Professional Documents

Culture Documents

Blue Gard 3200 Data Sheet

Blue Gard 3200 Data Sheet

Uploaded by

saidCopyright:

Available Formats

You might also like

- Q400.amm (76) .Amm05 11 00 992 802Document11 pagesQ400.amm (76) .Amm05 11 00 992 802Naresh Kumar5No ratings yet

- MB Pricelist 2 ND Hy 2012Document81 pagesMB Pricelist 2 ND Hy 2012khaloodcdNo ratings yet

- Introduction Into Object Orientation - Oops Introduction Into Object OrientationDocument30 pagesIntroduction Into Object Orientation - Oops Introduction Into Object OrientationManoj MahajanNo ratings yet

- Garlock Blue Gard 3200 Data SheetDocument1 pageGarlock Blue Gard 3200 Data SheetsaidNo ratings yet

- Garlock 9900 Data Sheet PDFDocument1 pageGarlock 9900 Data Sheet PDFMartin Andrew TugadeNo ratings yet

- Garlock Style 3000 Spec Sheet - (NA) 2016-11 enDocument1 pageGarlock Style 3000 Spec Sheet - (NA) 2016-11 enalan2003_1_29040No ratings yet

- GarlockGAS9800SpecSheetJan2016 ENDocument2 pagesGarlockGAS9800SpecSheetJan2016 ENLAKHTIRINo ratings yet

- Garlock Style 9900 Spec Sheet - (NA) 2021-09 ENDocument1 pageGarlock Style 9900 Spec Sheet - (NA) 2021-09 ENDrojanle MezbraNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNo ratings yet

- Garlock 700Document1 pageGarlock 700Jairo ArroyoNo ratings yet

- Garlock Graph Lock 3125ssDocument1 pageGarlock Graph Lock 3125ssJhon AlarconNo ratings yet

- 3504 Blue Gylon Data Sheet PDFDocument1 page3504 Blue Gylon Data Sheet PDFYnuzneNo ratings yet

- Garlock GYLON 3500Document1 pageGarlock GYLON 3500echavarriNo ratings yet

- Garlock Style 700 Spec Sheet - (NA) 2016-11 enDocument1 pageGarlock Style 700 Spec Sheet - (NA) 2016-11 enMarín HernándezNo ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enAndres Rodriguez HerreraNo ratings yet

- Garlock Style 5500 Spec SheetDocument1 pageGarlock Style 5500 Spec SheetSreekanthNo ratings yet

- Garlock Style 5500 Spec Sheet - (NA) 2016-11 ENDocument1 pageGarlock Style 5500 Spec Sheet - (NA) 2016-11 ENALONSO GOMEZNo ratings yet

- Gar Lock 3500Document2 pagesGar Lock 3500Stefano SalicchiNo ratings yet

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDocument1 pageGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungNo ratings yet

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- Garlock Hi TempDocument4 pagesGarlock Hi Temprock starNo ratings yet

- Style 2900 Data SheetDocument1 pageStyle 2900 Data SheetRicardo OrdoñezNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsRicardo Perez VerdugoNo ratings yet

- Garlock 22 Red SBR Rubber Sheet Data SheetDocument1 pageGarlock 22 Red SBR Rubber Sheet Data SheetkasebNo ratings yet

- Polyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISDocument2 pagesPolyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISAMARENDRA SINo ratings yet

- Ki LSHF 3401 IsDocument2 pagesKi LSHF 3401 IsjamilNo ratings yet

- Eddy Current Converter en 1723496Document4 pagesEddy Current Converter en 1723496Miguel Bartolo CruzNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- Tafa 30TDocument4 pagesTafa 30TSidgrunionNo ratings yet

- 90MXC - UltraHardDocument4 pages90MXC - UltraHardSidgrunionNo ratings yet

- Garlock Style 706 Data SheetDocument1 pageGarlock Style 706 Data SheetArturo Gasperin BarrigaNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- Coupling Grinnell G110!08!2018Document4 pagesCoupling Grinnell G110!08!2018Claudia YanesNo ratings yet

- INTIME-ABC-6-40%-SP-Data (UPDATED)Document1 pageINTIME-ABC-6-40%-SP-Data (UPDATED)uday245No ratings yet

- 8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationDocument2 pages8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationIrving Alan Uc FernandezNo ratings yet

