Professional Documents

Culture Documents

TC 11

TC 11

Uploaded by

Greshy FieldCopyright:

Available Formats

You might also like

- Summer Internship Project On Jindal Steel and PowerDocument24 pagesSummer Internship Project On Jindal Steel and PowerMeetBaghel100% (1)

- Development of A Rare-Earth-Free SR Motor With High Torque Density For Hybrid VehiclesDocument8 pagesDevelopment of A Rare-Earth-Free SR Motor With High Torque Density For Hybrid VehiclesLalbahadur MajhiNo ratings yet

- Susp BRGDocument16 pagesSusp BRGmailbkraoNo ratings yet

- 3-Bid Document Volume-III-Substation Specifiations - 1Document126 pages3-Bid Document Volume-III-Substation Specifiations - 1KaminiSurendraReddyNo ratings yet

- No. El/1.3.10/3 Date: 24.08.2018: NF (K.K Iwoz E/ Jsyos) Fcykliqj & 495 004Document3 pagesNo. El/1.3.10/3 Date: 24.08.2018: NF (K.K Iwoz E/ Jsyos) Fcykliqj & 495 004CMS Lab ELS KYNNo ratings yet

- Government of India Ministry of Railways Research, Designs & Standards OrganisationDocument2 pagesGovernment of India Ministry of Railways Research, Designs & Standards OrganisationGulshan DubeyNo ratings yet

- TC 43Document2 pagesTC 43Greshy FieldNo ratings yet

- LOCO Project With PLC LadderDocument60 pagesLOCO Project With PLC LadderSupriya YenniNo ratings yet

- MTR Handout 03.07.18Document8 pagesMTR Handout 03.07.18Lokesh Kuppili100% (1)

- ACSR ConductorDocument13 pagesACSR ConductorHrshiya SharmaNo ratings yet

- Seed Fund Req. LetterDocument4 pagesSeed Fund Req. Letterkrisbhaskar22-1No ratings yet

- Wag5 23Document3 pagesWag5 23Amit Kumar MaityNo ratings yet

- Internship ReportDocument24 pagesInternship ReportaylaNo ratings yet

- Ti Mi 0008 Rev11562Document2 pagesTi Mi 0008 Rev11562Himalaya ChoureNo ratings yet

- Manufacturing Process at Rail Wheel FactoryDocument75 pagesManufacturing Process at Rail Wheel Factorymarcus100% (1)

- Physica C: Superconductivity and Its Applications: SciencedirectDocument8 pagesPhysica C: Superconductivity and Its Applications: SciencedirectRawaz Hama Aziz H.KarimNo ratings yet

- 1 Introduction To Visakhapatnam Steel Plant: TH THDocument31 pages1 Introduction To Visakhapatnam Steel Plant: TH THSwathi SwapnaNo ratings yet

- Reaffirmed 1997Document7 pagesReaffirmed 1997Uppala Krishna ChaitanyaNo ratings yet

- Analysis of In-Wheel Switched Reluctance Motor: Review-IDocument24 pagesAnalysis of In-Wheel Switched Reluctance Motor: Review-ISuresh Kumar RNo ratings yet

- A Selection of Electrical Machine As An Electromechanical Battery For Earth Orbit SatelliteDocument6 pagesA Selection of Electrical Machine As An Electromechanical Battery For Earth Orbit SatelliteAli DurazNo ratings yet

- NadcaDocument8 pagesNadcaSandeep SNo ratings yet

- Fabrication of Power Generation by UsingDocument4 pagesFabrication of Power Generation by UsingRAJESH MNo ratings yet

- Electric Loco Shed, GhaziabadDocument19 pagesElectric Loco Shed, Ghaziabadagni98100% (1)

- VVER NpcilDocument24 pagesVVER NpcilSiddhartha PramanickNo ratings yet

- Jfe Technical Report No. 4 (Nov. 2004)Document7 pagesJfe Technical Report No. 4 (Nov. 2004)shank7304No ratings yet

- Design and Analysis of Connecting Rod Using Different MaterialsDocument15 pagesDesign and Analysis of Connecting Rod Using Different MaterialsIJRASETPublicationsNo ratings yet

