Professional Documents

Culture Documents

Pattern

Pattern

Uploaded by

bereket tekleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pattern

Pattern

Uploaded by

bereket tekleCopyright:

Available Formats

College of Electrical and Mechanical Engineering

Department of Mechanical Engineering

Metal Casting Technology

Assignment Ⅱ

Name: Kalid Mohammed

ID NO: ETS0688/13

Submitted To: Mr. Mohammed A.

Submission date: March 21, 2024

1. Master Pattern: is the original pattern, other patterns are made depending on the master

pattern. The master pattern has double the shrinkage allowance and other allowances and is

very accurate as it is the base line of the that specific product.

2. Core Print: is what we use open space in the mold and is supporting the positioning of the core.

The print must be strong enough to resist the buoyancy force of the molten metal

3. A wooden pattern is used to cast a gear with a smaller diameter of 100mm and larger diameter

of 150mm from aluminum.

Shrinkage allowance for aluminum is 17mm per meter

Draft allowance for wooden pattern is at a height from 21 to 50mm and taper angle from

1.5 to 2.5o

As the gear does not have any v or u-shaped parts distortion allowance is not needed

In the wooden pattern we add the shrinkage, draft and machining allowance.

The allowance added to the patten due to: shrinkage is 17mm as is the material is

aluminum

Draft is 150-100 = 50mm, by taking 1 degree

taper angle the taper length = 50*tan (1) = 0.87275. the

allowance is half of the taper length which equals to

0.87/2 = 0.436

Machining 1.5mm

i.e the dimension is going to be smaller diameter = 100 + 0.436 + 1.5 + 17 = 118.936mm and the

larger diameter = 150 + 0.436 + 1.5 + 17 = 168.936mm

4. Materials used for pattern making are: wood, plastic, metal, gypsum, ceramic, wax, etc

a. Wood: low cost, needs to be changed after a few productions, easily shaped, easily

available, low weight

b. Plastic: high precision, great repeatability, low cost, higher lead time

c. Metal: high cost, can be used for mass production, remains in tact for a long period of

time, good surface finish, high strength, good machinability

d. Gypsum: easy installation, low cost

e. Ceramic: very expensive, low maintenance,

5. Pattern: is the replica of the object to be made by the casting process with some modification

(pattern allowances and provisions for core print)

Pattern defers from the actual product because the additional dimension added to the pattern to

compensate for the shrinkage of the material while cooling, machining process, to avoid

bending, to avoid damage or distortion while removal, etc

6. Pattern material selection depends on: - Service requirement

- Possibility of design change

- Type of production of casting

- Type of molding method and equipment to be used

- Possibility of repeat

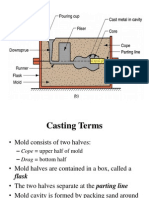

Split Pattern: also called two pieces

Is made in two pieces which are joined at the parting line by means of dowel

pins. The splitting at the parting line is done to facilitate the withdrawal.

Sweep Pattern: shapes the cavity by rotating a wooden board along one edge.

A cavity is created in the vertical direction while the base is attached with sand

Match-Plate Pattern: is made in two halves and is mounted on the opposite sides of the wooden

or metallic plate, known as match plate.

You might also like

- @eotc Books by PDFDocument427 pages@eotc Books by PDFbereket tekleNo ratings yet

- Engine Block Manufacturing ProcessDocument12 pagesEngine Block Manufacturing ProcessFadirul Ezwan100% (3)

- Astm A923 PDFDocument10 pagesAstm A923 PDFQcsss SHPLNo ratings yet

- Foudry TechnologyDocument10 pagesFoudry TechnologyBiren kumar SamalNo ratings yet

- Unit I - 3Document22 pagesUnit I - 3thirunaarasuNo ratings yet

- Manufacturing Process - CastingDocument81 pagesManufacturing Process - CastingArnab HazraNo ratings yet

- Lectures Notes On: Manufacturing Science and TechnologyDocument53 pagesLectures Notes On: Manufacturing Science and TechnologyDr ShanthakumarlNo ratings yet

- ME8351 Manufacturing Technology - I: 1.1castingDocument96 pagesME8351 Manufacturing Technology - I: 1.1castingBalu ChanderNo ratings yet

- Pattern (Assign Fin)Document7 pagesPattern (Assign Fin)bereket tekleNo ratings yet

