Professional Documents

Culture Documents

Fewa Ge Gen TS 0111

Fewa Ge Gen TS 0111

Uploaded by

Joe PsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fewa Ge Gen TS 0111

Fewa Ge Gen TS 0111

Uploaded by

Joe PsCopyright:

Available Formats

Electricity Directorate – Asset Management دائرة الكهرباء – إدارة اﻷصول

Form Name: Technical Specifications المواصفات الفنية:اسم النموذج

GENERAL TECHNICAL SPECIFICATION

FEWA-GE-GEN-TS-0111, Rev 0, Sep 2019

PROCESS NAME: MAINTAIN ENGINEERING SPECIFICATIONS

FEWA-ED-L2-AM-P05-F01 REV. NO. 0 REV. DATE: Sep 2019 PAGE 1 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

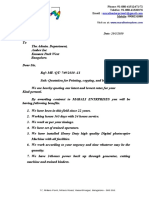

184E/2020

TABLE OF CONTENTS

1. INTRODUCTION ....................................................................................................................... 5

2. INTENT OF SPECIFICATION ................................................................................................... 5

3. SCOPE OF WORK .................................................................................................................... 5

3.1. Site Surveys .......................................................................................................................... 5

3.2. Standards .............................................................................................................................. 7

3.3. Compliance with Specification ............................................................................................ 7

3.4. Plant Design .......................................................................................................................... 7

3.4.1. General ............................................................................................................................. 7

3.4.2. Experience ........................................................................................................................ 8

3.4.3. Standard Materials and Equipment ................................................................................... 8

3.5. Layout of Plant and Buildings ............................................................................................. 9

3.6. Drawings and Schedules ...................................................................................................... 9

3.7. Manuals and Books ............................................................................................................ 11

3.8. Approval Procedure ............................................................................................................ 11

3.8.1. General ........................................................................................................................... 11

3.8.2. Distribution of Documents ................................................................................................ 13

3.8.3 Approval of Documents ................................................................................................... 15

3.8.4. Dispatch of Approved Documents .................................................................................... 16

3.9. Way Leaves, Temporary Roads, Site and Route Approvals............................................ 16

3.10. Quality of Material and Workmanship ............................................................................ 16

3.11. Substitution of Material and Equipment ........................................................................ 17

3.12. Inspection and Testing during Manufacture .................................................................. 17

3.13. Access to Workshops ...................................................................................................... 18

3.14. Packing and Marking ....................................................................................................... 18

3.15. Manufacture Progress Information ................................................................................. 19

3.16. Project Schedule / Program ............................................................................................ 20

3.17. Progress Reports ............................................................................................................. 21

3.17.1. Summary ......................................................................................................................... 21

3.17.2. Project Schedule / Program ............................................................................................ 21

3.17.3. Updated Schedules ......................................................................................................... 22

3.17.4. Financial Report .............................................................................................................. 22

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 2 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

3.17.5. Site Report ...................................................................................................................... 23

3.18. Transport .......................................................................................................................... 23

3.18.1. Shipping Documents ....................................................................................................... 23

3.18.2. Transport to Port of Embarkation, Loading & Unloading ................................................. 24

3.18.3. Overseas Transport ........................................................................................................ 24

3.18.4. Local Transport ............................................................................................................... 24

3.18.5. Receiving-Cum-Damage Reports ................................................................................... 25

3.18.6. Title to the Plant .............................................................................................................. 25

3.19. Erection Work ................................................................................................................... 25

3.19.1. Commencement of Erection ............................................................................................ 25

3.19.2. Unloading and Storage at Site ........................................................................................ 26

3.19.3. Performance of Erection ................................................................................................. 26

3.19.4. Clearance of Site............................................................................................................. 26

3.19.5. Surplus Material .............................................................................................................. 27

3.19.6. Contractor's and Sub-Contractor's Personnel ................................................................. 27

3.19.7. Visa Formalities............................................................................................................... 29

3.19.8. Safety for Workmen and Public ....................................................................................... 29

3.19.9 Temporary Supply of Electric Power and Water ............................................................. 30

3.19.10. Temporary Offices and Sanitary Accommodation, Etc. ................................................. 30

3.19.11. Accommodation for Contractor's Personnel .................................................................. 30

3.19.12. Transport Facilities for Personnel.................................................................................. 31

3.19.13. First Aid Facilities .......................................................................................................... 31

3.19.14. Watching, Lighting and Fencing .................................................................................... 31

3.19.15. Fire Fighting Equipment ................................................................................................ 31

3.19.16. Signboards .................................................................................................................... 31

3.19.17. Erection Progress Report .............................................................................................. 31

3.19.18. Site Records ................................................................................................................. 32

3.20. Training of Authority's Personnel .................................................................................. 32

3.21. Examination of Work Before Covering Up ..................................................................... 32

3.22. Existing Services ............................................................................................................. 33

3.23. Planning of Works and Levels ........................................................................................ 33

3.24. System of Works and Cooperation with Other Contractors at Site ............................. 34

3.24.1. System of Work ............................................................................................................... 34

3.24.2. Cooperation with Other Contractor.................................................................................. 34

3.25. Spare Parts, Special and Workshop Tools .................................................................... 34

3.25.1. Tools and Appliances ...................................................................................................... 36

3.25.2. Spares ............................................................................................................................. 36

3.26. Connecting of Plant with Existing Plant ........................................................................ 37

3.27. Quality Assurance............................................................................................................ 37

3.28. Erection Marks ................................................................................................................. 38

3.29. Cleaning and Painting ..................................................................................................... 38

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 3 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

3.30. Rating Plates, Nameplates and Labels ........................................................................... 39

3.31. Tropicalisation.................................................................................................................. 39

3.32. Nuts, Bolts, Studs and Washers ..................................................................................... 40

3.33. Rivets ................................................................................................................................ 40

3.34. Forgings ............................................................................................................................ 41

3.35. Castings ............................................................................................................................ 41

3.36. Welding ............................................................................................................................. 41

3.37. Galvanized Work .............................................................................................................. 42

3.38. Chromium Plating ............................................................................................................ 43

3.39. Oil or Compound Filled Chambers ................................................................................. 43

3.40. Locking Facilities ............................................................................................................. 43

3.41. Lubrication ....................................................................................................................... 44

3.42. Internal Cleaning of Pipes ............................................................................................... 44

3.43. Pipe Supports ................................................................................................................... 44

3.44. Valves................................................................................................................................ 45

3.45. Oil Level Indicators .......................................................................................................... 45

3.46. Pressure Gauges.............................................................................................................. 45

3.47. Thermometer Pockets ..................................................................................................... 46

3.48. GAUGE CUBICLES AND PANELS .................................................................................. 46

3.48.1 List of Standards .............................................................................................................. 46

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 4 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

1. INTRODUCTION

The Federal Electricity and Water Authority (FEWA) of the United Arab Emirates (UAE) intends

to construct new 132/11kV, 132/33/11kV and 33/11kV Substations and modifications/

extension etc. in the existing substations in Northern Emirates as detailed in the scope of work,

B.O.Q. etc.