- 3510 Off White Gylon Data SheetDocument1 page3510 Off White Gylon Data SheetJose CarlosNo ratings yet

- 5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Document8 pages5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Nicholas RichardsonNo ratings yet

- Superlite 111: Technical Data Sheet Material CompositionDocument4 pagesSuperlite 111: Technical Data Sheet Material CompositionSrikumar Krishnamuruthy100% (1)

- Ifg 5500Document1 pageIfg 5500Amir100% (1)

- EMKARATE RL 170H Product Data SheetDocument1 pageEMKARATE RL 170H Product Data SheetNibaldo KamelNo ratings yet

- Hyvolt IibrochureDocument1 pageHyvolt Iibrochuresamuel cruz menddozaNo ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- SECCO S2040: Polypropylene, HomopolymerDocument2 pagesSECCO S2040: Polypropylene, HomopolymerManuel Lopez100% (1)

- Chemonit 181Document4 pagesChemonit 181Zack OsNo ratings yet

- 3107A TechdataDocument2 pages3107A TechdataComercial FirenoNo ratings yet

- Masico M025 ResealDocument4 pagesMasico M025 ResealDEIVYNo ratings yet

- 347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Document4 pages347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Prem NautiyalNo ratings yet

- TDS - Flexible AluminiumDocument3 pagesTDS - Flexible Aluminiumvysakh5588No ratings yet

- 2.66 Klingersil c4400 TdsDocument2 pages2.66 Klingersil c4400 TdsAndhy JwNo ratings yet

- Iig - ENERWRAP - MA - 960DataSheetDocument1 pageIig - ENERWRAP - MA - 960DataSheettmp_rootsNo ratings yet

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocument2 pagesHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNo ratings yet

- 1.4845 EnglDocument3 pages1.4845 EnglpdmsNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- BS7531 Grade X. MASTERDocument1 pageBS7531 Grade X. MASTERKishor JadhavNo ratings yet

- TDS 01ofg V08 enDocument2 pagesTDS 01ofg V08 enDenisTarasNo ratings yet

- TDS Hips 2551Document3 pagesTDS Hips 2551jokotrianto13No ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- Design and Dynamic Analysis of Steel Chimney in Staad Pro: Vol. 8, No. 9, 2023, PP. 38 - 42Document5 pagesDesign and Dynamic Analysis of Steel Chimney in Staad Pro: Vol. 8, No. 9, 2023, PP. 38 - 42saidNo ratings yet

- Partner Juli EngineeringDocument3 pagesPartner Juli EngineeringsaidNo ratings yet

- Askeland FMDocument2 pagesAskeland FMsaidNo ratings yet

- Mathematical Model and Factors of Paste Thickener Rake TorqueDocument5 pagesMathematical Model and Factors of Paste Thickener Rake TorquesaidNo ratings yet

- Mechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期Document1 pageMechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期saidNo ratings yet

- Process, Plant and Equipment UP-TIME: Belt Bucket Elevator Design, Use & CareDocument27 pagesProcess, Plant and Equipment UP-TIME: Belt Bucket Elevator Design, Use & CaresaidNo ratings yet

- Cross Flow Heat ExchangerDocument9 pagesCross Flow Heat ExchangerEmmanuel AgdeppaNo ratings yet

- Re - 1990-11Document100 pagesRe - 1990-11Anonymous kdqf49qb100% (1)

- Daniel Hutto Radical EnactivismDocument269 pagesDaniel Hutto Radical Enactivismandre magela100% (5)

- After Action Report 755th Tank BattalionDocument103 pagesAfter Action Report 755th Tank Battalioncjnjr1No ratings yet

- Computer Network System Administrator Interview QuestionDocument4 pagesComputer Network System Administrator Interview Questionkk4953No ratings yet

- Huawei V1R8 V3R5 Software Upgrade Guide v1 2Document58 pagesHuawei V1R8 V3R5 Software Upgrade Guide v1 2ivanjcm85No ratings yet

- The Lean Enterprise (Memory Jogger III)Document172 pagesThe Lean Enterprise (Memory Jogger III)bhnodar100% (1)

- Window AC Breeze Master R410ADocument2 pagesWindow AC Breeze Master R410ARAFID SUHAILNo ratings yet

- Method Statement For Concrete Repairing.Document10 pagesMethod Statement For Concrete Repairing.Smart ShivaNo ratings yet

