Professional Documents

Culture Documents

Control Philosophy & Interlock Description - 9650-11-PCP-00-0002 R-04

Control Philosophy & Interlock Description - 9650-11-PCP-00-0002 R-04

Uploaded by

mouadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Philosophy & Interlock Description - 9650-11-PCP-00-0002 R-04

Control Philosophy & Interlock Description - 9650-11-PCP-00-0002 R-04

Uploaded by

mouadCopyright:

Available Formats

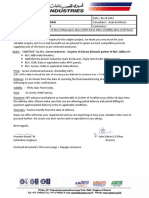

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

CONTROL PHILOSOPHY & INTERLOCK

DESCRIPTION

PROJECT: 50 MPTD (Cl2 BASIS) CHLOR ALKALI

PLANT - 9650

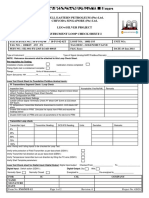

Rev. Date Description Originator Reviewer Approver

00 23.01.2019 Issue for Review DH S.K.S V.G

01 02.05.2019 Revised As Marked A.L S.K.S V.G

02 17.07.2019 Revised As Marked A.L S.K.S V.G

03 05.10.2019 Revised As Marked A.L S.K.S V.G

04 09.04.2021 Revised As Marked SM S.K.S V.G

Project : 9650 Page 1 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9650-11-PID-00-001

BRINE RE-SATURATOR AREA

1. The flow of saturated brine from saturated pump P-01 A/B is maintained and controlled by

flow control valve 001-FCV-01 as per set point of 001-FICA-01. When the flow increases

above the set point control valve opening will decrease.

2. The flow transmitter 001-FI-01 gives alarm when it becomes either High (H) or Low (L).

3. Interlock (5)

When level indication 001-LI-01 of 001-T-02 becomes Low-Low (LL), the Saturated

brine pump (001-P-01 A/B) shall trip. (With interlock by pass switch)

4. The level indication 001-LI-01 of 001-T-02 gives alarm when it becomes either High (H) or

Low (L).

5. Motor/Drive provision of Start and Stop from DCS shall be provided.

001-P-01 A/B - STOP & START

6. All Interlocks should have Bypass switch available on common DCS screen. And the

indication of Bypass switch activated or deactivated should be available on each Interlock

number on each screen.

Project : 9650 Page 2 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9650-11-PID-00-0002( 1 OF 2 )

PRIMARY BRINE TREATMENT

1. The level indication 002-LI-060 of the Flocculants Tank D-060 gives alarm when it becomes either

High – High (HH) or High (H) or Low – Low (LL) or Low (L).

2. Interlock (I-060)

When level indication LI-060 of the Flocculants Tank D-060 becomes Low-Low (LL), the

Agitator A-062 shall trip.

3. The temperature indication 002-TI-01 gives alarm when it becomes either High (H) or Low (L).

4. The temperature Indication 002-TI-02 gives alarm when it becomes either High (H) or Low (L).

5. Motor/Drive provision of Start and Stop from DCS shall be provided.

A-062 - STOP AND START

002-A-01 - STOP AND START (Emergency Power)

002-A-02 - STOP AND START (Emergency Power)

6. The flow transmitter 002-FI-01 gives alarm when it becomes either High (H) or Low (L).

7. The flow transmitter 002-FI-05 gives alarm when it becomes either High (H) or Low (L).

8. The flow transmitter 002-FI-03 gives alarm when it becomes either High (H) or Low (L).

9. The flow of 18% Caustic soda is maintained & controlled by Flow control valve 002-FCV-05 as per

the set point of 002-FICA-05.

10. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each Interlock number on each screen.

Project : 9650 Page 3 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9650-11-PID-00-0002 (2 of 2)

PRIMARY BRINE TREATMENT

1. The level indication 002-LI-01 of the Treated Brine Tank 002-T-04 gives alarm when it becomes

either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

2. Interlock (6)

When level indication 002-LI-01 of the Treated Brine Tank 002-T-04 becomes Low-Low (LL),

the Treated Brine Pump 002-P-02A/B shall trip.

3. The temperature indication 002-TI-03 (for water) of the Clarifier gives alarm when it becomes

either High – High (HH) or High (H).

4. The temperature indication 002-TI-04 (for brine) of the Clarifier gives alarm when it becomes either

High – High (HH) or High (H).

5. Differential Temperature indication DTI-03 measures the differential temperature of the brine

clarifier. The median of 002-TI-03 & 002-TI-04 value is taken as the measured value.

6. Interlock (I-090)

When Pressure indication 0026-PI-090 of the Filter press F-090 feed line High-High (HH), the

Brine settler mud Pump 002-P-01A/B shall trip.

7. The Flow transmitter 002-FI-04 gives alarm when it becomes either High (H) or Low (L).

8. Interlock (7)

When level switch 002-LS-05 of settler mud tank 002-T-05 becomes Low (L) the Brine settler

mud Pump 002-P-01A/B as well as Agitator 002-A-05 shall trip.

9. Motor/Drive provision of Start and Stop from DCS shall be provided.

002-P-01A/B - STOP & START

002-A-03 - STOP & START (EMERGENCY)

002-P-02A/B - STOP & START

10. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each Interlock number on each

screen.

Project : 9650 Page 4 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9650-11-PID-00-0003(1OF 3)

BRINE FILTER

1. The level indication 003-LI-01 of the Filtered Brine Tank 003-T-01 gives Alarm when it becomes

either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

2. Interlock (9)

When level indication 003-LI-01 of the Filtered Brine Tank 003-T-01 becomes Low-Low (LL),

the Filtered Brine Pump 003-P-01A/B shall trip and the flow control valve FV-1401A/B of

running Polish filter (F-140A/B) shall close.

3. The level in the Filtered Brine Tank 003-T-01 is maintained by controlling the Flow of brine by Flow

Control Valve 003-FV-01 as per the set point of 003-LICA-01 or as per the set point of 003-FICA-01.

When flow increases above set point valve opening will reduce.( through selector switch on DCS)

Selector Switch

The flow shall change within minimum & maximum range as per the se point of 003-LICA-01.

Flow Controller (003-FICA-01) - When flow increases above set point the valve opening will reduce.

Level Controller (003-LICA-01) - When level increases above set point, the valve opening will

reduce.

4. The flow of brine through Filter is controlled by Flow control valve 003-FCV-01 as per the set point

of 003-FICA-01. When flow increases above set point valve opening will reduce.

5. The flow transmitter 003-FIA-01 gives alarm when it becomes either High (H) or Low (L).

6. The flow of process water during back wash of Filter is controlled by Flow control valve 003-FCV-02

as per the set point of 003-FICA-02. When flow increases above set point valve opening will reduce.

7. The flow transmitter 003-FIA-02 gives alarm when it becomes either High (H) or Low (L).

8. Differential pressure indicatior 003-DPIA-01A/B gives alarm when it become High (H) & Low (L).

9. Motor/Drive provision of Start and Stop from DCS shall be provided.

003-P-01A/B - START & STOP (EMERGENCY)

Project : 9650 Page 5 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

10. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each Interlock number on each screen.

For the first time fill the filter 003-F-01A with water by selecting the switch is to manual mode open the

following valve –

003-XV-05A ,003-XV-02A and 003-FV-01 to set point 18 m3/hr for 30 min.

Settling Of anthracite:-

After 60 min close valve 003-XV-05, 003-XV-02 and 003-FV-02 for 5 min.

Resetting:-

After 5 min open the valve 003-XV-01, 003-XV-06 and 003-FCV-01 to set value 18 m3/hr. for 10 min and

open the manual valve to 009-T-01.

Preparation Prior to operation:-

After 10 min check the gpl. If it is greater than 280 open block valve to clarified brine tank for 05 min.

Operation:-

Condition check: The filter will check, No back wash/ Backwash complete, switch is stop.

After 01 min open valve 003-XV-07 and close 003-XV-06 and filter will come into operation. 003-F-01A will

be in operation and keep 003-F-01B in standby. Select switch A (O)-B(S) and put the whole operation into

auto mode in which A will be in operation and B will be in standby.