This contract shall be undertaken in accordance with the General and Special Conditions of

Contract and the Technical Specifications enclosed.

2. INTENT OF SPECIFICATION

This specification covers the general requirements for design, engineering, construction,

supply, manufacture, testing, delivery, storing at site, installation, testing, commissioning and

putting into efficient and trouble-free commercial operation on a turnkey basis of the equipment

and materials for the new/extension and/or modification of existing 132/11kV, 132/33/11kV

and 33/11kV substations, interfacing with 132/33kV transmission lines/cables installed under

separate FEWA contract, matching with TRANSCO/ENG opposite circuits/ends and auxiliary

systems complete with all materials and accessories.

It is intended that this specification section, together with the applicable Technical

Specifications, drawings, Instruction to Tenderers, General Conditions of Contract, Special

Conditions of Contract, Technical details of offered equipment and Tender Forms shall form

the Tender Documents which will ultimately become a part of the Contract between the

Authority and the Contractor for the project.

3. SCOPE OF WORK

3.1. SITE SURVEYS

The scope shall include all necessary site surveys, investigations, which are to be carried out

by the Contractor before finalizing the detailed design and extent of work.

The cost of these surveys/investigations and the requirements coming out of these are deemed

to be included in the tender price. Site surveys shall include the following as minimum

requirements:

1. To establish the site levels, site boundaries, drainage arrangement etc. at each site,

2. Sub soil study at each site for foundation design,

3. Assessment of exact requirements each station included in SCMS / FEWA CC and

communication system to finalize the data base, plant interface requirement, power

supplies, etc.,

4. To establish the complete requirements of the modification works on primary and

protection/control equipment at each location, wherever the modification works are to be

carried out, and

5. Measurement of earth resistivity at each site to finalize the earthing design.

The detailed scope of work is specified in the tender documents.

The scope of work under the present contract shall also include but not be limited to the

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 5 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

following:

a) Special tools and tackles for operation

b) Spare parts for three (3) years of operation. The validity of spare parts, special tools,

recommended tools and tackles shall be 3 years from the date of last issue of Provisional

Taking Over Certificate (PTOC) of the works included in the contract.

c) All relevant drawings, data, calculation and instruction manuals.

The Tenderer shall include in his proposal a list of recommended tools, tackles test equipment

etc. and spares together with unit prices of each part.

The Authority will select the items to be procured within the validity period and the same will

be ordered accordingly within the validity period as above.

The scope of services under the present contract shall include but not be limited to the following

systems and facilities:

a) Obtaining final approval/demarcation of the sites by the appropriate local authorities for

the main substations and cable routes, approach/access roads etc. Obtaining necessary

No Objection Certificate from local authorities connected with services like gas, oil,

electricity, telephone, water, sewerage, drainage etc. All expenditure/deposit required by

the local authorities shall be paid by the Contractor and no extra payment shall be made

to the Contractor in this regard.

b) Site services & Site office facilities.

c) Unloading, inspection for shipping damage, storing of equipment.

d) Commissioning of all plant and equipment

e) Maintenance for Two years after commencement of commercial operation including

break down maintenance, preventive maintenance, defect liability including periodic

general maintenance as specified by the equipment manufacturers.

f) Project management.

g) Training of Authority’s operation, maintenance, protection, SCMS/ FEWA CC and

telecommunication personnels.

h) Coordination with other Contractors, Statutory Bodies, Outside Agencies and the

Authority/Engineer.

i) For work associated with an existing plant or plant under construction, the Contractor

shall be responsible for obtaining from the Contractor or Manufacturer of the plant (or the

Authority, if applicable) any drawings and/or information he may require in connection

with modifications and extensions to be carried out under this contract. The costs involved

are deemed to be included in the contract.

The Tenderer is to note that the information furnished in the specifications and drawings

regarding various sites represent the best available data and are solely for the purpose of

information/guidance. The Authority/Engineer do not assume any responsibility for the

correctness of the same. The Tenderer, prior to bidding, shall carefully visit every plant and

site and collect all information necessary for correctly estimating the extent of work and the

conditions under which the contract will be carried out. Any variations of Authority/Engineer

furnished data with the actual data obtained during the tender stage or execution stage shall

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 6 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

not be the cause for any price increase or other commercial/contractual implication

whatsoever.

3.2. STANDARDS

Wherever possible, and except where a specific standard has been mentioned in the Tender

Documents, materials used shall comply with the latest issues of the appropriate standards to

be valid at the date of contract award or later as mentioned in the instructions to

Tenderers.

The Contractor may apply other approved codes and standards belonging to the country of

manufacture of any equipment if not specified in the specification but this shall not be permitted

unless the Contractor proves to the satisfaction of the Authority/Engineer that these standards

are equivalent to the codes and standards applicable to this Specification, and the

Authority/Engineer issues in writing his approval of the same to the Contractor.

It shall be the responsibility of the Contractor to prove wherever required that the selected

codes and standards are equivalent or more onerous to the standards and codes indicated in

this Specification.

3.3. COMPLIANCE WITH SPECIFICATION

Notwithstanding any descriptions, drawings or illustrations which may have been submitted

with the Tender, all details other than those shown on the Schedule of deviations will be

deemed to be in accordance with the Specification and the standard specifications and codes

referred to therein.

No deviations from the Specification except those shown on the Schedule of deviations and

approved by the Authority, shall be made.

3.4. PLANT DESIGN

3.4.1. General

In complying with the requirements of the Specification both with respect to arrangement and

detail, all design is to conform to the best current engineering practice. Each of the several

parts of the plant shall be of the manufacturer's standard design provided that such design is

in general accordance with the Specification and proven to be satisfactory in its past

operational experience. The essence of design is to be simplicity and reliability in order to give

long continuous service with high economy and low maintenance cost.

The design, dimensions and materials of all parts shall be such that they will not suffer damage

as a result of stresses under the most severe service conditions.

The materials used in the construction of the plant shall of the highest quality and selected

particularly to meet the duties required of them.

All similar parts of the plant shall be interchangeable.

All equipment shall operate without undue vibration and with the least possible amount of noise

and is not to cause a nuisance.

All items of equipment which may have to be lifted for erection or maintenance shall be

provided with lifting eyes, jacking pads or alternative handling facilities.

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 7 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

All equipment shall be designed to minimize the risk of fire and damage which may be caused

in the event of fire.

The equipment shall also be designed to prevent the ingress of all vermin, accidental contact

with live parts and to minimize the ingress of dust and dirt. The use of materials which may be

liable to attack by termites or other insects shall be avoided.

The Contractor shall be bound to adhere to the design data and design criteria as stated in the

Technical Specifications and Schedules or elsewhere in these Contract Documents. If, during

the execution of the Contract, the Contractor intends to deviate from these data and/or criteria,

he is obliged to ask the Authority/Engineer for approval, and to state the reasons for the same.

