Professional Documents

Culture Documents

Hot Dip Galvani Sheet

Hot Dip Galvani Sheet

Uploaded by

Adrià DraperCopyright:

Available Formats

You might also like

- ASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFDocument2 pagesASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFCésar Santana50% (4)

- Annex A: (Normative)Document6 pagesAnnex A: (Normative)calvente27No ratings yet

- Hot Dip Galv Sheet Emw Catalogue 102017Document5 pagesHot Dip Galv Sheet Emw Catalogue 102017Pedro MaiaNo ratings yet

- Hot Dip Galvani SheetDocument3 pagesHot Dip Galvani SheetumarNo ratings yet

- Continuous Hot Dip Coating. Galvanised.Document9 pagesContinuous Hot Dip Coating. Galvanised.marjan banooNo ratings yet

- Hot Dip Galvanized SheetDocument5 pagesHot Dip Galvanized SheetBrian KnightNo ratings yet

- Hot Dip Galvanized Sheet DX52DDocument10 pagesHot Dip Galvanized Sheet DX52DiocephNo ratings yet

- Hot Dip Galvanized SheetDocument2 pagesHot Dip Galvanized SheetgorakdiasNo ratings yet

- Valori Rezistente Materiale AlinDocument2 pagesValori Rezistente Materiale AlinAndrei DinicăNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document5 pagesStructural Steel Plate and Strip To EN 10025Mbalekelwa MpembeNo ratings yet

- Ferritic and Martensitic Casting MaterialsDocument2 pagesFerritic and Martensitic Casting MaterialsSinan YıldızNo ratings yet

- MetalfaesDocument2 pagesMetalfaesviyfNo ratings yet

- Gasnitriding - Plasmanitriding - SaltbathnitridingDocument4 pagesGasnitriding - Plasmanitriding - SaltbathnitridingKevin ThomasNo ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- SDR0503 Series - SMD Power Inductors: Features ApplicationsDocument3 pagesSDR0503 Series - SMD Power Inductors: Features ApplicationsJoseph Abou El OulaNo ratings yet

- En 10268Document4 pagesEn 10268Alex LacerdaNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document4 pagesStructural Steel Plate and Strip To EN 10025Ibrahim BashaNo ratings yet

- STANDARD - ASTM A653 - Brief DescriptionDocument7 pagesSTANDARD - ASTM A653 - Brief DescriptionSeyong ParkNo ratings yet

- ChemicalComposition FBDocument1 pageChemicalComposition FBSibasish SarkhelNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- Mild Steels Voestalpine EN 09082019Document5 pagesMild Steels Voestalpine EN 09082019Alma Aliza VillaberNo ratings yet

- Thành phần hóa học thép - Steel bars for concrete reinforcementDocument3 pagesThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNo ratings yet

- Grade & SpcficDocument6 pagesGrade & SpcficANBUNo ratings yet

- Pakistan Ssteel Mills Mild Steel Grades SpecificationDocument3 pagesPakistan Ssteel Mills Mild Steel Grades SpecificationWaqas WaqasNo ratings yet

- TNMG 160404 NN LT 10 108Document1 pageTNMG 160404 NN LT 10 108fabioNo ratings yet

- Instrumentation Tubing ENDocument5 pagesInstrumentation Tubing ENLuis CasasNo ratings yet

- 34crnimo6: Steel GradeDocument6 pages34crnimo6: Steel GradeBiju KNo ratings yet

- Stainless Steel 441 UNS S43940Document5 pagesStainless Steel 441 UNS S43940Enrique Ruiz HonoratoNo ratings yet

- MS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)Document10 pagesMS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)khalilNo ratings yet

- Catalog MBH - Catalogue Carbon Steel Low Alloy SteelDocument12 pagesCatalog MBH - Catalogue Carbon Steel Low Alloy SteelCarlos Anibal OrtizNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- 38 MN VS6Document2 pages38 MN VS6Pramod NautiyalNo ratings yet

- BS EN 10293 InformationDocument2 pagesBS EN 10293 Informationchief_of_stuffNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Techinfo WorkpieceDocument1 pageTechinfo Workpiecesototo90No ratings yet

- STD, Inch Sizes TCM 12-163226Document13 pagesSTD, Inch Sizes TCM 12-163226SHANENo ratings yet

