width scenario that, in this

<bJ=2b/a. . ....................................... (3) case, results in a calculated fracture porosity of 1. 1 %.

Fracture-width studies of cores can be misleading from several

(Type D) Cubes:

standpoints. Fractures may be observed and reported, but commen-

<br3b/a . ........................................ (4) tary may be missing about whether the fractures are open or closed.

Fractures that are open in cores may be closed in situ from

Here, a=matrix size, in. [cm], b=fracture width, I-'m [mm], and mineralization 7 or by tar or kerogen materials. Overburden stress-

<bJ=fracture porosity, %. es are seldom taken into account, and the width of a fracture at

Warren and RootS used an idealized model in their study of the reservoir conditions will be a function of the net confining pres-

behavior of primary and secondary porosity. They assumed that sure; i.e., the effective compressive stresses are the difference be-

all the secondary porosity was contained within an orthogonal sys- tween the total compressive stresses and the pore pressures."

tem of continuous, uniform fractures that are oriented so that each Matrix core porosities normally are adjusted according to reser-

fracture is parallel to one of the principal axes of permeability. This voir stress conditions, and the same approach should be taken to

is the same as the Type D4 fracture model that yields the maxi- evaluate fracture widths.

mum fracture porosity; however, the mathematics suggested by Fracture widths of 200 pm seem reasonable; however, 6,OOO-l-'m

Warren and Root holds true for any type of fracture system. extension fractures existing at overburden-stress conditions appear

unlikely or may have been created during the coring/core-retrieval

processes. The data shown in Table 1 appear to make Aguilera'S'

'Now retired.

"paper-thin," minimum-fracture-width statement somewhat out of

order when one considers that common copy-machine paper is about

Copyright 1989 Society of Petroleum Engineers 400 I-'m thick.

SPE Fonnation Evaluation, December 1989 531

/i-----------------"lI

· ~I-"- - 1 " -----+l~1 / I I

T

/ I I

/ I

/ I

r::'" I

/

/

/

I

I

I

I // a2 I

//1

//

/;=======-=- 1"

/

/

f---- ---...Ll-------

1

-.01'~ // I

T:Z=::::;:=======7 I I

I II

/--------

I

}-.l.------ --I

/

/

/ J---- I

/

I

/ I/ a3 I

I

Fig. 1-Baslc fracture porosity model: .p, =1%. II / I

1 / 1

I

I I I I

b / / I I

-2'

, I ',1

,I

L,_____________________ J ~

Fig. 3-Deflnition of fracture porosity (after Reiss 4 ).

a b Fracture Porosity Discussion

My observations indicate that fracture porosity may be overesti-

mated, particularly in dual-porosity systems. Fractures have such

a dramatic impact on reservoir performance that their hydrocar-

bon storage capacities may tend to be inflated.

Pittman 12 subdivides porosities into f<;>ur groups - intergranu-

lar, dissolution, microporosity, and fractures. He states that frac-

ture porosity is rarely greater than a few percent and is usually

<1%. ,

Table 2 shows the results of a literature survey of docu-

mented 7,8,10,12,13 fracture porosity values. Note that the values

generally support Pittman's conclusion. Bergosh and Lord's8

reported fracture porosity of 9.64 % was determined on one sam-

ple. Bergosh* stated that all porosity measurements were made on

full-diameter samples of an undefined diameter and that the sam-

c d ples were generally 2 to 3 in. [5 to 8 cm] long.

Of the four models suggested by Reiss, 4 maximum porosity re-

Fig. 2-Typical fracture networks. Arrows indicate possible sults from a fracture network represented by cubes. The relation-

directions of flow.

'During discussion portion of Ref. 8 at oral presentation.

TABLE 1-FRACTURE WIDTHS AND SPACINGS

Formation Fracture Widths (mm) Fracture Spacing/

Reference Information Range Frequency Comments

Aguilera' General statement Paper thin. 6 +

Elkins 9 Spraberry sandstone 0.33 (maximum) 0.051 Few inches to a few feet

Snow'o Selected dam sites 0.051 to 0.10 4 to 14 It

Aguilera 1 La paz·Mara field 6.35 (maximum)"

Confidential study Monterey 0.01 * 3 to 336 fractures/It

Weber and Bakker 7 Small joints' 0.01 to 0.10

Weber and Bakker 7 Extension fractures' 0.1 to 1 0.2

Weber and Bakker 7 Major extension 0.2 to 2t

fractures'

'Unidentified reservoirs.