- Precast Concrete Precast ConcreteDocument32 pagesPrecast Concrete Precast Concreteflower lilyNo ratings yet

- PR 6 2022Document38 pagesPR 6 2022Beh Jing HongNo ratings yet

- Data Mining and Data Warehouse BYDocument12 pagesData Mining and Data Warehouse BYapi-19799369100% (1)

- Stamping It OutDocument8 pagesStamping It OutKurt Phelps100% (1)

- Money of The FutureDocument321 pagesMoney of The FutureWeb Financial Group100% (1)

- Bibhuti ChowdhuryDocument4 pagesBibhuti ChowdhuryramkumargobpoNo ratings yet

- 1a Solarity Project-Charter-TEMPLATEDocument5 pages1a Solarity Project-Charter-TEMPLATEMehar AliNo ratings yet

- Desenllantadora Marca Coseng Modelo Cd540aDocument42 pagesDesenllantadora Marca Coseng Modelo Cd540ajhan123j100% (1)

- Eberspacher Airtronic D2 InstructionsDocument34 pagesEberspacher Airtronic D2 InstructionsDavid Butler100% (1)

- Sally Blake, Denise Winsor, Lee Allen-Technology and Young Children - Bridging The Communication-Generation Gap - Information Science Pub (2011)Document326 pagesSally Blake, Denise Winsor, Lee Allen-Technology and Young Children - Bridging The Communication-Generation Gap - Information Science Pub (2011)Daniela CracanNo ratings yet

- An Assignment ON Wealth Management Organisation: Submitted by S. Ramnath (098004100038) Ii Mba-BimDocument5 pagesAn Assignment ON Wealth Management Organisation: Submitted by S. Ramnath (098004100038) Ii Mba-Bimanon_552306714No ratings yet

- Daily Lesson Log in Research 2Document1 pageDaily Lesson Log in Research 2Mylz Villarin100% (5)

- VSWR Rru AirkelikDocument3 pagesVSWR Rru AirkelikDwicahyo Aris WinartoNo ratings yet

- The Toyota Way20060913024959Document4 pagesThe Toyota Way20060913024959Nishant GuptaNo ratings yet

- Roll FormingDocument19 pagesRoll FormingIstvan WunderlichNo ratings yet

- For Office Use Only: Important InstructionsDocument4 pagesFor Office Use Only: Important InstructionsAmit SrivastavaNo ratings yet

- Unit 16 Food Packaging (CRC) PDFDocument44 pagesUnit 16 Food Packaging (CRC) PDFdineshsirasatNo ratings yet

- Six SigmaDocument59 pagesSix Sigmasumit15509270No ratings yet

Blue Gard 3200 Data Sheet

Blue Gard 3200 Data Sheet

Uploaded by

saidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blue Gard 3200 Data Sheet

Blue Gard 3200 Data Sheet

Uploaded by

saidCopyright:

Available Formats

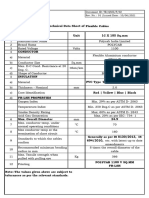

Technical Data Sheet

MATERIAL PROPERTIES*: Blue-Gard® 3200

Colour: Off-White

Composition: Aramid fibres with a

SBR binder

Fluid Services: Water, saturated

steam3 inert gases

Asbestos Free

Temperature1 , °F (°C)

Minimum: -100 (-73)

Continuous Maximum: +400 (+205)

Maximum: +700 (+371)

Pressure1 , Maximum, psig (bar): 1200 (83)

P x T (max.)1 , psig x °F (bar x °C):

1/32 and 1/16”: 350,000 (12,000)

1/8” 250,000 (8,600)

Meets Specifications: ABS (American Bureau of Shipping) and MIL-DTL-24696

Type II4

TYPICAL PHYSICAL PROPERTIES*:

ASTM F36 Compressibility, average, %: 10

ASTM F36 Recovery, %: 50

ASTM F38 Creep Relaxation, %: 18

ASTM D1708 Tensile, Across Grain, psi (N/mm2 ): 2250 (15)

ASTM F1315 Density lbs/ft3 (grams/cm3): 100 (1.60)

ASTM F433 Thermal Conductivity (K), W/m°K (Btu in/ hr ft2 °F): 0.29 - 0.38 (2.00 - 2.65)

SEALING CHARACTERISTICS*

ASTM F37B – Fuel A ASTM F37B – Nitrogen DIN 3535 - Nitrogen

Gasket Load, psi (N/mm2): 500 (3.5) 3000 (20.7) 4640 (32)

Internal Pressure, psig (bar): 9.8 (0.7) 30 (2) 580 (40)

Leakage 0.3 ml/hr. 0.7 ml/hr 0.03 cc/min

Notes: * This is a general guide and should not be the sole means of selecting or rejecting this material. This data sheet covers basic

information, for more comprehensive information, please contact us.