- MFG Casting - SparkAcademyDocument156 pagesMFG Casting - SparkAcademybenNo ratings yet

- Pattern SDocument40 pagesPattern SanilNo ratings yet

- Pattern AllowancesDocument2 pagesPattern AllowancesQuanta BosonNo ratings yet

- Class3 - PatternDocument57 pagesClass3 - PatternSriharsha SarmaNo ratings yet

- Lecture 02Document16 pagesLecture 02Aditya kothimbireNo ratings yet

- Experiment No 1 - ManualDocument6 pagesExperiment No 1 - ManualVivekumNo ratings yet

- Casting Processes: DR Ajay BatishDocument46 pagesCasting Processes: DR Ajay BatishAlisha GuptaNo ratings yet

- Pattern Materials - HAFDocument10 pagesPattern Materials - HAFZaky MuzaffarNo ratings yet

- Ch-21 Sand CastingDocument156 pagesCh-21 Sand CastingDivya SoniNo ratings yet

- MT Notes Unit IDocument226 pagesMT Notes Unit IsivasaNo ratings yet

- Metal CastingDocument153 pagesMetal CastingSUVARNA TALPENo ratings yet

- Ch-21 Sand CastingDocument156 pagesCh-21 Sand CastingMANJEET KUMARNo ratings yet

- Ch-21 Sand Casting PDFDocument123 pagesCh-21 Sand Casting PDFKartik BhararaNo ratings yet

- Pp1 Module1 FundamentalsDocument15 pagesPp1 Module1 FundamentalsAnand BalajiNo ratings yet

- Ch-21 Sand CastingDocument130 pagesCh-21 Sand CastingJimmy JindalNo ratings yet

- Pattern Making &foundaryDocument26 pagesPattern Making &foundaryAshish SinghNo ratings yet

- CastingDocument243 pagesCastingJoaNo ratings yet

- Foundry TechnologyDocument64 pagesFoundry TechnologyanubhavsundarrayNo ratings yet

- MT 1 PatternDocument8 pagesMT 1 PatternRavasaheb BholeNo ratings yet

- BMP Module IDocument36 pagesBMP Module IBiswajit LME016No ratings yet

- Foundry: Pattern MakingDocument7 pagesFoundry: Pattern MakingLourencoNo ratings yet

- Unit 1 Casting ProcessDocument77 pagesUnit 1 Casting ProcessAquib AhmedNo ratings yet

- Best Metal Casting DesignDocument71 pagesBest Metal Casting DesignVijay Pawar100% (2)

- Permanent Mold CastingDocument15 pagesPermanent Mold CastingEka RosmitaliaNo ratings yet

- MC25 Lec 6 Metal CastingDocument78 pagesMC25 Lec 6 Metal Castingtvishal8No ratings yet

- 1 Hareesha N G Dept Aero Engg, DSCE, BloreDocument47 pages1 Hareesha N G Dept Aero Engg, DSCE, Bloremahammad kamaluddeenNo ratings yet

- INTRODUCTION To MANUFACTURING PROCESS PART-2 (2) .PpsDocument47 pagesINTRODUCTION To MANUFACTURING PROCESS PART-2 (2) .Ppsmahammad kamaluddeenNo ratings yet

- Industrial Production Engineering - 1-1Document71 pagesIndustrial Production Engineering - 1-1Freby Tony ENo ratings yet

- 1 Sand CastingDocument21 pages1 Sand CastingMayank GroverNo ratings yet

- Casting: Process, Terminology & StepsDocument12 pagesCasting: Process, Terminology & StepsمحمودالوصيفNo ratings yet

- 2,. CastingDocument37 pages2,. Castingmohit s sNo ratings yet

- Chapter 3 CastingDocument76 pagesChapter 3 CastingHiteshkumar ShahNo ratings yet

- Advance Casting ProcesssDocument42 pagesAdvance Casting ProcesssPrikshit Gothwal100% (1)

- Sheet Metal Design GuidelinesDocument17 pagesSheet Metal Design GuidelinesOmar YoushimatzNo ratings yet

- Epl RecordDocument63 pagesEpl RecordTishbian MeshachNo ratings yet

- Chapter 3 CastingDocument77 pagesChapter 3 CastingGaurav Kumar Badhotiya100% (1)