'';Converted to metric units.

Partial infilling.

fAssigned.

532 SPE Formation Evaluation. December 1989

TABLE 2-POROSITIES OF FRACTURED RESERVOIRS

References Formation Information Porosity Units

Pittman 12 General statement 1

Snow 10 Beaver gas field 0.05 to 5

Stearns and Friedman 13 Austin chalk 0.2

Confidential study Monterey 0.01 to 1.1

Weber and Bakker 7 South African karst zone 1 to 2

Bergosh and Lord 8 CT scan examples' 1.53 to 2.57

Bergosh and Lord 8 Epoxy injection examples' 1.81 to 9.64

'Three unidentified samples.

TYPE 0 TYPES B&C TYPE A

TYPE 0

FRACTURE WIDTH-MICRONS FRACTURE WIDTH-MICRONS

Fig. 4-Porosity-fracture-wldth relationships for various frac- Fig. 5-Poroslty-fracture-wldth relationships for various frac-

ture models with a 1-cm block size. ture models with 4-cm block sizes.

ship of fracture porosity with fracture width for a constant block

size may be developed from Fig. A.3.8 of Reiss. 4 Fig. 4 shows

these relationships for a very optimistic block size of 0.4 in. [1 cm].

Note that fracture widths of 200, 300, and 700 ILm are required TYPE 0

to develop 6 % porosity for the four fracture systems. Fig. 5 depicts

the drastic change in porosity as the block size is increased to 1.6

in. [4 cm]. Fig. 6 shows the relationship between porosity and block

size for a constant fracture width. An arbitrary 200-ILm fracture

width was chosen for this example. This graph demonstrates the ....z

reduction in porosity with increasing block size. Note that a w

o

a:

maximum porosity of abOut 2 % is associated with a I-in. [2.5-cm] ~I

block size. >

!::

An exception to this may be found in California's onshore/ <I)

~ 3

offshore Monterey formation, which has reservoirs that may have oa.

abnormally high fracture porosities. Redwine ll focused his work

on the Monterey shale. He qualifies the term "shale" to connote

that the rock is made up of clay-to-silt-sized particles and is lami-

nated, fissile, or both. His shale term does not imply that the rock

has a significant content of clay minerals. He speaks of the Santa

Maria area where fracturing is almost ubiquitous, with the dominant

type being well-ordered and systematic. He states that the rocks

of this area usually are dense and brittle, and extension fracturing

and brecciation are intense. It is conceivable that a breccia-type

rock could contain the porosities (and permeabilities) to explain the BLOCK SIZE-CENTIMETERS

high production rates of heavy, viscous oil recorded from some

wells. Sangree 14 discusses breccias in detail and cautions that a Fig. 6-Poroslty-block-slze relationships for various fracture

models with a 200-"m fracture width.

core box full of drilling-induced rubble should not be called a brec-

cia. Given the previous mathematics for calculating fracture porosi-

ty, it is still unlikely that a breccia-type rock would yield porosities

much greater than 2 to 3 %.

SPE Fonnation Evaluation, December 1989 533

Weber and Bakker7 discuss the chert associated with the Mon- Acknowledgments

terey and state that porosities of some 8 % are possible. On the ba- I thank Sun E&P Co. for permission to publish this paper. I also

sis of their thin-bed chert occurrence, examinations of long intervals thank Sam Bass, Joan Hahne, and Lynda Chandler for their valua-

of Monterey core, 8 and my observations, it is unlikely that such a ble assistance in the preparation of various parts of the paper. A

lithology condition exists for a vertical interval2! 100ft [2! 30.5 m]. special thanks is due Eve Sprunt of Mobil R&D Corp. for her many

Fracture studies often yield extremely low fracture porosity helpful suggestions and overall guidance.

values, as Table 2 shows. Indirect estimates (e.g., wireline logs)

sometimes yield significant storage space assigned to the fracture References

system; however, the fracture-width and block-size considerations I. Aguilera, R.: "Geological Aspects," Naturally Fractured Reservoirs,

previously documented make these estimates appear overly optimis- PennWell Publishing Co., Tulsa, OK (1980).

tic with a few possible exceptions. 2. "The Fundamentals of Core Analysis," Core Laboratories, Dallas, Sec.

