Professional Documents

Culture Documents

Flow Valves

Flow Valves

Uploaded by

Alin ChehadeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Valves

Flow Valves

Uploaded by

Alin ChehadeCopyright:

Available Formats

FLOW CONTROL VALVES

These valves control flow rates in hydraulic circuits and are grouped as follows

according to the control to be achieved in respective circuits.

5-1 Restrictors/One Way Restrictors

5-2 Flow Control Valves/Flow Control and Check Valves

5-3 Deceleration Valves/Deceleration and Check Valves

5-4 Feed Control Valves

5-5 Pilot Operated Flow Control and Check Valves

5-1 Restrictors/One Way Restrictors

These valves regulate flow rates in hydraulic circuits. They have the advantages of plain structure, simple operation,

and wide range of adjustment. On the other hand, they cannot accurately control the flow; even through the fixed

restriction, the flow varies with the inlet-outlet differential pressure and the fluid viscosity. Therefore, these valves are

placed where the pressure difference varies little, and high control accuracy is not required. The one-way restrictors

regulate flow in one way, while allowing reversed flow to freely pass through.

Restrictor

One-Way Restrictor

Graphic Symbol

Fig. 5.1 Restrictor

Viscosity of Hydraulic Fluid: 30 mm2/s

[ΔP: Differential Pressure MPa]

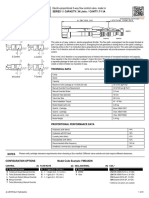

●SRG −06, SRCT

SRT

SRCG −06

P:25

120

P:20

P:16

100

P:10

P:7

80

P:4

Flow Rate

60 P:2

P:1

L/min 40 P:0.5

20

0 1 2 3 4 5 6 7 8 9 10

Adj. Handle Position (Number of Turns) Fully Open

Fig. 5.2 Metred Flow vs. Adjustment Handle Revolutions

FLOW CONTROL VALVES ■ 32

5-2 Flow Control Valves/Flow Control and Check Valves

These valves consist of a pressure compensator (pressure reducing valve that keeps the pressure difference constant)

and a restrictor. They maintain a constant flow rate, independent of the inlet-outlet differential pressure. Provided with

a sharp-edge orifice, they can also work regardless of fluid temperature or viscosity.

In a circuit where the flow rate is regulated to a low level, the control flow may be momentarily exceeded, leading to

jumping of the actuator. This phenomenon is related to a time lag until the pressure compensating piston is properly

positioned for flow control. To prevent the phenomenon, the piston stroke should be adjusted according to the inlet-

outlet differential pressure.

Flow Control Valve

Flow Control and Check Valve

Graphic Symbols

Fig. 5.3 Flow Control Valve

Flow control valves are basically used as follows.

(1) Meter-In Control

The control valve is connected in series with the cylinder inlet to directly control the input flow. Prior to the

control valve, a relief valve is applied to excess flow, which escapes through a relief valve. In a circuit where

load is applied in the direction of piston travel, the control valve may lose cylinder speed control.

(2) Meter-Out Control

The control valve is connected in series with the cylinder outlet to directly control the output flow. Prior to the

control valve, excess flow escapes through a relief valve to a tank. This circuit design is used for applications

where the piston could move down faster than a control speed, as in the case of vertical drilling machines, or

where there should always be a back pressure in the cylinder. Careful attention should be paid to the fact that

the cylinder outlet pressure may rise above the relief pressure produced in the circuit.

(3) Bleed-Off Control

The control valve is installed on a by-pass line to regulate flow to the tank and control the actuator speed.

Compared to the other control circuits, this circuit works with small power consumption because the pump’ s

discharge pressure is fully delivered to the load resistance. Given that the bleed flow is constant, the fluctuation

of pump flow determines the actuator speed. In other words, the pump discharge flow directly influences the

load and the pump’ s volumetric efficiency.

This circuit does not allow for control of multiple actuators.

