Professional Documents

Culture Documents

Construction Materials Notes Chapter 5

Construction Materials Notes Chapter 5

Uploaded by

Anupama Thakur0 ratings0% found this document useful (0 votes)

4 views5 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views5 pagesConstruction Materials Notes Chapter 5

Construction Materials Notes Chapter 5

Uploaded by

Anupama ThakurCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 5

### Unit V: Modified Materials

#### Modified Bitumen Using Plastic or Polymers

##### Properties

1. **Increased Elasticity:** Modified bitumen exhibits greater flexibility and elasticity

compared to conventional bitumen, enhancing its ability to withstand temperature fluctuations

without cracking.

2. **Enhanced Adhesion:** Improved bonding with aggregates, resulting in better pavement

performance and durability.

3. **Resistance to Deformation:** Higher resistance to rutting and permanent deformation under

heavy traffic loads.

4. **Improved Temperature Susceptibility:** Reduced susceptibility to temperature changes,

making it suitable for use in both hot and cold climates.

5. **Durability:** Increased resistance to aging and oxidation, leading to longer service life.

##### Advantages

1. **Environmental Benefits:** Utilizes waste plastics, reducing landfill waste and promoting

recycling.

2. **Economic Benefits:** Extended lifespan of roads reduces maintenance costs and the

frequency of repairs.

3. **Improved Performance:** Better performance under varying climatic conditions and heavy

traffic loads.

##### Applications

1. **Road Construction:** Used in flexible pavements for highways, urban roads, and airport

runways.

2. **Waterproofing:** Utilized in roofing materials and waterproofing membranes.

#### Modified Cement Concrete Using Various Industrial Ashes

##### Types of Industrial Ashes

1. **Fly Ash:** By-product of coal combustion in power plants.

2. **Blast Furnace Slag:** By-product from the production of iron in blast furnaces.

3. **Silica Fume:** By-product of silicon and ferrosilicon alloy production.

4. **Rice Husk Ash:** By-product of burning rice husks.

##### Properties

1. **Improved Workability:** Enhanced workability due to the fine particle size of ashes, which

acts as a filler and lubricant.

2. **Increased Strength:** Pozzolanic reaction contributes to the development of additional

cementitious compounds, increasing the strength of concrete.

3. **Reduced Permeability:** Improved impermeability, reducing the ingress of harmful

substances like chlorides and sulfates.

4. **Durability:** Enhanced resistance to chemical attacks, sulfate attack, and alkali-silica

reaction.

##### Advantages

1. **Sustainability:** Utilizes industrial by-products, reducing environmental impact and

promoting waste management.

2. **Cost-Effectiveness:** Potential reduction in the cost of concrete production by replacing a

portion of Portland cement with industrial ashes.

3. **Improved Performance:** Better long-term performance and durability of concrete

structures.

##### Applications

1. **Building Construction:** Used in the construction of residential and commercial buildings.

2. **Infrastructure Projects:** Applied in roads, bridges, dams, and other large infrastructure

projects.

3. **Precast Concrete Products:** Used in manufacturing precast elements like blocks, pipes,

and panels.

##### Properties of Slag- and Polymer-Stabilized Soil

1. **Increased Strength:** Improved load-bearing capacity and shear strength.

2. **Reduced Swelling and Shrinkage:** Minimized volume changes in expansive soils.

3. **Improved Durability:** Enhanced resistance to erosion, weathering, and chemical attack.

4. **Reduced Permeability:** Lowered permeability, preventing water infiltration and

increasing soil stability.

##### Advantages

1. **Enhanced Performance:** Provides better soil performance in terms of strength, stability,

and durability.

2. **Environmental Benefits:** Utilizes industrial by-products like slag, reducing waste and

promoting recycling.

3. **Cost Savings:** Reduces the need for new materials and minimizes construction and

maintenance costs.

##### Applications

1. **Road Construction:** Stabilized subgrades and base layers for roads and highways.

2. **Foundation Engineering:** Improved soil properties for building foundations and

embankments.

3. **Erosion Control:** Stabilized soils for slopes, embankments, and coastal protection.