Various types of studies may be conducted to provide fracture 2, 10.

porosity values. The same rules should apply for naturally frac- 3. Jones, F.O. Jr.: "A Laboratory Study of the Effects ofConfming Pres-

tured reservoirs as for more conventional reservoirs when the va- sure on Fracture Flow and Storage Capacity in Carbonate Rocks, " JPT

lidity of the data derived is considered. Be it a well test, a series (Jan. 1975) 21-27.

4. Reiss, L.H.: The Reservoir Engineering Aspects of Fractured Forma-

of downhole logs, or core studies, only a small portion of the reser-

tions, Gulf Publishing Co., Houston, TX (1980).

voir is represented. This presents such valid questions as whether 5. Warren, J.E. and Root, P.J.: "The Behavior of Naturally Fractured

the areal representation of the total lithology is adequate; i.e., do the Reservoirs," SPEJ (Sept. 1963) 245-55; Trans., AIME, 228.

data tend to high grade or low grade because of the well's position? 6. Aguilera, R.: "Relative Permeability Concepts for Predicting the Per-

The same holds true regarding the vertical cross section. Ques- formance of Naturally Fractured Reservoirs," J. Cdn. Pet. Tech.

tions to address include (1) was the complete section cored; (2) was (Sept. -Oct. 1982) 41-48.

the core recovery satisfactory both from a quantitative and qualita- 7. Weber, K.J. and Bakker, M.: "Fracture and Vuggy Porosity," paper

tive standpoint; (3) was the wellbore in satisfactory condition to SPE 10332 presented at the 1981 SPE Annual Technical Conference

produce reliable results from logs; and (4) were the well tests ham- and Exhibition, San Antonio, Oct. 5-7.

8. Bergosh, J.L. and Lord, G.D.: "New Developments in the Analysis

pered in any manner. Additional valid questions may deal with the

of Cores From Naturally Fractured Reservoirs," paper SPE 16805

analyses, data handling, and data interpretation. If a core study was presented at the 1987 SPE Annual Technical Conference and Exhibi-

conducted, did the analyst unintentionally high grade or low grade tion, Dallas, Sept. 27-30.

on the basis of sample sites? Was the proper analysis method used? 9. Elkins, L.F.: "Reservoir Performance and Well Spacing, Spraberry

Did the log analyst use proper judgment and analytical procedures? Trend Area Field of West Texas," JPT (July 1953) 177-96; Trans.,

Did the reservoir-simulation engineer use state-of-the-art models, AIME,198.

and were there uncertainties resulting from lack or quality of 10. Snow, D. T.: "Rock Fracture Spacing Openings and Porosities," Ameri-

input data? can Soc. of Civil Engineers, Soil Mechanics and Foundation Div. (1968)

These comments are not meant to demean any of the many ana- 94,73-91.

1I. Redwine, L.: "Hypothesis Combining Dilation, Natural Hydraulic Frac-

lytical tools. Instead, they are intended to present a challenge for

turing, and Dolomitization to Explain Petroleum Reservoirs in Mon-

the prudent engineer/technologist to probe deeply into all facets of terey Shale, Santa Maria Area, California," The Monterey Formation

each evaluation system and not blindly to accept any assigned frac- and Related Siliceous Rocks of California, Soc. of Economic Paleon-

ture porosity value without considering the possible limitations re- tologists and Mineralogists, Pac. Sec. (1981) 221-48.

garding accuracy and representation. 12. Pittman, E.D.: Porosity, Diagenesis and Productive Capability ofSand-

stone Reservoirs, SEPM Special Publication No. 26, Soc. of Econom-

ic Paleontologists and Mineralogists, Tulsa, OK (March 1979) 159-73.