The Authority/Engineer is free to accept or reject such deviations proposed by the Contractor.

Where equipment is provided as an extension or alteration to existing substations or plant all

efforts shall be made to ensure the conformity of dimensions and colours of new equipment

with existing equipment.

3.4.2. Experience

Tenderers should offer equipment of well proven design and should submit documentary

evidence of its satisfactory operation for a duration of not less than 3 years under climatic

conditions similar to those prevailing in the U.A.E. Tenders which are not accompanied with

the details of experience may be summarily rejected. Details of past experience of sub-

contractors and manufacturers shall also be enclosed with the offer.

If identical equipment/items from the same manufacturer are supplied to the Authority in the

past, details of purchase order No., contract No., type and quantity of items supplied may be

clearly indicated in the schedule of manufacturer's past experience.

3.4.3. Standard Materials and Equipment

The Contractor shall propose type and sizes of equipment, materials, accessories, etc. which

shall generally comply with Authority/Engineer standardization. The Contractor's proposal

shall, however, be subject to Authority's/Engineer’s approval in each and every case.

The contractor shall carryout all necessary cabling, wiring and works and provide all necessary

arrangements, equipment and accessories required for the proper function of the complete

integrated system as per FEWA/Engineer requirements.

The contractor shall be responsible for submitting all schematics, wiring, drawings,

arrangements, layout, functions, etc. for proper arrangement and functions of the system and

this shall be subject to FEWA approval in the design stage .

Within 10 days of award of contract, Main contractor in coordination with Sub vendors are

responsible to submit PQ / base design document lists, detailed design before FAT documents

lists, detailed design before SAT documents lists to FEWA/Engineers review / comments /

follow up process subject to further revisions / iterations until successful completion of project.

Submission of PQ documents & Base design documents including OEL interface supporting

documents within 30days to FEWA/Engineers review / approval process (this point applicable

for all BOQ items & all discipline /all Lots). Un prized Po copy for all BOQ items to be submitted

by Main Contractor to FEWA/Engineer (Applicable for all LOTS).

Main Contractor in coordination with all Sub vendors/manufacturers are responsible for all

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 8 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

interdisciplinary like Civil, Electrical, Telecom, MEP, SCMS, SCADA and all equipment

requirements proposal to FEWA /Engineer for review, comments, approval process,

compliance to the requirements without any deviations and contractual implications to FEWA.

3.5. LAYOUT OF PLANT AND BUILDINGS

The Tender Drawings show the preferred layouts of all plant, equipment and buildings.

Dimensions in these Drawings have been based on typical sizes of plant and equipment.

Room sizes shall not generally be smaller than shown on the Tender Drawings but may be

larger if necessary to meet the requirements of the Plant actually being supplied and the details

in the Schedule of Basic Design principles and Dimensions. Site boundaries may not be

enlarged except under written consent from the Authority/Engineer.

The Contractor should ascertain for himself during the tender stage that the plant he proposes

to supply will be suitable for the arrangements shown on Tender Drawings, and the Contract

Price is deemed to include the cost of any modified layout to meet the Authority's design

principles. Failure of the Authority/Engineer to comment on drawings submitted by the

contractor during the tender stage which show modified arrangements not complying with

Tender Drawings and Design Principles shall not be accepted as approving such

arrangements; any modifications proposed should be clearly stated in the Schedule of

Deviations.

3.6. DRAWINGS AND SCHEDULES

The Contractor shall prepare all necessary detail drawings, designs, etc. giving full and

complete information to enable the Authority/Engineer to properly consider the design of the

work.

Drawings and design data shall be submitted without delay in the order in which they are

required for ordering of material and/or installation at site. The Authority/Engineer shall have

the right at all reasonable times to see, at the Contractor drawing offices, all drawings of any

portion of the work.

The Authority/Engineer's approval of the Contractor’s and Subcontractor's drawings shall not

relieve the Contractor from his responsibility for errors or omissions which may exist, even

though work are done in accordance with such approved drawings. Where such errors or

omissions are discovered later, they shall be made good by the Contractor out of his expenses

irrespective of any approval of the Authority/Engineer.

The Contractor shall submit for approval a list of drawings/drawing schedule, indicating:

- Each kind of drawing per job site, and the estimated first submission date.

- Enough number of columns indicating approval stages and dates.

This list of drawing shall be updated whenever necessary until completion of the work.

All drawings and design data prepared or furnished by the Contractor shall be marked with the

title of the work and shall be transmitted to the Authority/Engineer. Each transmittal of drawings

and design data shall be accompanied by a Document Transmittal Sheet (DTS) giving the titles

and numbers thereof. The forms of the drawing list and DTS are subject to approval of the

Authority/ Engineer.

At monthly intervals or otherwise instructed by Engineer, and if required with any drawing sent

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 9 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

for approval, the Contractor shall submit copies of his drawing lists or parts thereof, having

incorporated the updated drawing schedule as mentioned above, and the latest transmittal

sheets, see below. These lists shall clearly indicate the actual status of every drawing, (i.e.)

for information only, for approval, resubmitted for approval, approved or as- built.

Modified drawings shall bear a revision letter and revision date, and the nature of the

modification shall be clearly stated, no matter if the drawing was already approved, approved

except as noted, revised or not approved.

All drawings shall have a title block, serial number, issue and revision dates, the system subject

to approval of the Authority/Engineer. The title shall include the name, the logo and the address

of the Authority and the Engineer as per samples available from the Authority/Engineer.

All drawings shall be plotted in and shall show the scales of the metric system, and all

descriptive wording shall be in the English language.

All drawings, in particular the ones to be incorporated in the operating instructions and

maintenance manuals as well as all key drawings, i.e. General arrangement drawings, system

diagrams, single line diagrams, control diagrams, etc. shall have a size according to the A -

series of DIN 476, and scales (DIN 476) as follows:

- for reduction: M 1:2.5, 1:5, 1:10, 1:50, 1:100, 1:200, 1:500, 1:1000, 1:5000

- For enlargement: M 2:1, 5:1, 10:1

Drawings shall be folded according to DIN 824 (A4) being 297 mm in height.

All site works shall be carried out only as per approved drawings with all Authority/

Engineer’s comments incorporated. These drawings shall be clearly and tidily updated with

red pencil incorporating all changes carried out at site during the erection and testing works.

The changed or cancelled items shall not be deleted by eraser or liquid corrector, but crossed

only, in order to keep visible the cancelled part. Two sets of these “Marked Up” drawings shall

be handed over before the energizing of any section of works (one set to the Authority and one

set to the Engineer)

Final drawings and technical data sheets of the work as completed, the so-called "as -built"

documents, shall be prepared by the Contractor based on the Marked up drawings approved

by the Engineer. These documents properly bound in files with separation between the

Engineering disciplines, i.e. civil lay-out, electrical (control/protection), etc. shall be in

sufficient detail to enable the Authority to maintain, dismantle, reassemble, and adjust all parts

of the work. Contents of the “as built” documentation and file arrangement shall be subject to

approval by the Authority/ Engineer.