#### Polymers in Civil Engineering

Polymers are macromolecules composed of repeating structural units called monomers. They can

be classified into various types based on their chemical structure, properties, and applications.

Here are some common types of polymers:

1. **Polyethylene (PE):**

- **Properties:** High strength, flexibility, and chemical resistance.

- **Applications:** Packaging films, bottles, pipes, and containers.

2. **Polypropylene (PP):**

- **Properties:** High stiffness, heat resistance, and chemical resistance.

- **Applications:** Packaging, automotive parts, textiles, and medical devices.

3. **Polyvinyl Chloride (PVC):**

- **Properties:** Versatile, durable, and flame-retardant.

- **Applications:** Pipes, window frames, flooring, and cables.

4. **Polystyrene (PS):**

- **Properties:** Lightweight, rigid, and good electrical insulation.

- **Applications:** Packaging materials, disposable cups, and insulation.

5. **Polyethylene Terephthalate (PET):**

- **Properties:** Transparent, lightweight, and strong.

- **Applications:** Beverage bottles, food packaging, and textile fibers.

6. **Polyurethane (PU):**

- **Properties:** High elasticity, toughness, and resistance to abrasion.

- **Applications:** Foam insulation, coatings, adhesives, and footwear.

7. **Polytetrafluoroethylene (PTFE):**

- **Properties:** Non-stick, chemical resistance, and high-temperature stability.

- **Applications:** Non-stick cookware, gaskets, seals, and industrial coatings (e.g., Teflon).

8. **Polyethylene Glycol (PEG):**

- **Properties:** Water-soluble, biocompatible, and non-toxic.

- **Applications:** Pharmaceuticals, personal care products, and lubricants.

9. **Polyvinyl Alcohol (PVA):**

- **Properties:** Water-soluble, biodegradable, and film-forming.

- **Applications:** Textile sizing, adhesives, and paper coatings.

10. **Polyacrylonitrile (PAN):**

- **Properties:** High strength, chemical resistance, and thermal stability.

- **Applications:** Fibers for textiles, carbon fibers, and membranes.

##### Properties

1. **High Strength:** Polymers offer high tensile and compressive strength.

2. **Flexibility:** Can be molded into various shapes and forms.

3. **Durability:** Resistant to chemicals, moisture, and UV radiation.

4. **Lightweight:** Lower density compared to traditional construction materials, reducing

overall structure weight.

##### Advantages

1. **Versatility:** Wide range of applications due to the ability to tailor properties for specific

needs.

2. **Reduced Maintenance:** Long-lasting and resistant to environmental factors, reducing

maintenance costs.

3. **Ease of Installation:** Lightweight and easy to handle, speeding up construction processes.

##### Applications

1. **Polymer-Modified Concrete:** Enhanced durability and performance in harsh

environments.

2. **Geosynthetics:** Used in soil stabilization, erosion control, and drainage systems.

3. **Adhesives and Sealants:** Applied in bonding and sealing applications in construction.

4. **Coatings:** Protective coatings for structures to improve durability and resistance to

environmental factors.

You might also like

- Civil Engineering PlasticsDocument5 pagesCivil Engineering PlasticsMahawa KabbaNo ratings yet

- Construction Materials Notes Chapter 3Document5 pagesConstruction Materials Notes Chapter 3Anupama ThakurNo ratings yet

- Construction Materials Notes Chapter 6Document16 pagesConstruction Materials Notes Chapter 6Anupama ThakurNo ratings yet

- Application of ResinsDocument2 pagesApplication of Resinsjonesmuta769No ratings yet

- Overview of Adm-WPS OfficeDocument3 pagesOverview of Adm-WPS OfficeMahawa KabbaNo ratings yet

- Civil Engineering Paint NoteDocument4 pagesCivil Engineering Paint NoteMahawa KabbaNo ratings yet

- Construction MaterialsDocument9 pagesConstruction Materialsmalikarslan536No ratings yet

- Line8: Quality, Efficiency, Sustainability and Available Standards of Dry Mix MortarsDocument8 pagesLine8: Quality, Efficiency, Sustainability and Available Standards of Dry Mix Mortarsniteen_mulmule485No ratings yet