Conclusions 13. Steams, D.W. and Friedman, M.: "Reservoirs in Fractured Rock,"

1. Fractures, either naturally occurring or induced, are the life- AAPG Memoir 16, Tulsa, OK (1972) 82-106.

blood of many reservoirs because of their influence on well deliver- 14. Sangree, J.B.: "What You Should Know to Analyze Core Fractures,"

ability. World Oil (April 1969) 69-72.

2. Overestimating fracture porosity potentially can lead to eco- 51 Metric Conversion Factors

nomic failures in the development of naturally fractured reservoirs. ft x 3.048* E-Ol m

3. Fracture porosity generally may be insignificant with respect in. x 2.54* E+OO cm

to the total reservoir hydrocarbon storage space.

4. Fracture porosity, in many instances, is less than 1 %. 'Conversion factor is exact. SPEFE

5. Technical personnel and financial planners should look criti- Original SPE manuscript received for review Sept. 27, 1987. Paper accepted for publica·

tion June 12, 1989. Revised manuscript received Jan. 17, 1989. Paper (SPE 16806) first

cally at hydrocarbon-storage-space values associated with the frac- presented at the 1987 SPE Annual Technical Conference and Exhibition held in Dallas,

ture network through whatever means of assignment. Sept. 27-30.

534 SPE Formation Evaluation, December 1989

You might also like

- The Cohesive Zone Model Advantages, Limitations PDFDocument2 pagesThe Cohesive Zone Model Advantages, Limitations PDFA0% (1)

- Plaster of Paris As A Model Material For Brittle Porous SolidsDocument7 pagesPlaster of Paris As A Model Material For Brittle Porous SolidsportyukiNo ratings yet

- Brio UK Lit Dec 2007Document8 pagesBrio UK Lit Dec 2007Neil HoggNo ratings yet

- Bench Stability in Open Pit Mines A MethodologyDocument7 pagesBench Stability in Open Pit Mines A Methodologycleiton.moraespf75No ratings yet

- Definition of Fracture PorosityDocument6 pagesDefinition of Fracture PorositySumarniNo ratings yet

- Spe 184820 MS PDFDocument13 pagesSpe 184820 MS PDFSSNo ratings yet

- Corteii, YacimientosDocument10 pagesCorteii, YacimientosOswa LrNo ratings yet

- 1976 CCR Hillerborg p773 PDFDocument9 pages1976 CCR Hillerborg p773 PDFNilay GandhiNo ratings yet

- Lecture 4Document10 pagesLecture 4Yousef AhmadNo ratings yet

- SPE 130745 How To Propagate Petrophysical Properties in A Fracture Network For Naturally Fractured Carbonate Reservoirs Case Study: Cretaceous Formations at Maracaibo Lake, VenezuelaDocument14 pagesSPE 130745 How To Propagate Petrophysical Properties in A Fracture Network For Naturally Fractured Carbonate Reservoirs Case Study: Cretaceous Formations at Maracaibo Lake, VenezuelaRizky Dermawan HaqNo ratings yet

- 6.5 Summary: Trans. AIME, 251Document10 pages6.5 Summary: Trans. AIME, 251سحر سلامتیانNo ratings yet

- Pelloux - Crack Extension by Alternating ShearDocument12 pagesPelloux - Crack Extension by Alternating ShearDavid C HouserNo ratings yet

- Understanding Crack Growth in Fuselage Lap Joints - Jones2008Document13 pagesUnderstanding Crack Growth in Fuselage Lap Joints - Jones2008Raniero FalzonNo ratings yet

- Capitulo 5 Fracture Rock Properties VCDocument105 pagesCapitulo 5 Fracture Rock Properties VCemilioNo ratings yet

- Effect of Applying Screen and Honeycomb To The FloDocument12 pagesEffect of Applying Screen and Honeycomb To The FlojuanNo ratings yet

- Determination of The Optimum Crown Pillar Thickness Between OpenDocument8 pagesDetermination of The Optimum Crown Pillar Thickness Between OpenluisparedesNo ratings yet

- Dual Laterolog para FracturasDocument34 pagesDual Laterolog para FracturasÁngelNo ratings yet

- Well Test Analysis For Naturally Fractured Reservoirs With Transient Interporosity Matrix, Microfractures, and Fractures FlowDocument12 pagesWell Test Analysis For Naturally Fractured Reservoirs With Transient Interporosity Matrix, Microfractures, and Fractures FlowSatriaNo ratings yet