Figure 5.4 shows flow control circuits provided with the control types (1) to (3). PG* indicates the pressure at each

point observed when the cylinder is operated at the load pressure of 4 MPa (580 psi). The mechanisms of the meter-in

and -out control can be understood by comparing the positions and inlet/outlet pressures of the flow control valves and

the inlet/outlet pressures of the cylinders in the meter-in and -out control circuits. The higher cylinder outlet pressure in

the meter-out control circuit suggests that the cylinder area difference results in pressure intensification. Also,

differences between the bleed-off control and the other control types are clear in the relief valve pressures and the

cylinder inlet pressures. The pressure values in the figure are based on the assumption that there are no pipe

resistance and pressure loss through the valves.

33 ■ FLOW CONTROL VALVES

Load Pressure=4MPa Load Pressure=4MPa Load Pressure=4MPa

Ac=100cm2 Ah=50cm2 Ac=100cm2 Ah=50cm2 Ac=100cm2 Ah=50cm2

Pushing Pushing Pushing

Direction Direction Direction

PG-3 PG-4 PG-3 PG-4 PG-3 PG-4

=4MPa =0MPa =10MPa =12MPa =4MPa =0MPa

PG-2 PG-5 PG-2 PG-5 PG-2 PG-5

=10MPa =0MPa =10MPa =0MPa =4MPa =0MPa

10MPa 10MPa 10MPa

PG-1 PG-1 PG-1

=10MPa =10MPa =4MPa

Meter-In Control Meter-Out Control Bleed-Off Control

Fig. 5.4 Examples of Control Circuits Using Flow Control Valves

5-3 Deceleration Valves/Deceleration and Check Valves

These valves continuously regulate flow rates, using a cam mechanism. Pushing the spool down decreases the flow

rate for the normal open type and increases it for the normal close type. When the normal open type is installed to

cushion the cylinder piston, accurate stroke end control is difficult. In this case, the restrictor and directional control

valve should be adjusted so that the piston slowly returns to an intended position and then stops.

Deceleration Valve

Deceleration and Check Valve

Graphic Symbols

Fig. 5.5 Deceleration and Check Valve

(Normal Close Type)

FLOW CONTROL VALVES ■ 34

5.5 Pilot Operated Flow Control and Check Valves

These valves are pilot-operated. They control the flow with a hydraulic cylinder to accelerate or decelerate the

actuator without shock.

T P T P

O M O M

A B

A B

Pilot Operated Flow Pilot Operated Flow

Control Valve Control and

Check Valve

Graphic Symbols

Fig. 5.9 Pilot Operated Flow Control Valve

1 Pilot line“A”

Set with the Pilot Flow Adjustment Dial Decrease

2 Set with the Maximum Flow Adjustment Screw Decrease

3 Pilot line“B”

Set with the Pilot Flow Adjustment Dial Decrease

Flow Rate

4 4 Set with the Minimum Flow Adjustment Screw

Increase

T1 T2

Time

ON

OFF OFF

Solenoid Signal

Fig. 5.10 Control Pattern and Flow Rate Adjustment

Other flow control valves described below are available ● Priority Control Valves

● Flow Control and Relief Valves These valves are incorporated in power source systems

These valves contain a flow control valve and a relief for vehicles, etc. If pump supply flow is at or below a

valve, the combination of which achieves a pump preset level, the valves allow all of the flow to go to the

discharge pressure almost equal to the load pressure. priority line. If it is above the preset level, they direct

Even when the load pressure is low, the pump the excess flow to the bypass line.

discharge pressure does not increase to the control

limit, ensuring power-saving operation of the system. ● Shut Off Valves

These valves prevent counter load from decreasing

● Flow Dividers when the cylinder outlet pressure falls because of

These valves are used to synchronize two or more damaged piping or rubber hoses. When detecting that

actuators. They have one inlet port and two outlet the cylinder is rapidly moving down, these valves

ports so that the inlet and outlet flows can be regulated quickly close to shut off the flow.

to certain levels, regardless of the load.