- FVBDocument6 pagesFVBCNo ratings yet

- 20160331071021-6541 23MnNiCrMo52Document1 page20160331071021-6541 23MnNiCrMo52rusf123No ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Design: Technical DetailsDocument4 pagesDesign: Technical DetailsDanialNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- Sepction - 3Document3 pagesSepction - 3k koradiaNo ratings yet

- Mac CalDocument4 pagesMac Calvhs mechatronicsNo ratings yet

- Casting Material Alloy Steel G20Mn5 EN 1.6220Document3 pagesCasting Material Alloy Steel G20Mn5 EN 1.6220nethaji nethajiNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- 4G 2G 2F 3G Uphill 3G DownhillDocument1 page4G 2G 2F 3G Uphill 3G Downhillamit singhNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNo ratings yet

- Aero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196Document2 pagesAero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196jayalakshmivinothNo ratings yet

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetDocument4 pagesElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováNo ratings yet

- Studytheme 2.24 - Other Metals and AlloysDocument14 pagesStudytheme 2.24 - Other Metals and AlloysMarno PrinslooNo ratings yet

- Soft Unalloyed Steels For Cold Forming: Steel GradesDocument8 pagesSoft Unalloyed Steels For Cold Forming: Steel GradesHemachandra ShrotriNo ratings yet

- HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Document4 pagesHPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Er Umesh RohitNo ratings yet

- Material Kapal Bki Wi Ui AlimsaadiDocument12 pagesMaterial Kapal Bki Wi Ui AlimsaadiSaadi AlimNo ratings yet

- Wear Characterization of LM29 Alloy With40 Micron Sized B4C Reinforced Metal CompositesDocument9 pagesWear Characterization of LM29 Alloy With40 Micron Sized B4C Reinforced Metal CompositesIJAR JOURNALNo ratings yet

- Seamless and Welded Steel Pipe For Low-Temperature Service and Other Applications With Required Notch ToughnessDocument8 pagesSeamless and Welded Steel Pipe For Low-Temperature Service and Other Applications With Required Notch ToughnessTim SharpNo ratings yet

- General Chemistry 2 - LAS 2 LEARNING CAPSULEDocument5 pagesGeneral Chemistry 2 - LAS 2 LEARNING CAPSULEMark RazNo ratings yet

- 403 Ore Microscopy-1-22Document27 pages403 Ore Microscopy-1-22SURVIVAL MOTLHANKANo ratings yet

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification Foralucard375No ratings yet

- Multiple Choice Questions (Q1-Q10)Document2 pagesMultiple Choice Questions (Q1-Q10)veenaNo ratings yet

- Periodic Table of The ElementsDocument1 pagePeriodic Table of The ElementsGeorgeNo ratings yet

- 2014 - 11 - Elkem Alloys in Special ApplicationsDocument27 pages2014 - 11 - Elkem Alloys in Special Applicationsfelipe100% (1)

- RRR RRR Emerging Producers Investor PresentationDocument21 pagesRRR RRR Emerging Producers Investor PresentationSahil RSNo ratings yet

- Carbon Enrichment in Mo SteelDocument50 pagesCarbon Enrichment in Mo SteelDhananjay ShimpiNo ratings yet

- ASTM B 338 Seamless & Welded Titanium Abd Titanium Alloy Tubes For Condensers & Heat Exchangers - 1995Document6 pagesASTM B 338 Seamless & Welded Titanium Abd Titanium Alloy Tubes For Condensers & Heat Exchangers - 1995ecsuperalNo ratings yet

- Page 0002Document1 pagePage 0002has sas100% (1)

- Basic CorrosionDocument11 pagesBasic CorrosionmohdluthfiNo ratings yet

- Aluminum & ConcreteDocument4 pagesAluminum & Concretenetzonetechnical managerNo ratings yet

- Aluminium Bronze To Bs 1400: Ab1Document1 pageAluminium Bronze To Bs 1400: Ab1Fred Duarte CaldeiraNo ratings yet

- Xii Chemistry Previous Questions by Anil Kumar K.L (Hsslive - In)Document3 pagesXii Chemistry Previous Questions by Anil Kumar K.L (Hsslive - In)thiripura sundari100% (1)

- A 297 A 297MDocument3 pagesA 297 A 297Mمحمد العيسوىNo ratings yet

- Specification For Carbon Steel Forgings For Piping ApplicationsDocument10 pagesSpecification For Carbon Steel Forgings For Piping ApplicationsMauricio Esteban Fernandez RamirezNo ratings yet