- Proper Selection OF Drill Bits AND Their USE: Sent To The Society ofDocument12 pagesProper Selection OF Drill Bits AND Their USE: Sent To The Society ofBahman MatouriNo ratings yet

- Hydraulic Flow UnitsDocument6 pagesHydraulic Flow UnitscoreabzNo ratings yet

- Dr. Fadhil Luctures-2Document25 pagesDr. Fadhil Luctures-2ckcp7sy2ztNo ratings yet

- Speidoe: SPEIDOE 13857 Hydraulic Fracture Treatment Design of Wells With Multiple ZonesDocument8 pagesSpeidoe: SPEIDOE 13857 Hydraulic Fracture Treatment Design of Wells With Multiple ZonesbayuNo ratings yet

- International Journal of Heat and Mass Transfer: Tongjun Miao, Boming Yu, Yonggang Duan, Quantang FangDocument6 pagesInternational Journal of Heat and Mass Transfer: Tongjun Miao, Boming Yu, Yonggang Duan, Quantang FangTabish HaiderNo ratings yet

- PermDocument26 pagesPermFarid GhasemiNo ratings yet

- Predictions of Widespread Fatigue Damage Thresholds in Aging AircraftDocument8 pagesPredictions of Widespread Fatigue Damage Thresholds in Aging AircraftMona AwadNo ratings yet

- Gong RossenDocument9 pagesGong RossenRonaldo RumbekwanNo ratings yet

- C Ste 397629Document5 pagesC Ste 397629khudhayer1970No ratings yet

- 1 s2.0 0956715194905029 Main PDFDocument13 pages1 s2.0 0956715194905029 Main PDFPeterNo ratings yet

- Fracture Toughness Testing of Non Standard Specimens: Etienne Mfoumou Sharon Kao-WalterDocument17 pagesFracture Toughness Testing of Non Standard Specimens: Etienne Mfoumou Sharon Kao-WalteruzumakhinarutoNo ratings yet

- Loading Rate Effect As A Function of The Span-To-Depth Ratio in Three-Point Bend Testing of Unidirectional Puitruded CompositesDocument7 pagesLoading Rate Effect As A Function of The Span-To-Depth Ratio in Three-Point Bend Testing of Unidirectional Puitruded CompositesShital ChaudhariNo ratings yet

- Factor de Recuperación en Yacimientos FracturadosDocument4 pagesFactor de Recuperación en Yacimientos FracturadosJorge Leopoldo VeraNo ratings yet

- SPE 93747 Mechanics of Borehole Ballooning in Naturally-Fractured FormationsDocument7 pagesSPE 93747 Mechanics of Borehole Ballooning in Naturally-Fractured FormationsRama KusumaNo ratings yet

- Review of The Splitting-Test Standards From A Fracture Mechanics Point of ViewDocument10 pagesReview of The Splitting-Test Standards From A Fracture Mechanics Point of ViewaramosgavilanNo ratings yet

- Paper Sabria TunisiaDocument12 pagesPaper Sabria TunisiaRani Juliarini RahayuNo ratings yet

- Effect of Stacking Sequence On Open-Hole Tensile Strength of Composite LaminatesDocument20 pagesEffect of Stacking Sequence On Open-Hole Tensile Strength of Composite Laminatesming tsaiNo ratings yet

- SPWLA 1980 vXXIn2a1Document11 pagesSPWLA 1980 vXXIn2a1amin peyvandNo ratings yet

- Of Matrix: Estimation Block Size Distribution in Naturally Fractured ReservoirsDocument52 pagesOf Matrix: Estimation Block Size Distribution in Naturally Fractured Reservoirstomk2220No ratings yet

- IADC/SPE 133735 Optimizing in Four Steps Composite Lost-Circulation Pills Without Knowing Loss Zone WidthDocument13 pagesIADC/SPE 133735 Optimizing in Four Steps Composite Lost-Circulation Pills Without Knowing Loss Zone WidthmiladNo ratings yet

- Fracture ApartureDocument14 pagesFracture ApartureRonaldo RumbekwanNo ratings yet