After 24 hrs or turbidity greater than 2 whichever is earlier, it will generate an alarm for filter A time

exhaust. Select switch B (O)-A(S)

Then 003-XV-01, 003-XV-07 will open and remain open, 003-XV-01 and 003-XV-07 will remain open for

120sec after 120 sec 003-XV-14 and 003-XV-13 will open, 003-XV-01, 003-XV-07 will close.

Back wash of 003-F-01A:-

Condition check: The filter should not be in operation (inlet outlet valve should be close).

Select switch start only when 003-LS-145 is low (operator decision)

1. Brine Draining:-

003-XV-03, 003-XV-06 will open and brine will drain to 002-T-04 for 300 sec.

2. Preparation for backwash. :-

After 300 sec. 003-XV-03, 003-XV-06 will close and 003-XV-05, 003-XV-02 will open for 30 sec.

3. Backwash:-

Project : 9650 Page 6 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

After 30 sec 003-XV-04 will open and 003-FCV-02 will open at set point 18 m3/hr (set value can be changed

if required) and other valve 003-XV-02 and 003-XV-05 will remain open for 30 min.

4. Settling of anthracite:

After 30 min 003-XV-04, 003-XV-05 and 003-XV-02 will close and 003-FCV-02 will close with a ‘0’ set value

for 300 sec.

5. Resetting:-

After 300Sec 003-XV-01 and 003-XV-06 will open for 600sec

6. Backwash finish:-

After 600sec check the gpl manually and if it is greater than 280 then select backwash finish then 003-XV-

01, 003-XV-06 will close.

After 24 hours of backwash finish it will generate alarm for filter B time exhaust Select switch A (O)-B(S)

(operator decision)

Back wash of 003-F-01B:-

Condition check: The filter should not be in operation (inlet outlet valve should be close).

Select switch start only when 003-LS-145 is low (operator decision)

1. Brine Draining:-

003-XV-10, 003-XV-13 will open and brine will drain to 002-T-04 for 300 sec.

2. Preparation for backwash. :-

After 300 sec. 003-XV-10, 003-XV-13 will close and 003-XV-12, 003-XV-09 will open for 30 sec.

3. Backwash:-

After 30 sec 003-XV-11 will open and 003-FCV-02 will open at set point 18 m3/hr (set value can be changed

if required) and other valve 003-XV-09 and 003-XV-12 will remain open for 30 min.

4. Settling of anthracite:

After 30 min 003-XV-11, 003-XV-12 and 003-XV-09 will close and 003-FCV-02 will close with a ‘0’ set value

for 300 sec.

5. Resetting:-

After 300Sec 003-XV-08 and 003-XV-13 will open for 600sec

Project : 9650 Page 7 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

6. Backwash finish:-

After 600sec check the gpl and if it is greater than 280 then select backwash finish then 003-XV-08, 003-XV-

13 will close.

After 24 hours of backwash finish it will generate alarm for filter B time exhaust Select switch A (O)-B(S)

(operator decision)

NOTE

1. Every step should have a skip selector so that if it is selected it will skip to the next step

2. Manual mode if back wash is selected for the filter .it should start back wash from step 1 till step 6

3. All timings should be adjustable from the screen.

11. The following documents are to be referred for Polish brine Filter Sequence operation.

Sl. NO Description Annexure No

1. LOGIC TIME CHART Annexure-E

2. SEQUENCE OPERATION Annexure-F

Project : 9650 Page 8 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9650-11-PID-00-0003(2 OF 3)

BRINE FILTRATION

(Option for Manual & Automatic Operation on DCS Screen)

1. METHOD OF INITIAL START-UP

a) Set F-140A Operation switch turn “RUN” position. F-140A Brine filter advances each step

automatically, in turn, from Preparation of Process (Step No.101) and the following step.

• Liquid Filling 1 (Step No.102)

• Over Flow (Step No.103)

• Liquid Filling 2 (Step No.104)

• Precoat tank liquid filling (Step No.105)

The indicator lamp “PRECOAT AID PREPARATION” is indicated. Dose α-cellulose into pre-coat

tank Push “PRECOAT AID PREPARATION FINISH” Button. pre-coat tank carries out the following

steps automatically.

The indicator lamp “BODY FEED AID DOSING” is indicated. Dose α-cellulose into body feed

tank. (See terms E. 2. (4)

Push “BODY FEED AID DOSED COMPLETION” Button.

• Agitation (Step No.106)

b) After that,F-140A carries out the following steps automatically.

• Agitation (Step No.301)

• Preparation of Process (Step No.302)

• Mixing (Step No.303)

• Pre-coating (Step No.304)

• Flow rate change (Step No.305)

• Overlapping (Step No.306)

• Pre-coat tank liquid discharge (Step No.307)

• Overlapping (Step No.308)

• Recirculation (Step No.309)

• Overlapping (Step No.310)

c) Start Filtered Brine pump (003-P-01A/B) by manual before Recirculation step (Step No.309).

d) After F-140A Brine Filter is in filtration process Step No.401),set F-140B Operation switch turn

“RUN” position.

F-140B Brine filter advances each step, automatically as per the Following. Stand-by mode :

Project : 9650 Page 9 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

F-140B keep on the Waiting process (Step No.200) until F-140A satisfy the filtration finish

condition.

e) When F-140A satisfy the filtration finish conditions (as follow).

• When the filtration time has reached the setting time.

• When the differential pressure in filtration has reached 2.0 kg/cm2 .

• When “FILTRATION FINISH” button has been pushed.

F-140A advances the washing process and return to preparation of precoat process (Step

No.101 ~ 105). Such an operation is repeated in turn.

2. METHOD OF OPERATION STOP

a) Don’t dose α-cellulose into pre-coat tank, even if the indicator lamp “PRECOAT AID

PREPARATION” is indicated, after filtration process.

Don’t push “PRECOAT AID PREPARATION FINISH” button.

b) F-140A advances washing process and return to preparation of pre-coat process. After

preparation of pre-coat process, F-140A keep on Waiting process.

c) Set F-140A Operation switch turn “STOP” position.

d) In an emergency, Operation switch turn “STOP” position immediately. When you start the

operation again, please advance steps to washing process by “MANUAL STEP ADVANCE” button. In

this case, please check that liquid are filled into the filter vessel.

e) If power outage occurs the filter unit simultaneously stops. The filter might cause the following

malfunctions due to the power outage.

• Falling or peeling of precoat layer

• Occurrence of clogging of element in serial use after the power recovery

• Deterioration of filtration

Out of the above reasons, when the power is recovered, skip the process with the “MANUAL STEP

ADVANCE” button, perform cleaning, and restart the operation from precoat preparation (Step

No.101) process.

3. PROCESS DESCRIPTION FOR BRINE FILTER UNIT

(I) The operation process can be mainly divided into four (4) processes.

Normally, the following operation in performed, in turn, namely,

Preparation of precoat Precoat Filtration Washing Preparation of precoat

Precoat Filtration Washing ……. (in this repetition )

Project : 9650 Page 10 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

a) Preparation of precoat

Filtrate Brine in the required quantity is filled into filter vessel. This process is performed

immediately after the completion of washing process except for the initial start. α-cellulose

in the required quantity is dosed into precoat tank.

When “PRECOAT AID PREPARATION FINISH” button has been pushed and the required

time has passed, filtered brine is filled into precoat tank and the agitation starts.

b) Precoat

Filtered Brine mixed with α-cellulose is sent into filter vessel α-cellulose powder is

attached evenly on the surface of filter elements, the precoat layers with

α-cellulose are formed. The layers contribute to achieve a fine filtration quality by

preventing filter elements from blinding. The washing efficiency of filter elements is also

increased.

c) Filtration

When saturated brine has passed through precoat layers formed on the surface of filter

elements, from upstream side to downstream side, the fine impurities are body feed is

performed during (Step No.309) Recirculation and Filtration.

d) Washing

The impurities attached and α-cellulose on the surface of filter elements are removed and

washed by sending the clean brine through filter elements from inside to outside quickly.

By washing, filter elements can be restored to the state before the use.