In addition to equipment data submitted for approval, the Contractor shall also submit a full

equipment schedule, sectionalized by the different sites and sub-divided into main

component parts. This schedule shall be prepared in a computerized format and be updated

and reissued on a monthly basis until such time as full equipment approval is obtained. This

schedule shall form part of the "As-Built" documentation.

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 10 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

3.7. MANUALS AND BOOKS

a) The Contractor shall prepare and submit preliminary draft operation and maintenance

instructions to the Authority/Engineer for his comments and approval, at least two months

before the programmed start of erection or pre-commissioning tests, as applicable.

b) The No. of volumes/parts making one set of complete manual and the content of each

volume shall be subject to the approval of the Authority/Engineer and, generally, grouped

major equipment wise. Each volume shall, in general, contain the operating and

maintenance instructions, relevant approved drawings, factory routine test reports,

associated approved design calculation etc.

c) All instruction sheets shall be in the English language properly bound in book form

containing all information, description of equipment, diagrams, etc., necessary to

enable the Authority/Engineer to properly operate, dismantle, reassemble and maintain

the whole of the Works including all possible operating procedures. The various

instructions shall be written in a style easily intelligible for the operating and maintenance

personnel giving full explanatory details.

d) The approved preliminary instruction manuals as above shall be submitted to the

Authority/Engineer in required copies for use during erection and pre-commissioning

works and the Contractor's Site Engineer shall have these identical sets in each and every

site during the entire period of works completion. The same to be submitted as softcopy

in CD also for easy reference.

e) The Contractor shall revise and/or update the above preliminary operating and

maintenance instruction manuals and introduce modifications into the finally bound

copies, to the approval of the Authority/Engineer. The type of binding and other general

information shall be to the approval of the Authority/Engineer. The finally bound copies

along with "As-built" drawings, in required sets, shall be supplied before issue of the

Provisional Taking Over Certificate for the Works or earlier, if requested by the

Authority/Engineer.

f) Should any changes/modifications be required to the operation and maintenance

instructions arising from operation, failure, repair, modification etc. of the Works during the

Maintenance Guarantee period, the Contractor shall incorporate such

changes/modifications in the Instruction Manuals and submit in the form of

amendment, which can be easily inserted/replaced in the original volumes and the cost of

such works shall be deemed to be included in the Contract price. Incorporation of such

changes/modifications by the Contractor shall be to the satisfaction and approval of the

Authority/Engineer and is to be effected not later than the Contractor's application

date for issue of the Final Taking Over Certificate.

3.8. APPROVAL PROCEDURE

3.8.1. General

a) Specifications, drawings, reports, design calculation and data are concerned, they are

subject to the Authority/Engineer's approval. Comments or approval shall be given by the

Authority/ Engineer within 21 working days after receipt of such documents. Any

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 11 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

manufacturing/construction/installation work carried out prior to such approval will be at

the Contractor's own risk and expense.

b) If the Authority/Engineer fails to approve or comment on the documents submitted by the

Contractor within the above period, the Contractor may, after obtaining the

Authority/Engineer's acknowledgement in writing, proceed with the fabrication.

c) The Contractor shall be responsible for any discrepancies, errors, mistakes,

omissions or deficiencies in the documents or the material and equipment as supplied by

him subsequently, whether such documents have been approved or not.

d) Each document for which no approval is required shall be clearly marked "FOR

INFORMATION ONLY" in a visible place. The Authority/Engineer may, however, decide

to treat such document as sent for approval, if deemed necessary.

e) Each document sent for approval shall be clearly marked "FOR APPROVAL" in a visible

place. The Authority/Engineer may, however, decide to mark such document "not subject

to approval", if deemed necessary.

f) The Contractor must in no case distribute any document without either one of the above

g) mentioned marks or his approval of a Subcontractor's drawing or the mark

"Approved, Date, Signature. ". Documents distributed otherwise may be regarded as non-

existent.

h) As far as documents submitted for approval are concerned, the Authority/Engineer will

notify the Contractor by returning one copy marked with one of the following categories:

Cat. No. 1 : "APPROVED"

Cat. No. 2 : "APPROVED EXCEPT AS NOTED" Cat. No. 3 : "NOT APPROVED"

Cat. No. 4 : "NOT SUBJECT TO APPROVAL"

i) The notification "APPROVED" authorizes the Contractor to commence or to proceed with

the fabrication in compliance with his contractual obligations. However the Contractor shall

obtain “RELEASED FOR CONSTRUCTION” (RFC) stamp from the Engineer prior to

proceeding with the execution of works. All RFC Drawings should be distributed to all

concerned parties as per Document distribution schedule specified elsewhere.

j) The notification "APPROVED EXCEPT AS NOTED" authorizes the Contractor to

commence or to proceed with preparatory works only. However to proceed with

construction /manufacturing the Contractor shall revise the drawings as required and

resubmit for approval along with the compliance report for the comments issued by

Authority/Engineer and obtain the Approval and RFC status for the drawings.

k) The notification "NOT APPROVED" indicates that the document must be revised and

resubmitted for approval before proceeding with the manufacture.

l) The notifications "APPROVED", "APPROVED EXCEPT AS NOTED" or "NOT

APPROVED" shall, however, be understood as result of sample checks only, i.e. it will not

prevent the Authority/Engineer from any further claim during the development of the entire

project until issuance of the Final Acceptance Certificate.

m) When the Contractor receives the notification that a document is "APPROVED" by the

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 12 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

Authority/Engineer, he shall immediately enter the mark "APPROVED BY THE

Authority/Engineer on" in the original (transparency), e.g. on top of the title block, and

distribute copies to the Authority/Engineer as stipulated below within the subsequent two

weeks.

n) If such document is modified for any reason afterwards (see also item d) below), it is

understood that the previous notification of the Authority/Engineer is automatically null and

void.

o) The Contractor is hence obliged to immediately notify the Authority and the Engineer of

the existence of such further modification, to delete the pertinent remarks from the original,

and such document shall undergo the above mentioned procedure once again.

p) During the preliminary stage of his design work, the Contractor may submit to the

Authority/Engineer drawings and documents for information and general review along with

lists of deviations (if any), being basis for eventual design meetings. At the latest when

quality, completeness and conformity with the contractual documents have reached a

satisfactory level, the Contractor shall submit these documents for approval.

q) Each of the drawings/documents for a subject as will be submitted shall be reviewed and

checked properly by the contractor before submitting to Authority/Engineer and the

Authority/Engineer shall reviewed up to two times so as to reach the status "APPROVED",

see above.

r) Minimum 48 hours prior to starting any work, the Contractor shall have in hand copies of

the pertinent documents being approved, and shall have supplied the required number of

copies to the Authority/Engineer at site.

s) The Authority/Engineer may order the interruption of the execution of any work for which

the Contractor cannot present approved drawings. Such an interruption shall not relieve

the Contractor from executing his work as stipulated in the Contract and shall be no reason

whatsoever for claiming a delay.

t) As mentioned above, all basic drawings and design data are to be approved by the

Authority/Engineer. For all work, the following shall be submitted to the Authority's

approval as well:

- Lay-out, elevations and disposition drawings,

- Front views, architectural drawings

- Control panel views,

- Translations of labels into Arabic language

3.8.2. Distribution of Documents

All documents, correspondence, etc., shall be submitted in hard and soft copies and distributed

in accordance with a Contract Procedure to be agreed with the Authority/ Engineer but

based upon the following tentative schedule:

Any document submitted without soft copy (CD) will not be accepted.