- Iron OreDocument2 pagesIron OreSanjay SinghNo ratings yet

- F1852Document8 pagesF1852mrezaiNo ratings yet

- Catalogo Cañas Fendwick Berkley Mitchel Abu GarciaDocument142 pagesCatalogo Cañas Fendwick Berkley Mitchel Abu GarciaGonzalo FioreNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Flare Tip Material Selection - GBADocument2 pagesFlare Tip Material Selection - GBADpto SSO SimbioNo ratings yet

- Materials Selection: Lecturer: Muhammad SulaimanDocument15 pagesMaterials Selection: Lecturer: Muhammad SulaimanHussain AliNo ratings yet

- North American Die Casting Association: Membership Directory 2022-2023Document31 pagesNorth American Die Casting Association: Membership Directory 2022-2023f3rNo ratings yet

- Sa 105 PDFDocument10 pagesSa 105 PDFkumarNo ratings yet

- Hiten Kadu 6.1Document104 pagesHiten Kadu 6.1Pranjal DograNo ratings yet

- Chemistry Progress 12 PDFDocument87 pagesChemistry Progress 12 PDFMapalo Chirwa100% (2)

Hot Dip Galvani Sheet

Hot Dip Galvani Sheet

Uploaded by

Adrià DraperOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Dip Galvani Sheet

Hot Dip Galvani Sheet

Uploaded by

Adrià DraperCopyright:

Available Formats

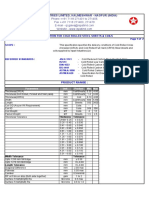

Delivery Programme

3

1. Hot rolled sheet and strip

2. Cold rolled sheet

3. Hot-dip galvanised sheet

4. Electrolytic zinc coated sheet

Hot-dip galvanised sheet 5. Hot aluminised sheet

Limitations, parameters for testing and

Grades and properties exceptional arrangements are to be taken

from the pertinent standard.

Mild steel grades

continuous hot-dip galvanised strip and sheet for cold forming, DIN EN 10346 (Z/ZF/ZA/AZ)

Designation to Mechanical properties Chemical composition

EN EN Symbol for Re Rm A80 r n C Si Mn P S Ti

10346 10027-2 the type of [N/mm2] [N/mm2] [%] [%] [%] [%] [%] [%] [%]

Material hot-dip min. min. min. max. max. max. max. max. max.

No. coating

DX51D 1.0226 +Z, +ZA, +AZ – 270 to 500 22 – – 0.18 0.50 1.20 0.12 0.045 0.30

DX51D 1.0226 +ZF – 270 to 500 22 – – 0.18 0.50 1.20 0.12 0.045 0.30

DX52D 1.0350 +Z, +ZA, +AZ 140 to 300 * 270 to 420 26 – – 0.12 0.50 0.60 0.10 0.045 0.30

DX52D 1.0350 +ZF 140 to 300 * 270 to 420 26 – – 0.12 0.50 0.60 0.10 0.045 0.30

DX53D 1.0355 +Z, +ZA, +AZ 140 to 260 270 to 380 30 – – 0.12 0.50 0.60 0.10 0.045 0.30

DX53D 1.0355 +ZF 140 to 260 270 to 380 30 – – 0.12 0.50 0.60 0.10 0.045 0.30

DX54D 1.0306 +Z, +ZA 120 to 220 260 to 350 36 1.6 0.18 0.12 0.50 0.60 0.10 0.045 0.30

DX54D 1.0306 +ZF 120 to 220 260 to 350 34 1.4 0.18 0.12 0.50 0.60 0.10 0.045 0.30

DX54D 1.0306 +AZ 120 to 220 260 to 350 36 – – 0.12 0.50 0.60 0.10 0.045 0.30

DX56D 1.0322 +Z, +ZA 120 to 180 260 to 350 39 1.9 0.21 0.12 0.50 0.60 0.10 0.045 0.30

DX56D 1.0322 +ZF 120 to 180 260 to 350 37 1.7 0.20 0.12 0.50 0.60 0.10 0.045 0.30

DX57D 1.0853 +Z, +ZA 120 to 170 260 to 350 41 2.1 0.22 0.12 0.50 0.60 0.10 0.045 0.30