(II) DETAILED PROCESS DESCRIPTION

The explanation about F-140A Filter is described blow. So, for automatic valve and level switch

number of F-1401B filter, replace A with B.

a) Preparation of precoat

-1. Preparation of process (Step No.101)

Filter wash pump (003-P-03) is started before a Liquid filling process start.

• Setting time: 10 sec.

-2. Liquid filling 1 (Step No.102)

To secure precoat liquid, filtrate brine is filled into filter up to the required level. Filter wash pump

(003-P-03) is started, Washing brine inlet valve (XV-1406A), Upstream air vent valve (XV-

1411A, XV-1416A, XV-1417A), drain valve (XV-1415) are opened, and the liquid

is filled into filter vessel until its level (LS-1402-A) reaches “H”.

Project : 9650 Page 11 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

-3. Over flow (Step No.103)

Vent the air under the condition of Liquid filling 1 (Step No.102) process.

• Setting time: 10 sec.

-4. Liquid filling 2 (Step No.104)

Upstream air vent valve (XV-1411A, XV-1416A, XV-1417A) and Upstream drain valve (XV-1415)

are Closed, Washing brine inlet valve (XV-1406A), Downstream air vent valve (XV-1408A) is

opened, and then liquid is filled into filter vessel until its level (LS-1401-A)reaches “HH” for 5 sec.

-5. Precoat tank liquid filling (Step No.105)

Filter wash pump (003-P-03) remains running after 5 sec. XV-1413 open and XV-1406 A closed

and XV-1408 remains open , Precoat tank supply valve (XV-1413) is opened, and the liquid filled

into precoat tank until its level (LIA-120) reaches “H”. When level (LIA-120) has reached “H”,

Precoat tank supply valve (XV-1413) is closed, Filter wash pump (003-P-03) is stopped, and the

precoat tank filling of liquid is completed. Downstream air vent valve (XV-1408A) closes.

-6. Precoat aid dosage

Dose precoat aid(α-cellulose)into the Precoat tank and push the “PRECOAT AID

PREPARATION FINISH” button.

-7. Agitation (Step No.106)

Precoat tank agitator (A-122) .

• Setting time : 10 min A-122 keeps running.

b) Preperation of precoating

-1. Agitation (Step No.301)

Precoat tank agitator (A-122) is started.

Setting time : 5 min

-2. Preparation of process (Step No.302)

Precoat pump (P-124) is started before a Mixing process start.

Setting time : 10 sec

-1. After 10 sec. of precot preparation P-124 will start automatically for 10 sec

-2. Mixing (Step No.303)

The mixing aims at making “The liquid mixed with α-cellulose in precoat tank” and “The brine in

filter vessel” circulate concentration. Precoat inlet valve (XV-1403A), FV-1401A with set point ,

Upstream air vent valve (XV-1411A, 1416A, 1417A), Precoat return valve (XV-1414) are opened,

Project : 9650 Page 12 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

and the liquid mixed with α-cellulose, which left Precoat tank (D-120), is returned again into the

Precoat tank, via filter vessel upstream side by Precoat pump (P-124).

• Setting flow rate: 33 ㎥/hr.

• Setting time: 10 min.

-3. Precoating (Step No.304)

After 10 min. XV-1402 A will open and upstream air vent valve (XV-1411A ,1416 A ,XV-1417A, XV-

1403.XV-1414) will closed.

• Setting flow rate : 33 ㎥/hr.

• Setting time : 30 min.

-4. Flow rate change (Step No.305)

Proceed to Precoat (2) (Step No.10) from Precoat (1) (Step No.9) process. Precoat liquid is returned

into Precoat tank(D-120)through filter element, letting precoat layer of α-cellulose form on the

surface of filter element. Change the flow rate from precoat flow rate (33 ㎥/hr.) to design filtration

flow rate (26 ㎥/hr.) by flow control system (FIC-140A)

• Setting flow rate : 26 ㎥/hr.

• Setting time : 5 min.

• A will Stop

Avoid as possible a flow stop or sudden flow change in this process which affect precoat layer,

inducing clogging of filter element.

-5. Overlapping (Step No.306)

After 5 min XV-1412 open and all the valve will remain as it is.

Overlapping process opens the valve before and behind a process change simultaneously in order

not to stop the flow of liquid.

• Setting flow rate : 26 ㎥/hr.

• Setting time : 5sec.

-6. Precoat tank liquid discharge (Step No.307)

In order to retrieve the residual liquid in precoat tank (D-120), open Brine recycle valve (XV-1412)

and close Precoat return valve (XV-1414) in 5 seconds. The residual liquid in the tank is returned

into primary purified brine tank until precoat tank level (LIA-120) lowers below “L”.after LIA-120

becomes L XV-1401 will open.

-7. Overlapping (Step No.310)

Project : 9650 Page 13 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

Overlapping process opens the valve before and behind a process change simultaneously in order

not to stop the flow of liquid. Change the flow rate from design filtration flow rate (26㎥/hr.)

to calculated filtration flow rate (F ㎥/hr.) by flow control system (FIC-140A)

• Setting flow rate: F ㎥/hr.(As required change it or will remain 26 m3/hr.)

• Setting time: 5sec.

-8. Recirculation (Step No.309)

With filtrate rather unstable at the beginning of filtration, filtered brine is returned into Feed brine

tank (D-040). Feed brine inlet valve (XV-1401A) open, and Precoat inlet valve (XV-1403A) and

Precoat pump (P-124) stop and rest valve remain as it is .

• Setting flow rate: F ㎥/hr.

• Setting time : 5 min

-9. Overlapping (Step No.310)

If 003-LIA-02 is less than high then XV-1404 A will open for 5 sec otherwise all the valves will

remain as it is till 003-LIA-02 becomes Less than high

Overlapping process opens the valve before and behind a process change simultaneously in order

not to stop the flow of liquid.

• Setting flow rate: F ㎥/hr.

• Setting time: 5sec.

c) Filtration

-1. Filtration (Step No.401)

When overlapping has been completed, Brine inlet valve (XV-1401A) and Filtered brine outlet

valve (XV-1404A) remain open and proceed to filtration process.

-2. Conditions of filtration finish

• When the filtration time has reached 48 hours.

• When the differential pressure in filtration has reached 2.0 kg/cm2.

• When “Filtration finish” button has been pushed.

Press fiteration finish F-140 B then XV-1408 will open and XV-1401B ,XV-1404 B and FV-1401 B

will close.

-3. Conditions of Recirculation (Step No.411) during filtration

When finish filtered brine tank level (003-LIA-02) has reached “H”. But, when another operating

filter is in one of “Preparation of Precoat”, “Precoat” or “Washing” process, the filter in Filtration

process cannot enter this Recirculation process.

-4. Conditions that recirculation return to filtration

Project : 9650 Page 14 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

When finish filtered brine tank level (003-LIA-02) is less than “H”.

d) Washing

Normally, washing process is repeated in 4 times, and the washing steps to be made each time are

as follows.

Three Upstream air vent valves (XV-1416A, XV-1417A, XV-1411A) are mounted at the intervals of

120 degrees. During overflow in 3 times, three valves are opened, one by one, in turn, at each

overflow in order to wash evenly the surface under perforated plate.

1st Washing: Discharge 1

• Draining:-Valve XV-1408 A will remain open and XV-1411 A, XV-1416A, XV 1417-A and XV-1415

will open for 60 sec.

• Filling:-Valve 1411 A, XV-1416A ,XV-1417A and XV-1415 will remains open till the LS1402A

becomes H after that Valve XV-1411 A, XV-1416A KV 1417-A and XV-1415 will closed and valve

XV-1406 A remains open and pump 003-P-03 will started till LS1401 A becomes HH. When LS

1401A becomes HH Pump 003-P-03 will stop and XV-1406 A and XV-1408 A will closed.

• Pressurization:-Valve XV-1407A will open for 10 Sec.

• Flash Washing:-Valve XV-1405A will open for 5 sec.

• Discharge:-XV-1405 A will remains open and valve XV-1408 A will open after 5 Sec for 180 sec. After

180 sec. XV-1405 A will closed.