FLOW CONTROL VALVES ■ 36

You might also like

- Caraka-Samhita - Eng. Vol. 1Document582 pagesCaraka-Samhita - Eng. Vol. 1calatorulfaradrum84% (70)

- Global Business 4th Edition Ebook PDFDocument42 pagesGlobal Business 4th Edition Ebook PDFrobert.higa747100% (40)

- Rubrik CDM Version 6.0 CLI Reference Guide (Rev. B3)Document86 pagesRubrik CDM Version 6.0 CLI Reference Guide (Rev. B3)Chill BeatzNo ratings yet

- DC School Text Book: Intermediate DC Hydraulic CircuitDocument53 pagesDC School Text Book: Intermediate DC Hydraulic CircuitmikeNo ratings yet

- SUMMER PROJECT REPORT (Bajaj Capital0Document39 pagesSUMMER PROJECT REPORT (Bajaj Capital0Rishabh JainNo ratings yet

- Quaker Oats & SnappleDocument5 pagesQuaker Oats & SnappleemmafaveNo ratings yet

- Part 4 Hydraulic Control Principle and ParametersDocument22 pagesPart 4 Hydraulic Control Principle and ParametersrohanNo ratings yet

- Chapter 7 Rev 2 Rotation CircuitsDocument19 pagesChapter 7 Rev 2 Rotation CircuitsAnonymous 340A7vnwV1No ratings yet

- 8 299efi9fi9ef6545505tkkg, MBG BM M KMB KMGTKBMV, GTG, BVFV FGV 02iDocument19 pages8 299efi9fi9ef6545505tkkg, MBG BM M KMB KMGTKBMV, GTG, BVFV FGV 02idhruvNo ratings yet

- Valve Technology: - by Fabian C. GonzalezDocument106 pagesValve Technology: - by Fabian C. GonzalezNyoman RakaNo ratings yet

- © Festo Didactic GMBH & Co. KG, 02/2003 Subject To ChangeDocument2 pages© Festo Didactic GMBH & Co. KG, 02/2003 Subject To ChangecioranescuNo ratings yet

- Z2FS 6 New Series... 40BDocument6 pagesZ2FS 6 New Series... 40Bnemi90No ratings yet

- Flow Control Valves: Hydraulic ComponentsDocument28 pagesFlow Control Valves: Hydraulic ComponentsMohamed IbrahimNo ratings yet

- m731 e K3 v04 5554 en PDFDocument22 pagesm731 e K3 v04 5554 en PDFtsdcnNo ratings yet

- 198 - Adj - VALV. REG. FLUJO CON DESCARGA FC 51 1 SARGENTDocument2 pages198 - Adj - VALV. REG. FLUJO CON DESCARGA FC 51 1 SARGENTjuanNo ratings yet

- Control ValveDocument35 pagesControl Valveshivani DubeyNo ratings yet

- Flow Contrl ValveDocument10 pagesFlow Contrl ValvePremangshu SahaNo ratings yet

- Z2FS 6, 16, 22 Modular Throttle Check ValveDocument6 pagesZ2FS 6, 16, 22 Modular Throttle Check Valvenemi90No ratings yet

- 1.1.1 Functions of Flow-Control ValvesDocument24 pages1.1.1 Functions of Flow-Control Valvesatashi baran mohantyNo ratings yet

- Hydraulic/Hydrostatic Schematic S175 (S/N 525215000 AND ABOVE) (S/N 525315000 AND ABOVE) S185 (S/N 525015000 AND ABOVE) (S/N 525115000 AND ABOVE)Document2 pagesHydraulic/Hydrostatic Schematic S175 (S/N 525215000 AND ABOVE) (S/N 525315000 AND ABOVE) S185 (S/N 525015000 AND ABOVE) (S/N 525115000 AND ABOVE)alexandrNo ratings yet