- Mold DesignDocument9 pagesMold DesignA MahmoodNo ratings yet

- Casting DetailsDocument8 pagesCasting DetailsudayraochNo ratings yet

- Metal CastingDocument75 pagesMetal CastingRajaSekarsajjaNo ratings yet

- Lecture2casting 160411082846Document190 pagesLecture2casting 160411082846IgnatiusAbbyNo ratings yet

- Advantages of Metal CastingDocument6 pagesAdvantages of Metal CastingHarshGuptaNo ratings yet

- MP Material by SravanDocument189 pagesMP Material by Sravankiran kittuNo ratings yet

- Metal Casting 3Document23 pagesMetal Casting 3bhushan wandreNo ratings yet

- Chapter 3 CastingDocument77 pagesChapter 3 CastingAmirDeshmukhNo ratings yet

- ME8351 Manufacturing Technology I Unit I Metal Casting ProcessesDocument7 pagesME8351 Manufacturing Technology I Unit I Metal Casting ProcessesAyyanrajNo ratings yet

- Production Technology - I: Metal CastingDocument20 pagesProduction Technology - I: Metal CastingAbishek AbhNo ratings yet

- MPT CH-2Document60 pagesMPT CH-2Seare TekesteNo ratings yet

- Foundary or CastingDocument88 pagesFoundary or CastingThulasi RamNo ratings yet

- Manuafcturing Science 1 - Metal CastingDocument28 pagesManuafcturing Science 1 - Metal CastingSudit SharmaNo ratings yet

- Mechanical Engineering Manufacturing-Process Machine-Drawing Notes PDFDocument10 pagesMechanical Engineering Manufacturing-Process Machine-Drawing Notes PDFahmed titoNo ratings yet

- Design For Manufacturing, CASTINGDocument10 pagesDesign For Manufacturing, CASTINGDarbhalaPavanKumarNo ratings yet

- Color Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueFrom EverandColor Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueNo ratings yet

- Art N ScifiDocument24 pagesArt N Scifibereket tekleNo ratings yet

- C-h four, CiMDocument6 pagesC-h four, CiMbereket tekleNo ratings yet

- Sports 2Document71 pagesSports 2bereket tekleNo ratings yet

- College of Applied and Natural Science Department of Food Science and Applied Nutrition Nutrition Assessment (FSAN3122) 2Cr - HRDocument42 pagesCollege of Applied and Natural Science Department of Food Science and Applied Nutrition Nutrition Assessment (FSAN3122) 2Cr - HRbereket tekleNo ratings yet

- Sec. 25 TopicsDocument1 pageSec. 25 Topicsbereket tekleNo ratings yet

- 2016-1st Year SIM-II Schedule For StudentsDocument2 pages2016-1st Year SIM-II Schedule For Studentsbereket tekleNo ratings yet

- MGCourse Plan For Communicative English Skills IIDocument9 pagesMGCourse Plan For Communicative English Skills IIbereket tekleNo ratings yet

- Pattern (Assign Fin)Document7 pagesPattern (Assign Fin)bereket tekleNo ratings yet

- Biochemical Engineering Toutorial QuestionsDocument3 pagesBiochemical Engineering Toutorial Questionsbereket tekleNo ratings yet

- Psychology Midterm Exam 11 (AMU)Document3 pagesPsychology Midterm Exam 11 (AMU)bereket tekleNo ratings yet

- Experiment FiveDocument7 pagesExperiment Fivebereket tekleNo ratings yet

- Psychology Midterm Exam 13 (AAU)Document1 pagePsychology Midterm Exam 13 (AAU)bereket tekleNo ratings yet

- Energy Transport by Heat, Work and MassDocument23 pagesEnergy Transport by Heat, Work and Massbereket tekleNo ratings yet

- Article 1Document10 pagesArticle 1bereket tekleNo ratings yet

- Mesfi 2Document15 pagesMesfi 2bereket tekleNo ratings yet

- Mesurement ch2 & 3Document7 pagesMesurement ch2 & 3bereket tekleNo ratings yet

- Polyboard: Bitumen Impregnated Compressible Fibre Filler BoardDocument2 pagesPolyboard: Bitumen Impregnated Compressible Fibre Filler Boardmpandy1984No ratings yet

- L.T DetailDocument1 pageL.T DetailEeswar AtluriNo ratings yet

- Manufacturing Lab ManualDocument41 pagesManufacturing Lab ManualAftaab AlamNo ratings yet