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 13 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

FEWA ENGINEER

Document

Transmit by:- Dubai Site Head Office Site

Office Offices Offices

Draft Contract Documents Letter 1 - 1 -

Final Contract Document Letter TBA TBA TBA TBA

Priced (6 Copies)

Final Contract Document Letter TBA TBA TBA TBA

Un-Priced (6 Copies)

Technical schedule, DTS 1+PDF CD 1 2 + PDF CD 1

Specification and other

Technical Documents

Codes and Standards DTS 1+PDF CD - 1+ PDF CD -

(wherever applicable )

Vendor / Sub Contractor DTS 3+PDF CD - 2 + PDF CD -

Approval Requests

Vendor / Sub Contractor Letter - 1 - 1

Approval Copies

Material Approval MTS 1+PDF CD - 2 + PDF CD -

Requests

Material Approval Copies Letter - 1 - 1

Request for Information RFI 2 - 2 -

All Electrical Design DTS 1 + soft copy - 2 + soft copy -

Calculations CD CD

Drawings for Approval DTS 2+PDF CD - 3 + PDF CD -

Approved Drawings DTS 1+PDF CD 1 2 + PDF CD 1

RFC Drawings (Released DTS 1+PDF+ CAD 1 2 + PDF+ 1

for Construction) CD CAD CD

Drawing for Information DTS 1+PDF CD 1 2 + PDF CD 1

Draft As Built Drawings – DTS - 1 1+ PDF CD 1

Marked-up

As Built Drawings final DTS 6+PDF + CAD 1 2+ PDF + 1

prints CD CAD CD

As Built Drawings final – DTS 6 CD - 2 CD -

Auto CAD – Compact disc

(CD)

As Built Drawings final DTS 2 Sets - 2 Sets -

reproducible Transparency

Preliminary Manuals for DTS 1+ PDF CD 1 1+ PDF CD 1

approval

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 14 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

FEWA ENGINEER

Document

Transmit by:- Dubai Site Head Office Site

Office Offices Offices

Approved final Manuals DTS 6+ PDF 1 2+ PDF CD 1

CD

Acceptance test procedure DTS 2+ PDF CD 1 2 + PDF CD 1

for approval

Approved Acceptance DTS 2+PDF CD 1 2 + PDF CD 1

Test Procedures

Test Reports - Working sets DTS - 1 1 + PDF CD 1

Test Reports - Final sets DTS 2+ PDF CD 1 2 + PDF CD 1

Manufacture progress Letter 1 - 1 -

information

Insurance Certificates Letter 2 - 1 -

Receiving cum Damage Letter 2 1 2 1

Reports

Accident Report Letter 1+1 1 1+1 1

Minutes of Meeting Letter 2 - 2 -

Weekly progress Report Letter 1+1CD 1 1+1CD 1

Erection Progress Reports Letter 1+ 1CD 1 1+ 1CD 1

Monthly Progress Reports Letter 2+MSP CD - 2 + MSP CD -

Master Program Letter 2+MSP CD 1 2 + MSP CD 1

Correspondence - General Letter 2 - 2 -

Correspondence – Site Letter 1 1 1 1

Matters

Payment Invoice Letter 1+CD - 3+CD -

QA / QC documents DTS 1+ PDF CD 1 2 + PDF CD 1

In the case of documentation being either addressed or copied to site and that documentation

being relevant to the particular sites, then the stated number of copies of the documentation shall be

dispatched to each site separately, for the Authority’s and Engineer’s representative.

3.8.3 Approval of Documents

The approval of drawings/documents etc. shall be followed as described above in the

approval procedure.

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 15 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

3.8.4. Dispatch of Approved Documents

When the Contractor receives the advice that a document has been approved by the

Authority he shall immediately enter the mark "Approved" with the approval reference and date

of approval on the original and distribute the required number of copies to Authority/Engineer as

per document distribution schedule.

3.9. WAY LEAVES, TEMPORARY ROADS, SITE AND ROUTE APPROVALS

a) Way leaves shall be the responsibility of the Contractor.

b) The Contractor shall be responsible to arrange way leaves required by the Contractor in

connection with access to Site.

c) The Contractor shall provide and maintain all temporary roads and tracks and other

means necessary for movement of plants and materials, and clear the same away at

completion and make good all work damaged or disturbed to the satisfaction of the

Authority/Engineer.

d) Site and Route Approvals

Some of the sites and routes given in the enclosed documents have been

tentatively approved by the concerned Municipalities. The Contractor shall be

responsible to carry out detailed survey of the sites and routes and submit the

detailed drawings for Authority/Engineer's approval. Subsequently, the Contractor

shall obtain the approval of concerned Municipality and commence the work

accordingly.

All the sites and routes given in the documents are deemed to have been handed

over to the Contractor on the date of signing of the agreement. Should there be

any change in the above due to reason beyond the control of the

Authority/Engineer, alternative sites/routes shall be given by the Authority to

the Contractor. No claims for any additional payments shall be considered by the

Authority in such cases.

In case of underground cable routes and substation locations, the Contractor shall

obtain the signature and stamp of the concerned Municipality on the "As-built"

drawings and submit the required copies to the Authority / Municipality.

3.10. QUALITY OF MATERIAL AND WORKMANSHIP

a) All plant and equipment to be provided and all work to be carried out under the Contract

shall be manufactured and executed in the manner set out in the Technical Specifications,

Schedules of Technical Data and other Contact Documents, or, where not set out, to the

satisfaction of the Authority/Engineer.

b) All equipment and material shall be of the best quality available.

c) The work shall be executed in the best and most workmanlike manner by qualified, careful

and efficient personnel.

d) All material, equipment and plant components shall be tropicalized to resist

deterioration due to severe prevailing local conditions. Such topicalization shall include

but not be restricted to extra coatings of protective materials, insulations, etc., Such

topicalization shall be subject to approval by the Authority/Engineer.

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 16 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

e) All materials buried under the ground shall be suitable to withstand aggressive soil

conditions.

f) Also relevant clause of Special Conditions of Contract shall be applicable.