→ Pressurization → Flash washing → Discharge 2

→ Air vent → Preparation of process

→ Liquid filling 1 (XV-1411A) → Over flow (XV-1411A)

→ Liquid filling 2

2nd Washing:

• Filling:-Valve 1411 A, XV-1416A ,XV 1417 A and XV-1415 will remains open till the LS1402 A

becomes H after that Valve XV-1411 A, XV-1416A XV 1417-A and XV-1415 will closed and valve

XV-1406 A remains open and pump 003-P-03 will started till LS1401 A becomes HH. When LS

1401A becomes HH Pump 003-P-03 will stop and XV-1406 A and XV-1408 A will closed.

• Pressurization:-Valve XV-1407A will open for 10 Sec.

• Flash Washing:-Valve XV-1405A will open for 5 sec.

• Discharge:-XV-1405 A will remains open and valve XV-1408 A will open after 5 Sec for 180 sec. After

180 sec. XV-1405 A will closed.

Project : 9650 Page 15 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

→Pressurization → Flash washing →Discharge 2

→ Air vent → Preparation of process

→ Liquid filling 1 (XV-1416A) → Over flow (XV-1416A)

→ Liquid filling 2

3rd Washing:

• Filling:-Valve 1411 A, XV-1416A ,XV 1417 A and XV-1415 will remains open till the LS1402 A

becomes H after that Valve XV-1411 A, XV-1416A XV 1417-A and XV-1415 will closed and valve

XV-1406 A remains open and pump 003-P-03 will started till LS1401 A becomes HH. When LS

1401A becomes HH Pump 003-P-03 will stop and XV-1406 A and XV-1408 A will closed

• Pressurization:-Valve XV-1407A will open for 10 Sec.

• Flash Washing:-Valve XV-1405A will open for 5 sec.

• Discharge:-XV-1405 A will remains open and valve XV-1408 A will open after 5 Sec for 180 sec.After

180 sec. XV-1405 A will closed.

→Pressurization → Flash washing → Discharge 2

→ Air vent → Preparation of process

→ Liquid filling 1 (XV-1417A) → Over flow (XV-1417A)

→ Liquid filling

4th Washing:

• Filling:-Valve 1411 A, XV-1416A ,XV 1417 A and XV-1415 will remains open till the LS1402 A

becomes H after that Valve XV-1411 A, XV-1416A XV 1417-A and XV-1415 will closed and valve

XV-1406 A remains open and pump 003-P-03 will started till LS1401 A becomes HH. When LS

1401A becomes HH Pump 003-P-03 will stop and XV-1406 A and XV-1408 A will closed

• Pressurization:-Valve XV-1407A will open for 10 Sec.

• Flash Washing:-Valve XV-1405A will open for 5 sec.

• Discharge:-XV-1405 A will remains open and valve XV-1408 A will open after 5 Sec for 180 sec.

After 180 sec. XV-1405 A will closed.

• Filling:-After 180 sec. valve XV-1406 A will open and pump 003-P-03 will started till LS1401 A

becomes HH.

→Pressurization → Flash washing →Discharge 2

→ Air vent

When Air vent (Step No.506) has been completed, the step skips to

Preparation of Precoat

-1. Filtration Finish (Step No.501)

Project : 9650 Page 16 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

This process checks Filter slurry tank level (LS-145).

When tank level (LS-145) is over "H", it does not step next process.

-2. Discharge (Step No.502)

The liquid is discharged from filter vessel outlet in order to secure a required air zone for

pressurization. Downstream air vent valve (XV-1408A) and Precoat outlet valve (XV-1402A)

is opened.

• Setting time : 2 min.

-3. Pressurization (Step No.503)

Precoat outlet valve (XV-1402A), Downstream air vent valve (XV-1408A) close, and Air

pressurization valve (XV-1407A) opens.

• Setting condition : Timer 5sec. and pressure 4.5 kg/cm2g.

-4. Flash Washing (Step No.504)

Air pressurization valve (XV-1407A) is closed and Mud discharge valve (XV-1405A) is opened to

perform the flush washing.

• Setting time : 10 sec.

At the initial start, the full opening time of Mud discharge valve (XV-1405A) must be set at 3 second

by the speed controller attached on the valve. In the normal operation, the full opening time of this

valve must also be kept at 3 second.

-5. Discharge 2 (Step No.505)

Downstream air vent valve (XV-1408A) is opened, and the residual in filter is discharge

• Setting time : 3 min.

-6. Air vent (Step No.506)

Mud discharge valve (XV-1405A) closes, and the air is discharged from downstream air vent valve

(XV-146A).

• Setting time : 10 sec.

When 4th washing has been completed. step jumps to the said Liquid filling (Step

No.101), preparation of precoat.

Project : 9650 Page 17 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

-7. Liquid filling 1 (Step No.508)

Washing brine inlet valve (XV-1406A) and Upstream air vent valve (1st time=XV-1411A,

2nd time=XV-1416A, 3rd time=XV-1417A), Drain valve (XV-1415) are opened, and filtered

brine is filled into filter until its level (LS-1402-A) reaches “H”.

-8. Over flow (Step No.509)

Washing brine is overflow from Upstream air vent valve (1st time=XV-1411A, 2nd time=XV-1416A,

3rd time=XV-1417A), and the filter cake accumulated under perforated plate is washed away.

• Setting time: 25 sec.

-9. Liquid filling 2 (Step No.510)

When Upstream air vent valve (1st time=XV-1411A, 2nd time=XV-1416A, 3rd

time=XV-1417A) and Drain valve (XV-1415) close, Downstream air vent valve (XV-1408A)

opens. Washing brine is filled into the filter until the level (LS-1401-A) reaches “HH”.

When the Liquid filling (2) is completed, Washing brine inlet valve (XV-1406A) closes.

4. The level indication LI-120 of the Precoat Tank D-120 gives alarm when it becomes either High –

High (HH), High (H), Low – Low (LL), Low (L).

5. Interlock (I-120)

When level indication LI-120 of the Precoat Tank D-120 becomes Low-Low (LL), the Precoat

Pump P-124 as well as Agitator A-122 shall trip.

6. The level indication LI-130 of the Body Feed Tank D-130 gives alarm when it becomes either High –

High (HH) or High (H) or Low – Low (LL) or Low (L).

7. Interlock (I-130)

When level indication LI-130 of the Body Feed Tank D-130 becomes Low-Low (LL), the Body

Feed Pumps P-134A/B as well as Agitator A-132 shall trip.

8. The level switch LS-145 of the Filter Slurry Pit PI-145 gives Alarm when it becomes either high (H)

or Low (L) or Low – Low (LL).

9. Interlock (I-145)

When level switch LS-145 of the Filter Slurry Pit PI-145 becomes Low-Low (LL), the Filter

Slurry Pumps P-144 as well as Agitator A-142A/B shall trip.

10. The level indication 003-LI-02 of the Polished Brine Tank 003-T-02 gives Alarm when it becomes

either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

Project : 9650 Page 18 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

11. Interlock (10)

The level indication 003-LI-02 of the Polished Brine Tank 003-T-02 becomes Low-Low (LL),

the Polished Brine Pumps 003-P-02A/B and Filter Wash Pumps (003-P-03) shall trip.

12. The Flow of brine from Filtered brine pump (003-P-01A/B) to brine polishing filter (F-140 A) is

controlled by FV-1401 A as per the set point of FIC-1401 A. when flow increases above set point

valve opening will reduce.

13. The Flow of brine from Filtered brine pump (003-P-01A/B) to brine polishing filter (F-140 B) is

controlled by FV-1401 B as per the set point of FIC-1401 B. when flow increases above set point

valve opening will reduce.

14. The flow indication FI-1401 A of the Brine Polish filter F-140A gives alarm when it becomes either

High – High (HH) or High (H) or Low – Low (LL) or Low (L.

15. The flow indication FI-1401 B of the Brine Polish filter F-140B gives alarm when it becomes either

High – High (HH) or High (H) or Low – Low (LL) or Low (L).