- Repair Welding Considerations For Cr-Mo Steel Pressure Vessels ARTICLE 2.15Document7 pagesRepair Welding Considerations For Cr-Mo Steel Pressure Vessels ARTICLE 2.15romanosky11No ratings yet

- VC March 2021Document34 pagesVC March 2021rekhabaghel041992No ratings yet

- SABIC®-PP QR6731K Global Technical Data SheetDocument2 pagesSABIC®-PP QR6731K Global Technical Data SheetPhahad HasimNo ratings yet

- Declaration of PerformanceDocument2 pagesDeclaration of PerformanceMihaelaBeatriceVladNo ratings yet

- Electrical BOQ FinalDocument45 pagesElectrical BOQ FinalmahasubbuNo ratings yet

- Metal Forming Lubricants: Wire Drawing Cold Forming Sheet Metal Forming RollingDocument7 pagesMetal Forming Lubricants: Wire Drawing Cold Forming Sheet Metal Forming RollingNokiabhre WijayaNo ratings yet

- (QTC) Quarter Turn Anchor CatcherDocument1 page(QTC) Quarter Turn Anchor CatcherCarlos HolguinNo ratings yet

- BS 812-120-1989 Testing Aggregates. Method For Testing and Classifying Drying Shrinkage of Aggregates in ConcreteDocument13 pagesBS 812-120-1989 Testing Aggregates. Method For Testing and Classifying Drying Shrinkage of Aggregates in ConcreteHaris KyriazisNo ratings yet

- CONSTRUCTION FIELDWORK (Group 10)Document30 pagesCONSTRUCTION FIELDWORK (Group 10)Belcena, Emily Faith D.No ratings yet

- TDS - Masterflex J SealDocument3 pagesTDS - Masterflex J SealVenkata RaoNo ratings yet

- Basic Oxygen SteelmakingDocument11 pagesBasic Oxygen SteelmakingRahul Pandey100% (1)

- MULTI-PURPOSE DepED PDFDocument8 pagesMULTI-PURPOSE DepED PDFKhalid Ali Saif Al-ShamsiNo ratings yet

- KB Rebar BrochureDocument4 pagesKB Rebar BrochureJun Xian Wai100% (1)

- Ba YaDocument8 pagesBa YaRokhmad AsrofiNo ratings yet

- Upvc PipesDocument8 pagesUpvc Pipesnawazeee2840No ratings yet

- Sika Bond - LA: Water Resistant Bonding AgentDocument2 pagesSika Bond - LA: Water Resistant Bonding AgentsaravanakumarpalaniNo ratings yet

- Session 7Document16 pagesSession 7DendeNo ratings yet

- MATERIALS ENGINEER REVIEWER - II (Concrete & Concrete Products)Document25 pagesMATERIALS ENGINEER REVIEWER - II (Concrete & Concrete Products)pablojabNo ratings yet

- Metal Forming Processes Questions and Answers - SanfoundryDocument2 pagesMetal Forming Processes Questions and Answers - Sanfoundryrahma100% (3)

- ACI 207.1R-05 Guide To Mass ConcreteDocument31 pagesACI 207.1R-05 Guide To Mass ConcreteLukusa Badimuena100% (3)

- MTO #6 Fase VII, Accesorios de Instrumentacion PDFDocument3 pagesMTO #6 Fase VII, Accesorios de Instrumentacion PDFdavidseins2009No ratings yet

- Lecture 16 - Cracking: RC14-1334: Concrete Structures 1Document16 pagesLecture 16 - Cracking: RC14-1334: Concrete Structures 1'Riky Dwi Prasetyo'No ratings yet

- Model 043-B Service Regulator: Technical DataDocument2 pagesModel 043-B Service Regulator: Technical Dataramiro rincon suarezNo ratings yet

- The Potentials of Groundnut Shell Ash As ConcreteDocument9 pagesThe Potentials of Groundnut Shell Ash As ConcreteGener NavarroNo ratings yet

- Steel Surfaces A Guide To Alloys Finishes Fabrication and Maintenance in Architecture and Art 1St Edition L William Zahner All ChapterDocument68 pagesSteel Surfaces A Guide To Alloys Finishes Fabrication and Maintenance in Architecture and Art 1St Edition L William Zahner All Chaptercharlotte.nichols292100% (6)