3.11. SUBSTITUTION OF MATERIAL AND EQUIPMENT

If the Contractor desires to propose a method to use material or equipment other than

specifically described in the Technical Specifications, he shall in all cases submit the same for

consideration to the Authority/Engineer and he shall not make the substitution unless approved

by the Authority/Engineer in writing. In his submission the Contractor must identify the

proposed deviations from the Technical Specifications. If the substitute offered is not approved

by the Authority/Engineer, the Contractor is bound to furnish the component under

consideration in compliance with the Technical Specifications.

3.12. INSPECTION AND TESTING DURING MANUFACTURE

a) The Contractor shall be responsible for the carrying out of material and plant inspection

and testing. He shall be responsible for any inspection and testing normally carried out by

the Manufacturer/Contractor/Sub-Contractor and for those carried out according to the

manufacturing and fabrication standards of the material/plant and/or rules, regulations and

practices of the manufacturing country.

b) The Authority and his representative shall be entitled at all reasonable times during the

manufacture, to inspect, examine and witness tests on the Manufacturer's Contractor's

and Sub-Contract's premises the material and workmanship of all plant to be provided

under the Contract. If part of the said plant is being manufactured in other premises, the

Contractor shall obtain for the Authority/Engineer and his representatives, permission to

inspect, examine and witness tests as if the said plant is being manufactured at the

Contractor's premises. Such inspection, examination and/or testing shall not release the

Contractor from any of his obligations under the Contract.

c) The Contractor shall be responsible for arranging all the necessary documents required

to obtain Visas.

d) Upon reasonable request of the Authority/Engineer or his representatives, the

Contractor shall furnish to the Authority or his representatives, for approval, adequate

samples of all devices, hardware, material finishes, etc., that he proposes to use in the

Work. Such samples shall be submitted within a reasonable period of time to permit tests

and examination thereof. All items and material installed and finally supplied shall be

identical to the approved samples. Samples of devices, hardware material and similar

items will be returned to the Contractor, if requested for incorporation into the Work. The

costs associated with such tests and examinations, if requested shall be borne by the

Contractor.

e) The Contractor shall notify the Authority/Engineer or his representatives in writing forty-

five (45) days in advance of the date on and the place at which any plant, material or

equipment will be ready for testing. Should any postponement become necessary, the

Contractor shall provide written notification of the same at least one week prior to the

originally scheduled date. The Authority or his representatives shall give the Contractor

72 hours’ notice in writing of their intention to attend the tests, whereupon the plant,

material or equipment shall remain available for inspection and test up to a minimum of10

days beyond the agreed date of attendance.

f) Should the Authority or his representatives not advise attendance at the tests at the place

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 17 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

named and at the date which the Contractor has stated in his notice, the Contractor shall

inform the Authority in writing and may proceed with the tests, which shall be deemed to

have been made in their presence, and shall forthwith forward to them duly certified copies

of the test readings.

g) For tests on the premises of the Contractor or Sub-Contractor, the Contractor shall provide

such assistance, labour, material, electricity, fuel stores, apparatus and instruments as

may be reasonably demanded to carry out such tests efficiently, at no extra cost to the

Authority.

h) Should the Authority or his representative be of the opinion that the material, equipment

or workmanship actually or proposed to be inspected or tested does not comply with the

Technical Specifications or the best engineering practice, he shall notify the Contractor in

writing of his objections. The Contractor shall rectify and remove the causes of such

objections and at the discretion of the Authority, the inspection or test shall then be

undertaken or repeated in accordance with relevant clauses in special conditions of

contract. Rejected material, equipment or workmanship shall not release the Contractor

from any obligation under the Contract nor shall any extension of time be allowed.

i) The Contractor shall furnish copies of the relevant test data relating to the tests carried

out to the Authority/Engineer's offices as detailed in the schedule in relevant Clause of the

Special Conditions of Contact.

j) Detailed requirements for quality assurance during manufacture, inspection and testing

are given in section.1 (General Technical specification) - TS-0411 of the Specification.

k) Also relevant clause of Special Conditions of Contract shall be applicable.

3.13. ACCESS TO WORKSHOPS

The Authority and his representatives as well as any authorized representative or person

named by them shall have free access to the Manufacturers, Contractor's and Sub-

Contractor's workshops at all reasonable times for inspection and/or testing purposes and the

Contractor and/or Sub-Contractor shall provide all reasonable assistance as deemed

necessary.

3.14. PACKING AND MARKING

a) All equipment and material shall be packed in accordance with BS 1133 Packing Code in

bundles or sea worthy containers or packing and no second hand timer shall be used.

b) All packing shall be suitable for the type of equipment involved and for transport from

factories to the port of embarkation, sea/air freight, rough handling at the port of destination

and movement to and on the Site.

c) Impact Recorders capable of indicating all maximum horizontal and vertical impacts, shall

be rigidly attached to each transformer main tank shipping unit. Provisions must be made

to ensure that these indicators are sealed, that they will be completely functional without

interruption of indicating records during the entire period of shipment, including loading

and unloading and to ensure that the Authority will receive clearly indicated data by

breaking the seal. Instruction for interpretation of recorded data shall be provided prior to

shipment.

d) All equipment and material, together with the applicable instruction books, packing lists

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 18 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

and special site storage instructions, shall carefully be boxed, crated or other-wise

adequately protected for overseas shipment. Flanges, studs and exposed machine

surfaces shall be thoroughly greased and protected before shipment. Any equipment

susceptible to damage by water or high humidity shall be encased in water-tight and/or

air-tight container to ensure a low humidity atmosphere therein.

e) Special provisions shall be made regarding the prevailing severe local climatic

conditions.

f) Shipping weights and dimensions of each box or package shall be determined in such a

way as to facilitate handling.

g) All boxes, cases and/or bundles containing material and/or equipment shall be clearly

marked on all sides and further identified by a broad coloured band completely running

around the box. Colour of the band and serial number for the different components shall

be proposed by the Contractor and shall be subject to the Authority's approval.

h) The marking on the box, case and/or bundle shall be of block letters not less than 50 mm

in height, stenciled with black indelible paint. The following information shall be shown on

each box, case and/or bundle:

CONTRACTOR/SUBCONTRACTOR NAME ………………………..

CONTRACT NO. ……..

CONTRACT TITLE: SUCH AS 132/33/11kV SUBSTATION WORKS IN

NORTHERN EMIRATES

NAME OF SUPPLIER

PORT OF DESTINATION

CONSIGNMENT

SERIAL NO.

GROSS WEIGHT

NET WEIGHT

i) SIZE OF BOX OR BUNDLE (LENGTH x WIDTH x HEIGHT)

j) BRIEF INDICATION OF CONTENTS

k) The Contractor shall be entirely responsible for ensuring that the packing is suitable for

transit and he shall be liable for any loss or damage due to faulty packing, having due

regard to the distance and the nature of the voyage.

3.15. MANUFACTURE PROGRESS INFORMATION

Within two weeks of the issue of the Notification of Award of Contract the Contractor shall

forward to the Authority/Engineer respectively two copies of a proposed Master Program in

Primavera / MS Projects software in accordance with the Special Conditions of Contract and

relevant Clause of these Conditions, detailing the activities relating to the Plant's

manufacture, delivery and erection for the complete Contract work for comment and approval

as regards its logic, detail and time scale. Copies of the approved program as required by the

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 19 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

Authority/Engineer shall be provided by the Contractor.