- Summer Training Report On Diesel Locomotive Works VaranasiDocument52 pagesSummer Training Report On Diesel Locomotive Works VaranasiGaurav PandeyNo ratings yet

- Design, Analysis and Fabrication of Eddy Current Braking SystemDocument11 pagesDesign, Analysis and Fabrication of Eddy Current Braking SystemTEJAS V ANo ratings yet

- Development of A CNG Auto Rickshaw Drive Shaft From A Locally Available MaterialDocument8 pagesDevelopment of A CNG Auto Rickshaw Drive Shaft From A Locally Available Materialomegamedicalcomplex1000No ratings yet

- Sponge Iron Project ProfileDocument6 pagesSponge Iron Project ProfilevuonghnNo ratings yet

- Pipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda TpsDocument36 pagesPipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda Tpsஅம்ரு சாந்திவேலு100% (1)

- SLR English Exe - SummaryDocument31 pagesSLR English Exe - SummarybalaasenthilNo ratings yet

- Iron SeparatorsDocument23 pagesIron SeparatorsFavorSea Industrial Channel LimitedNo ratings yet

- SMI 284 Q20SettingDocument3 pagesSMI 284 Q20Settingmr bhartiya hackerNo ratings yet

- Project Management PDF FinalDocument103 pagesProject Management PDF FinalShivam JawalkarNo ratings yet

- 2 67 1490941748 14.ijmperdapr201714Document11 pages2 67 1490941748 14.ijmperdapr201714u2005044No ratings yet

- Project On Bullhead HammersDocument55 pagesProject On Bullhead HammersManoj BallaNo ratings yet

- SMI 301 - InductionHeaterEndFrameDocument3 pagesSMI 301 - InductionHeaterEndFrameKuldeep SinghNo ratings yet

- Copper in The Rotor For Lighter Longer Lasting MotDocument15 pagesCopper in The Rotor For Lighter Longer Lasting MotVisanFlorinNo ratings yet

- KrbioDocument5 pagesKrbionvchinaiNo ratings yet

- Acsr ConductorDocument8 pagesAcsr ConductorKoushik BhaumikNo ratings yet

- WDG4D 4500 HP (Mp-Misc-312) Jan-2016Document17 pagesWDG4D 4500 HP (Mp-Misc-312) Jan-2016raja shekarNo ratings yet

- Material Selection and Optimisation of An Eddy Current Braking System With RegenerationDocument10 pagesMaterial Selection and Optimisation of An Eddy Current Braking System With RegenerationAnjali BiramaneNo ratings yet

- 2 Effects of Material On Efficiency in Alternators Used in Wind EnergyDocument10 pages2 Effects of Material On Efficiency in Alternators Used in Wind Energykadir ylmazNo ratings yet

- Plant Name & CodeDocument16 pagesPlant Name & CodeDevnarayam SahuNo ratings yet

- Helical Coil SpringDocument36 pagesHelical Coil SpringmailbkraoNo ratings yet

- G S Earth WireDocument10 pagesG S Earth WiresaratNo ratings yet

- Railway Steel Grade PDFDocument4 pagesRailway Steel Grade PDFv4lkr3yNo ratings yet

- Welding Procedures Specification For Flux Cored Arc Welding of Wind TowersDocument10 pagesWelding Procedures Specification For Flux Cored Arc Welding of Wind TowersMuhammad Nursalam ZulkifliNo ratings yet

- Pipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda TpsDocument37 pagesPipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda Tpsஅம்ரு சாந்திவேலுNo ratings yet

- Development of 700°C Class Steam Turbine TechnologyDocument6 pagesDevelopment of 700°C Class Steam Turbine TechnologyJuve100% (1)

- Module - НЕС01/Program-НЕС012 Technology and equipment for welding of heavy and power generation (including nuclear) engineeringDocument11 pagesModule - НЕС01/Program-НЕС012 Technology and equipment for welding of heavy and power generation (including nuclear) engineeringVishwas Rao MNo ratings yet

- RSP ReportDocument26 pagesRSP ReportSwastik MohapatraNo ratings yet

- 1414664966158-Ti Mi 0001Document2 pages1414664966158-Ti Mi 0001Kamlesh MhatreNo ratings yet