DX57D 1.0853 +ZF 120 to 170 260 to 350 39 1.9 0.21 0.12 0.50 0.60 0.10 0.045 0.30

* only valid for surface qualities B and C

Micro-alloyed grades

continuous hot-dip galvanised high yield strength steel strip and sheet for cold forming, DIN EN 10346

Designation to Mechanical properties Chemical composition

Symbol for Re BH2 Rm A80 r n C Si Mn P S Al Ti Nb

EN 10346 EN 10027-2 the type of [N/mm2] [N/mm2] [N/mm2] [%] [%] [%] [%] [%] [%] [%] [%] [%]

Material No. hot-dip across across across across across across

coating min. min. min. min. max. max. max. max. max. max. max.

HX160YD 1.0910 +Z, +ZF, +ZA, +AZ 160 to 220 – 300 to 360 37 1,9 0.20 0.01 0.15 0.70 0.06 0.025 ≤ 0.10 0.12 0.09

HX180YD 1.0921 +Z, +ZF, +ZA, +AZ 180 to 240 – 340 to 400 34 1.7 0.18 0.01 0.15 0.70 0.06 0.025 ≤ 0.10 0.12 0.09

HX180BD 1.0914 +Z, +ZF, +ZA, +AZ 180 to 240 35 290 to 360 34 1.5 0.16 0.10 0.50 0.70 0.06 0.025 ≤ 0.10 0.12 0.09

HX220YD 1.0923 +Z. +ZF, +ZA, +AZ 220 to 280 – 340 to 420 32 1.5 0.17 0.01 0.20 0.90 0.08 0.025 ≤ 0.10 0.12 0.09

HX220PD* 1.0358 +Z, +ZF, +ZA, +AZ 220 to 280 – 340 to 400 32 1.3 0.15 0.06 0.50 0.70 0.08 0.025 ≥ 0.02 – –

HX220BD 1.0919 +Z, +ZF, +ZA, +AZ 220 to 280 35 320 to 400 32 1.2 0.15 0.10 0.50 0.70 0.08 0.025 ≤ 0.10 0.12 0.09

HX260YD 1.0926 +Z, +ZF, +ZA, +AZ 260 to 320 – 380 to 440 30 1.4 0.16 0.01 0.25 1.60 0.10 0.025 ≤ 0.10 0.12 0.09

HX260PD* 1.0431 +Z, +ZF, +ZA, +AZ 260 to 320 – 380 to 440 28 – – 0.11 0.50 0.70 0.10 0.025 ≥ 0.02 – –

HX260BD 1.0924 +Z, +ZF, +ZA, +AZ 260 to 320 35 360 to 440 28 – – 0.10 0.50 0.80 0.10 0.025 ≤ 0.10 0.12 0.09

HX260LAD 1.0929 +Z, +ZF, +ZA, +AZ 260 to 330 – 350 to 430 26 – – 0.12 0.50 0.60 0.030 0.025 ≥ 0.015 0.12 0.09

HX300PD* 1.0443 +Z, +ZF, +ZA, +AZ 300 to 360 – 400 to 480 26 – – 0.11 0.50 0.70 0.12 0.025 ≥ 0.02 – –

HX300YD 1.0927 +Z, +ZF, +ZA, +AZ 300 to 360 – 390 to 470 27 1.3 0.15 0.01 0.30 1.30 0.10 0.025 ≤ 0.10 0.12 0.09

HX300BD 1.0930 +Z, +ZF, +ZA, +AZ 300 to 360 35 400 to 480 26 – – 0.11 0.50 0.80 0.12 0.025 ≤ 0.10 0.12 0.09

HX300LAD 1.0932 +Z, +ZF, +ZA, +AZ 300 to 380 -– 380 to 480 23 – – 0.11 0.50 1.00 0.030 0.025 ≥ 0.015 0.15 0.09

HX340LAD 1.0933 +Z, +ZF, +ZA, +AZ 340 to 420 -– 410 to 510 21 – – 0.11 0.50 1.00 0.030 0.025 ≥ 0.015 0.15 0.09

HX380LAD 1.0934 +Z, +ZF, +ZA, +AZ 380 to 480 – 440 to 560 19 – – 0.11 0.50 1.40 0.030 0.025 ≥ 0.015 0.15 0.09

HX420LAD 1.0935 +Z, +ZF, +ZA, +AZ 420 to 520 – 470 to 590 17 – – 0.11 0.50 1.40 0.030 0.025 ≥ 0.015 0.15 0.09