- B - PVG - Hands On - v4 PDFDocument57 pagesB - PVG - Hands On - v4 PDFJose Manuel Barroso PantojaNo ratings yet

- V 0566legend 2Document2 pagesV 0566legend 2alexandrNo ratings yet

- V 0716legend 2Document2 pagesV 0716legend 2alexandrNo ratings yet

- Hydraulic CircuitsDocument10 pagesHydraulic CircuitsAlin ChehadeNo ratings yet

- F10 & F50 Flow SwitchesDocument12 pagesF10 & F50 Flow SwitchesarmadityaNo ratings yet

- Proportional Remote Control Valves Series PVC6: December, 2007Document4 pagesProportional Remote Control Valves Series PVC6: December, 2007Taller PahrNo ratings yet

- Adcatraining Control Valve 5 Rev 01Document36 pagesAdcatraining Control Valve 5 Rev 01Fendy ShirahNo ratings yet

- CV Exp 6Document7 pagesCV Exp 6Mohd RehanNo ratings yet

- Hydraulic Symbols: Service Training Manual CM 760/780Document23 pagesHydraulic Symbols: Service Training Manual CM 760/780victor lara100% (1)

- Flow Meter Lab ReportDocument11 pagesFlow Meter Lab ReportDaniel PhilpottNo ratings yet

- Linde - HPV Data and SpecificationsDocument33 pagesLinde - HPV Data and SpecificationsxxshNo ratings yet

- Fichas OFRS-15Document3 pagesFichas OFRS-15Hernan AlvarezNo ratings yet

- Self-Operated Pressure Regulators Type 41-73 Universal Excess Pressure ValveDocument8 pagesSelf-Operated Pressure Regulators Type 41-73 Universal Excess Pressure ValveChakravarthi NagaNo ratings yet

- ME471SimpleHydraulicCircuits PDFDocument4 pagesME471SimpleHydraulicCircuits PDFnguyennguyenNo ratings yet

- DX80R Control Valve 9SX14Document34 pagesDX80R Control Valve 9SX14ZawminhtunNo ratings yet

- Solenoid Valve No. 1, No. 2, No. 3 and No.4Document3 pagesSolenoid Valve No. 1, No. 2, No. 3 and No.4bob loblawNo ratings yet

- Van Can Bang Tu Dong Dieu Chinh Cartridge 118 ItalyDocument4 pagesVan Can Bang Tu Dong Dieu Chinh Cartridge 118 Italyluan nguyenNo ratings yet

- IH RedukDocument14 pagesIH RedukPioneer PaperboyNo ratings yet

- Instructions RPE4-10 RPEW4-10 Ha0061 ENDocument1 pageInstructions RPE4-10 RPEW4-10 Ha0061 ENVito LaudicinaNo ratings yet

- 150C VOLVO Steering.&.Hydraulic DiagramDocument5 pages150C VOLVO Steering.&.Hydraulic Diagramgabriel pomaNo ratings yet

- Kombiventil F4006 - 6x - EN - 09 - 12Document10 pagesKombiventil F4006 - 6x - EN - 09 - 12FareethAbdullahNo ratings yet

- Lcbca/Lcbcg/Lcbch: 工作 OperationDocument2 pagesLcbca/Lcbcg/Lcbch: 工作 Operationதமிழன் இராமசாமிNo ratings yet

- Gk247a A-008Document35 pagesGk247a A-008WidiMufantoNo ratings yet

- Info On DRS, MRS, SRDocument23 pagesInfo On DRS, MRS, SRsushant shirsatNo ratings yet

- GK247D A-008 PDFDocument35 pagesGK247D A-008 PDFPallavi ChoudharyNo ratings yet

- V 0715legend 2Document2 pagesV 0715legend 2alexandrNo ratings yet

- 17 SP-Spreader Valves CatalogDocument8 pages17 SP-Spreader Valves CatalogHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Control Chapter 5 - RemoteDocument86 pagesControl Chapter 5 - RemoteWilmar Antonio Zuluaga ArangoNo ratings yet

