Professional Documents

Culture Documents

Acryloc Rust Converter-PDS

Acryloc Rust Converter-PDS

Uploaded by

Ragam LestariCopyright:

Available Formats

You might also like

- Wehrhahn - AAC - Info Catalogue-EnDocument49 pagesWehrhahn - AAC - Info Catalogue-EnJavier F. Via Giglio100% (1)

- Acrabond KE45 Type RTV Silicone SealantDocument5 pagesAcrabond KE45 Type RTV Silicone SealantdrvikaasNo ratings yet

- Anti Condensation CatalogueDocument8 pagesAnti Condensation CatalogueBoBo KyawNo ratings yet

- Sika PDS E Sikagard-950Document4 pagesSika PDS E Sikagard-950lwin_oo2435No ratings yet

- Transclean 801Document2 pagesTransclean 801carmaNo ratings yet

- Sila Tech RD TdsDocument2 pagesSila Tech RD TdsChemicalProgrammerNo ratings yet

- Acrylic Sealer: One Component, Low Viscosity SealerDocument2 pagesAcrylic Sealer: One Component, Low Viscosity SealerHerul VetonkNo ratings yet

- SikabondConstAdhesive PdsDocument2 pagesSikabondConstAdhesive PdsGeorge OnashsNo ratings yet

- Sikasil - AP: Neutral Curing Silicone SealantDocument3 pagesSikasil - AP: Neutral Curing Silicone SealantLim VandoeunNo ratings yet

- Ard 2480 TDDocument2 pagesArd 2480 TDRajajeevan AtputharajahNo ratings yet

- Silver Zinc Guard - PROTECT TDS ENDocument3 pagesSilver Zinc Guard - PROTECT TDS ENYouyouNo ratings yet

- Water ProofingDocument30 pagesWater ProofingMuhammad Irfan ButtNo ratings yet

- TDS 0004 FlexoPrime 202003Document3 pagesTDS 0004 FlexoPrime 202003Mearg NgusseNo ratings yet

- Sikagard - PW: High Chemical Resistance, Non Toxic Epoxy CoatingDocument2 pagesSikagard - PW: High Chemical Resistance, Non Toxic Epoxy Coatingthe pilot0% (1)

- Sika PDS - E - Sikalastic - 490 TDocument4 pagesSika PDS - E - Sikalastic - 490 Tlwin_oo2435No ratings yet

- CorrotecKL10K - Coil Coating v1.1Document6 pagesCorrotecKL10K - Coil Coating v1.1ajajsainNo ratings yet

- Weldbrite TDS ESDocument3 pagesWeldbrite TDS ESJeremy OngNo ratings yet

- S Weld Passivator Solution TDSDocument2 pagesS Weld Passivator Solution TDSMustafa SharadahNo ratings yet

- Ferreko No 3 pc560Document2 pagesFerreko No 3 pc560vijayarangam1984No ratings yet

- Sika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcreteDocument2 pagesSika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcretepouyaNo ratings yet

- Res Q SteelDocument4 pagesRes Q SteelTrịnh Minh KhoaNo ratings yet

- 1050 Plastigard 100 Percent Acrylic High Build CoatingDocument1 page1050 Plastigard 100 Percent Acrylic High Build Coatingjustin trochezNo ratings yet

- Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLDocument2 pagesSellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLEleazar MendezNo ratings yet

- IMP Chlorinated-Rubber Alkyd PrimerDocument3 pagesIMP Chlorinated-Rubber Alkyd PrimerBalakrishna G SettyNo ratings yet

- Sikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarDocument4 pagesSikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarAnonymous v1blzDsEWANo ratings yet

- Masterprotect 1813: Amine-Cured, Pitch Free EpoxyDocument2 pagesMasterprotect 1813: Amine-Cured, Pitch Free EpoxyGavriel Ng100% (1)