HX460LAD 1.0990 +Z, +ZF, +ZA, +AZ 460 to 560 – 500 to 640 15 – – 0.15 0.50 1.70 0.030 0.025 ≥ 0.015 0.15 0.09

HX500LAD 1.0991 +Z, +ZF, +ZA, +AZ 500 to 620 – 530 to 690 13 – – 0.15 0.50 1.70 0.030 0.025 ≥ 0.015 0.15 0.09

B bake hardening P phosphorous alloyed Y interstitial-free (IF Steel) LA low alloy (micro-alloyed) * Grade not included in the latest norm (formerly: DIN EN 10292:2000)

Becker Stahl-Service GmbH · Weetfelder Straße 57 · 59199 Bönen

Phone +49(0)2383/934-0 · Fax +49(0)2383/934-208 · info@becker-stahl-service.de · www.becker-stahl-service.de

edited: September 10

Structural steels

continuous hot-dip galvanised structural steel strip and sheet for cold forming, DIN EN 10346 (Z/ZF/ZA/AZ)

Designation to Mechanical properties Chemical composition

EN EN Symbol for Re Rm A80 C Si Mn P S

10346 10027-2 the type of [N/mm2] [N/mm2] [%] [%] [%] [%] [%] [%]

Material hot-dip min. min. min. max. max. max. max. max.

No. coating

S220GD 1.0241 +Z, +ZA 220 300 20 0.2 0.6 1.70 0.10 0.045

S220GD 1.0241 +ZF, +AZ 220 300 20 0.2 0.6 1.70 0.10 0.045

S250GD 1.0242 +Z, +ZA 250 330 19 0.2 0.6 1.70 0.10 0.045

S250GD 1.0242 +ZF, +AZ 250 330 19 0.2 0.6 1.70 0.10 0.045

S280GD 1.0244 +Z, +ZA 280 360 18 0.2 0.6 1.70 0.10 0.045

S280GD 1.0244 +ZF, +AZ 280 360 18 0.2 0.6 1.70 0.10 0.045

S320GD 1.0250 +Z, +ZA 320 390 17 0.2 0.6 1.70 0.10 0.045

S320GD 1.0250 +ZF, +AZ 320 390 17 0.2 0.6 1.70 0.10 0.045

S350GD 1.0529 +Z, +ZA 350 420 16 0.2 0.6 1.70 0.10 0.045

S350GD 1.0529 +ZF, +AZ 350 420 16 0.2 0.6 1.70 0.10 0.045

S550GD 1.0531 +Z, +ZA 550 560 – 0.2 0.6 1.70 0.10 0.045

S550GD 1.0531 +ZF, +AZ 550 560 – 0.2 0.6 1.70 0.10 0.045

Multi-phase steel

continuous hot-dip galvanised multi-phase steel for cold forming, DIN EN 10346

Designation to Mechanical properties Chemical composition

EN 10346 EN 10027-2 Symbol for Re BH2 Rm A80 n C Si Mn P S Al Cr+Mo Nb+Ti V B

Material No. the type of [N/mm2] [N/mm2] [N/mm2] [N/mm2]

hot-dip across across across across across [%] [%] [%] [%] [%] [%] [%] [%] [%] [%] [%]

coating min. min. min. min. max. max. max. max. max. min. max. max. max. max. max.

FB-Steel

HDT450F 1.0961 +Z, +ZF 320 to 420 30 450 23 – 0.180 0.500 1.200 0.030 0.010 0.015 – 0.30 0.05 0.15 0.005

HDT560F 1.0959 +Z, +ZF 460 to 570 30 560 16 – 0.180 0.500 1.800 0.025 0.010 0.015 – 0.30 0.15 0.15 0.005

DP-Steel

HCT450X 1.0937 +Z, +ZF 260 to 340 30 450 27 0.16 0.140 0.800 2.000 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HCT500X 1.0939 +Z, +ZF 300 to 380 30 500 23 0.15 0.140 0.800 2.000 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HCT600X 1.0941 +Z, +ZF 340 to 420 30 600 20 0.14 0.170 0.800 2.200 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HDT580X 1.0936 +Z, +ZF 330 to 460 30 580 19 0.13 0.170 0.800 2.200 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HCT780X 1.0943 +Z, +ZF 450 to 560 30 780 14 – 0.180 0.800 2.500 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HCT980X 1.0944 +Z, +ZF 600 to 750 30 980 10 – 0.230 0.800 2.500 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