16. The level of Polished Brine Tank 003-T-02 is controlled by Flow Control Valve FV-1401 A/B as per

the set point of 003-LI-02.The flow shall change within maximum & minimum flow range as per the

set point of level. (optional)

17. Motor/Drive provision of Start and Stop from DCS shall be provided

A-122 - START & STOP

P-124 - START & STOP

A-132 - START & STOP

P-134 A/B - START & STOP

P-144 - START & STOP

A-142 A/B - START & STOP

18. All Interlocks should have bypass switch available on common DCS screen. And the indication of

by pass switch activated or deactivated should be available on each interlock number on each

screen.

Project : 9650 Page 19 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

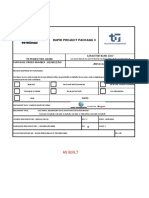

19. The following documents are to be referred for Polish brine Filter Sequence operation.

Sl. NO Description Annexure No

OPERATING TIME CHART FOR BRINE

1. Annexure-A

FILTER UNIT

2. FLOW CONTROL LOGIC Annexure-B

20 All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each Interlock number on each

screen.

Project : 9650 Page 20 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9650-11-PID-00-0003( 3 OF 3)

BRINE FILTRATION

1. The level indication 003-LI-02 of the Polished Brine Tank 003-T-02 gives Alarm when it

becomes either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

2. The Temperature indication 003-TI-01 give alarm when it becomes High-High (HH) or High

(H).

3. The temperature of the Polished Brine is controlled by steam inlet control valve, 003-TCV-

01 which regulates the steam Flow from Brine Pre Heater 003-E-01 as per the set point of

003-TI-01.when temperature increased above set point valve opening will reduce.

4. The temperature switch 003-TSZ-03 gives alarm when it becomes either High (H) or High-

High (HH).

5. Interlock (Z-12)

If High-High (HH) temperature is detected by temperature switch 003-TSZ-03 on

Brine Heater 003-E-01.Then steam control valve 003-TCV-01 will close.

6. Interlock (10)

When the level indication 003- LI-02 of Polished Brine tank (003-T-02) becomes Low-Low

(LL), the Polished Brine Pump 003-P-02 A/B & 003-P-03 shall trip.

7. Motor/Drive provision of Start and Stop from DCS shall be provided.

003-P-02 A/B - START & STOP

003-P-03 - START & STOP

8. All Interlocks should have Bypass switch available on common DCS screen. And the

indication of Bypass switch activated or deactivated should be available on each interlock

number on each screen.

Project : 9650 Page 21 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9650-11-PID-00-0004

ION EXCHANGE PURIFICATION

1. The Flow Indication FI-160 of Brine from Polish Brine Pump 003-P-02A/B to Ion exchange column

T-160 A/B/C gives alarm when it becomes either High (H) or Low (L).

2. The Flow of brine from Polish Brine Pump 003-P-02A/B to Ion exchange column T-160 A/B/C is

controlled by FV-160 as per the set point of FIC-160. When flow increase above set point, the valve

opening shall reduce.

3. The Flow indication FI-163 of brine from Polish Brine Pumps 003-P-02A/B to Ion exchange column

T-160 A/B/C gives alarm when it becomes either High (H) or Low (L).

4. The Flow indication FI-164 of DM water from DM water header to Ion exchange column T-160

A/B/C gives alarm when it becomes either High (H) or Low (L).

5. The Flow indication FI-169 of 32% caustic to Ion exchange column T-160 A/B/C gives alarm when

it becomes either High (H) or Low (L).

6. The Flow indication FI-162 of 18% HCL to Ion exchange column T-160 A/B/C gives alarm when it

becomes either High (H) or Low (L).

7. The flow of DM water from DM water Header to Ion Exchange column T-160 A/B/C is controlled by

flow control valve FV-164 as per the set point of FIC-164.when flow increases above set point valve

opening will reduce.

8. The Flow Indication FI-161 of Brine from Purified Brine Strong Pump 005-P-01A/B to Ion Exchange

column T-160 A/B/C gives alarm when it becomes either High (H) or Low (L).

9. The level indication 005-LI-01 of the Purified Brine Tank 005-T-01 gives alarm when it becomes

either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

10. The level indication LI-160 of the Waste Alkali Tank D-160 gives alarm when it becomes either

High – High (HH) or High (H) or Low – Low (LL) or Low (L).

11. The flow of 18% HCl control by Flow control valve FV-162 as per the set point of FICA-162. When

flow increases above set point valve opening will reduce.

12. The flow of 32% Caustic control by Flow control valve FV-169 as per the set point of FICA-169.

When flow increases above set point valve opening will reduce.

Project : 9650 Page 22 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

13. The flow of polished brine is controlled by 004-FCV-160 as per the set point of 004-FICA-160 or by

005-LI-01 through selector switch.

Flow Control When flow increase above set point valve opening will reduce.

Level Control When Level increase above set point valve opening will reduce.

14. Motor/Drive provision of Start & Stop in DCS shall be provided in DCS to MCC panel

P-164 - START & STOP

15. Interlock (I-160)

When the level indication 004- LI-160 of waste alkali tank D-160 becomes Low-Low (LL), the

Transfer Pump for Waste Alkali Tank P-164 shall trip.

16. The following documents are to be referred for Ion Exchange Column (T-160 A/B/C)

Regeneration, Time Chart and Sequence operation.

Sl. NO Description Annexure No

9. LOGIC TIME CHART Annexure-C

10. LOGIC TIME CHART Annexure-D

17. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each interlock number on each screen.

Project : 9650 Page 23 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

PURE BRINE FEED AREA

9650-11-PID-00-0005

1. The level indication 005-LI-01 of the Purified brine Stroage tank 005-T-01 gives alarm when it

becomes either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

2. The level indication 005-LI-03 of pure brine Top-up tank gives alarm when it becomes either Low –

Low (LL) or Low (L).

3. Interlock (Z-16)

When level indication 005-LI-01 of Purified brine tank 005-T-01 becomes Low-Low. The

Pure pumps 005-P-01A/B shall trip and Steam Heating control valve 006-TCV-01A shall close.

4. Interlock (IZ-170)

When any one of pump 005-P-01 A or B shall trip another pump will start automatically. If

following condition is normal–

• 005-LI-01 is not Low – Low (LL).

• Another Pump trip signal from MCC is not coming.

5. Interlock (Z-13)

If a motor STOP signal is detected on both of Pure brine Pump 005-P-01 A/B for certain

period (> 60 seconds to allow for auto-changeover), than On-off valve 007-XV-04 shall open

and Control valve 007-FCV-01 , 006-TCV-01A will close.

An activation signal will be sent to Interlock Z-1.

6. Motor/Drive provision of Start & Stop in DCS shall be provided.

005-P-01 A&B - START & STOP (EMERGENCY)

7. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each interlock number on each

screen.

Project : 9650 Page 24 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

PURE BRINE HEAT CONDITIONING

9650-11-PID-00-0006

1. The temperature of the Feed Brine is controlled by steam inlet control valve, 006-TCV-01A which

regulates the steam Flow to Feed brine heater 006-E-01 as per the set point of 006-TIC-01. When

temperature increased above set point valve opening will reduce.

2. The temperature Indicator 006-TI-01 of feed brine to electrolyser gives alarm when it either High-

High (HH) or High (H) or Low(L).

3. The changeover of heating mode & cooling mode is done manually through DCS by selector switch

in DCS & in field will be done by field operator for startup brine Heater/Cooler 006-E-01.

4. The temperature of feed brine to electrolyser is controlled by cooling water inlet control valve 006-

TCV-01B, which regulate the cooling water flow to 006-E-01 as per the set point of 006-TICA-01.

When temperature increase above set point, valve opening will increase.

5. The Flow indication 006-FI-01 of the DM Water gives alarm when it becomes either High (H) or Low

(L).

6. Interlock (Z-14)

When the temperature at the outlet of feed brine heater 006-E-01 becomes High-High (HH)

temperature control valve 006-TCV-01A shall close.

This valve will remain interlocked until the temperature drops below High.

7. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each interlock number on each

screen.