The program shall indicate the various phases of the Work for all items of the Contract from

the Commencement of the Contract to its final completion, i.e. design, submission of drawings,

ordering of materials, manufacture, delivery, erection and commissioning.

If at any time during the execution of the Contract it is found necessary to modify the approved

Program, the Contractor shall inform the Authority/Engineer and submit a modified Program

for approval clearly indicating the reasons for such modifications/delay and the remedial

measures being undertaken to complete the contract without delay. Such approval shall not

be deemed to be consent to any amendment of the completion date stated in the Contract.

At monthly intervals after approval of the program referred to above, the Contractor shall

submit to the Authority/Engineer written detailed progress reports in accordance with the

Special Conditions of Contract and Clause 3.16 of these Conditions, indicating the stage

reached in design, ordering of material, manufacture, delivery and erection of all components

of plant. These reports shall be forwarded promptly so that on receipt by the

Authority/Engineer, the information contained therein is no more than five days out of date and

shall be submitted before 5th day of every calendar month.

3.16. PROJECT SCHEDULE / PROGRAM

The Contractor shall submit within one month of Contract award a master program sub- divided

in such a way as to give full information on the following:

Design/document submissions

Placing of orders for manufacture

Periods of manufacture

Works tests

Factory Inspections

Transportation and Shipment

Civil Construction

Plant Erection

Plant Commissioning

Delivery of Spares and Tools

Training of Authority Staff

Trial Operation

The erection and commissioning section shall be particularly detailed to clearly show required

power system shutdown and durations.

The master program must be consistent with the guaranteed dates of delivery of information,

drawings and equipment as required by the contract and is to cover all phases of the works for

all items of the Contract, from the commencement of the Contract to its final completion. Upon

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 20 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

approval of the master program a further four copies are to be provided by the Contractor.

Sub-programs based on and containing similar information to the master program shall be

provided by the Contractor basis and in the same number of copies as the master program at

the discretion and request of the Authority/Engineer.

Both the master and sub program shall be of clear presentation to illustrate the relevant

calendar dates / activity durations and be based on either a CPM or PERT network

representation of the project. This shall be prepared in Primavera / MS Projects software.

The approved programs shall be marked up by the Contractor to record the actual and forecast

progress for the purpose of Contract control and shall be submitted to the Authority/Engineer

at monthly intervals. In the event of any unscheduled delays occurring, the Contractor shall

inform the Authority and advise the policy or methods to be implemented to eliminate or

minimize such delays.

All programs shall be subject to approval by the Authority/Engineer and once approved shall

not be amended unless specifically agreed by the Authority/Engineer. Further, each

resubmission and update of the programs must include a dated signature of the

Authority/Engineer or his representative to confirm the project status claimed by the Contractor

is a true and accurate one.

The aforementioned programs shall also make allowance for the situation which will exist in

the U.A.E. during the periods of the Holy Month of Ramadan, Hajj, Eid El Fitr and Eid al Adha

and Summer break hours.

The program shall consider the works to be carried out in a phased manner with minimum

possible shut-down period requirement for removal of existing equipment/ replacement with

new equipment, changeover of existing loads. The shut-down programs during summer peak

loads which involve supply interruption to the consumers will not be acceptable and hence the

overall project program shall take into account such constraints and the best possible program

shall be prepared and adhered to.

3.17. PROGRESS REPORTS

For the duration of the Contract the Contractor shall submit to the Authority/Engineer in

duplicate by the fifth (5th) day of each calendar month, an approved overall project progress

report for the previous month. The project report shall be issued in accordance with the Special

Conditions of Contract and include as a minimum the following items.

3.17.1. Summary

A descriptive summary of key progress during the month highlighting those items behind

schedule and the remedial actions taken to recover project delays. The summary must

conclude by stating an estimation of the completion date of the project, based upon the

program outlined in Clause 3.16 of these Conditions.

3.17.2. Project Schedule / Program

Copies of the programs outlined in Clause 3.16 of these Conditions shall also be included.

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 21 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

3.17.3. Updated Schedules

The following updated schedules shall be included.

Equipment/Material approval status

Drawing Schedule (Clause 3.6 above)

Equipment Schedule (Clause 3.6 above) -Correspondence List

The drawing schedule shall detail the current status of the individual drawings in accordance

with Sub-Clause 3.8.1 of these Conditions.

The equipment schedule shall be subject to the approval of the Authority/Engineer and the

individual equipment/materials, identified as one of the following categories:

Submitted for Approval (AS)

Approved (AP)

Approved Subject to Comments (AC)

Returned with Comments (RC)

Examination not Required (NE)

% Manufactured (MA)

Works Tested (WT)

Factory Inspected (FI)

Under Transportation/Shipment (TR)

Site Inspected (SI)

% Erected (ER)

% Commissioned (CO)

Key dates relating to the above shall also be shown. The equipment identified shall be sub-

divided only up to main component parts.

Any changes within the equipment schedule since the last issue shall be highlighted by

including the revision number of the latest issue of the schedule next to the particular item. Any

equipment removed shall still be detailed but shall be indicated as deleted.

3.17.4. Financial Report

A financial report comprising a summary sheet of invoicing/payments to date plus payment

status against a payment scheduled of individual items as agreed in the Contract. The payment

schedule shall take the form of a matrix and shall include a total comprising of specific subtotals

against an agreed item of equipment/work/ specification requirement. The payment schedule

shall be subject to the approval of the Authority/Engineer and once agreed shall be modified

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 22 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

only in accordance with the current completion/payment status of the equipment/work/

specification requirement.

3.17.5. Site Report

A site report containing a summary of those details required by these Conditions, in addition to the

following:

a) Site manpower forecast and returns (including arrival and departure date of

supervisory staff).

b) Plant and Machinery returns (including arrival and departure dates), signed as

satisfactorily inspected and accepted on site by both the Contractor and the Authority.

c) Site Erection and Commissioning progress made during the month.

d) An accident report related to personal injuries.

e) A damage report related to plant and machinery.

f) A fully detailed schedule of works proposed for the following month ahead including

erection, commissioning, etc.

g) A schedule of equipment shipment and site arrival dates (anticipated and actual).

h) Any delay in the last month's program and reasons for such delays and the remedial

measures proposed to overcome the delays in the current month.

i) Dated site photographs. The site photographs shall be in colour and suitably marked in

loose leaf pages for insertion into a albums to be supplied by the Contractor. Each

photograph shall be titled and dated.

The vantage point of each photograph shall be to the approval of the Authority or his

Representative. Vantage points may however be changed or added, with the prior approval of

the Authority or his Representative, to suit the progress of work on site.