ASTM test results in accordance with ASTM F-104; properties

1

Based on ANSI RF flanges at our preferred torque. When approaching maximum pressure, continuous operating temperature, minimum

temperature or 50% of maximum PxT, consult Garlock Applications Engineering. Minimum temperature rating is conservative.

2

Indicates electric current arced around and not through the gasket. Dielectric strength is higher than indicated.

3

These styles are not preferred choices for steam service, but are successful when adequately compressed Minimum recommended assembly

stress = 4,800psi. Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16" strongly preferred. Re-torque the bolts/studs prior to

pressurizing the assembly. For saturated steam above 150psig or superheated steam, consult us.

4

To ensure receipt of product branded Mil-DTL-24696, certification will be required- - fees associated based on quantity. Refer to ""Military

Specifications"" in the Gasketing Terms section of the Engineered Gasket Products catalogue for order/inquiry requirements.

Contact

Care should be taken in selecting the most suitable

Telephone: +44 (0)1625 573971

quality for each application. Advice is available, but

FAX: +44 (0)1625 573250

final responsibility remains with the customer.

Munsch & Co/PTM Ltd

Units AG2/3 Clarence Mill

Web: www.epdm.co.uk Clarence Road, Bollington

E-Mail: Sales@epdm.co.uk Macclesfield, Cheshire

SK10 5JZ

United Kingdom

You might also like

- Q400.amm (76) .Amm05 11 00 992 802Document11 pagesQ400.amm (76) .Amm05 11 00 992 802Naresh Kumar5No ratings yet

- MB Pricelist 2 ND Hy 2012Document81 pagesMB Pricelist 2 ND Hy 2012khaloodcdNo ratings yet

- Introduction Into Object Orientation - Oops Introduction Into Object OrientationDocument30 pagesIntroduction Into Object Orientation - Oops Introduction Into Object OrientationManoj MahajanNo ratings yet

- Garlock Blue Gard 3200 Data SheetDocument1 pageGarlock Blue Gard 3200 Data SheetsaidNo ratings yet

- Garlock 9900 Data Sheet PDFDocument1 pageGarlock 9900 Data Sheet PDFMartin Andrew TugadeNo ratings yet

- Garlock Style 3000 Spec Sheet - (NA) 2016-11 enDocument1 pageGarlock Style 3000 Spec Sheet - (NA) 2016-11 enalan2003_1_29040No ratings yet

- GarlockGAS9800SpecSheetJan2016 ENDocument2 pagesGarlockGAS9800SpecSheetJan2016 ENLAKHTIRINo ratings yet

- Garlock Style 9900 Spec Sheet - (NA) 2021-09 ENDocument1 pageGarlock Style 9900 Spec Sheet - (NA) 2021-09 ENDrojanle MezbraNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNo ratings yet

- Garlock 700Document1 pageGarlock 700Jairo ArroyoNo ratings yet

- Garlock Graph Lock 3125ssDocument1 pageGarlock Graph Lock 3125ssJhon AlarconNo ratings yet

- 3504 Blue Gylon Data Sheet PDFDocument1 page3504 Blue Gylon Data Sheet PDFYnuzneNo ratings yet

- Garlock GYLON 3500Document1 pageGarlock GYLON 3500echavarriNo ratings yet

- Garlock Style 700 Spec Sheet - (NA) 2016-11 enDocument1 pageGarlock Style 700 Spec Sheet - (NA) 2016-11 enMarín HernándezNo ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enAndres Rodriguez HerreraNo ratings yet

- Garlock Style 5500 Spec SheetDocument1 pageGarlock Style 5500 Spec SheetSreekanthNo ratings yet

- Garlock Style 5500 Spec Sheet - (NA) 2016-11 ENDocument1 pageGarlock Style 5500 Spec Sheet - (NA) 2016-11 ENALONSO GOMEZNo ratings yet

- Gar Lock 3500Document2 pagesGar Lock 3500Stefano SalicchiNo ratings yet

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDocument1 pageGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungNo ratings yet