- Acronal IA 734 AP PIDocument3 pagesAcronal IA 734 AP PIkishanptlNo ratings yet

- Sika Rustoff 100: Rust Remover Cum PassivatorDocument2 pagesSika Rustoff 100: Rust Remover Cum PassivatorAnonymous Gb9LeJcINo ratings yet

- Antisol-A 2010-07 - 1Document2 pagesAntisol-A 2010-07 - 1Hamza TarikNo ratings yet

- Securea SCDocument2 pagesSecurea SCAutumn HernandezNo ratings yet

- Sikacrete 114Document2 pagesSikacrete 114the pilotNo ratings yet

- Sikadur 53Document2 pagesSikadur 53the pilotNo ratings yet

- ( (SL907 (PA) ) SL907 (PA) ) : Technical Manual For Technical Manual For General Glazing General Glazing Sealant SealantDocument10 pages( (SL907 (PA) ) SL907 (PA) ) : Technical Manual For Technical Manual For General Glazing General Glazing Sealant Sealantstretfordend92No ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetBenjaminNo ratings yet

- Sika PDS - E - Icosit KC 340-65Document4 pagesSika PDS - E - Icosit KC 340-65lwin_oo2435No ratings yet

- Epiz 3Document3 pagesEpiz 3Bobbie RuckNo ratings yet

- S Weld Passivator Gel TDSDocument3 pagesS Weld Passivator Gel TDSSuryana MamanNo ratings yet

- Sikacrete - 114: Free Flowing Microconcrete For Grouting and RepairDocument3 pagesSikacrete - 114: Free Flowing Microconcrete For Grouting and RepairQazinadeemNo ratings yet

- Sikaflex®-11 FC: Product Data SheetDocument3 pagesSikaflex®-11 FC: Product Data SheetHaradhon DattaNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- 2 Sikacrete-114 PDS GCC (06-2018) 1 1Document3 pages2 Sikacrete-114 PDS GCC (06-2018) 1 1Sri KanthNo ratings yet

- Sikaflex 11FC - PDS PDFDocument4 pagesSikaflex 11FC - PDS PDFrajeevNo ratings yet

- TDS - SealantDocument2 pagesTDS - Sealantriteish singhNo ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- Ipd Pds Sikaflex221 Us 1Document4 pagesIpd Pds Sikaflex221 Us 1Dennis UbillusNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- Sika® Rokkon C-Id: Product Data SheetDocument2 pagesSika® Rokkon C-Id: Product Data Sheetal mukarramahNo ratings yet

- Anti Toxic PicklingDocument2 pagesAnti Toxic PicklingGaurav Bedi0% (1)

- Sika® Antisol® A: Product Data SheetDocument2 pagesSika® Antisol® A: Product Data SheettashadzureenNo ratings yet

- Sika Wall Coat - EGDocument2 pagesSika Wall Coat - EGthe pilotNo ratings yet

- 15 07 17 FT SiMP High TackDocument4 pages15 07 17 FT SiMP High TackAmon AlastorNo ratings yet

- TP 9202 18 Surface Preparation and Application of Glass Flake CoatingsDocument3 pagesTP 9202 18 Surface Preparation and Application of Glass Flake CoatingsSaranik DattaNo ratings yet

- Coaltar EpoxyDocument2 pagesCoaltar EpoxyAnonymous YN4aNlNo ratings yet

- Elastomeric Waterproofing: Resin Powder Grey Powder WhiteDocument2 pagesElastomeric Waterproofing: Resin Powder Grey Powder WhiteUpulHettiarachchiNo ratings yet

- Silica Fume 92% Technical Data Sheet: Description Physical PropertiesDocument1 pageSilica Fume 92% Technical Data Sheet: Description Physical PropertiesDileepa DissanayakeNo ratings yet

- Davco k11 Slurry613Document3 pagesDavco k11 Slurry613Harold PicoNo ratings yet

- X-Shield AcrylCoatDocument2 pagesX-Shield AcrylCoatEGO AnimationNo ratings yet

- Sikagard ElastoColor-675 WDocument4 pagesSikagard ElastoColor-675 WAgung RahmadiNo ratings yet