3.18. TRANSPORT

3.18.1. Shipping Documents

a) The Contractor shall submit complete shipping documents as soon as possible after

shipping, in order to reach the Authority/Engineer before the arrival of the ship.

Responsibility for delays, loss or savages of shipping documents shall rest with the

Contractor.

b) The shipping documents shall be distributed as follows:

Documents Engineer &Authority

Dubai Office - Site Office

Shipping Invoice for the Consignments

Original 1 -

Copy 1 1

Packing List 2 1

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 23 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

Bill of Lading

Original 1 -

Copy 1 1

Certificate of Origin

Original 1 -

Copy 1 1

Manufacturer's Certificate

Original 1 -

Copy 1 1

Confirmation of Declaration of 2 1

Insurance

Certificate of Inspection 2 1

Authority

3.18.2. Transport to Port of Embarkation, Loading & Unloading

The Contractor shall arrange and provide for the transport of material, equipment and plant

components from the manufacturer's works to the port of embarkation. The Contractor shall assign

special personnel to supervise the transport, loading and unloading of material, equipment and plant

components. They shall take all skill and care in the performance of transport, loading and unloading.

3.18.3. Overseas Transport

a) When carrying out overseas transport either by sea or by air the special provisions of the

Boycott of Israel laws and regulations shall be taken into consideration and adhered to

scrupulously.

b) The Contractor shall be responsible for the selection of the overseas transport as well as for

the whole transport period. The transport shall be carried out at his own risk.

c) Should the Work or any part thereof, the manufacture and/or supply of any material, equipment

or plant component as well as any equipment or tool required for the Work be delayed with

respect to the relevant time schedules, the Contractor shall transport the part or component

delayed by air at no extra cost to the Authority.

d) All freight consignments shall be delivered to an appropriate sea port of the U.A.E.

3.18.4. Local Transport

a) The Contractor shall arrange and carry out under his own responsibility and supervision

the local transport from the port of destination to the Site.

b) The Contractor shall, at his own convenience, gather all necessary information and arrange

for all necessary provisions in order to obtain accurate information about unloading at the port

of destination and inland transport facilities as well as prevailing conditions, particularly the

safe load bearing capacity of highways and bridges. The Contractor shall bear every and all

expenses related therewith.

c) The Contractor shall use every reasonable means and care to prevent any of the highways or

bridges on the route to Site from being damaged or injured by any traffic of the Contractor or

any of his Sub-Contractors and in particular select, choose and use vehicles and restrict and

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 24 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

distribute loads so that any such extraordinary traffic that will inevitably arise from moving of

Contractor's equipment and material from and to the Site shall be limited as far as reasonably

possible and so that no damage or injury may be occasions to such highways and bridges.

d) If during the carrying out of the work or at any time thereafter the Contractor receives any claim

arising out of the execution of the Works in respect of damage or injury to the highways or

bridges, he shall immediately report the same to the Authority and thereafter he shall make

the settlement of any payment of all sums due to respect of such claim and in respect of all

claims, demands, proceedings, damages, costs, charges and expenses in relation thereto

without any obligation to the Authority.

e) The Contractor shall use every reasonable means and care to prevent any of the shores,

jetties and sea structures from being damaged or injured by vessels loading and unloading

equipment of the Contractor or any of his Sub-Contractors.

f) If during the carrying out of the work or at any time thereafter the Contractor receives any claim

arising out of the Works in respect of damage or injury to shores, jetties or sea structures, he

shall immediately notify the Authority and thereafter he shall settle payment of all sums due

in respect of such claim, and in respect of all claims, demands, proceedings, damages,

costs, charges and expenses in relation thereto without any obligation to the Authority.

g) The unloading and storage at Site shall be carried out by the Contractor, who for these

purposes shall make all necessary provisions and arrange for all necessary equipment.

3.18.5. Receiving-Cum-Damage Reports

a) The Contractor shall submit receiving reports to the Authority/Engineer to cover each individual

shipment received and checked at the job site. Each shipment on arrival at job site shall be

unloaded, opened and carefully checked for any damage in transit and the Contractor shall

immediately submit a damage report, countersigned by the Authority/Engineer to the Insurance

Company with copies to the Authority. Where damage has occurred in Marine Transportation,

a copy of the damage report shall also be sent to the registered appointed surveyor.

b) In all cases of irreparable damages, the Contractor shall immediately notify the relevant

manufacturer(s). He shall also immediately notify the Authority/Engineer of the actions he will

be initiating and undertaking in order to repair or replace the damaged part(s) and of the

consequences this damage will have on the completion date of the Works. Any repairs

proposed by the Contractor will be subject to the approval of the Authority/Engineer.

3.18.6. Title to the Plant

Title to the Plant shall pass to the Authority upon delivery ex-factory, but the Contractor shall maintain

total and exclusive care, custody, and control including all risk or loss until Provisional Acceptance.

3.19. ERECTION WORK

3.19.1. Commencement of Erection

As soon as the Notification of Award of Contract has been issued, the Contractor shall notify

the Authority/Engineer of the date he intends to commence the execution of the Works and

material erection and subject to the approval of the Authority/Engineer shall proceed with the

same with due expedition and without delay.

FEWA-GE-GEN-TS-0111, REV 0, Sep 2019 PAGE 25 OF 47

GENERAL TECHNICAL SPECIFICATION FEDERAL ELECTRICITY AND WATER AUTHORITY

184E/2020

3.19.2. Unloading and Storage at Site

a) The Contractor shall unload all imported equipment and material at the Site from trucks

and trailers and delivery vehicles (including barges if any) as the case may be. Items of

permanent installation shall be properly and neatly stored in areas designated by the

Authority and shall be protected to prevent damage or deterioration of any type. Storage

methods shall be such as to cause minimum inconvenience to others and shall be

arranged to facilitate inspection and withdrawing from stores. All equipment and

material storage shall be subject to the approval of the Authority/Engineer.

b) All packing boxes, (excluding shipping containers belonging to shipping lines or other

agencies but used by Contractors in bringing material to Site), planking, covering etc.,

shall become the property of the Authority as soon as the equipment and material which

is contained therein arrives at Site. The Authority, on application from the Contractor, may

permit the Contractor to use some of the boxes, containers, etc., for equipment and

material storage purposes until the items are installed or erected by the Contractor.

c) Also relevant clause of Special Conditions of Contract shall be applicable

3.19.3. Performance of Erection

a) The Contractor shall be fully responsible for the execution of the Works and

performance of erection work carried out by his own personnel, by his Sub-Contractor's

personnel or by locally engaged skilled or unskilled personnel.

b) The Contractor shall supply and provide all erection and construction equipment and

material, both for temporary and permanent work, tools, tackles, stores, etc., as well as

consumables required for the execution and completion of the Works.

c) The execution of the Works shall be carried out during normal working hours. Overtime,

Friday, holiday or night work shall be carried out with the permission of the

Authority/Engineer. The provisions of this paragraph shall not be applicable in the case of

any work which is customarily carried out by rotating or double shifts.