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- Garlock Hi TempDocument4 pagesGarlock Hi Temprock starNo ratings yet

- Style 2900 Data SheetDocument1 pageStyle 2900 Data SheetRicardo OrdoñezNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsRicardo Perez VerdugoNo ratings yet

- Garlock 22 Red SBR Rubber Sheet Data SheetDocument1 pageGarlock 22 Red SBR Rubber Sheet Data SheetkasebNo ratings yet

- Polyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISDocument2 pagesPolyolefin Copolymer Halogen Free Cable Insulation Compound: KI-LSHF-3401-ISAMARENDRA SINo ratings yet

- Ki LSHF 3401 IsDocument2 pagesKi LSHF 3401 IsjamilNo ratings yet

- Eddy Current Converter en 1723496Document4 pagesEddy Current Converter en 1723496Miguel Bartolo CruzNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- Tafa 30TDocument4 pagesTafa 30TSidgrunionNo ratings yet

- 90MXC - UltraHardDocument4 pages90MXC - UltraHardSidgrunionNo ratings yet

- Garlock Style 706 Data SheetDocument1 pageGarlock Style 706 Data SheetArturo Gasperin BarrigaNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- Coupling Grinnell G110!08!2018Document4 pagesCoupling Grinnell G110!08!2018Claudia YanesNo ratings yet

- INTIME-ABC-6-40%-SP-Data (UPDATED)Document1 pageINTIME-ABC-6-40%-SP-Data (UPDATED)uday245No ratings yet

- 8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationDocument2 pages8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationIrving Alan Uc FernandezNo ratings yet

- 3510 Off White Gylon Data SheetDocument1 page3510 Off White Gylon Data SheetJose CarlosNo ratings yet

- 5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Document8 pages5.0 MM Dia Led Lamp 540R2GBC-CC: REV:A / 0Nicholas RichardsonNo ratings yet

- Superlite 111: Technical Data Sheet Material CompositionDocument4 pagesSuperlite 111: Technical Data Sheet Material CompositionSrikumar Krishnamuruthy100% (1)

- Ifg 5500Document1 pageIfg 5500Amir100% (1)

- EMKARATE RL 170H Product Data SheetDocument1 pageEMKARATE RL 170H Product Data SheetNibaldo KamelNo ratings yet

- Hyvolt IibrochureDocument1 pageHyvolt Iibrochuresamuel cruz menddozaNo ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- SECCO S2040: Polypropylene, HomopolymerDocument2 pagesSECCO S2040: Polypropylene, HomopolymerManuel Lopez100% (1)

- Chemonit 181Document4 pagesChemonit 181Zack OsNo ratings yet

- 3107A TechdataDocument2 pages3107A TechdataComercial FirenoNo ratings yet

- Masico M025 ResealDocument4 pagesMasico M025 ResealDEIVYNo ratings yet

- 347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Document4 pages347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Prem NautiyalNo ratings yet

- TDS - Flexible AluminiumDocument3 pagesTDS - Flexible Aluminiumvysakh5588No ratings yet

- 2.66 Klingersil c4400 TdsDocument2 pages2.66 Klingersil c4400 TdsAndhy JwNo ratings yet

- Iig - ENERWRAP - MA - 960DataSheetDocument1 pageIig - ENERWRAP - MA - 960DataSheettmp_rootsNo ratings yet

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocument2 pagesHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNo ratings yet

- 1.4845 EnglDocument3 pages1.4845 EnglpdmsNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- BS7531 Grade X. MASTERDocument1 pageBS7531 Grade X. MASTERKishor JadhavNo ratings yet

- TDS 01ofg V08 enDocument2 pagesTDS 01ofg V08 enDenisTarasNo ratings yet

- TDS Hips 2551Document3 pagesTDS Hips 2551jokotrianto13No ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- Design and Dynamic Analysis of Steel Chimney in Staad Pro: Vol. 8, No. 9, 2023, PP. 38 - 42Document5 pagesDesign and Dynamic Analysis of Steel Chimney in Staad Pro: Vol. 8, No. 9, 2023, PP. 38 - 42saidNo ratings yet

- Partner Juli EngineeringDocument3 pagesPartner Juli EngineeringsaidNo ratings yet