Project : 9650 Page 25 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

CELLROOM ELECTROLYSER

9650-11-PID-00-0007

1. The Flow indication 007-FI-01 of the Feed brine to electrolyser gives alarm when it becomes either

High (H) or Low – Low (LL) or Low (L).

2. The flow of feed brine is maintained and controlled by flow control valve 007-FCV-01 as per set

point of 007-FIC-01. When the flow is increase above the set point control valve opening will reduce.

The flow setpoint is set by the plant control system, in ratio to the electrolyser running current

density (load), although there is the capability for trim this value.

The following algorithm describes the relationship between the setpoint for the pure brine feed

flow controller 007-FIC-01 and measured DC current:

Fb = 0.0151 C N P in the range 6.78 to 20.33 kA

Fb = 0.1037 N in the range 0 to 6.78 kA

Where:

Fb = Pure brine feed flowrate setpoint (m3/h)

C = Measured DC current to electrolyser (kA)

N = Number of modules in electrolyser (46 nos.)

P = Operator settable adjustment factor, limited to the range 0.9 to 1.1

3. The Flow indication 007-FI-02 of the Feed catholyte to electrolyser gives alarm when it becomes

either High (H) or Low – Low (LL) or Low (L).

4. The flow of feed catholyte is maintained and controlled by flow control valve 007-FCV-02 as per set

point of 007-FIC-02. When the flow is increase above the set point control valve opening will reduce.

The flow setpoint is set by the plant control system, in ratio to the electrolyser running current

density (load), although there is the capability for operator trim this value. This can be used to help

with temperature control.

The following algorithm describes the relationship between the setpoint for the catholyte feed flow

controller FICZ-02 and measured DC current:

Fc = 0.0151 C N P in the range 6.78 to 20.33 kA

Fc = 0.1037 N in the range 0 to 6.78 kA

Project : 9650 Page 26 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

Where:

Fc = Catholyte feed flowrate setpoint (m3/h)

C = Measured DC current to electrolyser (007-U-01) (kA)

N = Number of modules in electrolyser (0-90)

P = Operator settable adjustment factor, limited to the range 0.9 to 1.1

5. The Flow indication 007-FI-05 of the Nitrogen line to electrolyser gives alarm when it becomes

either High (H) or Low (L).

6. The Flow indication 007-FI-04 of the plant air line to electrolyser gives alarm when it becomes

either High (H) or Low (L).

7. The temperature Indicator 007-TI-02 of catholyte from electrolyser gives alarm when it either High

(H) or High – High (HH) or Low (L).

8. The PLC of Voltage Monitoring System(VMS) will give the feedback/data of individual of each cell to

DCS.

9. The temperature Indicator 007-TI-01 of anolyte from electrolyser gives alarm when it either High

(H) or Low (L).

10. The Pressure indication 007-PI-04 A/B/C of the Hydrogen gas from electrolyser gives alarm when it

becomes either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

11. The Pressure indication 007-PI-03 A/B/C of the Chlorine gas from electrolyser gives alarm when it

becomes either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

12. The Differential Pressure indication 007-DPI-01 A/B/C of the Chlorine gas & Hydrogen gas from

electrolyser gives alarm when it becomes either High – High (HH) or High (H) or Low – Low (LL) or

Low (L).

13. The Electrolyser Voltage 007-VIZ-01 gives alarm when it becomes either High – High (HH), High (H).

14. Individual Module voltage 007-VIZ-01 to 90 gives alarm when it becomes High(H) or High –

High(HH).

15. The Electrolyser Current 007-IIZ-01 gives alarm when it becomes either High – High (HH), High (H)

or Low - Low (LL) or Low (L).

Project : 9650 Page 27 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

16. Interlock (Z-1) Whole Cell room Trip

If there is a plant power failure resulting in loss of power to rectifier (007-U-01_TF)

OR a Low-Low (LL) level is detected by 005-LI-03 in Pure Brine top-up Tank (005-T-02).

OR a High-High(HH) level is detected by 008-LI-01A or 008-LI-01B in Anolyte Tank (008-T-

01).

OR a Low-Low (LL) level is detected by 008-LI-01A or 008-LI-01B in Anolyte Tank (008-T-

01).

OR a High-High (HH) level is detected by 010-LI-01 or 010-LI-02 in Catholyte Tank (010-T-01).

OR a Low-Low(LL) level is detected by 010-LI-01 or 010-LI-02 in Catholyte tank(010-T-01).

OR a Low-Low (LL) level is detected by 010-LI-04 in cathloyte top-up tank head tank (010-T-

02).

OR High-High (HH) pressure is detected by any two of three or all 007-PI-03A, 007-PI-03B,

007-PI-03C on the Cellroom Chlorine header.

OR High-High (HH) pressure is detected by any two of three or all 007-PI-04A, 007-PI-04B,

007-PI-04C on the Cellroom Hydrogen header.

OR a High-High (HH) Temperature is detected by 007-T-02 on the Catholyte header.

OR a High-High (HH) cell room differential pressure is detected by two out of three of 007-

DPI-01 A/B/C.

OR a Low-Low (LL) cell room differential pressure is detected by two out of three of 007-DPI-

01 A/B/C.

OR an emergency stop button is activated in 007-HS-01.

OR an Emergency stop switch is selected in DCS panel.

OR If there is a plant Instrument Air 038-PI-1050 pressure become Low-Low (LL).

Project : 9650 Page 28 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

OR High-High(HH) current is detected from the rectifier 007-U-01_CF.

OR Low-Low(LL) current is detected from rectifier 007-U-01_CF. (This Signal needs to be

ignored during Start-UP sequence)

OR trip/interlock 23 is activated.

OR trip/interlock Z3 is activated.

OR trip/interlock Z4 is activated.

OR trip/ interlock Z-18 is activated.

OR trip/interlock Z45 is activated.

OR trip/interlock 24 is activated.

OR trip/interlock Z-23 is activated.

OR trip/interlock Z-13 is activated.

OR trip/interlock Z-41 is activated.

OR Chlorine pressure control valve 016-PCV-02 is open > 10% for more than 5 minutes and

current 007-IIZ-01 is > 6.778 KA.

OR a High-High(HH) Pressure is detected by 015-PI-01 on chlorine feed to 015-C-01.

OR a motor STOP singal is detected by 015-XA-01A and 015-XA-01B on both chlorine

absorption pump 015-P-01 A&B for a sustained period of 60 Seconds ( to allow for auto

changeover).

OR a Low-Low (LL) flow is detected for a sustained period of 60 seconds by 015-FI-02 on the

circulation return to 015-C-01.

OR a Low-Low(LL) level is detected by 015-LI-02A in emergency absorber circulation tank

015-T-02A and 015-V-03A is OPEN.

Project : 9650 Page 29 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

OR a Low-Low(LL) level is detected by 015-LI-02B in emergency absorber circulation tank

015-T-02B and 015-V-03B is OPEN.

OR a motor STOP signal is detected by 015-XA-03A AND 015-XA-03B on both emergency

absorber Blowers 015-K-01A&B for a sustained period of 60 second ( to allow for auto change

over).

OR a Low-Low(LL) Level is detected by 015-LI_03 in 18% caustic tank 015-T-03.

OR a High-High(HH) chlorine absorption circulation temperature is detected by 015-TI-01.

OR a High-High(HH) emergency chlorine absorption column temperature is detected by 015-

TI-04.

OR Brine flow 007-FI-01 will show (-)20% deviation in flow from set point for 60 seconds.

OR Caustic flow 007-FI-02 will show (-)20% deviation in flow from set point for 60 seconds.

OR Rectifier stops (Rectifier inter logic fails).

OR HCL synthesis unit mail Interlock (Z-45) is activated. (By pass arrangement provided on

DCS screen).

THEN

A Signal will be sent to switch off rectifier and the polarizing rectifier will start

AND a signal will be sent to Plant air isolation valves 007-XV-02 and it will open.

AND a signal will be sent to Nitrogen isolation valves 007-XV-01 and it will open.