- Yarn Finish FormulationsDocument6 pagesYarn Finish Formulationsali rezaeiNo ratings yet

- Lindab ColourDocument1 pageLindab ColourNetrom76No ratings yet

- 5754 Aluminum CircleDocument2 pages5754 Aluminum Circlewei huaNo ratings yet

- A1 Poster - Adjustable WrenchDocument1 pageA1 Poster - Adjustable WrenchKah KiatNo ratings yet

- Aluminium WeldingDocument2 pagesAluminium WeldingARYANo ratings yet

- PWHT ProcedureDocument8 pagesPWHT ProcedureTuesou MachereNo ratings yet

- Characteristics of Cutting Steels and Saw Tooth Forms: Metal Cutting Circular Saws Vary in 7 AspectsDocument8 pagesCharacteristics of Cutting Steels and Saw Tooth Forms: Metal Cutting Circular Saws Vary in 7 AspectsAlvaro RochaNo ratings yet

- Te-Econom Plus Te-Econom Flow Te-Econom Bond Eco-Etch: Instructions For UseDocument40 pagesTe-Econom Plus Te-Econom Flow Te-Econom Bond Eco-Etch: Instructions For UseAngeles Jimenez SanchezNo ratings yet

- 0710 Bodycote PDFDocument13 pages0710 Bodycote PDFRuchira Chanda InduNo ratings yet

- TG Comparison With Shell BirdDocument572 pagesTG Comparison With Shell BirdJason SecretNo ratings yet

- Type of Steel OF Ikea CherasDocument5 pagesType of Steel OF Ikea CherasSiti HajarNo ratings yet

- Brosur Gradino Juli 2022Document16 pagesBrosur Gradino Juli 2022Khansa AnastyaNo ratings yet

- Saems 1000 V 003Document33 pagesSaems 1000 V 003kyletgerberNo ratings yet

- PJC Inorganic ChemistryDocument8 pagesPJC Inorganic ChemistryThint San Naing HeinNo ratings yet

- SCH3U - Acids & Bases WorksheetDocument2 pagesSCH3U - Acids & Bases WorksheetRuby Angel MannNo ratings yet

- Notes Chemistry DLP F4Document79 pagesNotes Chemistry DLP F4Aleisha SofeaNo ratings yet

- Termite Proofing: Construction Engineering CE-374 Dr. Rai Waqas Azfar KhanDocument24 pagesTermite Proofing: Construction Engineering CE-374 Dr. Rai Waqas Azfar KhanBilal Ashraf100% (1)

- Distilling ParrotDocument18 pagesDistilling Parrotapi-1821010100% (2)

- Ultimate Analysis of Coal and Coke Samples.: Energy Engineering LabDocument3 pagesUltimate Analysis of Coal and Coke Samples.: Energy Engineering LabHafiz hassanNo ratings yet

- Ansi-Aws A5 - 18-93Document37 pagesAnsi-Aws A5 - 18-93skrkulachiNo ratings yet

- Enhanced Mechanical and Thermal Properties of Rigid Polyurethane Foam Composites Containing Graphene Nanosheets and Carbon NanotubesDocument8 pagesEnhanced Mechanical and Thermal Properties of Rigid Polyurethane Foam Composites Containing Graphene Nanosheets and Carbon NanotubesBurcu UzunoğluNo ratings yet

- Study of Components (Hydrogen Chloride) : Lab Preparation of HCLDocument4 pagesStudy of Components (Hydrogen Chloride) : Lab Preparation of HCLSANDEEP SINGHNo ratings yet

- Technical Data Sheet: UHU Plus Endfest 300Document5 pagesTechnical Data Sheet: UHU Plus Endfest 300mitchiNo ratings yet