- Askeland FMDocument2 pagesAskeland FMsaidNo ratings yet

- Mathematical Model and Factors of Paste Thickener Rake TorqueDocument5 pagesMathematical Model and Factors of Paste Thickener Rake TorquesaidNo ratings yet

- Mechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期Document1 pageMechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期saidNo ratings yet

- Process, Plant and Equipment UP-TIME: Belt Bucket Elevator Design, Use & CareDocument27 pagesProcess, Plant and Equipment UP-TIME: Belt Bucket Elevator Design, Use & CaresaidNo ratings yet

- Cross Flow Heat ExchangerDocument9 pagesCross Flow Heat ExchangerEmmanuel AgdeppaNo ratings yet

- Re - 1990-11Document100 pagesRe - 1990-11Anonymous kdqf49qb100% (1)

- Daniel Hutto Radical EnactivismDocument269 pagesDaniel Hutto Radical Enactivismandre magela100% (5)

- After Action Report 755th Tank BattalionDocument103 pagesAfter Action Report 755th Tank Battalioncjnjr1No ratings yet

- Computer Network System Administrator Interview QuestionDocument4 pagesComputer Network System Administrator Interview Questionkk4953No ratings yet

- Huawei V1R8 V3R5 Software Upgrade Guide v1 2Document58 pagesHuawei V1R8 V3R5 Software Upgrade Guide v1 2ivanjcm85No ratings yet

- The Lean Enterprise (Memory Jogger III)Document172 pagesThe Lean Enterprise (Memory Jogger III)bhnodar100% (1)

- Window AC Breeze Master R410ADocument2 pagesWindow AC Breeze Master R410ARAFID SUHAILNo ratings yet

- Method Statement For Concrete Repairing.Document10 pagesMethod Statement For Concrete Repairing.Smart ShivaNo ratings yet

- Precast Concrete Precast ConcreteDocument32 pagesPrecast Concrete Precast Concreteflower lilyNo ratings yet

- PR 6 2022Document38 pagesPR 6 2022Beh Jing HongNo ratings yet

- Data Mining and Data Warehouse BYDocument12 pagesData Mining and Data Warehouse BYapi-19799369100% (1)

- Stamping It OutDocument8 pagesStamping It OutKurt Phelps100% (1)

- Money of The FutureDocument321 pagesMoney of The FutureWeb Financial Group100% (1)

- Bibhuti ChowdhuryDocument4 pagesBibhuti ChowdhuryramkumargobpoNo ratings yet

- 1a Solarity Project-Charter-TEMPLATEDocument5 pages1a Solarity Project-Charter-TEMPLATEMehar AliNo ratings yet

- Desenllantadora Marca Coseng Modelo Cd540aDocument42 pagesDesenllantadora Marca Coseng Modelo Cd540ajhan123j100% (1)

- Eberspacher Airtronic D2 InstructionsDocument34 pagesEberspacher Airtronic D2 InstructionsDavid Butler100% (1)

- Sally Blake, Denise Winsor, Lee Allen-Technology and Young Children - Bridging The Communication-Generation Gap - Information Science Pub (2011)Document326 pagesSally Blake, Denise Winsor, Lee Allen-Technology and Young Children - Bridging The Communication-Generation Gap - Information Science Pub (2011)Daniela CracanNo ratings yet

- An Assignment ON Wealth Management Organisation: Submitted by S. Ramnath (098004100038) Ii Mba-BimDocument5 pagesAn Assignment ON Wealth Management Organisation: Submitted by S. Ramnath (098004100038) Ii Mba-Bimanon_552306714No ratings yet

- Daily Lesson Log in Research 2Document1 pageDaily Lesson Log in Research 2Mylz Villarin100% (5)

- VSWR Rru AirkelikDocument3 pagesVSWR Rru AirkelikDwicahyo Aris WinartoNo ratings yet

- The Toyota Way20060913024959Document4 pagesThe Toyota Way20060913024959Nishant GuptaNo ratings yet

- Roll FormingDocument19 pagesRoll FormingIstvan WunderlichNo ratings yet

- For Office Use Only: Important InstructionsDocument4 pagesFor Office Use Only: Important InstructionsAmit SrivastavaNo ratings yet

- Unit 16 Food Packaging (CRC) PDFDocument44 pagesUnit 16 Food Packaging (CRC) PDFdineshsirasatNo ratings yet

- Six SigmaDocument59 pagesSix Sigmasumit15509270No ratings yet