- IJAMT Rao IndiaDocument54 pagesIJAMT Rao IndiaM R MANJU COMPUTERSNo ratings yet

- Training at IOCL ChaksuDocument22 pagesTraining at IOCL Chaksusarthak100% (2)

- Blast Furnace HydraulicsDocument36 pagesBlast Furnace Hydraulicssghane5674No ratings yet

- Golovatenko 2016 IOP Conf. Ser. Mater. Sci. Eng. 150 012002Document7 pagesGolovatenko 2016 IOP Conf. Ser. Mater. Sci. Eng. 150 012002Manshi SinghNo ratings yet

- Design and Crash Analysis of A Rollcage For Formula Sae Race CarDocument5 pagesDesign and Crash Analysis of A Rollcage For Formula Sae Race CarVipulNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Smi 306Document2 pagesSmi 306Greshy FieldNo ratings yet

- Smi 323Document4 pagesSmi 323Greshy FieldNo ratings yet

- Smi 160Document3 pagesSmi 160Greshy FieldNo ratings yet

- WAG9 Tools & PlantsDocument1 pageWAG9 Tools & PlantsGreshy FieldNo ratings yet

TC 11

TC 11

Uploaded by

Greshy FieldOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TC 11

TC 11

Uploaded by

Greshy FieldCopyright:

Available Formats

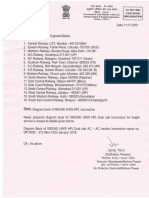

TECHNICAL CIRCULAR NO 11

No.EL. 3.2.13 Dated 28.01.98

Chief Electrical Engineer,

• Central Railway, Mumbai CST –400 001.

• Eastern Railway, Fairlie Place, Calcutta, 700 001.

• Northern Railway, Baroda House, New Delhi- 110001

• Southern Railway, Park Town, Madras-600 003.

• South Eastern Railway, Garden Reach . Calcutta-700 043.

• Westerm Railway. Churchgate. Mumbai-400 020.

• Chittaranjan Locomotive Works, Chittaranjan-713 331.

Sub. Material for the pins and bushes in the brake rigging of Electric Locomotives.

From time to time the material of pins and bushes used in the breake rigging of various

locomotives have been under discussions. Various committees nominated to study the reliability

aspects of locomotive bogies in the past have strongly recommended the use of magnese steel for

pins and bushes of break rigging due to their inherent characterstics of lesser wear and tear. Due

to non availability of many sources for the magnese steel pins and bushes. Some Railways have

also requested RDSO in the past to suggest alternate material in lieu of magnese steel. The above

issue was studied in details and it has been decided that henceforth the material for the pins and

bushes of brake rigging in the locomotive should be as follows:

Material Specification :

Steel as per IS: 1875 class I with case hardening of 58 ±2 RC with minimum case depth of 1

mm.

or

Magnese steel as per Specification IRS: R65-78.

Applicable to Locomotives :

WAM4, WAG5, WAG7, WAP1, WAP4, WCAM2, WCAM3, WCG2,

(O.H. Pandey)

Encl : NIL for Director General Elect.

60

You might also like

- Summer Internship Project On Jindal Steel and PowerDocument24 pagesSummer Internship Project On Jindal Steel and PowerMeetBaghel100% (1)

- Development of A Rare-Earth-Free SR Motor With High Torque Density For Hybrid VehiclesDocument8 pagesDevelopment of A Rare-Earth-Free SR Motor With High Torque Density For Hybrid VehiclesLalbahadur MajhiNo ratings yet

- Susp BRGDocument16 pagesSusp BRGmailbkraoNo ratings yet

- 3-Bid Document Volume-III-Substation Specifiations - 1Document126 pages3-Bid Document Volume-III-Substation Specifiations - 1KaminiSurendraReddyNo ratings yet

- No. El/1.3.10/3 Date: 24.08.2018: NF (K.K Iwoz E/ Jsyos) Fcykliqj & 495 004Document3 pagesNo. El/1.3.10/3 Date: 24.08.2018: NF (K.K Iwoz E/ Jsyos) Fcykliqj & 495 004CMS Lab ELS KYNNo ratings yet