- Experiment 19Document3 pagesExperiment 19Beenu SinghNo ratings yet

- General Purpose and Blended Cements: Australian StandardDocument7 pagesGeneral Purpose and Blended Cements: Australian StandardKrist Jan Jimenez SeparaNo ratings yet

- Chapter 1 (1-74) FinalDocument74 pagesChapter 1 (1-74) FinalAbdul Basit AnsariNo ratings yet

- Acids and BasesDocument13 pagesAcids and Basestismon86% (7)

- List of Companies/Llps Registered During The Year 1982Document156 pagesList of Companies/Llps Registered During The Year 1982Harsh PunmiyaNo ratings yet

- Wood Ash Vs Wood PowderDocument6 pagesWood Ash Vs Wood Powdervignesh natarajanNo ratings yet

Acryloc Rust Converter-PDS

Acryloc Rust Converter-PDS

Uploaded by

Ragam LestariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acryloc Rust Converter-PDS

Acryloc Rust Converter-PDS

Uploaded by

Ragam LestariCopyright:

Available Formats

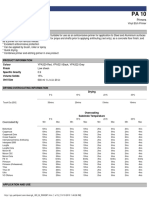

Data Sheet TECH15025 Ver.

8 Mar 2017

ACRYLOC® RUST CONVERTER

PRODUCT TYPE PACKAGING NOMINAL WEIGHT

Preparation Products 5L Heavy Duty Plastic Bottle 6kg

DESCRIPTION

Acryloc Rust Converter is an acid based treatment designed for chemical passivation and removal of light rust from

metal roof sheeting.

Acryloc Rust Converter is supplied as a concentrate and must be diluted before use. It removes and passivates light to

medium rust on metal as part of preparation for surface repainting. It also facilitates removal of minor deposits of oil and

grease as well as chemically etching the metal surface to ensure optimum adhesion of the subsequent primer coat.

SUITABLE SUBSTRATES

Zincalume® & Galvanised Iron

Iron & Steel

Colorbond®

APPLICATION

WARNINGS

Acryloc Rust Converter is a highly corrosive liquid containing Phosphoric Acid 30%w/w; it may produce severe

burns & skin irritation.

Suitable protective clothing must be worn when handling Acryloc Rust Converter, including rubber gloves & safety

goggles

For use on roofs, Rainwater tanks must be disconnected from the guttering system before application of

Acryloc Rust Converter and must remain disconnected until after application of all subsequent coatings. It is

essential that all residues are washed from the roof and from the guttering.

Dilution – always add Acryloc Rust Converter to water, do NOT add water to the Rust Converter

For Chemical etching of sound metal surfaces, slowly add one (1) part Acryloc Rust Converter to three (3) parts

clean water and mix well.

For removal & passivation of light rust, slowly add one (1) part Acryloc Rust Converter to one (1) part of clean water

and mix well.

NOTE: Do not use a metal container for dilution and mixing – use plastic or glass.

Method

Heavy rust deposits must be removed by wire wheel or sanding before application of Acryloc Rust Converter. The

surface must be cleaned and allowed to dry before application of Acryloc Rust Converter. Pressure cleaning is

recommended for best results.

Apply with brush, roller, mop or scouring pad to a dry, cool surface

Leave for minimum of 10-15 minutes to react. Agitation of the liquid into corroded areas using a plastic scourer or

broom can increase effectiveness. Rinse off with clean water. Avoid splashing

The treated area must be primed with the applicable Acryloc primer within 30 minutes of rinsing.

Important Notes

Avoid application on hot surfaces or in hot &/or windy conditions.

Clean-Up

Clean up with water

FOR TECHNICAL ADVICE CALL 1300 661 745 Page 1 of 2

The information provided herein is considered correct at the time of publication. It is the responsibility of those using this information to check that it is current prior to specifying or using any of the products or coating

systems. Any advice, recommendation or information provided by any of the officers of Acryloc Building Products in relation to goods manufactured by it for their use and application is given in good faith and is believed by

Acryloc Building Products to be appropriate and reliable. However, this advice, recommendation and information is provided without liability or responsibility without excluding or limiting responsibility under relevant

Government acts. Acryloc and other marks followed by the symbol ® or ™ are trademarks.