- Rebuild-Vol 9Document20 pagesRebuild-Vol 9ahtin618No ratings yet

- Introduction to-WPS OfficeDocument6 pagesIntroduction to-WPS OfficeMahawa KabbaNo ratings yet

- Wall FinishesDocument21 pagesWall Finishesbalajosh69No ratings yet

- Minor Project 1 PDFDocument42 pagesMinor Project 1 PDFSumit JoshiNo ratings yet

- Use Fo Waste Plastic in Road ConstructionDocument5 pagesUse Fo Waste Plastic in Road ConstructionVishal SalujaNo ratings yet

- Advanced Concrete Technology Past Paper QuestionsDocument8 pagesAdvanced Concrete Technology Past Paper QuestionsAsad QaziNo ratings yet

- Advanced Concrete Technology Past Paper Questions 1Document11 pagesAdvanced Concrete Technology Past Paper Questions 1Asad QaziNo ratings yet

- MDocument4 pagesMEmmanuel Vikthur Akinl'soseNo ratings yet

- Brick ManufacturingDocument3 pagesBrick Manufacturingveenau 1No ratings yet

- Lecture Notes On CementDocument4 pagesLecture Notes On CementMahawa KabbaNo ratings yet

- The Importance and Need For Mineral Admixtures in Concrete Construction Are Profound and MultifacetedDocument5 pagesThe Importance and Need For Mineral Admixtures in Concrete Construction Are Profound and MultifacetedAbdelaziz MohamedNo ratings yet

- PaintDocument4 pagesPaintMahawa KabbaNo ratings yet

- Polymer Impregnated Concrete - Uses, Properties of Polymers in ConcreteDocument4 pagesPolymer Impregnated Concrete - Uses, Properties of Polymers in ConcretesahilkaushikNo ratings yet

- Hemp-Derived Carbon Nanosheet Composites - Transforming Defense and Industrial ApplicationsDocument5 pagesHemp-Derived Carbon Nanosheet Composites - Transforming Defense and Industrial ApplicationsMarie Landry's Spy ShopNo ratings yet

- Composite MaterialsDocument22 pagesComposite MaterialsEr Ashish PoudelNo ratings yet

- Chapter 7-Other MaterialDocument20 pagesChapter 7-Other Materialمحمد أمير لقمانNo ratings yet

- ProcessDocument13 pagesProcessDuy Khanh HuynhNo ratings yet

- Cellular Lightweight Concrete Materials, Applications and AdvantagesDocument5 pagesCellular Lightweight Concrete Materials, Applications and Advantagesvenkateswara rao pothinaNo ratings yet

- Making Plastic BallsDocument6 pagesMaking Plastic Ballsforthework301No ratings yet

- Bitumen ModificationDocument3 pagesBitumen Modificationjamiulawansin5No ratings yet

- Application of The PolymerDocument3 pagesApplication of The PolymerMarul0% (1)

- Soil FormationDocument50 pagesSoil Formationtejasg605No ratings yet

- ASSIGNMENT 8 - SOMESH SIDDHARTH - A1988520002 (Incomplete)Document9 pagesASSIGNMENT 8 - SOMESH SIDDHARTH - A1988520002 (Incomplete)Somesh SiddharthNo ratings yet

- Civiil Engineering Material AssignmentDocument12 pagesCiviil Engineering Material AssignmentSaad AbbasiNo ratings yet

- Construction Materials NotesDocument14 pagesConstruction Materials NotesAnupama ThakurNo ratings yet

- Bitumen Modified With SBS Thermoplastic For Roofing ApplicationDocument9 pagesBitumen Modified With SBS Thermoplastic For Roofing ApplicationResearch and Development100% (1)

- Unit - Iii: Types of Concrete Aggregates and Concrete:: Lightweight AggregateDocument9 pagesUnit - Iii: Types of Concrete Aggregates and Concrete:: Lightweight AggregatedaraNo ratings yet

- CMTDocument3 pagesCMTJomar D. MarquezNo ratings yet

- Concrete Check ListDocument49 pagesConcrete Check ListlifetodaytomorrowandyesterdayNo ratings yet