- Government of India Ministry of Railways Research, Designs & Standards OrganisationDocument2 pagesGovernment of India Ministry of Railways Research, Designs & Standards OrganisationGulshan DubeyNo ratings yet

- TC 43Document2 pagesTC 43Greshy FieldNo ratings yet

- LOCO Project With PLC LadderDocument60 pagesLOCO Project With PLC LadderSupriya YenniNo ratings yet

- MTR Handout 03.07.18Document8 pagesMTR Handout 03.07.18Lokesh Kuppili100% (1)

- ACSR ConductorDocument13 pagesACSR ConductorHrshiya SharmaNo ratings yet

- Seed Fund Req. LetterDocument4 pagesSeed Fund Req. Letterkrisbhaskar22-1No ratings yet

- Wag5 23Document3 pagesWag5 23Amit Kumar MaityNo ratings yet

- Internship ReportDocument24 pagesInternship ReportaylaNo ratings yet

- Ti Mi 0008 Rev11562Document2 pagesTi Mi 0008 Rev11562Himalaya ChoureNo ratings yet

- Manufacturing Process at Rail Wheel FactoryDocument75 pagesManufacturing Process at Rail Wheel Factorymarcus100% (1)

- Physica C: Superconductivity and Its Applications: SciencedirectDocument8 pagesPhysica C: Superconductivity and Its Applications: SciencedirectRawaz Hama Aziz H.KarimNo ratings yet

- 1 Introduction To Visakhapatnam Steel Plant: TH THDocument31 pages1 Introduction To Visakhapatnam Steel Plant: TH THSwathi SwapnaNo ratings yet

- Reaffirmed 1997Document7 pagesReaffirmed 1997Uppala Krishna ChaitanyaNo ratings yet

- Analysis of In-Wheel Switched Reluctance Motor: Review-IDocument24 pagesAnalysis of In-Wheel Switched Reluctance Motor: Review-ISuresh Kumar RNo ratings yet

- A Selection of Electrical Machine As An Electromechanical Battery For Earth Orbit SatelliteDocument6 pagesA Selection of Electrical Machine As An Electromechanical Battery For Earth Orbit SatelliteAli DurazNo ratings yet

- NadcaDocument8 pagesNadcaSandeep SNo ratings yet

- Fabrication of Power Generation by UsingDocument4 pagesFabrication of Power Generation by UsingRAJESH MNo ratings yet

- Electric Loco Shed, GhaziabadDocument19 pagesElectric Loco Shed, Ghaziabadagni98100% (1)

- VVER NpcilDocument24 pagesVVER NpcilSiddhartha PramanickNo ratings yet

- Jfe Technical Report No. 4 (Nov. 2004)Document7 pagesJfe Technical Report No. 4 (Nov. 2004)shank7304No ratings yet

- Design and Analysis of Connecting Rod Using Different MaterialsDocument15 pagesDesign and Analysis of Connecting Rod Using Different MaterialsIJRASETPublicationsNo ratings yet

- Summer Training Report On Diesel Locomotive Works VaranasiDocument52 pagesSummer Training Report On Diesel Locomotive Works VaranasiGaurav PandeyNo ratings yet

- Design, Analysis and Fabrication of Eddy Current Braking SystemDocument11 pagesDesign, Analysis and Fabrication of Eddy Current Braking SystemTEJAS V ANo ratings yet

- Development of A CNG Auto Rickshaw Drive Shaft From A Locally Available MaterialDocument8 pagesDevelopment of A CNG Auto Rickshaw Drive Shaft From A Locally Available Materialomegamedicalcomplex1000No ratings yet

- Sponge Iron Project ProfileDocument6 pagesSponge Iron Project ProfilevuonghnNo ratings yet

- Pipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda TpsDocument36 pagesPipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda Tpsஅம்ரு சாந்திவேலு100% (1)

- SLR English Exe - SummaryDocument31 pagesSLR English Exe - SummarybalaasenthilNo ratings yet

- Iron SeparatorsDocument23 pagesIron SeparatorsFavorSea Industrial Channel LimitedNo ratings yet

- SMI 284 Q20SettingDocument3 pagesSMI 284 Q20Settingmr bhartiya hackerNo ratings yet