AUSTRALIAN OWNED, AUSTRALIAN MADE AND PROUD OF IT

Data Sheet TECH15025 Ver.8 Mar 2017

OTHER CONSIDERATIONS

Shelf-Life – Unopened Containers

Maximum two (2) years from date of manufacture when stored correctly

Transport & Storage

Pails should not be stacked more than three (3) high during transportation and must be transported upright

Store in a cool place, upright, out of direct sunlight and above 4C

For further information refer to MSDS for Acryloc Rust Converter

TECHNICAL DATA

APPEARANCE Dark green liquid

ODOUR Low

APPLICATION METHODS Roller, brush, spray

SPECIFIC GRAVITY (NOMINAL) 1.1 -1.2

THEORETICAL COVERAGE 10-15 m2/L in diluted form

DRY TIME (25C & 50% RH) Tack Free Recoat/ Overcoat Fully Dried

(APPROX) N/A Within 30 minutes N/A

SAFETY & HANDLING

Refer to MSDS for Acryloc Rust Converter before use. For further information on Material

Safety Data Sheets, call the Acryloc Tech – Info line on 1300 661 745 or visit

www.acryloc.com.au

When working with Acryloc Rust Converter observe the following precautions for as a minimum:

Avoid inhalation of the vapour, prolonged skin contact and particularly eye contact

Wear protective clothing to minimize skin contact and wear goggles where splatter is likely

Where spills occur, soak up liquid spillage with sand/sawdust and dispose of in a sensible

manner. Do not permit run-off to sewer, storm water or open bodies of water

FIRST AID MEASURES

Refer to MSDS for Acryloc Rust Converter before use. For further information on Material Safety Data Sheets, call the

Acryloc Tech – Info line on 1300 661 745 or visit www.acryloc.com.au

If swallowed, wash out mouth with water. Do NOT induce vomiting. Drink at least two (2) glasses of water. Seek medical

attention.

Eye

Wash with copious amount of water for 15 minutes holding eyelid(s) open. Take care not to rinse contaminated water

into non-affected eye. Seek medical attention.

Advice to Doctor

Treat symptomatically

MANUFACTURED BY:

Bizfine Pty Ltd

T/A Acryloc Building Products

174 Cavan Rd

DRY CREEK

South Australia 5094

P: +61 8 8368 0222

F: +61 8 8368 0223

E: sales@acryloc.com.au

W: www.acryloc.com.au

FOR TECHNICAL ADVICE CALL 1300 661 745 Page 2 of 2

The information provided herein is considered correct at the time of publication. It is the responsibility of those using this information to check that it is current prior to specifying or using any of the products or coating

systems. Any advice, recommendation or information provided by any of the officers of Acryloc Building Products in relation to goods manufactured by it for their use and application is given in good faith and is believed by

Acryloc Building Products to be appropriate and reliable. However, this advice, recommendation and information is provided without liability or responsibility without excluding or limiting responsibility under relevant

Government acts. Acryloc and other marks followed by the symbol ® or ™ are trademarks.

AUSTRALIAN OWNED, AUSTRALIAN MADE AND PROUD OF IT

You might also like

- Wehrhahn - AAC - Info Catalogue-EnDocument49 pagesWehrhahn - AAC - Info Catalogue-EnJavier F. Via Giglio100% (1)

- Acrabond KE45 Type RTV Silicone SealantDocument5 pagesAcrabond KE45 Type RTV Silicone SealantdrvikaasNo ratings yet

- Anti Condensation CatalogueDocument8 pagesAnti Condensation CatalogueBoBo KyawNo ratings yet

- Sika PDS E Sikagard-950Document4 pagesSika PDS E Sikagard-950lwin_oo2435No ratings yet