AND a signal will be sent to Pure Brine control valve 007-FCV-01 to ensure they are in AUTO

with set point = 14 m3/hr. (NOTE-1)

AND a signal will be sent to catholyte control valve 007-FCV--02 to ensure they are in AUTO

with set point = 18.9 m3/hr. (Note-1)

(NOTE-1 Flow rates of brine & caustic are for 70 installed modules. If for the modules are

added then flow rate set point must be increased Proportionally to the number of modules for

90 installed modules, the flow rate for brine is 18 m3/hr and for caustic 24.3 m3/hr.)

Project : 9650 Page 30 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

AND a signal will be sent to Anolyte HCl flow control valve 008-ACV-01 and it will close after a

delayed of 30 min.

AND a signal will be sent to Anolyte HCl flow control valve to chlorate destruction 008-FCV-02

and it will close.

AND a signal will be sent to Caustic control valve 010-LCV-01 and it will close.

AND a signal will be sent to Catholyte tank nitrogen purge valve 010-XV-02 & it will open.

AND a signal will be sent to DM water flow control valve 011-FCV-01 & it will close.

AND a signal will be sent to Chlorine pressure control valve 016-PCV-01 & it will close.

AND a signal will be sent to Chlorine pressure control valve 016-PCV-02 & it will open.

AND a signal will be sent to Hydrogen pressure control valve 020-PDCV-01 & it will close.

AND a signal will be sent to Hydrogen pressure control valve 020-PDCV-02 to ensure it is in

AUTO with a set point equal to 250 mmwc.

AND a signal will be sent to HCL synthesis unit and Z-45 will trip.

A reset of the system, once the trips have cleared, will be via operation of local button in DCS.

17. Interlock (Z-3)

IF a LOW LOW electrolyser brine flow is detected by 007-FIC-01 for a sustained period of

60 seconds.

OR a HIGH HIGH module or electrolyser voltage is detected in the voltage monitoring

system (007-VIZ-01).

THEN a signal will be sent to pure brine emergency feed valve 007-XV-04 and it will OPEN,

AND an activation signal will be sent to Z1.

AND Polarisation rectifier will STOP after 50 minutes

A reset of the system, once the trips have cleared, will be via the pressing of a button in the

control room.

18. Interlock (Z-4)

Project : 9650 Page 31 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

IF a LOW LOW electrolyser caustic flow is detected by 007-FICZ-02 for a sustained period

of 60 seconds.

OR a HIGH HIGH module or electrolyser voltage is detected in the voltage monitoring

system, 007-VIZ-01.

THEN a signal will be sent to Catholyte emergency feed valve 007-XV-05 and it will OPEN,

AND an activation signal will be sent to Z1

A reset of the system, once the trips have cleared, will be via the pressing of a button in the

control room.

19. Interlock (Z-17)

IF totalised nitrogen purge flow 007-FI-05 is >16 Nm³

THEN ENABLE polarising rectifier 007-X-02 and main rectifier 007-X-01 to electrolyser.

This interlock will remain ENABLED during aborted start-ups, as long as nitrogen purge flow

remains > 16 Nm³/h

20. Interlock (Z-37)

IF a Low-Lo(LL) Pressure is detected by two out of three of 007-PI_04 A/B/C on the cell room

Hydrogen Header.

Then a signal will be sent to Nitrogen Purge valve 014-XV-02 AND it will open.

Main Rectifier Energisation

On initial energisation of the main rectifier the l o a d to the electrolyser is slowly increased from

buttons provided in plant over view graphics screen shall be change as per Plant/DCS

operator requirement –

TAN NO. R-230 UNIT

Rectifier

Load SV 007-IIZ-01 KA

In single press of button, valve of Rectifier load (AIC-230) will

increase to 0.1 KA.

Project : 9650 Page 32 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

In single press of button, valve of Rectifier load (AIC-230) will

decrease to 0.1 KA.

Pressure Controller Value on plant over view graphics screen shall be change as per

Plant/DCS operator requirement –

In single press of button, valve of controller will increase to 5 MMWC.

In single press of button, valve of controller will decrease to 5 MMWC.

Rectifier (RE-230) Control Philosophy

First DCS give ON command to Rectifier RE-230 to SWITCH ON the rectifier and rectifier will do

their internal checking and wait for some time for getting Rectifier RE-230 ON feedback or Trip

feedback.

If Trip feedback comes then we have to troubleshoot the problem at rectifier end. If ON feedback

comes then DCS give Process Healthy Feedback to rectifier RE-230 after checking all process

interlocks healthiness and in return rectifier gives “Ready to start feedback” to DCS after checking

all its internal alarms also by putting local / remote selector switch in remote position and this

feedback will comes to DCS .

After that DCS give current set point to rectifier for taking load and in return rectifier gives current

and voltage feedback to DCS .

DCS gives current set point in step by step i.e. in Single Press 0.1 KA will increase.

If any process trip comes due to interlock IZ-230 then DCS give process trip command to rectifier

RE-230 to stop the rectifier and if any trip comes at rectifier end then it gives Rectifier trip feedback

to DCS for stopping of plant.

Signals to be shown on DCS screen

• CD_RE-230_ON Command to Switch ON the rectifier

• FB_RE-230_ON/OFF TRIPFeedback of ON/OFF of rectifier will be shown on DCS screen.

• FB_RE-230_ TRIPFeedback of TRIP of rectifier will be shown on DCS screen.

• FB_IZ-230 Feedback of Process ready to rectifier i.e. healthy signal of Interlock IZ-230 will be

shown on DCS screen.

• FB_RE-230_READY Rectifier ready to start feedback comes on DCS screen.

Project : 9650 Page 33 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

• FB_RE-230_L/R Feedback of local / remote of rectifier will be shown on DCS screen.

• FB_RE-230_RUN Feedback of rectifier running will be shown on DCS screen.

• FB_RE-230_V Feedback of voltage (EI-230) from rectifier will be shown on DCS screen.

• FB_RE-230_C Feedback of current (AI-230) from rectifier will be shown on DCS screen.

• FB_RE-230_STOP Stop Button on DCS screen, Emergency trip command from DCS to stop the

rectifier.

Polarization Rectifier (PR-230) Control Philosophy

Before starting of Rectifier RE-230, Polarization rectifier PR-230 must be ready and in ON condition

and put local /remote switch in remote position.

If Main Rectifier RE-230 Trip then DCS gives RUN command to polarization rectifier PR-230 and

after getting ON feedback.

It gives current set point to polarization in define ramp rate of current (ramp up will be in

polarization panel) and in return polarization gives current and voltage feedback to DCS.

Polarizer rectifier PR-230, ON command till the main rectifier RE-230 current is less than 2 KA. So

when ever main rectifier current fall below 2 KA, polarizer will start to feed current in Electrolyser

Signals to be shown on DCS screen

• FB_RE-230_L/R Feedback of local / remote of polarization rectifier will be shown on DCS screen.

• FB_PR-230_ON/OFF/TRIP Feedback of On/Off/Trip of polarization rectifier will be shown on

DCS screen.

• FB_PR-230_RUN Feedback of polarization rectifier running will be shown on DCS screen.

• FB_PR-230_V Feedback of voltage from polarization rectifier will be shown on DCS screen.

• FB_PR-230_C Feedback of current from polarization rectifier will be shown on DCS screen.

21. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each interlock number on each

screen.

Project : 9650 Page 34 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

ANOLYTE HANDLING

9650-11-PID-00-0008(1of 2)

1. The PH Indicator 008-AI-01 gives alarm when it becomes either High (H) or Low (L).

2. The level indication 008-LI-01A of the Anolyte tank 008-T-01 gives alarm when it becomes either

High (H) or Low – Low (LL) or Low (L).

3. The level indication 008-LI-01A of the Anolyte tank 008-T-01 gives alarm when it becomes either

High (H) or Low – Low (LL) or Low (L).

4. The temperature Indicator TI-240 of Anolyte tank 008-T-01 gives alarm when it either High (H) or

Low (L).

5. The level of Anolyte tank 008-T-01 is maintained by controlling the Flow of Anolyte by Level Control

Valve 008-LCV-01 as per the set point of 008-LI-01A and 008-LI-01B .when level increases above

set point valve opening will increase.