- Project Management PDF FinalDocument103 pagesProject Management PDF FinalShivam JawalkarNo ratings yet

- 2 67 1490941748 14.ijmperdapr201714Document11 pages2 67 1490941748 14.ijmperdapr201714u2005044No ratings yet

- Project On Bullhead HammersDocument55 pagesProject On Bullhead HammersManoj BallaNo ratings yet

- SMI 301 - InductionHeaterEndFrameDocument3 pagesSMI 301 - InductionHeaterEndFrameKuldeep SinghNo ratings yet

- Copper in The Rotor For Lighter Longer Lasting MotDocument15 pagesCopper in The Rotor For Lighter Longer Lasting MotVisanFlorinNo ratings yet

- KrbioDocument5 pagesKrbionvchinaiNo ratings yet

- Acsr ConductorDocument8 pagesAcsr ConductorKoushik BhaumikNo ratings yet

- WDG4D 4500 HP (Mp-Misc-312) Jan-2016Document17 pagesWDG4D 4500 HP (Mp-Misc-312) Jan-2016raja shekarNo ratings yet

- Material Selection and Optimisation of An Eddy Current Braking System With RegenerationDocument10 pagesMaterial Selection and Optimisation of An Eddy Current Braking System With RegenerationAnjali BiramaneNo ratings yet

- 2 Effects of Material On Efficiency in Alternators Used in Wind EnergyDocument10 pages2 Effects of Material On Efficiency in Alternators Used in Wind Energykadir ylmazNo ratings yet

- Plant Name & CodeDocument16 pagesPlant Name & CodeDevnarayam SahuNo ratings yet

- Helical Coil SpringDocument36 pagesHelical Coil SpringmailbkraoNo ratings yet

- G S Earth WireDocument10 pagesG S Earth WiresaratNo ratings yet

- Railway Steel Grade PDFDocument4 pagesRailway Steel Grade PDFv4lkr3yNo ratings yet

- Welding Procedures Specification For Flux Cored Arc Welding of Wind TowersDocument10 pagesWelding Procedures Specification For Flux Cored Arc Welding of Wind TowersMuhammad Nursalam ZulkifliNo ratings yet

- Pipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda TpsDocument37 pagesPipe Conveyor System To Transport Coal From WCL Coal Mines To Koradi & Khaperkheda Tpsஅம்ரு சாந்திவேலுNo ratings yet

- Development of 700°C Class Steam Turbine TechnologyDocument6 pagesDevelopment of 700°C Class Steam Turbine TechnologyJuve100% (1)

- Module - НЕС01/Program-НЕС012 Technology and equipment for welding of heavy and power generation (including nuclear) engineeringDocument11 pagesModule - НЕС01/Program-НЕС012 Technology and equipment for welding of heavy and power generation (including nuclear) engineeringVishwas Rao MNo ratings yet

- RSP ReportDocument26 pagesRSP ReportSwastik MohapatraNo ratings yet

- 1414664966158-Ti Mi 0001Document2 pages1414664966158-Ti Mi 0001Kamlesh MhatreNo ratings yet

- IJAMT Rao IndiaDocument54 pagesIJAMT Rao IndiaM R MANJU COMPUTERSNo ratings yet

- Training at IOCL ChaksuDocument22 pagesTraining at IOCL Chaksusarthak100% (2)

- Blast Furnace HydraulicsDocument36 pagesBlast Furnace Hydraulicssghane5674No ratings yet

- Golovatenko 2016 IOP Conf. Ser. Mater. Sci. Eng. 150 012002Document7 pagesGolovatenko 2016 IOP Conf. Ser. Mater. Sci. Eng. 150 012002Manshi SinghNo ratings yet

- Design and Crash Analysis of A Rollcage For Formula Sae Race CarDocument5 pagesDesign and Crash Analysis of A Rollcage For Formula Sae Race CarVipulNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Smi 306Document2 pagesSmi 306Greshy FieldNo ratings yet

- Smi 323Document4 pagesSmi 323Greshy FieldNo ratings yet

- Smi 160Document3 pagesSmi 160Greshy FieldNo ratings yet

- WAG9 Tools & PlantsDocument1 pageWAG9 Tools & PlantsGreshy FieldNo ratings yet