- V 0444legend 2Document2 pagesV 0444legend 2alexandrNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC & 2 Speed Option: S175 (S/N A3l511001 - A3l519999)Document2 pagesHydraulic/Hydrostatic Schematic With SJC & 2 Speed Option: S175 (S/N A3l511001 - A3l519999)AlexandrNo ratings yet

- Automatic ValvesDocument33 pagesAutomatic ValvesManjeet kumarNo ratings yet

- Hydraulic Symbols: Service Training Manual ECM 720Document24 pagesHydraulic Symbols: Service Training Manual ECM 720victor lara100% (1)

- 651 Series ValvesDocument4 pages651 Series Valvesarij abbassiNo ratings yet

- Rexroth AA4VGDocument64 pagesRexroth AA4VGSedin MurtićNo ratings yet

- J-V Piston PumpDocument35 pagesJ-V Piston Pumpsaka dewaNo ratings yet

- Daikin V Piston - Pump CatDocument35 pagesDaikin V Piston - Pump CatsunhuynhNo ratings yet

- UPDATED6NOV2014-ClassNotes-CONTROL VALVESDocument40 pagesUPDATED6NOV2014-ClassNotes-CONTROL VALVESharrisNo ratings yet

- HuadeDocument8 pagesHuadejcardoso_964479No ratings yet

- Chapt 6 RotationDocument8 pagesChapt 6 RotationManuelNo ratings yet

- Lecture 6 - Pressure and Flow MeasurementsDocument76 pagesLecture 6 - Pressure and Flow MeasurementsMohamed SalaheldinNo ratings yet

- Hydraulic/Hydrostatic Schematic With 2 Speed Option: S175 (S/N A3L511001 - A3L519999)Document2 pagesHydraulic/Hydrostatic Schematic With 2 Speed Option: S175 (S/N A3L511001 - A3L519999)AlexandrNo ratings yet

- Lecture 8 - Control ValvesDocument35 pagesLecture 8 - Control ValvesMohamed SalaheldinNo ratings yet

- Class 7 Hydraulic CircuitsDocument57 pagesClass 7 Hydraulic Circuitsgeorge_zouridis100% (1)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Hydraulic CircuitsDocument10 pagesHydraulic CircuitsAlin ChehadeNo ratings yet

- Improved Form Factor For Drag Estimation of Fuselages With Various Cross SectionsDocument13 pagesImproved Form Factor For Drag Estimation of Fuselages With Various Cross SectionsAlin ChehadeNo ratings yet

- GP 341Document3 pagesGP 341Alin ChehadeNo ratings yet

- Residential Energy Storage User Manual AXE 5.0L Battery SystemDocument16 pagesResidential Energy Storage User Manual AXE 5.0L Battery SystemAlin ChehadeNo ratings yet

- L 9 Huvxd 1 GeimtsggbflxDocument2 pagesL 9 Huvxd 1 GeimtsggbflxAlin ChehadeNo ratings yet

- J 5 Emwk 2 V 0 Hsgxlks 3 AnhDocument2 pagesJ 5 Emwk 2 V 0 Hsgxlks 3 AnhAlin ChehadeNo ratings yet

- FMDA Full en Metric A4Document3 pagesFMDA Full en Metric A4Alin ChehadeNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4Alin ChehadeNo ratings yet

- Steel Grade: Material Data SheetDocument4 pagesSteel Grade: Material Data SheetAlin ChehadeNo ratings yet

- Mechanics of Deformable Bodies: Mapúa Institute of TechnologyDocument16 pagesMechanics of Deformable Bodies: Mapúa Institute of TechnologyAhsan AliNo ratings yet