- SPE 151448 Casing Wear PaperDocument15 pagesSPE 151448 Casing Wear PaperLilyShiNo ratings yet

- Creton 和 Ciccotti - 2016 - Fracture and Adhesion of Soft Materials a ReviewDocument58 pagesCreton 和 Ciccotti - 2016 - Fracture and Adhesion of Soft Materials a Review郭帅斐No ratings yet

- Germany FH-Aachen UibelDocument15 pagesGermany FH-Aachen UibelFilip CirovicNo ratings yet

- Prediction of Casing Wear in Extended-Reach DrillingDocument8 pagesPrediction of Casing Wear in Extended-Reach DrillingMile SikiricaNo ratings yet

- Deepak Gokaraju, Ming Gu, Dingding Chen, Mehdi E. Far, and John Quirein, HalliburtonDocument12 pagesDeepak Gokaraju, Ming Gu, Dingding Chen, Mehdi E. Far, and John Quirein, HalliburtonPAVEL130572No ratings yet

- SPE 148078 Dual-Permeability Model For Coupled Reservoir Geomechanical Modeling: Application For Field Production DataDocument10 pagesSPE 148078 Dual-Permeability Model For Coupled Reservoir Geomechanical Modeling: Application For Field Production DataRomel Angel Erazo BoneNo ratings yet

- Digitalizado em 31-8-2011 16-18123Document12 pagesDigitalizado em 31-8-2011 16-18123Pedro EymardNo ratings yet

- FPL 1309ocrDocument18 pagesFPL 1309ocrVijayGokulavasan SNo ratings yet

- P. SPE-144590-PA-P Petrophysics of Triple-Porosity Tight Gas Reservoirs With A Link To Gas ProductivityDocument12 pagesP. SPE-144590-PA-P Petrophysics of Triple-Porosity Tight Gas Reservoirs With A Link To Gas ProductivityPablo RaffinNo ratings yet

- The Pressure Dependence of PermeabilityDocument11 pagesThe Pressure Dependence of Permeabilityheberth julian rodriguezNo ratings yet

- 301-The Influence of End Restraint On The Compression Strength of A Cohesionless Soil, Bishop and GreenDocument3 pages301-The Influence of End Restraint On The Compression Strength of A Cohesionless Soil, Bishop and Greenد.م. محمد الطاهرNo ratings yet

- Improving Fracture Permeability Prediction by Combining Geomechanics and DiagenesisDocument7 pagesImproving Fracture Permeability Prediction by Combining Geomechanics and DiagenesisOscar Javier ArevaloNo ratings yet

- Composites: Part A: J.D. Fuller, M.R. WisnomDocument8 pagesComposites: Part A: J.D. Fuller, M.R. WisnomCarlo PignagnoliNo ratings yet

- Som ExperimentsDocument17 pagesSom ExperimentsAnudeex ShettyNo ratings yet

- Brittle Microtectonics Principles and PR PDFDocument21 pagesBrittle Microtectonics Principles and PR PDFMartin GriffinNo ratings yet

- Fracture Mechanics - Lecture 3Document15 pagesFracture Mechanics - Lecture 3Hayder AlsarajNo ratings yet

- 2 SPE 58793 OptibridgeDocument8 pages2 SPE 58793 OptibridgePT100% (1)

- Turbulent Fracture SurfacesDocument5 pagesTurbulent Fracture Surfacesstephane VernedeNo ratings yet

- 1 s2.0 S1876380420601227 MainDocument14 pages1 s2.0 S1876380420601227 Maindorian.axel.ptNo ratings yet

- CTOD - Fracture MechanicsDocument9 pagesCTOD - Fracture MechanicsFlavio BarrionuevoNo ratings yet

- A Practical Course in Wooden Boat and Ship BuildingFrom EverandA Practical Course in Wooden Boat and Ship BuildingRating: 4 out of 5 stars4/5 (1)

- Correlation DesignDocument43 pagesCorrelation DesignPuru TiwariNo ratings yet

- DR Carey Reams - The Story of RBTIDocument40 pagesDR Carey Reams - The Story of RBTINepthus Metal100% (3)

- All at Sea Caribbean 0917Document112 pagesAll at Sea Caribbean 0917Scott NeumanNo ratings yet