TRIP-Steel

HCT690T 1.0947 +Z, +ZF 430 to 550 40 690 23 0.18 0.320 2.200 2.500 0.120 0.015 – 2.00 0.60 0.20 0.20 0.005

HCT780T 1.0948 +Z, +ZF 470 to 600 40 780 21 0.16 0.320 2.200 2.500 0.120 0.015 – 2.00 0.60 0.20 0.20 0.005

CP-Steel

HCT600C 1.0953 +Z, +ZF 350 to 500 30 600 16 – 0.180 0.800 2.200 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HDT750C 1.0956 +Z, +ZF 620 to 760 30 750 10 – 0.180 0.800 2.200 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HCT780C 1.0954 +Z, +ZF 500 to 700 30 780 10 – 0.180 0.800 2.200 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HDT780C 1.0957 +Z, +ZF 680 to 830 30 780 10 – 0.180 0.800 2.200 0.080 0.015 – 2.00 1.00 0.15 0.20 0.005

HDT950C 1.0958 +Z, +ZF 720 to 920 30 950 9 – 0.250 0.800 2.200 0.080 0.015 – 2.00 1.20 0.15 0.20 0.005

HCT980C 1.0955 +Z, +ZF 700 to 900 30 980 7 – 0.250 0.800 2.200 0.080 0.015 – 2.00 1.20 0.15 0.22 0.005

MS-Steel

HDT1200M 1.0665 +Z, +ZF 900 to 1150 30 1200 5 – 0.250 0.800 2.000 0.060 0.015 – 2.00 1.20 0.15 0.22 0.005

Grade availability has to be checked individually.

Becker Stahl-Service GmbH · Weetfelder Straße 57 · 59199 Bönen

Phone +49(0)2383/934-0 · Fax +49(0)2383/934-208 · info@becker-stahl-service.de · www.becker-stahl-service.de

edited: September 10

Type of hot-dip coating Surface finish

Z hot-dip zinc coated zinc coat with 5% Al NA: unaffected solidification with differing bloom

size, normal surface

ZA Galfan zinc coat with 5% Al MA: targeted effect on the solidification

with reduced bloom size, normal surface

AZ Galvalume zinc coat with 55% Al to MB: targeted effect on the solidification,

1.6% Si, rest zinc cold re-rolled, best surface

MC: targeted effect on the solidification,

cold re-rolled, best surface

ZF galvannealed homogenised coating RA: normal surface

of zinc-iron RB: improved surface

RC: best surface

After treatment (Surface protection)

C chemically passivated

O oiled

CO chemically passivated and oiled

S sealed

U untreated

Becker Stahl-Service GmbH · Weetfelder Straße 57 · 59199 Bönen

Phone +49(0)2383/934-0 · Fax +49(0)2383/934-208 · info@becker-stahl-service.de · www.becker-stahl-service.de

edited: September 10

You might also like

- ASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFDocument2 pagesASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFCésar Santana50% (4)

- Annex A: (Normative)Document6 pagesAnnex A: (Normative)calvente27No ratings yet

- Hot Dip Galv Sheet Emw Catalogue 102017Document5 pagesHot Dip Galv Sheet Emw Catalogue 102017Pedro MaiaNo ratings yet

- Hot Dip Galvani SheetDocument3 pagesHot Dip Galvani SheetumarNo ratings yet

- Continuous Hot Dip Coating. Galvanised.Document9 pagesContinuous Hot Dip Coating. Galvanised.marjan banooNo ratings yet

- Hot Dip Galvanized SheetDocument5 pagesHot Dip Galvanized SheetBrian KnightNo ratings yet

- Hot Dip Galvanized Sheet DX52DDocument10 pagesHot Dip Galvanized Sheet DX52DiocephNo ratings yet

- Hot Dip Galvanized SheetDocument2 pagesHot Dip Galvanized SheetgorakdiasNo ratings yet

- Valori Rezistente Materiale AlinDocument2 pagesValori Rezistente Materiale AlinAndrei DinicăNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document5 pagesStructural Steel Plate and Strip To EN 10025Mbalekelwa MpembeNo ratings yet