- Transclean 801Document2 pagesTransclean 801carmaNo ratings yet

- Sila Tech RD TdsDocument2 pagesSila Tech RD TdsChemicalProgrammerNo ratings yet

- Acrylic Sealer: One Component, Low Viscosity SealerDocument2 pagesAcrylic Sealer: One Component, Low Viscosity SealerHerul VetonkNo ratings yet

- SikabondConstAdhesive PdsDocument2 pagesSikabondConstAdhesive PdsGeorge OnashsNo ratings yet

- Sikasil - AP: Neutral Curing Silicone SealantDocument3 pagesSikasil - AP: Neutral Curing Silicone SealantLim VandoeunNo ratings yet

- Ard 2480 TDDocument2 pagesArd 2480 TDRajajeevan AtputharajahNo ratings yet

- Silver Zinc Guard - PROTECT TDS ENDocument3 pagesSilver Zinc Guard - PROTECT TDS ENYouyouNo ratings yet

- Water ProofingDocument30 pagesWater ProofingMuhammad Irfan ButtNo ratings yet

- TDS 0004 FlexoPrime 202003Document3 pagesTDS 0004 FlexoPrime 202003Mearg NgusseNo ratings yet

- Sikagard - PW: High Chemical Resistance, Non Toxic Epoxy CoatingDocument2 pagesSikagard - PW: High Chemical Resistance, Non Toxic Epoxy Coatingthe pilot0% (1)

- Sika PDS - E - Sikalastic - 490 TDocument4 pagesSika PDS - E - Sikalastic - 490 Tlwin_oo2435No ratings yet

- CorrotecKL10K - Coil Coating v1.1Document6 pagesCorrotecKL10K - Coil Coating v1.1ajajsainNo ratings yet

- Weldbrite TDS ESDocument3 pagesWeldbrite TDS ESJeremy OngNo ratings yet

- S Weld Passivator Solution TDSDocument2 pagesS Weld Passivator Solution TDSMustafa SharadahNo ratings yet

- Ferreko No 3 pc560Document2 pagesFerreko No 3 pc560vijayarangam1984No ratings yet

- Sika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcreteDocument2 pagesSika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcretepouyaNo ratings yet

- Res Q SteelDocument4 pagesRes Q SteelTrịnh Minh KhoaNo ratings yet

- 1050 Plastigard 100 Percent Acrylic High Build CoatingDocument1 page1050 Plastigard 100 Percent Acrylic High Build Coatingjustin trochezNo ratings yet

- Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLDocument2 pagesSellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SLEleazar MendezNo ratings yet

- IMP Chlorinated-Rubber Alkyd PrimerDocument3 pagesIMP Chlorinated-Rubber Alkyd PrimerBalakrishna G SettyNo ratings yet

- Sikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarDocument4 pagesSikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarAnonymous v1blzDsEWANo ratings yet

- Masterprotect 1813: Amine-Cured, Pitch Free EpoxyDocument2 pagesMasterprotect 1813: Amine-Cured, Pitch Free EpoxyGavriel Ng100% (1)

- Acronal IA 734 AP PIDocument3 pagesAcronal IA 734 AP PIkishanptlNo ratings yet

- Sika Rustoff 100: Rust Remover Cum PassivatorDocument2 pagesSika Rustoff 100: Rust Remover Cum PassivatorAnonymous Gb9LeJcINo ratings yet

- Antisol-A 2010-07 - 1Document2 pagesAntisol-A 2010-07 - 1Hamza TarikNo ratings yet

- Securea SCDocument2 pagesSecurea SCAutumn HernandezNo ratings yet

- Sikacrete 114Document2 pagesSikacrete 114the pilotNo ratings yet

- Sikadur 53Document2 pagesSikadur 53the pilotNo ratings yet

- ( (SL907 (PA) ) SL907 (PA) ) : Technical Manual For Technical Manual For General Glazing General Glazing Sealant SealantDocument10 pages( (SL907 (PA) ) SL907 (PA) ) : Technical Manual For Technical Manual For General Glazing General Glazing Sealant Sealantstretfordend92No ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetBenjaminNo ratings yet