- Sop AntennaDocument27 pagesSop AntennaAltezza AtehNo ratings yet

- Potential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyDocument6 pagesPotential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyLuis Carlos SuarezNo ratings yet

- Land Reforms in IndiaDocument22 pagesLand Reforms in IndiaiRagpickerNo ratings yet

- Articulo 1Document8 pagesArticulo 1JESSICA ANDREA GUILOMBO GONZALEZNo ratings yet

- KS3 Human Reproduction Exam HigherDocument4 pagesKS3 Human Reproduction Exam HigherSarah KKCNo ratings yet

- QCP Native Form (Version 03)Document1 pageQCP Native Form (Version 03)paul mtimkuluNo ratings yet

- 04 Heat 1-19Document19 pages04 Heat 1-19Manas AgrawalNo ratings yet

- Down SyndromeDocument3 pagesDown SyndromeMargie Ballesteros Manzano100% (1)

- Daftar Pustaka: Historical and Perennial Issues, 349Document2 pagesDaftar Pustaka: Historical and Perennial Issues, 349Adelina JoseNo ratings yet

- Plastic Pallet 1219 X 1016 MMDocument1 pagePlastic Pallet 1219 X 1016 MMANANo ratings yet

- Filum Nematoda 2022Document45 pagesFilum Nematoda 2022RenjunNo ratings yet

- Level Past Paper Questions - Physics O: TOPIC-13 Electric Current PAPER-1 Multiple ChoiceDocument12 pagesLevel Past Paper Questions - Physics O: TOPIC-13 Electric Current PAPER-1 Multiple Choiceelty TanNo ratings yet

- Bearing Insulation ResistanceDocument10 pagesBearing Insulation Resistancemurty0077754No ratings yet

- Circumplex Model of Marital and Family Systems: I. Cohesion and Adaptability Dimensions, Family Types, and Clinical ApplicationsDocument20 pagesCircumplex Model of Marital and Family Systems: I. Cohesion and Adaptability Dimensions, Family Types, and Clinical ApplicationsLuis BernardoNo ratings yet

- TACA Times Sept/Oct 2010Document6 pagesTACA Times Sept/Oct 2010Bruce WileyNo ratings yet

- Reaction Paper KyleDocument4 pagesReaction Paper KyleRonaliza Durano SanchezNo ratings yet

- Perbandingan Metode Klamp Dan Lem Terhadap Penyembuhan Luka Pasca Sirkumsisi Pada AnakDocument6 pagesPerbandingan Metode Klamp Dan Lem Terhadap Penyembuhan Luka Pasca Sirkumsisi Pada Anaknanang prasetyoNo ratings yet

- Tourniquet Conversion Drew JSOM Fall 2015 Edition-2Document5 pagesTourniquet Conversion Drew JSOM Fall 2015 Edition-2Oleg ShubinNo ratings yet

- Treinamento - ForçaDocument30 pagesTreinamento - ForçaFilipe DuarteNo ratings yet

- Drugs Use in HemostasisDocument47 pagesDrugs Use in HemostasiskadibhaNo ratings yet

- The Vibrant Nature of Life: Scientific Secrets For Your Journey Through Space and TimeDocument424 pagesThe Vibrant Nature of Life: Scientific Secrets For Your Journey Through Space and TimeDr. Peter Fritz Walter100% (11)

- SS DM MCH 2020 - 2021 Schedule Nov 6th Update PDFDocument32 pagesSS DM MCH 2020 - 2021 Schedule Nov 6th Update PDFlakshminivas PingaliNo ratings yet

- Practice Test 17: Gramvocab: A. InconsistentDocument10 pagesPractice Test 17: Gramvocab: A. InconsistentHải Anh TrầnNo ratings yet

- At Home Training Guide: Workout BuilderDocument22 pagesAt Home Training Guide: Workout BuilderAnonymous NO0urGNo ratings yet

- Grade 10 English Achievement TestDocument4 pagesGrade 10 English Achievement TestJelaica Alarilla - GerminoNo ratings yet

- Southeast Asia Youth Leadership Program: Student Application FormDocument3 pagesSoutheast Asia Youth Leadership Program: Student Application FormAn ViNo ratings yet