- Ferritic and Martensitic Casting MaterialsDocument2 pagesFerritic and Martensitic Casting MaterialsSinan YıldızNo ratings yet

- MetalfaesDocument2 pagesMetalfaesviyfNo ratings yet

- Gasnitriding - Plasmanitriding - SaltbathnitridingDocument4 pagesGasnitriding - Plasmanitriding - SaltbathnitridingKevin ThomasNo ratings yet

- Supranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 309L: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- SDR0503 Series - SMD Power Inductors: Features ApplicationsDocument3 pagesSDR0503 Series - SMD Power Inductors: Features ApplicationsJoseph Abou El OulaNo ratings yet

- En 10268Document4 pagesEn 10268Alex LacerdaNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document4 pagesStructural Steel Plate and Strip To EN 10025Ibrahim BashaNo ratings yet

- STANDARD - ASTM A653 - Brief DescriptionDocument7 pagesSTANDARD - ASTM A653 - Brief DescriptionSeyong ParkNo ratings yet

- ChemicalComposition FBDocument1 pageChemicalComposition FBSibasish SarkhelNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- Mild Steels Voestalpine EN 09082019Document5 pagesMild Steels Voestalpine EN 09082019Alma Aliza VillaberNo ratings yet

- Thành phần hóa học thép - Steel bars for concrete reinforcementDocument3 pagesThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNo ratings yet

- Grade & SpcficDocument6 pagesGrade & SpcficANBUNo ratings yet

- Pakistan Ssteel Mills Mild Steel Grades SpecificationDocument3 pagesPakistan Ssteel Mills Mild Steel Grades SpecificationWaqas WaqasNo ratings yet

- TNMG 160404 NN LT 10 108Document1 pageTNMG 160404 NN LT 10 108fabioNo ratings yet

- Instrumentation Tubing ENDocument5 pagesInstrumentation Tubing ENLuis CasasNo ratings yet

- 34crnimo6: Steel GradeDocument6 pages34crnimo6: Steel GradeBiju KNo ratings yet

- Stainless Steel 441 UNS S43940Document5 pagesStainless Steel 441 UNS S43940Enrique Ruiz HonoratoNo ratings yet

- MS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)Document10 pagesMS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)khalilNo ratings yet

- Catalog MBH - Catalogue Carbon Steel Low Alloy SteelDocument12 pagesCatalog MBH - Catalogue Carbon Steel Low Alloy SteelCarlos Anibal OrtizNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- 38 MN VS6Document2 pages38 MN VS6Pramod NautiyalNo ratings yet

- BS EN 10293 InformationDocument2 pagesBS EN 10293 Informationchief_of_stuffNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Techinfo WorkpieceDocument1 pageTechinfo Workpiecesototo90No ratings yet

- STD, Inch Sizes TCM 12-163226Document13 pagesSTD, Inch Sizes TCM 12-163226SHANENo ratings yet

- FVBDocument6 pagesFVBCNo ratings yet

- 20160331071021-6541 23MnNiCrMo52Document1 page20160331071021-6541 23MnNiCrMo52rusf123No ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Design: Technical DetailsDocument4 pagesDesign: Technical DetailsDanialNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- Sepction - 3Document3 pagesSepction - 3k koradiaNo ratings yet

- Mac CalDocument4 pagesMac Calvhs mechatronicsNo ratings yet

- Casting Material Alloy Steel G20Mn5 EN 1.6220Document3 pagesCasting Material Alloy Steel G20Mn5 EN 1.6220nethaji nethajiNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- 4G 2G 2F 3G Uphill 3G DownhillDocument1 page4G 2G 2F 3G Uphill 3G Downhillamit singhNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNo ratings yet

- Aero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196Document2 pagesAero Metal Alliance Aluminium Alloy QQ A 2504 0 Sheet 196jayalakshmivinothNo ratings yet

- Electrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetDocument4 pagesElectrolytically Galvanized Sheet: EMW Delivery Range Coils Slit Strip Cut-To-Size SheetEvka AkováNo ratings yet

- Studytheme 2.24 - Other Metals and AlloysDocument14 pagesStudytheme 2.24 - Other Metals and AlloysMarno PrinslooNo ratings yet

- Soft Unalloyed Steels For Cold Forming: Steel GradesDocument8 pagesSoft Unalloyed Steels For Cold Forming: Steel GradesHemachandra ShrotriNo ratings yet

- HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Document4 pagesHPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Er Umesh RohitNo ratings yet

- Material Kapal Bki Wi Ui AlimsaadiDocument12 pagesMaterial Kapal Bki Wi Ui AlimsaadiSaadi AlimNo ratings yet

- Wear Characterization of LM29 Alloy With40 Micron Sized B4C Reinforced Metal CompositesDocument9 pagesWear Characterization of LM29 Alloy With40 Micron Sized B4C Reinforced Metal CompositesIJAR JOURNALNo ratings yet

- Seamless and Welded Steel Pipe For Low-Temperature Service and Other Applications With Required Notch ToughnessDocument8 pagesSeamless and Welded Steel Pipe For Low-Temperature Service and Other Applications With Required Notch ToughnessTim SharpNo ratings yet

- General Chemistry 2 - LAS 2 LEARNING CAPSULEDocument5 pagesGeneral Chemistry 2 - LAS 2 LEARNING CAPSULEMark RazNo ratings yet

- 403 Ore Microscopy-1-22Document27 pages403 Ore Microscopy-1-22SURVIVAL MOTLHANKANo ratings yet

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification Foralucard375No ratings yet

- Multiple Choice Questions (Q1-Q10)Document2 pagesMultiple Choice Questions (Q1-Q10)veenaNo ratings yet

- Periodic Table of The ElementsDocument1 pagePeriodic Table of The ElementsGeorgeNo ratings yet

- 2014 - 11 - Elkem Alloys in Special ApplicationsDocument27 pages2014 - 11 - Elkem Alloys in Special Applicationsfelipe100% (1)

- RRR RRR Emerging Producers Investor PresentationDocument21 pagesRRR RRR Emerging Producers Investor PresentationSahil RSNo ratings yet

- Carbon Enrichment in Mo SteelDocument50 pagesCarbon Enrichment in Mo SteelDhananjay ShimpiNo ratings yet

- ASTM B 338 Seamless & Welded Titanium Abd Titanium Alloy Tubes For Condensers & Heat Exchangers - 1995Document6 pagesASTM B 338 Seamless & Welded Titanium Abd Titanium Alloy Tubes For Condensers & Heat Exchangers - 1995ecsuperalNo ratings yet

- Page 0002Document1 pagePage 0002has sas100% (1)

- Basic CorrosionDocument11 pagesBasic CorrosionmohdluthfiNo ratings yet

- Aluminum & ConcreteDocument4 pagesAluminum & Concretenetzonetechnical managerNo ratings yet

- Aluminium Bronze To Bs 1400: Ab1Document1 pageAluminium Bronze To Bs 1400: Ab1Fred Duarte CaldeiraNo ratings yet

- Xii Chemistry Previous Questions by Anil Kumar K.L (Hsslive - In)Document3 pagesXii Chemistry Previous Questions by Anil Kumar K.L (Hsslive - In)thiripura sundari100% (1)

- A 297 A 297MDocument3 pagesA 297 A 297Mمحمد العيسوىNo ratings yet

- Specification For Carbon Steel Forgings For Piping ApplicationsDocument10 pagesSpecification For Carbon Steel Forgings For Piping ApplicationsMauricio Esteban Fernandez RamirezNo ratings yet

- Iron OreDocument2 pagesIron OreSanjay SinghNo ratings yet

- F1852Document8 pagesF1852mrezaiNo ratings yet

- Catalogo Cañas Fendwick Berkley Mitchel Abu GarciaDocument142 pagesCatalogo Cañas Fendwick Berkley Mitchel Abu GarciaGonzalo FioreNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Flare Tip Material Selection - GBADocument2 pagesFlare Tip Material Selection - GBADpto SSO SimbioNo ratings yet

- Materials Selection: Lecturer: Muhammad SulaimanDocument15 pagesMaterials Selection: Lecturer: Muhammad SulaimanHussain AliNo ratings yet

- North American Die Casting Association: Membership Directory 2022-2023Document31 pagesNorth American Die Casting Association: Membership Directory 2022-2023f3rNo ratings yet

- Sa 105 PDFDocument10 pagesSa 105 PDFkumarNo ratings yet

- Hiten Kadu 6.1Document104 pagesHiten Kadu 6.1Pranjal DograNo ratings yet

- Chemistry Progress 12 PDFDocument87 pagesChemistry Progress 12 PDFMapalo Chirwa100% (2)