- Sika PDS - E - Icosit KC 340-65Document4 pagesSika PDS - E - Icosit KC 340-65lwin_oo2435No ratings yet

- Epiz 3Document3 pagesEpiz 3Bobbie RuckNo ratings yet

- S Weld Passivator Gel TDSDocument3 pagesS Weld Passivator Gel TDSSuryana MamanNo ratings yet

- Sikacrete - 114: Free Flowing Microconcrete For Grouting and RepairDocument3 pagesSikacrete - 114: Free Flowing Microconcrete For Grouting and RepairQazinadeemNo ratings yet

- Sikaflex®-11 FC: Product Data SheetDocument3 pagesSikaflex®-11 FC: Product Data SheetHaradhon DattaNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- 2 Sikacrete-114 PDS GCC (06-2018) 1 1Document3 pages2 Sikacrete-114 PDS GCC (06-2018) 1 1Sri KanthNo ratings yet

- Sikaflex 11FC - PDS PDFDocument4 pagesSikaflex 11FC - PDS PDFrajeevNo ratings yet

- TDS - SealantDocument2 pagesTDS - Sealantriteish singhNo ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- Ipd Pds Sikaflex221 Us 1Document4 pagesIpd Pds Sikaflex221 Us 1Dennis UbillusNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- Sika® Rokkon C-Id: Product Data SheetDocument2 pagesSika® Rokkon C-Id: Product Data Sheetal mukarramahNo ratings yet

- Anti Toxic PicklingDocument2 pagesAnti Toxic PicklingGaurav Bedi0% (1)

- Sika® Antisol® A: Product Data SheetDocument2 pagesSika® Antisol® A: Product Data SheettashadzureenNo ratings yet

- Sika Wall Coat - EGDocument2 pagesSika Wall Coat - EGthe pilotNo ratings yet

- 15 07 17 FT SiMP High TackDocument4 pages15 07 17 FT SiMP High TackAmon AlastorNo ratings yet

- TP 9202 18 Surface Preparation and Application of Glass Flake CoatingsDocument3 pagesTP 9202 18 Surface Preparation and Application of Glass Flake CoatingsSaranik DattaNo ratings yet

- Coaltar EpoxyDocument2 pagesCoaltar EpoxyAnonymous YN4aNlNo ratings yet

- Elastomeric Waterproofing: Resin Powder Grey Powder WhiteDocument2 pagesElastomeric Waterproofing: Resin Powder Grey Powder WhiteUpulHettiarachchiNo ratings yet

- Silica Fume 92% Technical Data Sheet: Description Physical PropertiesDocument1 pageSilica Fume 92% Technical Data Sheet: Description Physical PropertiesDileepa DissanayakeNo ratings yet

- Davco k11 Slurry613Document3 pagesDavco k11 Slurry613Harold PicoNo ratings yet

- X-Shield AcrylCoatDocument2 pagesX-Shield AcrylCoatEGO AnimationNo ratings yet

- Sikagard ElastoColor-675 WDocument4 pagesSikagard ElastoColor-675 WAgung RahmadiNo ratings yet

- Yarn Finish FormulationsDocument6 pagesYarn Finish Formulationsali rezaeiNo ratings yet

- Lindab ColourDocument1 pageLindab ColourNetrom76No ratings yet

- 5754 Aluminum CircleDocument2 pages5754 Aluminum Circlewei huaNo ratings yet

- A1 Poster - Adjustable WrenchDocument1 pageA1 Poster - Adjustable WrenchKah KiatNo ratings yet