- Crim 01Document88 pagesCrim 01Marian Jewel VillanuevaNo ratings yet

- Occupational Therapy's Role in Post Concussion Management: Aimil Parmelee, MOT, OTR/L Marlaina Montgomery, MOT, OTR/LDocument27 pagesOccupational Therapy's Role in Post Concussion Management: Aimil Parmelee, MOT, OTR/L Marlaina Montgomery, MOT, OTR/Lsidney drecotteNo ratings yet

- System Center Data Protection Manager 2010 Troubleshooting GuideDocument220 pagesSystem Center Data Protection Manager 2010 Troubleshooting GuideHBNBILNo ratings yet

- Himachal Pradesh Public Service CommissionDocument4 pagesHimachal Pradesh Public Service CommissionHangrang Valley Kinnaur HPNo ratings yet

- Parent'S/Guardian Consent and Waiver Form: Batangas State UniversityDocument1 pageParent'S/Guardian Consent and Waiver Form: Batangas State UniversityGillian Lei Carandang SacisNo ratings yet

- Let's Celebrate Diversity!: Activity 2: Our Abilities Lead inDocument6 pagesLet's Celebrate Diversity!: Activity 2: Our Abilities Lead inSoy Lat GamerNo ratings yet

- The Philippine Marketing Environment: Bruto, Ivy Marijoyce Magtibay, Sarah Jane Guno, RhizaDocument26 pagesThe Philippine Marketing Environment: Bruto, Ivy Marijoyce Magtibay, Sarah Jane Guno, Rhizakenghie tv showNo ratings yet

- Test B Grammar VocabularyDocument2 pagesTest B Grammar Vocabularyთამუ ბაჯელიძეNo ratings yet

- Lec 9-Compatibility of Polymer BlendsDocument7 pagesLec 9-Compatibility of Polymer BlendsMua ban linh tinh100% (1)

- RUSLEDocument16 pagesRUSLEVivek KasarNo ratings yet

- Concept of LeadershipDocument142 pagesConcept of Leadershipv_sasivardhini100% (1)

- MANAGEMENT Spice JetDocument21 pagesMANAGEMENT Spice JetAman Kumar ThakurNo ratings yet

- Rain Water Harvesting!Document17 pagesRain Water Harvesting!SaadNo ratings yet

- Financial Literacy Strategy 2019Document32 pagesFinancial Literacy Strategy 2019sompasongNo ratings yet

- Pareto Dan Pasif KF HBJ 24 Maret 2022Document116 pagesPareto Dan Pasif KF HBJ 24 Maret 2022Indah C. KadullahNo ratings yet

- Rubric For Short Scene With Literary DevicesDocument1 pageRubric For Short Scene With Literary DevicespaympmnpNo ratings yet

- Sample 1Document26 pagesSample 1Vraizen LagnayoNo ratings yet

- Accenture AptitudeDocument122 pagesAccenture AptitudeHarshith P.BNo ratings yet

- Hate Speech - FinalDocument205 pagesHate Speech - FinalThavamNo ratings yet

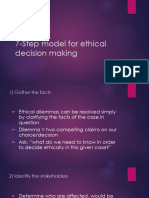

- 7-Step Model For Ethical Decision MakingDocument14 pages7-Step Model For Ethical Decision MakingjermorenoNo ratings yet

- Analysis of Satellite Constellations For The Continuous Coverage of Ground RegionsDocument10 pagesAnalysis of Satellite Constellations For The Continuous Coverage of Ground RegionsOksana VoloshenyukNo ratings yet

- New York State Senate Majority Conference Blue Book - Staff Analysis of The 2023 Executive Budget.Document192 pagesNew York State Senate Majority Conference Blue Book - Staff Analysis of The 2023 Executive Budget.New York Senate100% (1)

- Peru - July20.16.m PonenciasDocument230 pagesPeru - July20.16.m PonenciasedisonNo ratings yet

- Business and Business EnvironmentDocument63 pagesBusiness and Business EnvironmentanFasNo ratings yet