- Ilovepdf MergedDocument38 pagesIlovepdf Mergedalina.tlekkabylova270202No ratings yet

- Green Building Materials and Material EfficiencyDocument3 pagesGreen Building Materials and Material Efficiencyveenau 1No ratings yet

- 078BCE025Document27 pages078BCE025078bce025.anirudraNo ratings yet

- Polymer Concrete ReportDocument35 pagesPolymer Concrete ReportYatesh SkNo ratings yet

- Advanced Concrete TechnologyDocument9 pagesAdvanced Concrete TechnologyAsad QaziNo ratings yet

- Green ConcreteDocument2 pagesGreen ConcreteSandipan DuttaNo ratings yet

- Manufacturing of CementDocument3 pagesManufacturing of Cementveenau 1No ratings yet

- Absolutely, her-WPS OfficeDocument6 pagesAbsolutely, her-WPS Officehtetwyan54No ratings yet

- Styrofoam BasfDocument10 pagesStyrofoam Basfkunalji_jainNo ratings yet

- Effect of Natural Rubber On The Properties of Bitumen and Bituminious MixesDocument13 pagesEffect of Natural Rubber On The Properties of Bitumen and Bituminious MixesIAEME Publication100% (1)

- Project Report On Dough Moulding Compound (DMC), Bulk Moulding Compound (BMC), Sheet Moulding Compound (SMC)Document7 pagesProject Report On Dough Moulding Compound (DMC), Bulk Moulding Compound (BMC), Sheet Moulding Compound (SMC)EIRI Board of Consultants and Publishers33% (3)

- Green ConcreteDocument14 pagesGreen ConcretePankajKumar100% (1)

- Module 1 - Concrete As Construction MaterialDocument24 pagesModule 1 - Concrete As Construction Materialabinash choudharyNo ratings yet

- ICPIC2018 122 Final v4Document7 pagesICPIC2018 122 Final v4Long An DoNo ratings yet

- Green Concrete For Sustainable ConstructionDocument5 pagesGreen Concrete For Sustainable ConstructionInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Project On Finding An Alternative Binder For AsphaltDocument28 pagesProject On Finding An Alternative Binder For AsphaltStephen BoachieNo ratings yet

- Assignment 2 (Archit Todi 17 - 274)Document15 pagesAssignment 2 (Archit Todi 17 - 274)chemical todiNo ratings yet

- Civil Engineering GlassDocument4 pagesCivil Engineering GlassMahawa KabbaNo ratings yet

- Section 04200 - Masonry: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument4 pagesSection 04200 - Masonry: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Classification On The Future Developments in Composite MaterialsDocument5 pagesClassification On The Future Developments in Composite MaterialsberhaneNo ratings yet

- Polymer ConcreteDocument12 pagesPolymer ConcreteBharath Bhushan100% (2)

- Mineral Amineral Naturally Substance: ContrastDocument42 pagesMineral Amineral Naturally Substance: ContrastShreya ReddyNo ratings yet

- Fire CalculationsDocument29 pagesFire CalculationsAta AtefNo ratings yet

- Korea PDFDocument1,867 pagesKorea PDFCheryl BrigitaNo ratings yet

- Watermelon Mint Hand & Body Lotion - Humblebee & MeDocument22 pagesWatermelon Mint Hand & Body Lotion - Humblebee & MeShahid YousafNo ratings yet

- Real World Challenges in Challenges in Plastic Analysis AnalysisDocument24 pagesReal World Challenges in Challenges in Plastic Analysis AnalysisAlexSNo ratings yet

- Description of Reference Ranges for Organic Acids in Urine مهمDocument11 pagesDescription of Reference Ranges for Organic Acids in Urine مهمfarkad rawiNo ratings yet

- CHY1701-M4 - Dr. Krishnendu BiswasDocument58 pagesCHY1701-M4 - Dr. Krishnendu Biswaslalithkumaran LNo ratings yet

- The Fixed Bed Catalytic Reactor: Lecture OnDocument20 pagesThe Fixed Bed Catalytic Reactor: Lecture OnshubhamNo ratings yet