6. The pH of Anolyte tank 008-T-01 is maintained by controlling the Flow of HCl by Control Valve 008-

ACV-01 as per the set point of 008-AIC-01.When pH increases above set point valve opening will

increase.

7. Interlock (Z-18)

When the level indication 008-LI-01A or 008-LI-01B of Anolyte tank 008-T-01 becomes High-

High(HH).

Then a signal will be sent to pure brine flow control valves 007-FCV-01 and it will close.

AND a single will be sent to pure Brine emergency feed valve 007-XV-04 and it will open.

AND HCl flow control valve 008-ACV-01 & 008-FCV-02 and they will close.

AND a motor STOP signal will be sent to 005-NO-01A and 005-NO-01B pure brine pumps 005-

P-01 A and B.

AND activation signal will be sent to Z1.

8. Interlock (I-240)

When level indication 008-LI-01A or 008-LI-01B of Anolyte tank becomes Low-Low (LL). The

Anolyte pump 008-P-01 A/B shall trip.

AND 008-FCV-02 will close.

AND 008-ACV-01 will close.

Project : 9650 Page 35 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

9. Interlock (I-244)

When any one of pump 008-P-01 AorB shall trip another pump will start automatically. If

following condition is normal–

• 008-LI-01 A or 008-LI-01 B is not Low – Low (LL).

• Another Pump trip signal from MCC is not coming.

10. Motor/Drive provision of Start & Stop in DCS shall be provided.

008-P-01 A&B - START & STOP (EMERGENCY)

11. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each interlock number on each

screen.

Project : 9650 Page 36 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

CHLORATE DESTRUCTION

9650-11-PID-00-0008(2of 2)

1. The temperature Indicator 008-TI-03 of chlorate destruction tank 008-T-02 gives alarm when it

either High (H) or Low (L).

2. The temperature Indicator 008-TI-01 of acidic brine to chlorate destruction tank 008-T-02 gives

alarm when it either High-High (HH) or High (H) or Low (L).

3. The flow indication 008-FI-01 of Anolyte gives alarm when it becomes either High (H) or Low (L).

4. The flow indication 008-FI-02 of HCl gives alarm when it becomes either High (H) or Low (L).

5. The flow of HCl is maintained and controlled by flow control valve 008-FCV-02 as per set point of

008-FIC-02. When the flow is increase above the set point control valve opening will reduce.

6. The temperature of Acid brine to 008-T-02 is controlled by Steam inlet control valve 008-TCV-04,

which regulate the steam flow to 008-E-01 as per the set point of 008-TICA-01. When temperature

increase above set point, valve opening will reduce.

7. Interlock (Z-19)

When temperature indicator 008-T-01 becomes High-High (HH) , Steam control valve 008-

TCV-04 will close.

This valve will remain interlocked on till the temperature drops below High.

8. Motor/Drive provision of Start & Stop in DCS shall be provided.

008-P-02 A&B - START & STOP

9. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each interlock number on each

screen.

Project : 9650 Page 37 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

ANOLYTE DECHLORINATION

9650-11-PID-00-0009(1 OF 2)

1. The level indication 009-LI-03 of 18% HCL Dosing Tank (009-T-02) gives alarm when it becomes

either High – High (HH) or High (H) or Low – Low (LL) or Low (L).

2. The level indication 009-LI-01 of De-chlorination tower tank (009-T-280) gives alarm when it

becomes either High – High (HH) or High (H) or Low – Low (LL) or Low (L), an immediate

investigation and preventive action to be taken accordingly.

3. Interlock (I-284)

When the level of De-chlorination tower tank (009-T-280) 009-LI-01 becomes Low –Low (LL),

De- chlorination tower pumps (009-P-01A/B) & sodium sulphite Pumps (P-294 A/B)

shall trip. Caustic ON/OFF valve 012-XV-01 will close.

4. The level of De-chlorination tower tank (009-T-280) is controlled by level control valve (009-LCV-

01) as per the set point of 009-LIC-01.When level increases above set point, valve opening will

increase.

5. The pH of de -chlorinated brine is controlled by addition of 18 % caustic soda by pH control valve

009-FCV-01 as per the set point of 009-AIC-01 or by 009-FIC-01 through selector switch. when pH

increases above set point, valve opening will decrease.

Flow Control When flow increase above set point valve opening will decrease.

pH Control When pH increase above set point valve opening will decrease.

6. Interlock (Z-21)

IF a Low Low is detected by 009-FI-04 in air feed to dechlorination tower tank 009-T-280 for

a sustained period of 60 seconds

THEN a signal will be sent to anolyte tank level control valve 008-LCV-01 and it will close.

7. Interlock (Z-20)

IF a High-High level is detected by 009-LI-01 in dechlroniation tower tank 009-T-280.

THEN a signal will be sent to anolyte tank level control valve 008-LCV-01 and it will close.

AND a signal will be sent to caustic head tank valve 012-XV-01 and it will close after a delay of

15 minutes.

AND a signal will be sent to Sodium Sulfite flow control valve 025-FCV-02 and it will close

after a delay of 15 minutes.

These valves will remain interlocked untill the tank level falls below High-High.

Project : 9650 Page 38 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

8. The Pressure indication 009-PI-01 of De-chlorination Tank gives alarm when it becomes either

High – High (HH) or High (H) or Low – Low (LL) or Low (L).

9. The flow transmitter 009-FI-01 gives alarm when it becomes either High – High (HH) or High (H) or

Low – Low (LL) or Low (L ).

10. The pH transmitter 009-AI-01 gives alarm when it becomes either High (H) or Low (L).

11. The Differential Pressure indicator 009-DPI-01 gives alarm when it become High(H) or Low(L).

12. The Flow indication 009-FI-04 gives alarm when it becomes either High(H) or Low(L).

13. Interlock (I-20)

When any one of pump 009-P-01 AorB shall trip another pump will start automatically. If

following condition is normal–

• 009-LI-01 is not Low – Low (LL).

• Another Pump trip signal from MCC is not coming.

14. Interlock (I-21)

When any one of Blower 009-K-01 AorB shall trip another pump will start automatically. If

following condition is normal–

• Another Pump trip signal from MCC is not coming.

15. Motor/Drive provision of Start and Stop from DCS shall be provided.

009-P-01 A/B - STOP & START (EMERGENCY)

009-K-01 A/B - STOP & START (EMERGENCY)

16. All Interlocks should have Bypass switch available on common DCS screen. And the indication of

Bypass switch activated or deactivated should be available on each interlock number on each

screen.

Project : 9650 Page 39 of 79 Author: Shivam Mishra

Client: SCE, Morocco Doc. No.: 9650-11-PCP-00-0002 Revision: 04

CLIENT: CONTRACTOR:

PROJECT

50 MTPD CAPACITY (Cl2

BASIS) CHLOR ALKALI

PLANT

SOCIÉTÉ CHÉRIFIENNE D'ENGRAIS ET

NUBERG ENGINEERING LTD.

DE PRODUITS CHIMIQUES

LEAN BRINE STORAGE

9650-11-PID-00-0009(2 OF 2)

1. The level indication 009-LI-02 of the Lean Brine Tank 009-T-01 gives alarm when it becomes either

High – High (HH) or High (H) or Low – Low (LL) or Low (L).

2. Interlock (22)

When level indication 009-LI-02 of 009-T-01 becomes Low-Low (LL), the Lean Brine Pump

(009-P-02 A/B) shall trip.

3. The level of Lean Brine Tank 009-T-01 is maintained by controlling the Flow of Process Water by

Level Control Valve 009-LCV-03 as per the set point of 009-LIC-02.when level increases above set

point valve opening will reduce.

4. The flow transmitter 009-FI-01 of 18% HCL gives alarm when it becomes either High(H) or Low(L ).

5. The flow transmitter 009-FI-01 of PW water line gives alarm when it becomes either High (H) or

Low (L).

6. The pH indicator (009-AI-01) gives alarm when it becomes either High (H) or Low (L).

7. Motor/Drive provision of Start and Stop from DCS shall be provided.

009-P-02 A/B - START & STOP