- Aluminium WeldingDocument2 pagesAluminium WeldingARYANo ratings yet

- PWHT ProcedureDocument8 pagesPWHT ProcedureTuesou MachereNo ratings yet

- Characteristics of Cutting Steels and Saw Tooth Forms: Metal Cutting Circular Saws Vary in 7 AspectsDocument8 pagesCharacteristics of Cutting Steels and Saw Tooth Forms: Metal Cutting Circular Saws Vary in 7 AspectsAlvaro RochaNo ratings yet

- Te-Econom Plus Te-Econom Flow Te-Econom Bond Eco-Etch: Instructions For UseDocument40 pagesTe-Econom Plus Te-Econom Flow Te-Econom Bond Eco-Etch: Instructions For UseAngeles Jimenez SanchezNo ratings yet

- 0710 Bodycote PDFDocument13 pages0710 Bodycote PDFRuchira Chanda InduNo ratings yet

- TG Comparison With Shell BirdDocument572 pagesTG Comparison With Shell BirdJason SecretNo ratings yet

- Type of Steel OF Ikea CherasDocument5 pagesType of Steel OF Ikea CherasSiti HajarNo ratings yet

- Brosur Gradino Juli 2022Document16 pagesBrosur Gradino Juli 2022Khansa AnastyaNo ratings yet

- Saems 1000 V 003Document33 pagesSaems 1000 V 003kyletgerberNo ratings yet

- PJC Inorganic ChemistryDocument8 pagesPJC Inorganic ChemistryThint San Naing HeinNo ratings yet

- SCH3U - Acids & Bases WorksheetDocument2 pagesSCH3U - Acids & Bases WorksheetRuby Angel MannNo ratings yet

- Notes Chemistry DLP F4Document79 pagesNotes Chemistry DLP F4Aleisha SofeaNo ratings yet

- Termite Proofing: Construction Engineering CE-374 Dr. Rai Waqas Azfar KhanDocument24 pagesTermite Proofing: Construction Engineering CE-374 Dr. Rai Waqas Azfar KhanBilal Ashraf100% (1)

- Distilling ParrotDocument18 pagesDistilling Parrotapi-1821010100% (2)

- Ultimate Analysis of Coal and Coke Samples.: Energy Engineering LabDocument3 pagesUltimate Analysis of Coal and Coke Samples.: Energy Engineering LabHafiz hassanNo ratings yet

- Ansi-Aws A5 - 18-93Document37 pagesAnsi-Aws A5 - 18-93skrkulachiNo ratings yet

- Enhanced Mechanical and Thermal Properties of Rigid Polyurethane Foam Composites Containing Graphene Nanosheets and Carbon NanotubesDocument8 pagesEnhanced Mechanical and Thermal Properties of Rigid Polyurethane Foam Composites Containing Graphene Nanosheets and Carbon NanotubesBurcu UzunoğluNo ratings yet

- Study of Components (Hydrogen Chloride) : Lab Preparation of HCLDocument4 pagesStudy of Components (Hydrogen Chloride) : Lab Preparation of HCLSANDEEP SINGHNo ratings yet

- Technical Data Sheet: UHU Plus Endfest 300Document5 pagesTechnical Data Sheet: UHU Plus Endfest 300mitchiNo ratings yet

- Experiment 19Document3 pagesExperiment 19Beenu SinghNo ratings yet

- General Purpose and Blended Cements: Australian StandardDocument7 pagesGeneral Purpose and Blended Cements: Australian StandardKrist Jan Jimenez SeparaNo ratings yet

- Chapter 1 (1-74) FinalDocument74 pagesChapter 1 (1-74) FinalAbdul Basit AnsariNo ratings yet

- Acids and BasesDocument13 pagesAcids and Basestismon86% (7)

- List of Companies/Llps Registered During The Year 1982Document156 pagesList of Companies/Llps Registered During The Year 1982Harsh PunmiyaNo ratings yet

- Wood Ash Vs Wood PowderDocument6 pagesWood Ash Vs Wood Powdervignesh natarajanNo ratings yet