- Failure Modes of RCC Beams Strengthened With NSM FRP TechniquesDocument9 pagesFailure Modes of RCC Beams Strengthened With NSM FRP TechniquesfelixNo ratings yet

- Radial, Axial or Dual View ICP: Which Do You Choose?: Manny Almeida Teledyne Leeman Labs, Inc. Hudson, NH 03031Document33 pagesRadial, Axial or Dual View ICP: Which Do You Choose?: Manny Almeida Teledyne Leeman Labs, Inc. Hudson, NH 03031Ridwan HarahapNo ratings yet

- Named AllDocument16 pagesNamed AllAbhishek GumwantNo ratings yet

- Name of The Business: Fabricultured Reason For Choice of Name: The Name of The Business Is "Fabricultured". This Is A CombinationDocument13 pagesName of The Business: Fabricultured Reason For Choice of Name: The Name of The Business Is "Fabricultured". This Is A CombinationPrinces Aliesa BulanadiNo ratings yet

- Stock 16042022Document81 pagesStock 16042022NeetuNo ratings yet

- High Shrink Sleeves: Product DescriptionDocument2 pagesHigh Shrink Sleeves: Product DescriptionCristobal Leal ArandaNo ratings yet

- Hydrogen Sulfide (0.0001% - 0.05 %) in Nitrogen: Safety Data Sheet 50248Document9 pagesHydrogen Sulfide (0.0001% - 0.05 %) in Nitrogen: Safety Data Sheet 50248pcatruongNo ratings yet

- Introduction To The Structure and The Structural Role of Elements in GlassesDocument84 pagesIntroduction To The Structure and The Structural Role of Elements in GlassesBiswanath senNo ratings yet

- Worldwide Engineering Standards: Low Carbon Sheet SteelDocument13 pagesWorldwide Engineering Standards: Low Carbon Sheet SteelaldairlopesNo ratings yet

- To Study The Effects of Various Drugs On Rabbit EyeDocument2 pagesTo Study The Effects of Various Drugs On Rabbit EyeAbhinavcineplex moviesmaniaNo ratings yet

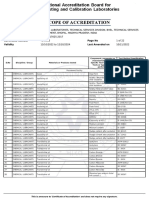

- NABL TestsDocument22 pagesNABL TestsSandeep YadavNo ratings yet

- Prep #21-23 Non-Aqueous Liquids - SpiritsDocument3 pagesPrep #21-23 Non-Aqueous Liquids - SpiritsKirsten Shayne ManingasNo ratings yet

- GPX Assay KitDocument6 pagesGPX Assay KitRodrigo OliveiraNo ratings yet

- Waste Management Plan: Project Name To Be Written HereDocument16 pagesWaste Management Plan: Project Name To Be Written HerePrashanth JeerNo ratings yet

- UNIVEX MSDS EN (1) Certifikat Za LjepiloDocument8 pagesUNIVEX MSDS EN (1) Certifikat Za LjepiloBojsan IzjelicaNo ratings yet

- Plant Physiology Lab 1Document11 pagesPlant Physiology Lab 1khushbakht zamirNo ratings yet

- Automatic Control ValvesDocument36 pagesAutomatic Control Valveshoxoxi1234No ratings yet

- Wolbers Solvent Gel Kit: Instructions For UseDocument3 pagesWolbers Solvent Gel Kit: Instructions For UseMaria SberaNo ratings yet

- 8 Ionic Equilibrium MCQsDocument8 pages8 Ionic Equilibrium MCQsANIKET BATTINWARNo ratings yet

- WOLFRACOAT C FLUID 099118 PI GB enDocument2 pagesWOLFRACOAT C FLUID 099118 PI GB enwajahat ali KhanNo ratings yet

- Chemistry Higher Level Paper 1: Instructions To CandidatesDocument17 pagesChemistry Higher Level Paper 1: Instructions To CandidatesSrushti ManeNo ratings yet

- B 308 - B 308M - 02 Qjmwoc9cmza4tqDocument6 pagesB 308 - B 308M - 02 Qjmwoc9cmza4tqGalih PutraNo ratings yet